ASTM D5685-11

(Specification)Standard Specification for "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) Pressure Pipe Fittings

Standard Specification for "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) Pressure Pipe Fittings

ABSTRACT

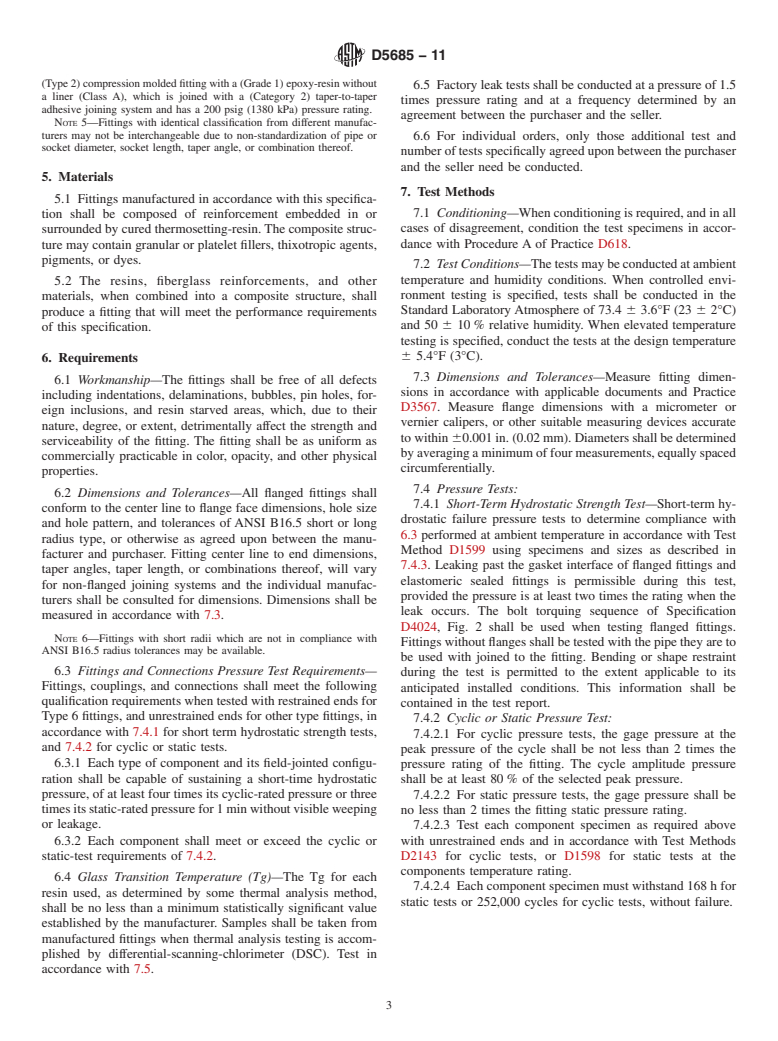

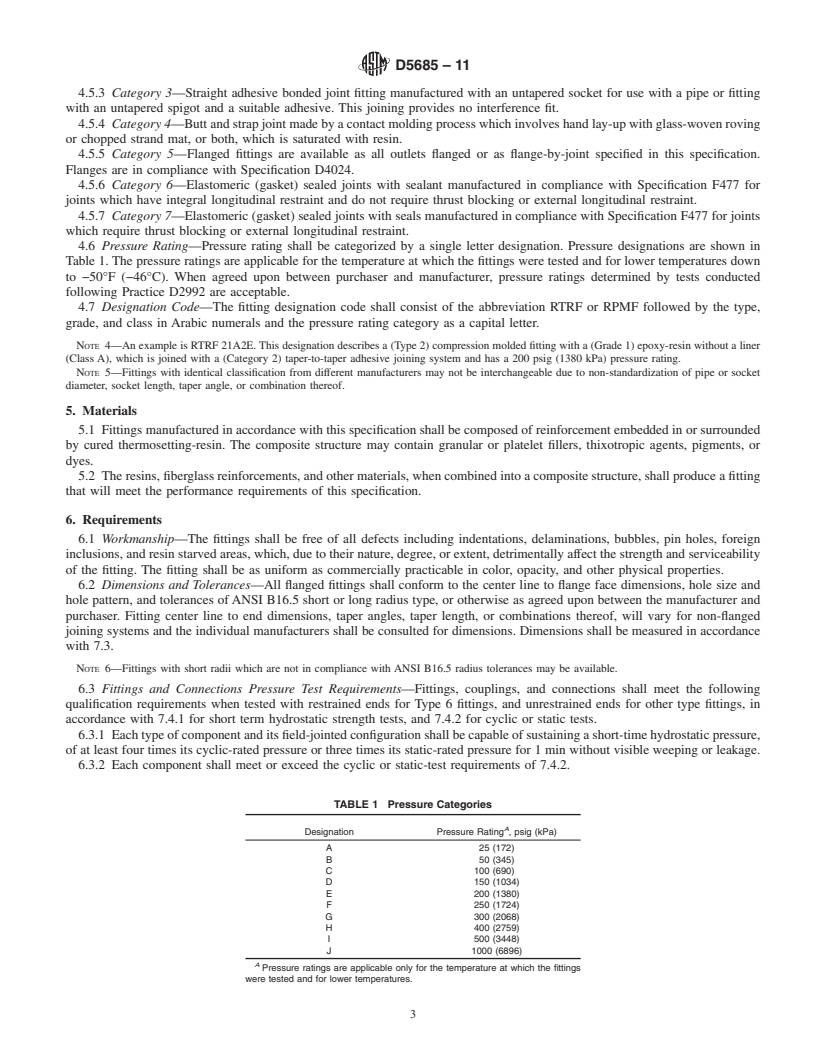

This specification covers "fiberglass" (glass-fiber-reinforced thermosetting-resin) pressure pipe fittings for use with filament wound or centrifugally cast fiberglass pipe. The fibreglass fittings are defined by type, grade, class, category, and pressure rating: type 1 - filament-wound fittings, type 2 - compression moulded fittings, type 3 - resin transfer molded fittings, type 4 - centrifugally cast fittings, and type 5 - contact molded fittings; grade 1 - epoxy-resin, grade 2 - polyester-resin, grade 3 - phenolic-resin, grade 4 - vinylester resin, and grade 7 - furan resin; class A - no liner, class B - polyester-resin liner (nonreinforced), class C - epoxy-resin liner (nonreinforced), class D - phenolic resin liner (nonreinforced), class E - polyester-resin liner (reinforced), class F - epoxy-resin liner (reinforced), class G - phenolic resin liner, class H - thermoplastic-resin liner, class I - furan-resin liner (reinforced), class J - vinylester resin liner (nonreinforced), and class K - vinylester resin liner (reinforced); category 1 - taper-to-taper adhesive bonded joint fittings, category 2 - straight-taper adhesive-bonded joint fitting, category 3 - straight adhesive bonded joint fitting, category 5 - flanged fittings, category 6 - elastomeric sealed joints with sealant, and category 7 - elastomeric sealed joints with seals. Short-term hydrostatic strength test and cyclic or static pressure test shall be performed to meet the requirements prescribed.

SCOPE

1.1 This specification covers “fiberglass” (glass-fiber-reinforced thermosetting-resin) fittings for use with filament wound or centrifugally cast fiberglass pipe, or both, in sizes 1 in. through 24 in. for pipe manufactured to Specification D2996 or D2997, or both.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 The following safety hazard caveat pertains only to the test method portion, Section 7, of this specification:

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—The term “fiberglass pipe” as described in Section 3 of this specification applies to both reinforced thermosetting resin pipe (RTRP) and reinforced polymer mortar pipe (RPMP).

Note 2—For the purposes of this standard, ploymer does not include natural polymers.

Note 3—There is no known ISO equivalent to this standard.

A1.1.1 This test determines whether the degree of cure of a fiberglass fitting test specimen meets the quality control requirements determined by statistical analysis of typical production products.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5685 −11 An American National Standard

Standard Specification for

“Fiberglass” (Glass-Fiber-Reinforced Thermosetting-Resin)

1

Pressure Pipe Fittings

This standard is issued under the fixed designation D5685; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1600TerminologyforAbbreviatedTermsRelatingtoPlas-

tics

1.1 This specification covers “fiberglass” (glass-fiber-

D2143 Test Method for Cyclic Pressure Strength of

reinforced thermosetting-resin) fittings for use with filament

Reinforced, Thermosetting Plastic Pipe

wound or centrifugally cast fiberglass pipe, or both, in sizes 1

D2310 Classification for Machine-Made “Fiberglass”

in. through 24 in. for pipe manufactured to Specification

(Glass-Fiber-Reinforced Thermosetting-Resin) Pipe

D2996 or D2997, or both.

D2992Practice for Obtaining Hydrostatic or Pressure De-

1.2 Thevaluesstatedininch-poundunitsaretoberegarded

sign Basis for “Fiberglass” (Glass-Fiber-Reinforced

as standard. The values given in parentheses are mathematical

Thermosetting-Resin) Pipe and Fittings

conversions to SI units that are provided for information only

D2996 Specification for Filament-Wound “Fiberglass’’

and are not considered standard.

(Glass-Fiber-Reinforced Thermosetting-Resin) Pipe

D2997Specification for Centrifugally Cast “Fiberglass”

1.3 The following safety hazard caveat pertains only to the

test method portion, Section 7, of this specification: (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe

D3567PracticeforDeterminingDimensionsof“Fiberglass”

1.4 This standard does not purport to address all of the

(Glass-Fiber-Reinforced Thermosetting Resin) Pipe and

safety concerns, if any, associated with its use. It is the

Fittings

responsibility of the user of this standard to establish appro-

D4024SpecificationforMachineMade“Fiberglass”(Glass-

priate safety and health practices and determine the applica-

Fiber-Reinforced Thermosetting Resin) Flanges

bility of regulatory limitations prior to use.

F412Terminology Relating to Plastic Piping Systems

NOTE 1—The term “fiberglass pipe” as described in Section 3 of this

F477Specification for Elastomeric Seals (Gaskets) for Join-

specification applies to both reinforced thermosetting resin pipe (RTRP)

ing Plastic Pipe

and reinforced polymer mortar pipe (RPMP).

2.2 ANSI Standard:

NOTE 2—For the purposes of this standard, ploymer does not include

3

natural polymers. B16.5Steel Pipe Flanges, Flanged Valves and Fittings

NOTE 3—There is no known ISO equivalent to this standard.

3. Terminology

2. Referenced Documents

3.1 Definitions:

2

2.1 ASTM Standards:

3.1.1 General—Definitions are in accordance with Termi-

D618Practice for Conditioning Plastics for Testing

nology D883 or F412. Abbreviations are in accordance with

D883Terminology Relating to Plastics

TerminologyD1600,unlessotherwiseindicated.Theabbrevia-

D1598Test Method for Time-to-Failure of Plastic Pipe

tion for fiberglass pipe is RTRP and the abbreviation for

Under Constant Internal Pressure

fiberglass fittings is RTRF.

D1599Test Method for Resistance to Short-Time Hydraulic

3.1.2 “fiberglass” pipe—tubular product containing glass

Pressure of Plastic Pipe, Tubing, and Fittings

fiber reinforcements embedded in or surrounded by cured

thermosetting resin. The composite structure may contain

aggregate, granular or platelet fillers, thixotropic agents,

1

This specification is under the jurisdiction of ASTM Committee D20 on

pigments, or dyes. Thermoplastic or thermosetting liners or

Plastics and is the direct responsibility of Subcommittee D20.23 on Reinforced

coatings may be included.

Plastic Piping Systems and Chemical Equipment.

Current edition approved Feb. 1, 2011. Published March 2011. Originally

3.1.3 reinforced thermosetting resin pipe—fiberglass pipe

approved in 1995. Last previous edition approved in 2005 as D5685-05. DOI:

without aggregate (RTRP).

10.1520/D5685-11.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5685−11

3.1.4 reinforced polymer mortar pipe—fiberglass pipe with 4.4.11 Class K—Vinylester resin liner (reinforced

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:D5685–05 Designation: D5685 – 11

Standard Specification for

“Fiberglass” (Glass-Fiber-Reinforced Thermosetting-Resin)

1

Pressure Pipe Fittings

This standard is issued under the fixed designation D5685; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope *

1.1 This specification covers “fiberglass” (glass-fiber-reinforced thermosetting-resin) fittings for use with filament wound or

centrifugally cast fiberglass pipe, or both, in sizes 1 in. through 24 in. for pipe manufactured to Specification D2996 or D2997,

or both.

1.2The following safety hazard caveat pertains only to the test method portion, Section

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 The following safety hazard caveat pertains only to the test method portion, Section 7, of this specification:

1.3

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

NOTE 1—The term “fiberglass pipe” as described in Section 3 of this specification applies to both reinforced thermosetting resin pipe (RTRP) and

reinforced polymer mortar pipe (RPMP).

NOTE 2—For the purposes of this standard, ploymer does not include natural polymers.

NOTE3—There is no similar or equivalent ISO standard. 3—There is no known ISO equivalent to this standard.

2. Referenced Documents

2

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

D883 Terminology Relating to Plastics

D1598 Test Method for Time-to-Failure of Plastic Pipe Under Constant Internal Pressure

D1599 Test Method for Resistance to Short-Time Hydraulic Pressure of Plastic Pipe, Tubing, and Fittings

D1600 Terminology for Abbreviated Terms Relating to Plastics

D2143 Test Method for Cyclic Pressure Strength of Reinforced, Thermosetting Plastic Pipe D2310

D2310 Classification for Machine-Made Fiberglass (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe

D2992 Practice for Obtaining Hydrostatic or Pressure Design Basis for Fiberglass (Glass-Fiber-Reinforced Thermosetting-

Resin) Pipe and Fittings

D2996 Specification for Filament-Wound Fiberglass’’ (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe

D2997 Specification for Centrifugally Cast Fiberglass (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe

D3567 Practice for Determining Dimensions of Fiberglass (Glass-Fiber-Reinforced Thermosetting Resin) Pipe and Fittings

D4024 Specification for Machine Made Fiberglass’’ (Glass-Fiber-Reinforced Thermosetting Resin) Flanges

F412 Terminology Relating to Plastic Piping Systems

F477 Specification for Elastomeric Seals (Gaskets) for Joining Plastic Pipe

2.2 ANSI Standard:

3

B16.5 Steel Pipe Flanges, Flanged Valves and Fittings

1

This specification is under the jurisdiction ofASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.23 on Reinforced Plastic Piping

Systems and Chemical Equipment.

Current edition approved Nov.Feb. 1, 2005.2011. Published November 2005.March 2011. Originally approved in 1995. Last previous edition approved in 20022005 as

D5685–02.D5685-05. DOI: 10.1520/D5685-05.10.1520/D5685-11.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5685 – 11

3. Terminology

3.1 Definitions:

3.1.1 General—Definitions are in accordance with Terminology D883 or F412. Abbreviations are in accordance with

Terminology D1600, unless otherwise indicated. The abbreviation for fiberglass pipe is RTRP and the abbreviation for fiberglass

fittings is

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.