ASTM E1710-05

(Test Method)Standard Test Method for Measurement of Retroreflective Pavement Marking Materials with CEN-Prescribed Geometry Using a Portable Retroreflectometer

Standard Test Method for Measurement of Retroreflective Pavement Marking Materials with CEN-Prescribed Geometry Using a Portable Retroreflectometer

SIGNIFICANCE AND USE

The quality of the stripe is determined by the coefficient of retroreflected luminance, RL, and depends on the materials used, age, and wear pattern. These conditions shall be observed and noted by the user.

Under the same conditions of illumination and viewing, larger values of RL correspond to higher levels of visual performance.

Retroreflectivity of pavement (road) markings degrade with traffic wear and require periodic measurement to ensure that sufficient line visibility is provided to drivers.

For a given viewing distance, measurements of RL made with a retroreflectometer having a geometry corresponding to that viewing distance are a good indicator of the visual ranking of material measured.

As specified by CEN, the measurement geometry of the instrument is based on a viewing distance of 30 m, a headlight mounting height of 0.65 m directly over the stripe, and an eye height of 1.2 m directly over the stripe.

It shall be the responsibility of the user to employ an instrument having the specified observation and entrance angles.

SCOPE

1.1 This test method covers measurement of the retroreflective properties of horizontal pavement marking materials containing retroreflecting beads, such as traffic stripes and surface symbols, using a portable retroreflectometer that can be placed on the road delineation to measure the retroreflection at a prescribed geometry.Note 1

The restriction to bead based materials is for the purpose of ensuring a sufficiently gradual optical response function (from points of the source aperture to points of the receiver aperture) to allow generous sized instrument source and receiver apertures.

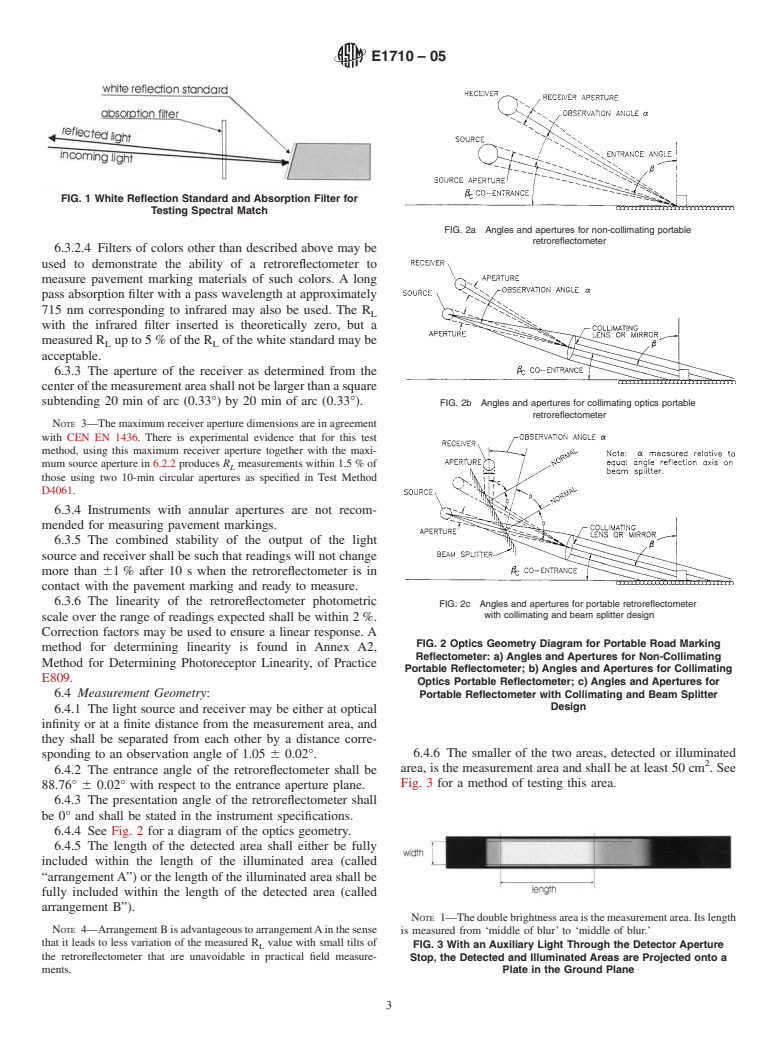

1.2 The entrance and observation angles of the retroreflectometer affect the readings. As specified by the European Committee for Standardization (CEN), the entrance and observation angles shall be 88.76 and 1.05, respectively.

1.3 This test method is intended to be used for field measurement of pavement markings but may be used to measure the performance of materials on sample panels before placing the marking material in the field.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1710 – 05

Standard Test Method for

Measurement of Retroreflective Pavement Marking Materials

with CEN-Prescribed Geometry Using a Portable

1

Retroreflectometer

This standard is issued under the fixed designation E1710; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Newly Applied Pavement Marking Using Portable Hand-

3

Operated Instruments

1.1 This test method covers measurement of the retroreflec-

E284 Terminology of Appearance

tive properties of horizontal pavement marking materials

E809 PracticeforMeasuringPhotometricCharacteristicsof

containing retroreflecting beads, such as traffic stripes and

Retroreflectors

surfacesymbols,usingaportableretroreflectometerthatcanbe

2.2 Other Standard:

placed on the road delineation to measure the retroreflection at

CEN EN 1436 Road Marking Materials—Road Marking

a prescribed geometry.

4

Performance for Road Users

NOTE 1—The restriction to bead based materials is for the purpose of

ensuring a sufficiently gradual optical response function (from points of

3. Terminology

the source aperture to points of the receiver aperture) to allow generous

3.1 The terminology used in this test method generally

sized instrument source and receiver apertures.

agrees with that used in Terminology E284.

1.2 The entrance and observation angles of the retroreflec-

3.2 Definitions—The delimiting phrase “in retroreflection”

tometer affect the readings. As specified by the European

applies to each of the following definitions when used outside

Committee for Standardization (CEN), the entrance and obser-

the context of this or other retroreflection test methods:

vation angles shall be 88.76° and 1.05°, respectively.

3.2.1 coeffıcient of retroreflected luminance, R , n—theratio

L

1.3 This test method is intended to be used for field

of the luminance, L, of a projected surface to the normal

measurement of pavement markings but may be used to

illuminance, E , at the surface on a plane normal to the

'

measure the performance of materials on sample panels before

incident light, expressed in candelas per square metre per lux

placing the marking material in the field. −2 −1

(cd·m ·lx ).

1.4 This standard does not purport to address all of the

3.2.1.1 Discussion—Becauseofthelowluminanceofpave-

safety concerns, if any, associated with its use. It is the

ment markings, the units used commonly are millicandelas per

responsibility of the user of this standard to establish appro- −2 −1

square metre per lux (mcd·m ·lx ).

priate safety and health practices and determine the applica-

3.2.2 co-entrance angle, b , n—the complement of the

C

bility of regulatory limitations prior to use.

entrance angle (90°− b).

3.2.3 co-viewing angle, n , n—the complement of the

C

2. Referenced Documents

viewing angle (90°− n).

2

2.1 ASTM Standards:

3.2.4 entrance angle, b, n—the angle between the illumi-

D4061 Test Method for Retroreflectance of Horizontal

nation axis and the retroreflector axis.

Coatings

3.2.5 observation angle, a, n—the angle between the illu-

D6359 Specification for Minimum Retroreflectance of

mination axis and the observation axis.

3.2.6 portable retroreflectometer, n—a hand-held instru-

ment that can be used in the field or laboratory for measure-

1

This test method is under the jurisdiction of ASTM Committee E12 on Color

ment of retroreflectance.

and Appearance and is the direct responsibility of Subcommittee E12.10 on

Retroreflection. 3.2.6.1 Discussion—In this test method, “portable retrore-

Current edition approved Jan. 1, 2005. Published February 2005. Originally

flectometer”referstoahand-heldinstrumentthatcanbeplaced

approved in 1995. Last previous edition approved in 1997 as E1710–97. DOI:

10.1520/E1710-05.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Withdrawn. The last approved version of this historical standard is referenced

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM on www.astm.org.

4

Standards volume information, refer to the standard’s Document Summary page on Available from European Committee for Standardization (CEN), 36 rue de

the ASTM website. Stassart, B-1050, Brussels, Belgium, http://www.cenorm.be.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E1710 – 05

over roadway delineation to measure the coefficient of retrore- 5.6 It shall be the responsibility of the user to employ an

flected luminance with a prescribed geometry. instrument having the specified observation and entrance

3.2.7 presentatio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.