ASTM D7051-05(2020)

(Test Method)Standard Test Method for Cyclic Thermal Shock of SBS-Modified Bituminous Roofing Sheets with Factory-Applied Metal Surface

Standard Test Method for Cyclic Thermal Shock of SBS-Modified Bituminous Roofing Sheets with Factory-Applied Metal Surface

SIGNIFICANCE AND USE

4.1 This test method is used to determine the dimensional changes and physical stability of the product upon exposure to specified cyclic thermal conditions. It is also useful in determining the integrity of the bond between the metal foil and the SBS-modified bituminous compound.

SCOPE

1.1 This test method covers the measurement of movement due to cyclic thermal exposure of SBS (styrene-butadiene-styrene)-modified bituminous sheets with a factory-applied metal foil surface.

1.2 The values stated in SI units are to be regarded as standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D7051 −05 (Reapproved 2020)

Standard Test Method for

Cyclic Thermal Shock of SBS-Modified Bituminous Roofing

Sheets with Factory-Applied Metal Surface

This standard is issued under the fixed designation D7051; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope the specimen length dimension is measured in relation to the

numberofcyclesandtemperaturevariation.Thistestappliesto

1.1 This test method covers the measurement of movement

metal foil surfaced SBS-modified bitumen roofing sheets.

due to cyclic thermal exposure of SBS (styrene-butadiene-

styrene)-modified bituminous sheets with a factory-applied

4. Significance and Use

metal foil surface.

4.1 This test method is used to determine the dimensional

1.2 The values stated in SI units are to be regarded as

changes and physical stability of the product upon exposure to

standard. The values in parentheses are for information only.

specified cyclic thermal conditions. It is also useful in deter-

1.3 This standard does not purport to address all of the mining the integrity of the bond between the metal foil and the

safety concerns, if any, associated with its use. It is the SBS-modified bituminous compound.

responsibility of the user of this standard to establish appro-

5. Apparatus

priate safety, health, and environmental practices and deter-

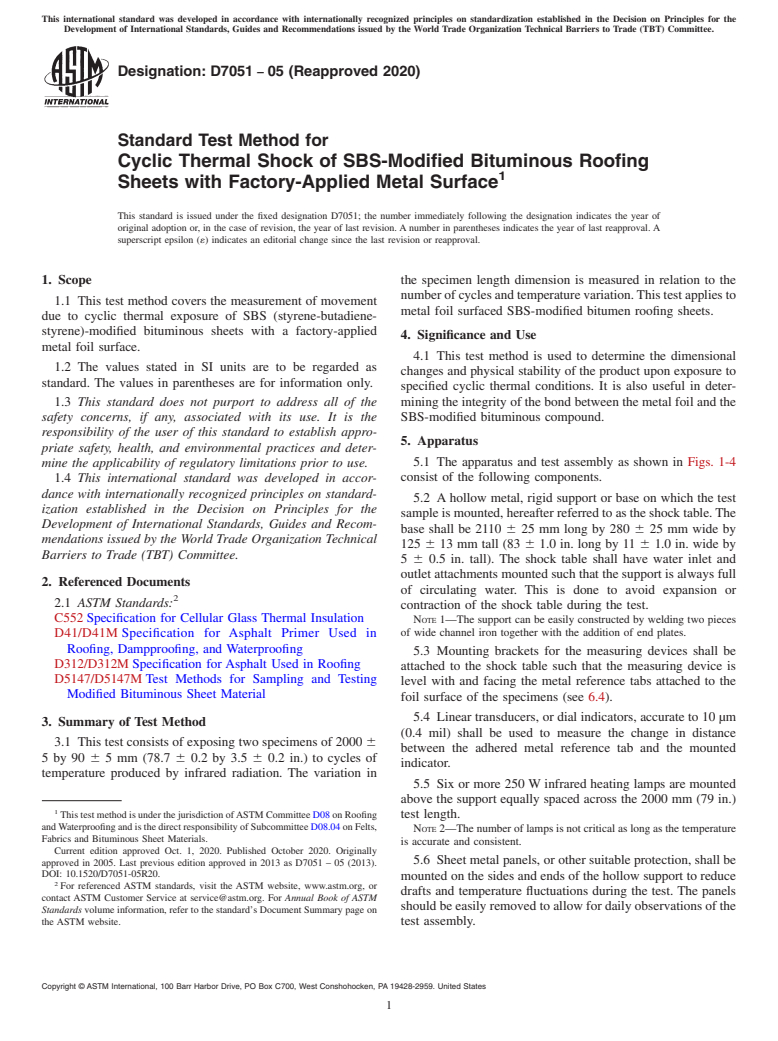

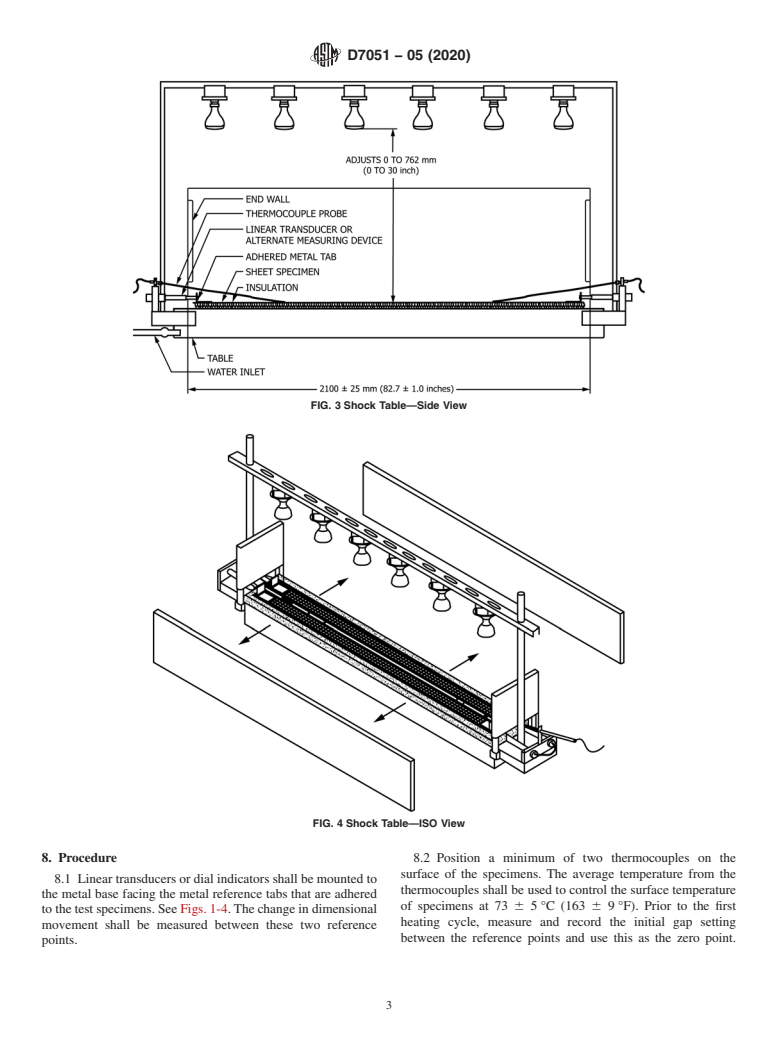

mine the applicability of regulatory limitations prior to use. 5.1 The apparatus and test assembly as shown in Figs. 1-4

consist of the following components.

1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard-

5.2 A hollow metal, rigid support or base on which the test

ization established in the Decision on Principles for the

sampleismounted,hereafterreferredtoastheshocktable.The

Development of International Standards, Guides and Recom-

base shall be 2110 6 25 mm long by 280 6 25 mm wide by

mendations issued by the World Trade Organization Technical

125 6 13 mm tall (83 6 1.0 in. long by 11 6 1.0 in. wide by

Barriers to Trade (TBT) Committee.

5 6 0.5 in. tall). The shock table shall have water inlet and

outlet attachments mounted such that the support is always full

2. Referenced Documents

of circulating water. This is done to avoid expansion or

2.1 ASTM Standards:

contraction of the shock table during the test.

C552 Specification for Cellular Glass Thermal Insulation NOTE 1—The support can be easily constructed by welding two pieces

of wide channel iron together with the addition of end plates.

D41/D41M Specification for Asphalt Primer Used in

Roofing, Dampproofing, and Waterproofing

5.3 Mounting brackets for the measuring devices shall be

D312/D312M Specification for Asphalt Used in Roofing

attached to the shock table such that the measuring device is

D5147/D5147M Test Methods for Sampling and Testing

level with and facing the metal reference tabs attached to the

Modified Bituminous Sheet Material

foil surface of the specimens (see 6.4).

5.4 Linear transducers, or dial indicators, accurate to 10 µm

3. Summary of Test Method

(0.4 mil) shall be used to measure the change in distance

3.1 This test consists of exposing two specimens of 2000 6

between the adhered metal reference tab and the mounted

5by90 6 5 mm (78.7 6 0.2 by 3.5 6 0.2 in.) to cycles of

indicator.

temperature produced by infrared radiation. The variation in

5.5 Six or more 250 W infrared heating lamps are mounted

above the support equally spaced across the 2000 mm (79 in.)

This test method is under the jurisdiction ofASTM Committee D08 on Roofing

test length.

andWaterproofingandisthedirectresponsibilityofSubcommitteeD08.04onFelts,

NOTE 2—The number of lamps is not critical as long as the temperature

Fabrics and Bituminous Sheet Materials.

is accurate and consistent.

Current edition approved Oct. 1, 2020. Published October 2020. Originally

5.6 Sheet metal panels, or other suitable protection, shall be

approved in 2005. Last previous edition approved in 2013 as D7051 – 05 (2013).

DOI: 10.1520/D7051-05R20.

mounted on the sides and ends of the hollow support to reduce

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

drafts and temperature fluctuations during the test. The panels

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

should be easily removed to allow for daily observations of the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. test assembly.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7051−05 (2020)

FIG. 1Shock Table—Top View

FIG. 2Shock Table—End Views

5.7 Aregulating system shall be used to maintain the timing cation D312/D312M Type IV asphalt applied at 218 6 14 °C

of the heating and cooling cycles. Temperature may be (425 6 25 °F). The specimens are applied parallel to each

maintained automatically or manually, but the temperature other, and shall be separated by a distance of 40 6 10 mm (1.6

shall be measured using thermocouples. 60.4in.).Ifpolyolefinfilmbackingexists,itshallbecarefully

melted away and dusted with a parting agent before applying

6. Preparation of Apparatus

the specimens with asphalt.

6.1 The top surface of the shock table shall be primed with

6.4 Metal reference tabs, minimum 0.5 mm (28 ga) thick,

Specification D41/D41M asphalt primer and allowed to dry.

shall be attached to the foil surface at both ends of eac

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.