ASTM E706-01

(Guide)Standard Master Matrix for Light-Water Reactor Pressure Vessel Surveillance Standards, E706(0)

Standard Master Matrix for Light-Water Reactor Pressure Vessel Surveillance Standards, E706(0)

SCOPE

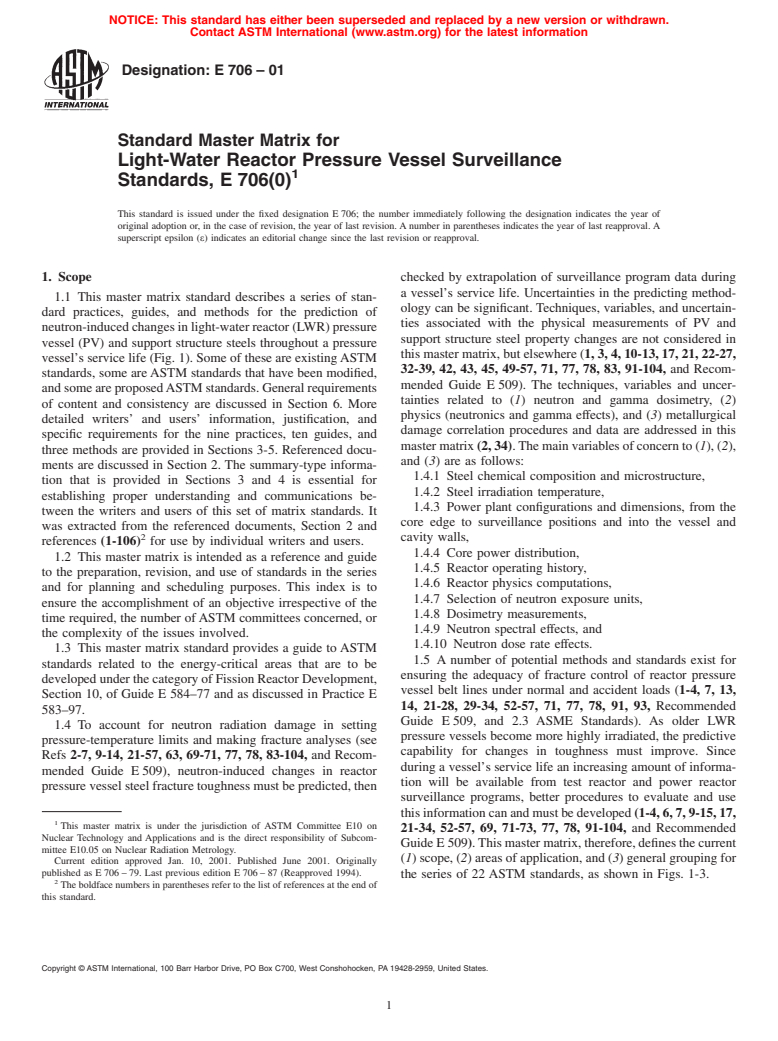

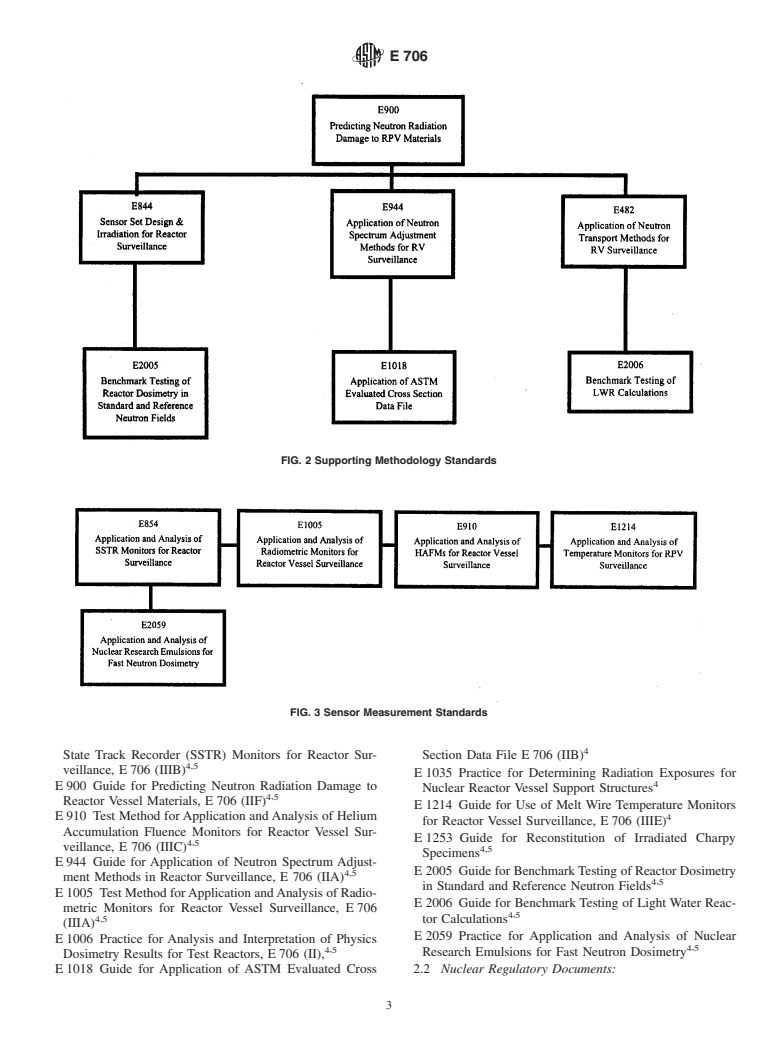

1.1 This master matrix standard describes a series of standard practices, guides, and methods for the prediction of neutron-induced changes in light-water reactor (LWR) pressure vessel (PV) and support structure steels throughout a pressure vessel's service life (Fig. 1). Some of these are existing ASTM standards, some are ASTM standards that have been modified, and some are proposed ASTM standards. General requirements of content and consistency are discussed in Section 6 . More detailed writers' and users' information, justification, and specific requirements for the nine practices, ten guides, and three methods are provided in Sections 3-5. Referenced documents are discussed in Section 2. The summary-type information that is provided in Sections 3 and 4 is essential for establishing proper understanding and communications between the writers and users of this set of matrix standards. It was extracted from the referenced documents, Section 2 and references (1-106) for use by individual writers and users.

1.2 This master matrix is intended as a reference and guide to the preparation, revision, and use of standards in the series and for planning and scheduling purposes. This index is to ensure the accomplishment of an objective irrespective of the time required, the number of ASTM committees concerned, or the complexity of the issues involved.

1.3 This master matrix standard provides a guide to ASTM standards related to the energy-critical areas that are to be developed under the category of Fission Reactor Development, Section 10, of Guide E584-77 and as discussed in Practice E583-97.

1.4 To account for neutron radiation damage in setting pressure-temperature limits and making fracture analyses (see Refs 2-7, 9-14, 21-57, 63, 69-71, 77, 78, 83-104 and Recommended Guide E509), neutron-induced changes in reactor pressure vessel steel fracture toughness must be predicted, then checked by extrapolation of surveillance program data during a vessel's service life. Uncertainties in the predicting methodology can be significant. Techniques, variables, and uncertainties associated with the physical measurements of PV and support structure steel property changes are not considered in this master matrix, but elsewhere (1, 3, 4, 10-13, 17, 21, 22-27, 32-39, 42, 43, 45, 49-57, 71, 77, 78, 83, 91-104, and Recommended Guide E509). The techniques, variables and uncertainties related to (1) neutron and gamma dosimetry, (2) physics (neutronics and gamma effects), and (3) metallurgical damage correlation procedures and data are addressed in this master matrix (2,34 ). The main variables of concern to (1), (2), and (3) are as follows:

1.4.1 Steel chemical composition and microstructure,

1.4.2 Steel irradiation temperature,

1.4.3 Power plant configurations and dimensions, from the core edge to surveillance positions and into the vessel and cavity walls,

1.4.4 Core power distribution,

1.4.5 Reactor operating history,

1.4.6 Reactor physics computations,

1.4.7 Selection of neutron exposure units,

1.4.8 Dosimetry measurements,

1.4.9 Neutron spectral effects, and

1.4.10 Neutron dose rate effects.

1.5 A number of potential methods and standards exist for ensuring the adequacy of fracture control of reactor pressure vessel belt lines under normal and accident loads (1-4, 6, 7, 13, 14, 21-28, 29-34, 52-57, 71, 77, 78, 91, 93, Recommended Guide E509, and 2.3 ASME Standards). As older LWR pressure vessels become more highly irradiated, the predictive capability for changes in toughness must improve. Since during a vessel's service life an increasing amount of information will be available from test reactor and power reactor surveillance programs, better procedures to evaluate and use this information can and must be developed (1-4, 6, 7, 9-15, 17, 21-34, 52-57, 69, 71-73, 77, 78, 91-104 and Recommended Guide E509). This master matrix, therefore, defines the current (1) scope, (2) areas of application, and (3) general groupin...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E706–01

Standard Master Matrix for

Light-Water Reactor Pressure Vessel Surveillance

1

Standards, E706(0)

This standard is issued under the fixed designation E706; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (ε) indicates an editorial change since the last revision or reapproval.

1. Scope checked by extrapolation of surveillance program data during

a vessel’s service life. Uncertainties in the predicting method-

1.1 This master matrix standard describes a series of stan-

ology can be significant. Techniques, variables, and uncertain-

dard practices, guides, and methods for the prediction of

ties associated with the physical measurements of PV and

neutron-inducedchangesinlight-waterreactor(LWR)pressure

support structure steel property changes are not considered in

vessel (PV) and support structure steels throughout a pressure

thismastermatrix,butelsewhere(1, 3, 4, 10-13, 17, 21, 22-27,

vessel’s service life (Fig. 1). Some of these are existingASTM

32-39, 42, 43, 45, 49-57, 71, 77, 78, 83, 91-104, and Recom-

standards, some areASTM standards that have been modified,

mended Guide E509). The techniques, variables and uncer-

andsomeareproposedASTMstandards.Generalrequirements

tainties related to (1) neutron and gamma dosimetry, (2)

of content and consistency are discussed in Section 6. More

physics (neutronics and gamma effects), and (3) metallurgical

detailed writers’ and users’ information, justification, and

damage correlation procedures and data are addressed in this

specific requirements for the nine practices, ten guides, and

mastermatrix (2, 34).Themainvariablesofconcernto(1),(2),

three methods are provided in Sections 3-5. Referenced docu-

and (3) are as follows:

ments are discussed in Section 2. The summary-type informa-

1.4.1 Steel chemical composition and microstructure,

tion that is provided in Sections 3 and 4 is essential for

1.4.2 Steel irradiation temperature,

establishing proper understanding and communications be-

1.4.3 Power plant configurations and dimensions, from the

tween the writers and users of this set of matrix standards. It

core edge to surveillance positions and into the vessel and

was extracted from the referenced documents, Section 2 and

2

cavity walls,

references (1-106) for use by individual writers and users.

1.4.4 Core power distribution,

1.2 This master matrix is intended as a reference and guide

1.4.5 Reactor operating history,

to the preparation, revision, and use of standards in the series

1.4.6 Reactor physics computations,

and for planning and scheduling purposes. This index is to

1.4.7 Selection of neutron exposure units,

ensure the accomplishment of an objective irrespective of the

1.4.8 Dosimetry measurements,

time required, the number ofASTM committees concerned, or

1.4.9 Neutron spectral effects, and

the complexity of the issues involved.

1.4.10 Neutron dose rate effects.

1.3 This master matrix standard provides a guide toASTM

1.5 A number of potential methods and standards exist for

standards related to the energy-critical areas that are to be

ensuring the adequacy of fracture control of reactor pressure

developedunderthecategoryofFissionReactorDevelopment,

vessel belt lines under normal and accident loads (1-4, 7, 13,

Section 10, of Guide E 584–77 and as discussed in Practice E

14, 21-28, 29-34, 52-57, 71, 77, 78, 91, 93, Recommended

583–97.

Guide E509, and 2.3 ASME Standards). As older LWR

1.4 To account for neutron radiation damage in setting

pressure vessels become more highly irradiated, the predictive

pressure-temperature limits and making fracture analyses (see

capability for changes in toughness must improve. Since

Refs 2-7, 9-14, 21-57, 63, 69-71, 77, 78, 83-104, and Recom-

during a vessel’s service life an increasing amount of informa-

mended Guide E509), neutron-induced changes in reactor

tion will be available from test reactor and power reactor

pressurevesselsteelfracturetoughnessmustbepredicted,then

surveillance programs, better procedures to evaluate and use

thisinformationcanandmustbedeveloped (1-4, 6, 7, 9-15, 17,

1

This master matrix is under the jurisdiction of ASTM Committee E10 on

21-34, 52-57, 69, 71-73, 77, 78, 91-104, and Recommended

Nuclear Technology and Applications and is the direct responsibility of Subcom-

GuideE509).Thismastermatrix,therefore,definesthecurrent

mittee E10.05 on Nuclear Radiation Metrology.

(1)scope,(2)areasofapplication,and(3)generalgroupingfor

Current edition approved Jan. 10, 2001. Published June 2001. Originally

published as E706–79. Last previous edition E706–87 (Reapproved 1994). the series of 22 ASTM standards, as shown in Figs. 1-3.

2

Theboldfacenumbersinparenthesesrefe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.