ASTM B546-98

(Specification)Standard Specification for Electric Fusion-Welded Ni-Cr-Co-Mo Alloy (UNS N06617), Ni-Fe-Cr-Si Alloys (UNS N08330 and UNS N08332),Ni-Cr-Fe-Al Alloy (UNS N06603), Ni-Cr-Fe Alloy (UNS N06025), and Ni-Cr-Fe-Si Alloy (UNS N06045) Pipe

Standard Specification for Electric Fusion-Welded Ni-Cr-Co-Mo Alloy (UNS N06617), Ni-Fe-Cr-Si Alloys (UNS N08330 and UNS N08332),Ni-Cr-Fe-Al Alloy (UNS N06603), Ni-Cr-Fe Alloy (UNS N06025), and Ni-Cr-Fe-Si Alloy (UNS N06045) Pipe

SCOPE

1.1 This specification covers electric fusion-welded nickel-chromium-cobalt-molybdenum alloy UNS N06617, nickel-iron-chromium-silicon alloys UNS N08330 and UNS N08332, Ni-Cr-Fe Alloy UNS N06025, and Ni-Cr-Fe-Si Alloy UNS N06045 pipe intended for heat resisting applications and general corrosive service.

1.2 This specification covers pipe in sizes 3 in. (76.2 mm) nominal diameter and larger and possessing a minimum wall thickness of 0.083 in. (2.11 mm).

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 546 – 98

Standard Specification for

Electric Fusion-Welded Ni-Cr-Co-Mo Alloy (UNS N06617),

Ni-Fe-Cr-Si Alloys (UNS N08330 and UNS N08332), Ni-Cr-

Fe-Al Alloy (UNS N06603), Ni-Cr-Fe Alloy (UNS N06025), and

Ni-Cr-Fe-Si Alloy (UNS N06045) Pipe

This standard is issued under the fixed designation B 546; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope Cobalt, and High-Temperature Alloys

2.2 ASME Standards:

1.1 This specification covers electric fusion-welded nickel-

Boiler and Pressure Vessel Code, Section VIII, Paragraph

chromium-cobalt-molybdenum alloy UNS N06617, nickel-

UW-51

iron-chromium-silicon alloys UNS N08330 and UNS N08332,

Boiler and Pressure Vessel Code, Section IX

Ni-Cr-Fe-Al Alloy (UNS N06603), Ni-Cr-Fe Alloy UNS

N06025, and Ni-Cr-Fe-Si Alloy UNS N06045 pipe intended

3. General Requirement

for heat resisting applications and general corrosive service.

3.1 Material furnished in accordance with this specification

1.2 This specification covers pipe in sizes 3 in. (76.2 mm)

shall conform to the applicable requirements of the current

nominal diameter and larger and possessing a minimum wall

edition of Specification B 775 unless otherwise provided

thickness of 0.083 in. (2.11 mm).

herein.

1.3 The values stated in inch-pound units are to be regarded

as the standard. The values given in parentheses are for

4. Classification

information only.

4.1 Two classes of pipe are covered as follows:

2. Referenced Documents 4.1.1 Class 1—All welded joints to be 100 % inspected by

radiography.

2.1 ASTM Standards:

4.1.2 Class 2—No radiographic examination is required.

B 168 Specification for Nickel-Chromium-Iron Alloys

(UNS N06600, N06601, and N06690) and Nickel-

5. Ordering Information

Chromium-Cobalt-Molybdenum Alloy (UNS N06617)

5.1 It is the responsibility of the purchaser to specify all

Plate, Sheet, and Strip

requirements that are necessary for the safe and satisfactory

B 536 Specification for Nickel-Iron-Chromium-Silicon Al-

performance of material ordered under this specification.

loys (UNS N08330 and N08332) Plate, Sheet, and Strip

Examples of such requirements include, but are not limited to,

B 775 Specification for General Requirements for Nickel

the following:

and Nickel Alloy Welded Pipe

5.1.1 Alloy (Table 1),

E 10 Test Method for Brinell Hardness of Metallic Materi-

5.1.2 ASTM designation and year of issue,

als

5.1.3 Class (See 4.1),

E 140 Hardness Conversion Tables for Metals (Relationship

5.1.4 Dimensions (standard pipe size and schedule),

Between Brinell Hardness, Vickers Hardness, Rockwell

5.1.5 Length (specific or random),

Hardness, Rockwell Superficial Hardness, and Knoop

3,4 5.1.6 Quantity (feet or number of pieces),

Hardness)

5.1.7 Certification—State if certification is required,

E 1473 Test Methods for Chemical Analysis of Nickel,

5.1.8 Whether type of filler metal and deposited composi-

tion is required (see 7.3),

5.1.9 Samples for Product (Check) Analysis—State whether

This specification is under the jurisdiction of ASTM Committee B-2 on

samples for product (check) analysis should be furnished, and

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

B02.07 on Refined Nickel and Cobalt and Their Alloys.

Current edition approved Dec. 10, 1998. Published January 1999. Originally

published as B 546 – 71. Last previous edition B 546 – 97.

2 5

Annual Book of ASTM Standards, Vol 02.04. Annual Book of ASTM Standards, Vol 03.06.

3 6

Annual Book of ASTM Standards, Vol 03.01. Available from the American Society of Mechanical Engineers, 345 E. 47th St.,

Annual Book of ASTM Standards, Vol 03.05. New York, NY 10017.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

B 546

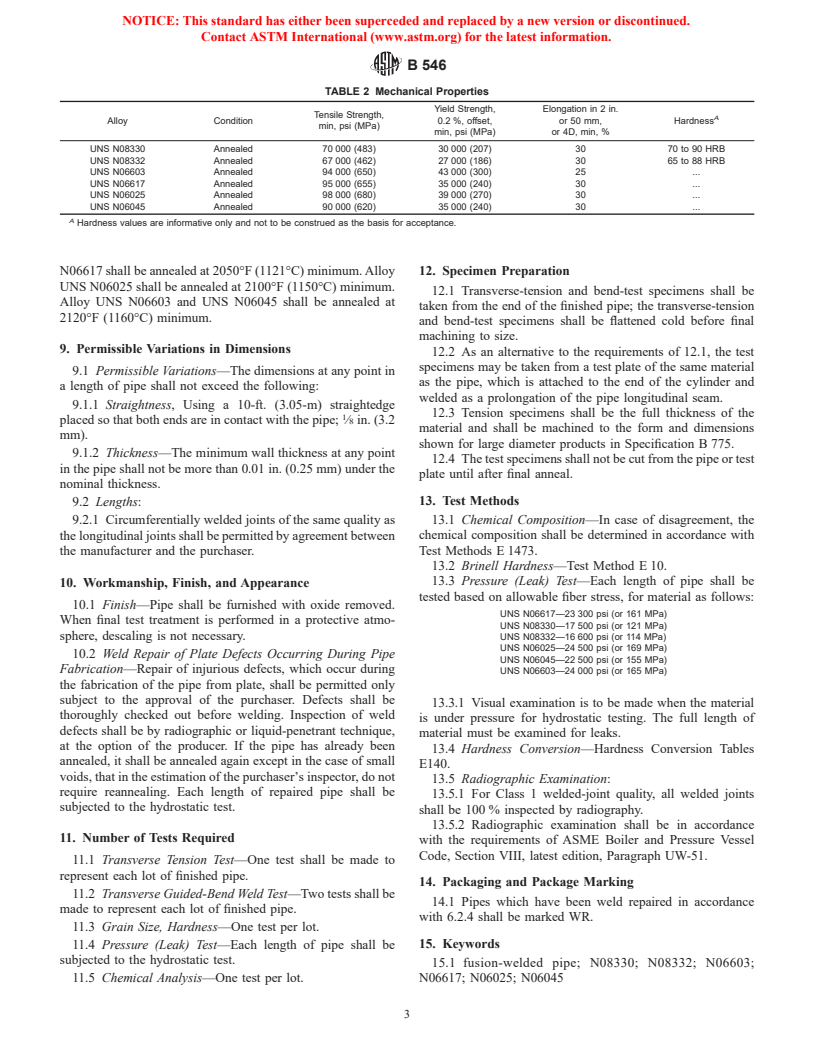

TABLE 1 Chemical Requirements

Composition Limits, %

Element

N08330 N08332 N06603 N06617 N06025 N06045

Carbon 0.08 max 0.05–0.10 0.20-0.40 0.05–0.15 0.15–0.25 0.05–0.12

Manganese 2.00 max 2.00 max 0.15 max 1.0 max 0.15 max 1.0 max

Phosphorus 0.03 max 0.03 max 0.20 max . 0.02 max 0.02 max

Sulfur 0.03 max 0.03 max 0.10 max 0.015 max 0.010 max 0.010 max

Silicon 0.75 to 1.50 0.75 to 1.50 0.50 max 1.0 max 0.5 max 2.5–3.0

Chromium 17.0 to 20.0 17.0 to 20.0 0.24-0.26 20.0–24.0 24.0–26.0 26.0–29.0

Nickel 34.0 to 37.0 34.0 to 37.0 Bal remainder Bal 45.0 min

Copper 1.00 max 1.00 max 0.50 max 0.5 max 0.1 max 0.3 max

Lead 0.005 max 0.005 max . . . .

Tin 0.025 max 0.025 max . . . .

A

Iron remainder remainder 8.0–11.0 3.0 max 8.0–11.0 21.0–25.0

Aluminum . . 2.4-3.0 0.8–1.5 1.8–2.4 .

Cobalt . . . 10.0–15.0 . .

Molybdenum . . . 8.0–10.0 . .

Zirconium . . 0.01–0.10 . 0.01–0.10 .

Yttrium . . 0.01–0.15 . 0.05–0.12 .

Cerium . . . . . 0.3–0.09

Titanium . . 0.010-0.025 . . .

A

Element shall be determined arithmetically by difference.

5.1.10 Purchaser Inspection—If purchaser wishes to wit- 7. Chemical Composition

ness tests or inspection of material at place of manufacture, the

7.1 The material shall conform to the composition limits

purchase order must so state indicating which tests or inspec-

specified in Table 1. One test is required for each lot as defined

tions are to be witnessed.

in Specification B 775.

7.2 If a product analysis is performed, it shall meet the

6. Materials and Manufacture

chemistry limits prescribed in Table 1, subject to the analysis

tolerances specified in Table 1 of Specification B 775.

6.1 Materials—The UNS N08330 and UNS N08332 alloy

7.3 The chromium and nickel content of the deposited weld

plate material shall conform to the requirements of Specifica-

metal shall conform to the minimum chromium and nickel

tion B 536. The UNS N06617, UNS N06603, UNS N06025,

contents required for the base metal. Note that the composition

and UNS N06045 alloy plate material shall conform to the

of the deposited weld metal may not be the same as the base

requirements of Specification B 168.

metal. The user should establish suitability for his particular

6.2 Welding:

application. When specified in the purchase order (see section

6.2.1 The joints shall be double-welded, full-penetration

5.1.8), the manufacturer shall report the type of filler metal

welds made by qualified operators in accordance with proce-

used along with a chemical analysis of the deposited weld

dures in the ASME Boiler and Pressure Vessel Code, Section

metal.

IX.

6.2.2 The weld shall be made either manually or automati-

8. Mechanical and Other Requirements

cally by an electric process involving the deposition of filler

8.1 Tensile Properties:

metal.

8.1.1 Transverse tension tests taken across the weld joints

6.2.3 The joint shall be reinforced at the center of the weld

shall meet the requirements shown in Table 2.

on each side of the formed plate by a weld bead at least ⁄16 in.

8.2 Transverse Guided-Bend Weld Tests:

(1.6 mm) but not more than ⁄8 in. (3.2 mm). This reinforce-

8.2.1 Two bend test specimens shall be taken transversely

ment (weld bead) may be removed at the manufacturer’s option

from the pipe. One shall be subject to a face guided-bend test

or by agreement between the manufacturer and the purchaser.

and the sec

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.