ASTM D2396-20

(Test Method)Standard Test Methods for Powder-Mix Time of Poly(Vinyl Chloride) (PVC) Resins Using a Torque Rheometer

Standard Test Methods for Powder-Mix Time of Poly(Vinyl Chloride) (PVC) Resins Using a Torque Rheometer

SIGNIFICANCE AND USE

5.1 The ability of PVC granules to accept a plasticizer and become a dry free-flowing powder is related to the internal pore structure of the resin, resin temperature, plasticizer temperature, and the plasticizer used. By choosing an applicable plasticizer and maintaining a uniform temperature for the resin and plasticizer, it is possible to classify resins by how rapidly they absorb plasticizer. Resin suitability for a specific intensive mixing operation can be ascertained using these test methods.

SCOPE

1.1 These test methods cover the determination of the powder-mix time of a general-purpose poly(vinyl chloride) (PVC) resin.

1.2 The values stated in SI units are to be regarded as standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: ISO 4574-2019 is covering the primary subject of this ASTM method.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D2396 − 20

Standard Test Methods for

Powder-Mix Time of Poly(Vinyl Chloride) (PVC) Resins

1

Using a Torque Rheometer

This standard is issued under the fixed designation D2396; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 These test methods cover the determination of the

3.1 Definitions:

powder-mix time of a general-purpose poly(vinyl chloride)

3.1.1 Terms used in this standard are defined in accordance

(PVC) resin.

with Terminology D883, and abbreviations are in accordance

withTerminology D1600 unless otherwise specified. For terms

1.2 The values stated in SI units are to be regarded as

relating to precision and bias and associated issues, the terms

standard.

used in this standard are defined in accordance with Terminol-

1.3 This standard does not purport to address all of the

ogy E456.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Summary of Test Methods

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

4.1 A sample of resin is heated and mixed in a bowl to the

test temperature.Ameasured amount of plasticizer is added to

NOTE 1—ISO 4574-2019 is covering the primary subject of thisASTM

the resin through a dispersing funnel. When the plasticizer is

method.

added to the resin, the mix becomes wet and an increase in

1.4 This international standard was developed in accor-

motortorqueisneededtomaintainthesamerotorspeed.Asthe

dance with internationally recognized principles on standard-

mixingcontinuesintheheatedbowl,theplasticizerisabsorbed

ization established in the Decision on Principles for the

into the resin and the resin granules become dry and free-

Development of International Standards, Guides and Recom-

flowing. When the mix reaches the dry and free-flowing state,

mendations issued by the World Trade Organization Technical

its resistance to stirring decreases and the motor torque needed

Barriers to Trade (TBT) Committee.

to maintain the same rotor speed decreases. By recording the

changes in motor torque with time, it is possible to measure the

2. Referenced Documents

time required for a resin to absorb a plasticizer.

2

2.1 ASTM Standards:

D883 Terminology Relating to Plastics 4.2 These test methods describe the use of two different

D1600 Terminology forAbbreviatedTerms Relating to Plas- mixing heads that can be mounted on a torque rheometer to

tics

perform this test.Test results obtained with these mixing heads

E456 Terminology Relating to Quality and Statistics

are compared in Section 14.

E691 Practice for Conducting an Interlaboratory Study to

4.2.1 A sigma mixing head is used in Test Method A.

Determine the Precision of a Test Method

4.2.2 A planetary mixing head is used in Test Method B.

E2935 Practice for Conducting Equivalence Tests for Com-

paring Testing Processes

5. Significance and Use

5.1 The ability of PVC granules to accept a plasticizer and

1 become a dry free-flowing powder is related to the internal

These test methods are under the jurisdiction of ASTM Committee D20 on

Plastics and are the direct responsibility of Subcommittee D20.15 on Thermoplastic

pore structure of the resin, resin temperature, plasticizer

Materials.

temperature, and the plasticizer used. By choosing an appli-

Current edition approved Dec. 1, 2020. Published December 2020. Originally

cable plasticizer and maintaining a uniform temperature for the

approved in 1969. Last previous edition approved in 2012 as D2396 - 94 (2012).

DOI: 10.1520/D2396-20.

resin and plasticizer, it is possible to classify resins by how

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

rapidly they absorb plasticizer. Resin suitability for a specific

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

intensive mixing operation can be ascertained using these test

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. methods.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2396 − 20

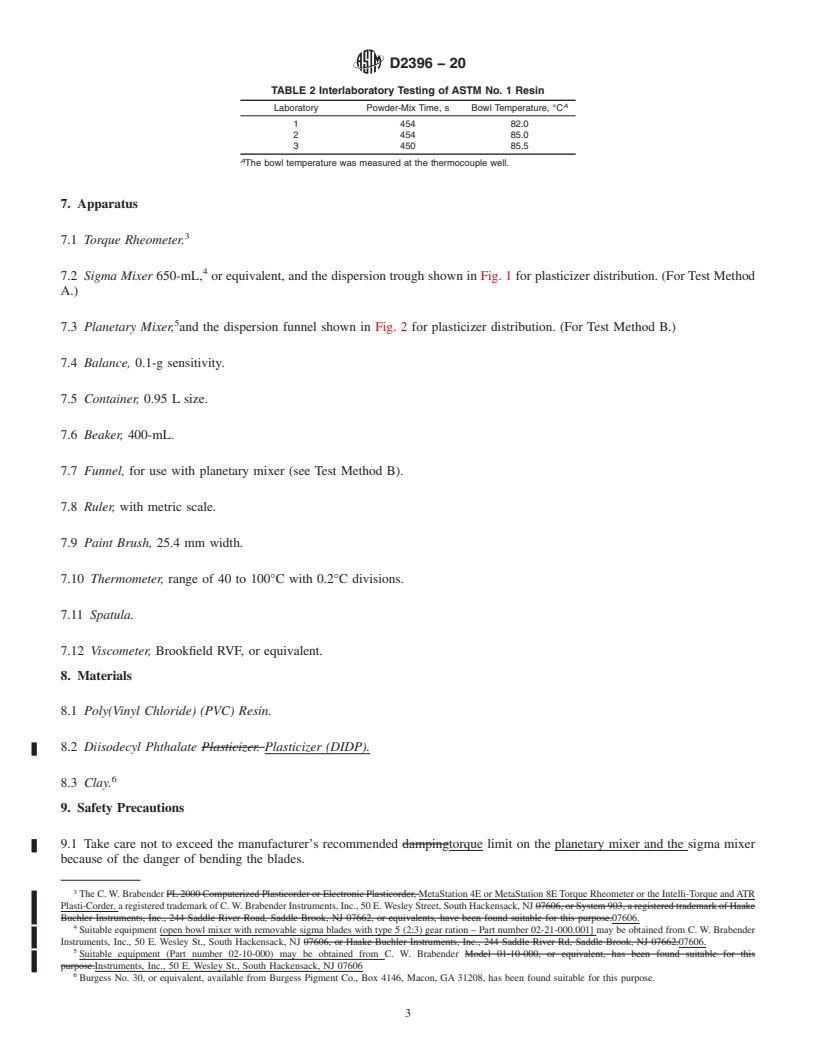

TABLE 1 Powder-Mix Time of ASTM No. 1 Resin TABLE 2 Interlaboratory Testing of ASTM No. 1 Resin

A

DIDP Viscosity, Bowl Mean Laboratory Powder-Mix Time, s Bowl Temperature, °C

Standard Number of

cP Temp

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D2396 − 94 (Reapproved 2012) D2396 − 20

Standard Test Methods for

Powder-Mix Time of Poly(Vinyl Chloride) (PVC) Resins

1

Using a Torque Rheometer

This standard is issued under the fixed designation D2396; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 These test methods cover the determination of the powder-mix time of a general-purpose poly(vinyl chloride) (PVC) resin.

1.2 The values stated in SI units are to be regarded as standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

NOTE 1—There is no ISO standard ISO 4574-2019 is covering the primary subject of thesethis ASTM test methods.method.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D883 Terminology Relating to Plastics

D1600 Terminology for Abbreviated Terms Relating to Plastics

E456 Terminology Relating to Quality and Statistics

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E2935 Practice for Conducting Equivalence Tests for Comparing Testing Processes

3. Terminology

3.1 General:Definitions:

3.1.1 Definitions are Terms used in this standard are defined in accordance with Terminology D883, and abbreviations are in

accordance with Terminology D1600 unless otherwise indicated.specified. For terms relating to precision and bias and associated

issues, the terms used in this standard are defined in accordance with Terminology E456.

1

These test methods are under the jurisdiction of ASTM Committee D20 on Plastics and are the direct responsibility of Subcommittee D20.15 on Thermoplastic Materials.

Current edition approved April 1, 2012Dec. 1, 2020. Published June 2012December 2020. Originally approved in 1969. Last previous edition approved in 20042012 as

D2396 - 94 (2004).(2012). DOI: 10.1520/D2396-94R12.10.1520/D2396-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2396 − 20

TABLE 1 Powder-Mix Time of ASTM No. 1 Resin

DIDP Viscosity, Bowl Mean

Standard Number of

cP Temperature, Powder-Mix

Deviation Samples

A B

(millipascals-s) °C Time, s

111 85 435 . 2

128 85 461 6.9 5

147 85 479 . 2

A

Viscosity was measured using a Brookfield RVF Viscometer, No. 1 spindle, 20

r/min, at 23°C.

B

The bowl temperature was measured at the thermocouple well.

4. Summary of Test Methods

4.1 A sample of resin is heated and mixed in a bowl to the test temperature. A measured amount of plasticizer is added to the resin

through a dispersing funnel. When the plasticizer is added to the resin, the mix becomes wet and an increase in motor torque is

needed to maintain the same rotor speed. As the mixing continues in the heated bowl, the plasticizer is absorbed into the resin and

the resin granules become dry and free-flowing. When the mix reaches the dry and free-flowing state, its resistance to stirring

decreases and the motor torque needed to maintain the same rotor speed decreases. By recording the changes in motor torque with

time, it is possible to measure the time required for a resin to absorb a plasticizer.

4.2 These test methods describe the use of two different mixing heads that can be mounted on a torque rheometer to perform this

test. Test results obtained with these mixing heads are compared in Section 14.

4.2.1 A sigma mixing head is used in Test Method A.

4.2.2 A planetary mixing head is used in Test Method B.

5. Significance and Use

5.1 The ability of PVC granules

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.