ASTM F3371-19

(Specification)Standard Specification for Polyolefin Pipe and Fittings for Drainage, Waste, and Vent Applications

Standard Specification for Polyolefin Pipe and Fittings for Drainage, Waste, and Vent Applications

SCOPE

1.1 This specification covers requirements for non-pressure polyolefin pipe and fittings for drainage, waste, and vent applications.

Note 1: This specification does not include requirements for pipe and fittings intended to be used to vent combustion gases.

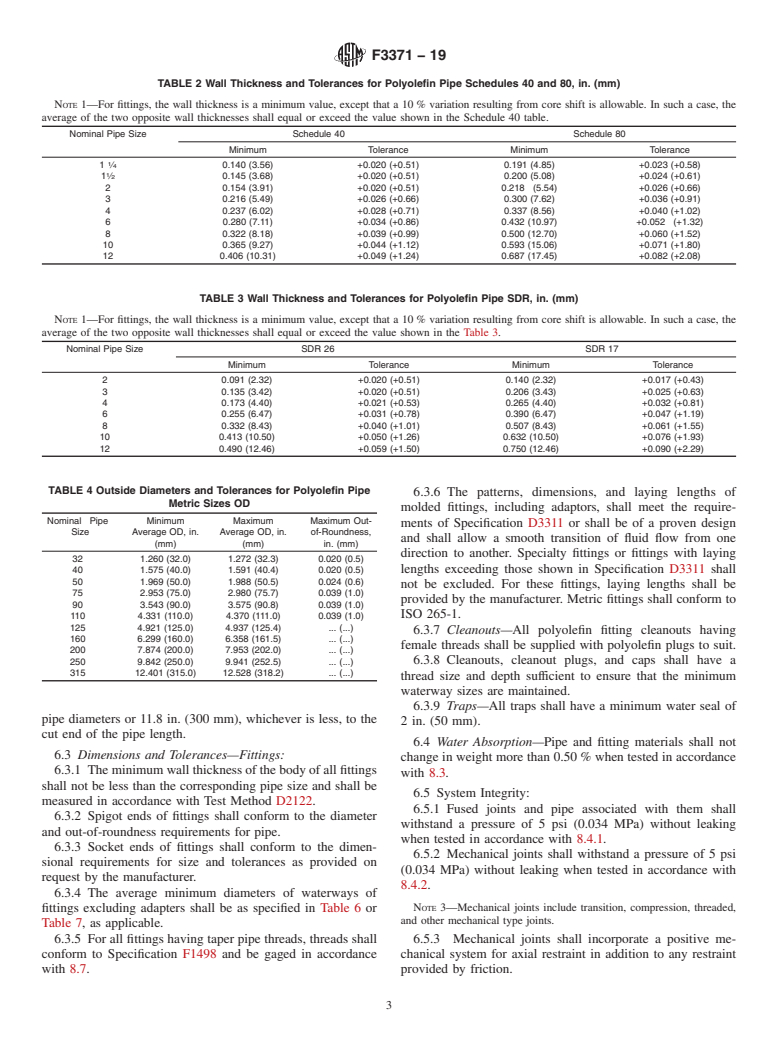

1.2 Pipe is produced in Schedule 40 and 80 IPS sizes, in metric sizes, and in DR IPS sizes for two polyolefins; polyethylene (PE) and polypropylene (PP).

1.3 The interchangeability of pipe and fittings made by different manufacturers is not addressed in this specification.

1.4 Pipe and fittings are joined by the heat fusion method (Practice D2657 for PP butt and saddle fusion, Practice F2620 for PE butt, saddle and socket fusion and Practice F1290 for polyolefin electrofusion) or by using mechanical or gasketed joints recommended by the pipe and fitting manufacturers.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.6 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.7 The following safety hazards caveat pertains only to the test methods portion, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F3371 −19 An American National Standard

Standard Specification for

Polyolefin Pipe and Fittings for Drainage, Waste, and Vent

1

Applications

This standard is issued under the fixed designation F3371; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.1 This specification covers requirements for non-pressure

polyolefin pipe and fittings for drainage, waste, and vent

2. Referenced Documents

applications.

2

2.1 ASTM Standards:

NOTE 1—This specification does not include requirements for pipe and

D570 Test Method for Water Absorption of Plastics

fittings intended to be used to vent combustion gases.

D618 Practice for Conditioning Plastics for Testing

1.2 Pipe is produced in Schedule 40 and 80 IPS sizes, in

D1600 Terminology forAbbreviatedTerms Relating to Plas-

metric sizes, and in DR IPS sizes for two polyolefins; polyeth-

tics

ylene (PE) and polypropylene (PP).

D2122 Test Method for Determining Dimensions of Ther-

1.3 The interchangeability of pipe and fittings made by

moplastic Pipe and Fittings

different manufacturers is not addressed in this specification.

D2321 PracticeforUndergroundInstallationofThermoplas-

tic Pipe for Sewers and Other Gravity-Flow Applications

1.4 Pipe and fittings are joined by the heat fusion method

D2412 Test Method for Determination of External Loading

(Practice D2657 for PP butt and saddle fusion, Practice F2620

Characteristics of Plastic Pipe by Parallel-Plate Loading

for PE butt, saddle and socket fusion and Practice F1290 for

D2444 Practice for Determination of the Impact Resistance

polyolefin electrofusion) or by using mechanical or gasketed

of Thermoplastic Pipe and Fittings by Means of a Tup

joints recommended by the pipe and fitting manufacturers.

(Falling Weight)

1.5 The values stated in inch-pound units are to be regarded

D2657 Practice for Heat Fusion Joining of Polyolefin Pipe

as standard. The values given in parentheses are mathematical

and Fittings

conversions to SI units that are provided for information only

D3212 Specification for Joints for Drain and Sewer Plastic

and are not considered standard.

Pipes Using Flexible Elastomeric Seals

1.6 The text of this specification references notes, footnotes,

D3311 Specification for Drain, Waste, and Vent (DWV)

and appendixes which provide explanatory material. These

Plastic Fittings Patterns

notesandfootnotes(excludingthoseintablesandfigures)shall

D3350 Specification for Polyethylene Plastics Pipe and Fit-

not be considered as requirements of the specification.

tings Materials

D4101 Classification System and Basis for Specification for

1.7 The following safety hazards caveat pertains only to the

Polypropylene Injection and Extrusion Materials

test methods portion, Section 8, of this specification: This

F412 Terminology Relating to Plastic Piping Systems

standard does not purport to address all of the safety concerns,

F477 Specification for Elastomeric Seals (Gaskets) for Join-

if any, associated with its use. It is the responsibility of the user

ing Plastic Pipe

of this standard to establish appropriate safety, health, and

F585 Guide for Insertion of Flexible Polyethylene Pipe Into

environmental practices and determine the applicability of

Existing Sewers

regulatory limitations prior to use.

F913 Specification for Thermoplastic Elastomeric Seals

1.8 This international standard was developed in accor-

(Gaskets) for Joining Plastic Pipe

dance with internationally recognized principles on standard-

F1290 PracticeforElectrofusionJoiningPolyolefinPipeand

ization established in the Decision on Principles for the

Fittings

Development of International Standards, Guides and Recom-

1 2

This test method is under the jurisdiction of ASTM Committee F17 on Plastic For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Piping Systems and is the direct responsibility of Subcommittee F17.63 on DWV. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved April 1, 2019. Published April 2019. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

F3371–19 the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F3371−19

F1498 Specification forTaper PipeThreads 60° forThermo- 5.3 The polyolefin material shall contain suitable stabilizers

plastic Pipe and Fittings and antioxidants and may contain pigments and fillers not

F

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.