ASTM D4168-95(2021)

(Test Method)Standard Test Methods for Transmitted Shock Characteristics of Foam-in-Place Cushioning Materials

Standard Test Methods for Transmitted Shock Characteristics of Foam-in-Place Cushioning Materials

SIGNIFICANCE AND USE

5.1 Data obtained by these methods may be used to determine the transmitted shock cushioning characteristics of foam-in-place packaging materials. These data allow design of cushioning systems that can provide adequate and efficient use of foam for protection of goods during a distribution life-cycle.

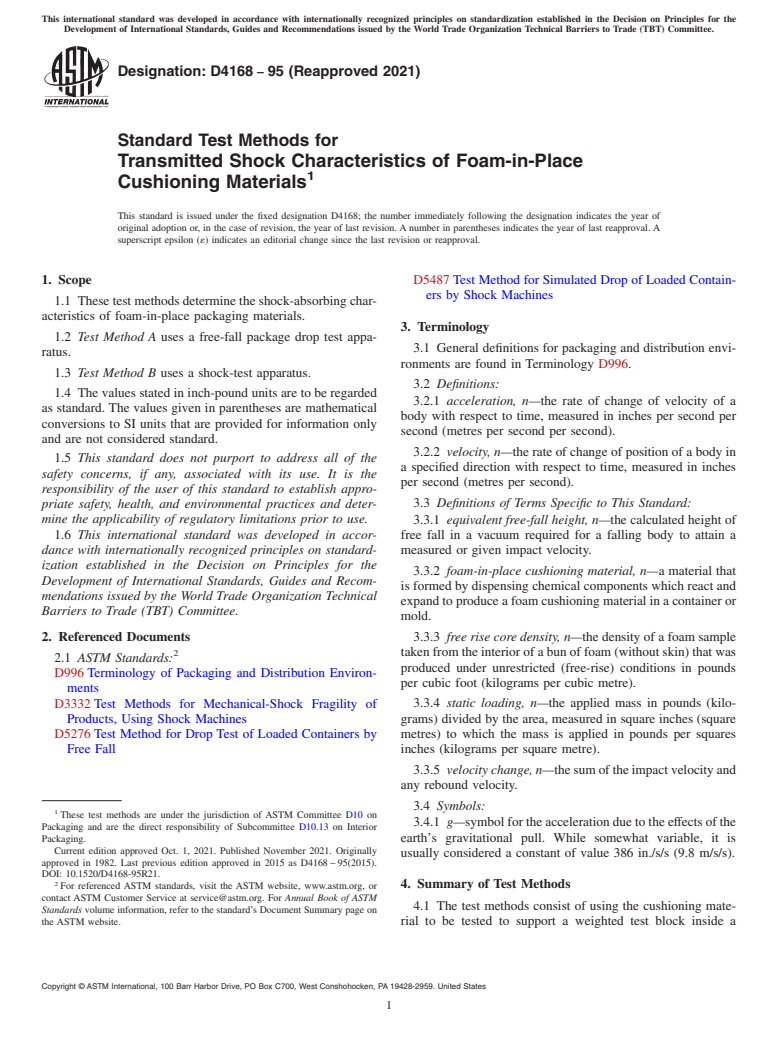

5.2 These methods, in contrast to other methods that usually test only the cushioning foam, are designed to evaluate foam-in-place cushioning materials in a manner in which the foam-in-place packaging material is used. In particular, the method includes simultaneous use of a plastic film, the foam, and the box usually used in this method of packaging. See Fig. 1.

FIG. 1 Specimen Ready For Test

SCOPE

1.1 These test methods determine the shock-absorbing characteristics of foam-in-place packaging materials.

1.2 Test Method A uses a free-fall package drop test apparatus.

1.3 Test Method B uses a shock-test apparatus.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4168 − 95 (Reapproved 2021)

Standard Test Methods for

Transmitted Shock Characteristics of Foam-in-Place

Cushioning Materials

This standard is issued under the fixed designation D4168; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D5487 Test Method for Simulated Drop of Loaded Contain-

ers by Shock Machines

1.1 These test methods determine the shock-absorbing char-

acteristics of foam-in-place packaging materials.

3. Terminology

1.2 Test Method A uses a free-fall package drop test appa-

3.1 General definitions for packaging and distribution envi-

ratus.

ronments are found in Terminology D996.

1.3 Test Method B uses a shock-test apparatus.

3.2 Definitions:

1.4 The values stated in inch-pound units are to be regarded

3.2.1 acceleration, n—the rate of change of velocity of a

as standard. The values given in parentheses are mathematical

body with respect to time, measured in inches per second per

conversions to SI units that are provided for information only

second (metres per second per second).

and are not considered standard.

3.2.2 velocity, n—the rate of change of position of a body in

1.5 This standard does not purport to address all of the

a specified direction with respect to time, measured in inches

safety concerns, if any, associated with its use. It is the

per second (metres per second).

responsibility of the user of this standard to establish appro-

3.3 Definitions of Terms Specific to This Standard:

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use. 3.3.1 equivalent free-fall height, n—the calculated height of

1.6 This international standard was developed in accor- free fall in a vacuum required for a falling body to attain a

dance with internationally recognized principles on standard- measured or given impact velocity.

ization established in the Decision on Principles for the

3.3.2 foam-in-place cushioning material, n—a material that

Development of International Standards, Guides and Recom-

is formed by dispensing chemical components which react and

mendations issued by the World Trade Organization Technical

expand to produce a foam cushioning material in a container or

Barriers to Trade (TBT) Committee.

mold.

2. Referenced Documents 3.3.3 free rise core density, n—the density of a foam sample

2 takenfromtheinteriorofabunoffoam(withoutskin)thatwas

2.1 ASTM Standards:

produced under unrestricted (free-rise) conditions in pounds

D996 Terminology of Packaging and Distribution Environ-

per cubic foot (kilograms per cubic metre).

ments

D3332 Test Methods for Mechanical-Shock Fragility of 3.3.4 static loading, n—the applied mass in pounds (kilo-

Products, Using Shock Machines grams) divided by the area, measured in square inches (square

D5276 Test Method for Drop Test of Loaded Containers by metres) to which the mass is applied in pounds per squares

Free Fall inches (kilograms per square metre).

3.3.5 velocitychange,n—thesumoftheimpactvelocityand

any rebound velocity.

3.4 Symbols:

These test methods are under the jurisdiction of ASTM Committee D10 on

3.4.1 g—symbolfortheaccelerationduetotheeffectsofthe

Packaging and are the direct responsibility of Subcommittee D10.13 on Interior

Packaging. earth’s gravitational pull. While somewhat variable, it is

Current edition approved Oct. 1, 2021. Published November 2021. Originally

usually considered a constant of value 386 in./s/s (9.8 m/s/s).

approved in 1982. Last previous edition approved in 2015 as D4168 – 95(2015).

DOI: 10.1520/D4168-95R21.

4. Summary of Test Methods

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.1 The test methods consist of using the cushioning mate-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. rial to be tested to support a weighted test block inside a

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4168 − 95 (2021)

package. The complete package is subjected to drops or monitor acceleration versus time histories at various points on

controlled shocks and the accelerations transmitted to the test the test apparatus and test specimen. The instrumentation

block are measured. systems shall have the following minimum properties:

6.3.1 Frequency response range from 2 Hz or less to at least

4.2 Either Test Method A or B may be used. However, the

1000 Hz.

two methods will not necessarily give the same result.

6.3.2 Accuracy of reading to be within 65 % of the actual

value.

5. Significance and Use

6.3.3 Cross-axis sensitivity less than 5 % of full scale.

5.1 Data obtained by these methods may be used to deter-

6.4 Test Block:

mine the transmitted shock cushioning characteristics of foam-

6.4.1 The test block shall have a rigid square bottom face of

in-place packaging materials. These data allow design of

not less than 8 in. (203 mm) on a side. Its height shall be a

cushioning systems that can provide adequate and efficient use

minimum of half the bottom square dimension and a maximum

of foam for protection of goods during a distribution life-cycle.

of the full bottom square dimension.

5.2 These methods, in contrast to other methods that usually

6.4.2 The test block shall include provisions for firmly

test only the cushioning foam, are designed to evaluate

mounting ballast weight to adjust its total weight to a desired

foam-in-place cushioning materials in a manner in which the

value.

foam-in-place packaging material is used. In particular, the

6.4.3 An accelerometer mounting attachment shall be pro-

method includes simultaneous use of a plastic film, the foam,

vidednearthecenterofgravityoftheblock.Theblockshallbe

and the box usually used in this method of packaging. See Fig.

designed and constructed to be as rigid as possible and to

1.

minimize motion of the various components.

6.4.4 A recommended configuration is shown in Fig. 2.

6. Apparatus

Also, it is suggested that the box weight be evenly distributed

6.1 Test Method A:

about the center of the bottom face of the test block.

6.1.1 The free-fall drop test apparatus shall conform to the

6.4.5 Ballast weights are added or removed to achieve the

requirements as described in Test Method D5276.

desired static loading on the cushioning material. The acceler-

6.2 Test Method B: ometer shall be considered as a portion of the ballast weight.

6.2.1 The shock test apparatus shall conform to the require-

6.5 Outer Container, shall be a regular, slotted container

ments as described in Test Method D5487.

(RSC) corrugated box fabricated with 200 psi (1380 kPa) test

6.3 Instrumention and Shock Sensors—Accelerometers, sig-

“C” flute fiberboard.

nal conditioners, and data storage apparatus are required to

7. Sampling

7.1 Because users form their own cushioning materials, it is

very important that accurate records be prepared of all physical

data pertaining to those materials for later identification. In

FIG. 1 Specimen Ready For Test FIG. 2 Test Block

D4168 − 95 (2021)

addition, the specific characteristics of the film used with the 9. Test Machine

cushion shall be recorded. Care must be taken to ensure that

9.1 Shock Test Apparatus Set-Up:

samples are of representative quality. It is recommended that

9.1.1 Calculate the required carriage velocity change using

all samples be allowed to cure and stabilize after being poured

the following equation:

for a minimum period of 24 h before they are tested.

∆V 5 =2 gh (1)

7.2 Specimens—IfanyoftherequirementsofSections7and

8 are not met, the container and cushioning material shall be

where:

discarded and the procedure repeated with new material. Fig. 1

∆V = required velocity change, in./s (m/s),

shows a typical specimen assembled and ready for test. 2 2

g = acceleration of gravity, in./s (m/s ), and

h = desired equivalent freefall drop height, in. (m).

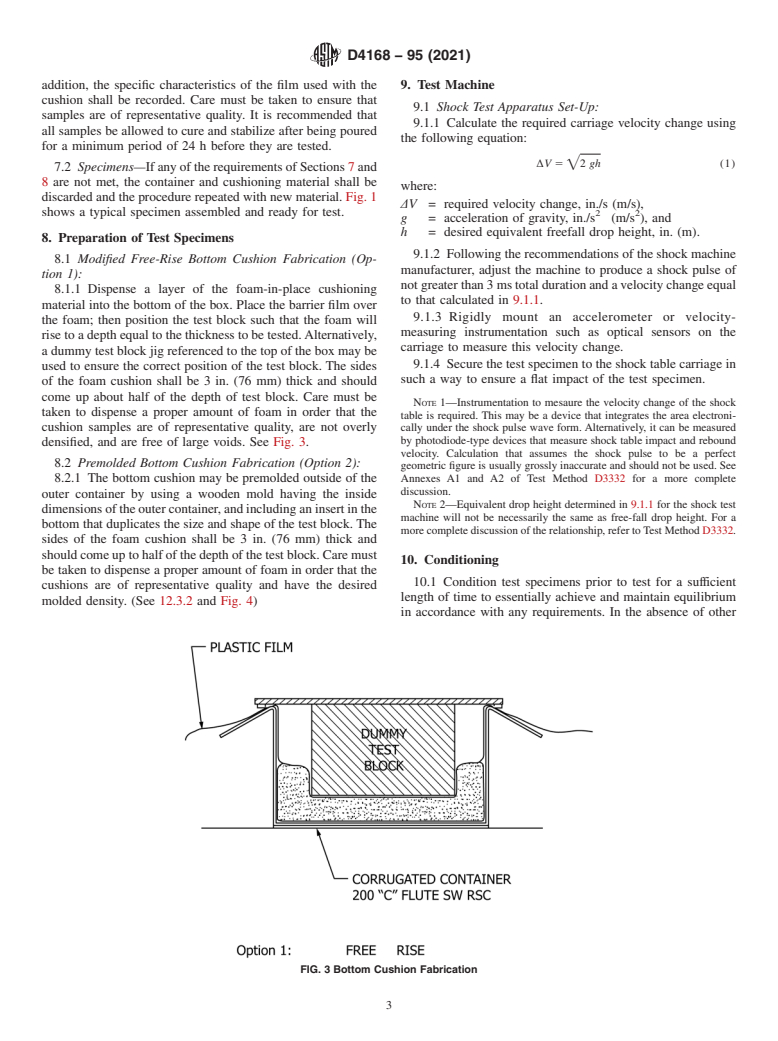

8. Preparation of Test Specimens

9.1.2 Following the recommendations of the shock machine

8.1 Modified Free-Rise Bottom Cushion Fabrication (Op-

manufacturer, adjust the machine to produce a shock pulse of

tion 1):

notgreaterthan3mstotaldurationandavelocitychangeequal

8.1.1 Dispense a layer of the foam-in-place cushioning

to that calculated in 9.1.1.

material into the bottom of the box. Place the barrier film over

9.1.3 Rigidly mount an accelerometer or velocity-

the foam; then position the test block such that the foam will

measuring instrumentation such as optical sensors on the

rise to a depth equal to the thickness to be tested.Alternatively,

carriage to measure this velocity change.

a dummy test block jig referenced to the top of the box may be

9.1.4 Secure the test specimen to the shock table carriage in

used to ensure the correct position of the test block. The sides

such a way to ensure a flat impact of the test specimen.

of the foam cushion shall be 3 in. (76 mm) thick and should

come up about half of the depth of test block. Care must be

NOTE 1—Instrumentation to mesaure the velocity change of the shock

taken to dispense a proper amount of foam in order that the

table is req

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.