ASTM D5874-02(2007)

(Test Method)Standard Test Method for Determination of the Impact Value (IV) of a Soil

Standard Test Method for Determination of the Impact Value (IV) of a Soil

SCOPE

1.1 This test method covers the determination of the Impact Value (IV) of a soil either in the field or a test mold.

1.2 The standard test method, using a 4.5 kg (10 lbm) hammer, is suitable for, but not limited to, evaluating the strength of an unsaturated compacted fill, in particular pavement materials, soils, and soil-aggregates having maximum particle sizes less than 37.5 mm (1.5 in.).

1.3 By using a lighter 0.5 kg (1.1 lbm) hammer, this test method is applicable for evaluating lower strength soils such as fine grained cohesion less, highly organic, saturated, or highly plastic soils having a maximum particle size less than 9.5 mm (0.375 in.).

1.4 By performing laboratory test correlations for a particular soil using the 4.5 kg (10 lbm) hammer, IV may be correlated with an unsoaked California Bearing Ratio (CBR) or may be used to infer percentage compaction.

1.5 The values stated SI are to be regarded as the standard. The values stated in parentheses are given for information only.

1.6 All observed and calculated values shall conform to the guidelines for significant digits and rounding established in Practice D 6026. The method used to specify how data are collected, calculated, or recorded in this standard is not directly related to the accuracy to which the data can be applied in design or other uses or both. How one applies the results obtained using this standard is beyond its scope.

1.7 This standard may involve hazardous materials, operations, and equipment This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Note 1The equipment and procedures contained in this test method are similar to those developed by B. Clegg in the 1970s at the University of Western Australia, Nedlands, Australia. Impact Value is also commonly known as Clegg Impact Value (CIV).

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5874 − 02(Reapproved 2007)

Standard Test Method for

Determination of the Impact Value (IV) of a Soil

This standard is issued under the fixed designation D5874; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

known as Clegg Impact Value (CIV).

1. Scope*

1.1 This test method covers the determination of the Impact

2. Referenced Documents

Value (IV) of a soil either in the field or a test mold.

2.1 ASTM Standards:

1.2 The standard test method, using a 4.5 kg (10 lbm)

D653 Terminology Relating to Soil, Rock, and Contained

hammer, is suitable for, but not limited to, evaluating the

Fluids

strength of an unsaturated compacted fill, in particular pave-

D698 Test Methods for Laboratory Compaction Character-

ment materials, soils, and soil-aggregates having maximum 3

istics of Soil Using Standard Effort (12 400 ft-lbf/ft (600

particle sizes less than 37.5 mm (1.5 in.).

kN-m/m ))

1.3 By using a lighter 0.5 kg (1.1 lbm) hammer, this test D1556 Test Method for Density and Unit Weight of Soil in

methodisapplicableforevaluatinglowerstrengthsoilssuchas

Place by Sand-Cone Method

fine grained cohesionless, highly organic, saturated, or highly D1557 Test Methods for Laboratory Compaction Character-

plastic soils having a maximum particle size less than 9.5 mm

istics of Soil Using Modified Effort (56,000 ft-lbf/ft

(0.375 in.). (2,700 kN-m/m ))

D1883 Test Method for California Bearing Ratio (CBR) of

1.4 By performing laboratory test correlations for a particu-

Laboratory-Compacted Soils

larsoilusingthe4.5kg(10lbm)hammer,IVmaybecorrelated

D2167 Test Method for Density and Unit Weight of Soil in

with an unsoaked California Bearing Ratio (CBR) or may be

Place by the Rubber Balloon Method

used to infer percentage compaction.

D2216 Test Methods for Laboratory Determination of Water

1.5 The values stated SI are to be regarded as the standard.

(Moisture) Content of Soil and Rock by Mass

Thevaluesstatedinparenthesesaregivenforinformationonly.

D2922 Test Methods for Density of Soil and Soil-Aggregate

1.6 All observed and calculated values shall conform to the in Place by Nuclear Methods (Shallow Depth) (With-

guidelines for significant digits and rounding established in

drawn 2007)

Practice D6026. The method used to specify how data are D2937 Test Method for Density of Soil in Place by the

collected,calculated,orrecordedinthisstandardisnotdirectly

Drive-Cylinder Method

related to the accuracy to which the data can be applied in D3740 Practice for Minimum Requirements for Agencies

design or other uses or both. How one applies the results Engaged in Testing and/or Inspection of Soil and Rock as

obtained using this standard is beyond its scope. Used in Engineering Design and Construction

D4643 Test Method for Determination of Water (Moisture)

1.7 This standard may involve hazardous materials,

Content of Soil by Microwave Oven Heating

operations, and equipment. This standard does not purport to

D4959 Test Method for Determination of Water (Moisture)

address all of the safety concerns, if any, associated with its

Content of Soil By Direct Heating

use. It is the responsibility of the user of this standard to

D6026 Practice for Using Significant Digits in Geotechnical

establish appropriate safety and health practices and deter-

Data

mine the applicability of regulatory limitations prior to use.

NOTE 1—The equipment and procedures contained in this test method

3. Terminology

are similar to those developed by B. Clegg in the 1970s at the University

3.1 Definitions:

ofWesternAustralia, Nedlands,Australia. ImpactValue is also commonly

1 2

ThistestmethodisunderthejurisdictionofASTMCommitteeD18onSoiland For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Rock and is the direct responsibility of Subcommittee D18.08 on Special and contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Construction Control Tests. Standards volume information, refer to the standard’s Document Summary page on

CurrenteditionapprovedMay1,2007.PublishedJuly2007.Originallyapproved the ASTM website.

in 1995. Last previous edition approved in 2002 as D5874 – 02. DOI: 10.1520/ The last approved version of this historical standard is referenced on

D5874-02R07. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5874 − 02 (2007)

3.1.1 Except as listed below, all definitions are in accor-

dance with Terminology D653.

3.1.2 impact value (IV), n—the value expressed in units of

tens of gravities (g) derived from the peak decelaration of a 4.5

kg (10 lbm) instrumented compaction hammer 50 mm (1.97

in.) in diameter free falling 450 mm (18 in.).

3.1.3 light impact value (IV/L), n—the IV derived from

using a 0.5 kg (1.1 lbm) mass hammer 50 mm (1.97 in.) in

diameter free falling 300 mm (12 in.).

3.1.4 impact soil tester, n—testing apparatus used to obtain

an IV of a soil.

3.1.5 target iv, n—the desired strength, in terms of IV, to be

achieved in the field for a particular material and construction

process. This may also be referred to as target strength.

4. Summary of Test Method

4.1 The test apparatus is placed on the material to be tested

either in a mold or on naturally occurring or compacted soil in

the field. The hammer is raised to a set height and allowed to

free fall. The instrumentation of the test apparatus displays a

value in tens of gravities (g) of the peak deceleration of the

hammer’s impact as recorded by an accelerometer fitted to the

top of the hammer body. A total of four blows of the hammer

are applied on the same spot to determine the IV for each test

performed.

4.2 A light hammer of 0.5 kg (1.1 lbm) may be used for

softer conditions or fragile materials instead of the 4.5 kg (10

lbm) standard hammer to determine the IV. When used the

resulting value is termed the Light Impact Value (IV/L).

FIG. 1 Illustration of Target IV for Material With No Peak but

Drop

5. Significance and Use

5.1 Impact Value, as determined using the standard 4.5 kg from laboratory testing or field trials for a desired density and

water content. If testing is performed after compaction when

(10 lbm) hammer, has direct application to design and con-

struction of pavements and a general application to earthworks conditionsaresuchthatthewatercontenthaschangedfromthe

critical value, determination of the actual water content by

compaction control and evaluation of strength characteristics

laboratory testing enables the field density to be inferred from

of a wide range of materials, such as soils, soil aggregates,

regression equations using IV, density and water content.

stabilized soil and recreational turf. Impact Value is one of the

properties used to evaluate the strength of a layer of soil up to

NOTE 2—Impact Value may be used as a means to improve the

about 150 mm (6 in.) in thickness and by inference to indicate

compaction process by giving instant feedback on roller efficiency,

the compaction condition of this layer. Impact Value reflects uniformity, confirming the achievement of the target strength, and by

inference the achieved density. When inferring density from IV, however,

and responds to changes in physical characteristics that influ-

it should be considered as only indicative of density. Where strict

ence strength. It is a dynamic force penetration property and

acceptance on a density ratio basis is required, test methods that measure

may be used to set a strength parameter.

density directly shall be used.

5.2 This test method provides immediate results in terms of

5.4 This test method may be used to monitor strength

IV and may be used for the process control of pavement or

changes during a compaction process or over time due to

earthfill activities where the avoidance of delays is important

seasonal, environmental or traffic changes.

and where there is a need to determine variability when

NOTE 3—For in-place soil strength evaluation where there may be a dry

statistically based quality assurance procedures are being used.

and hard surface layer (crust), testing both the crust and the underlying

layer may be required.

5.3 This test method does not provide results directly as a

percentage of compaction but rather as a strength index value 5.5 The standard instrument is based on a 4.54 kg (10 lbm)

from which compaction may be inferred for the particular compaction hammer using a 457.2 mm (18 in.) drop height.

moisture conditions. From observations, strength either re- The hammer has been equipped with an accelerometer and

mains constant along the dry side of the compaction curve or instrumented using a peak hold electronic circuit to read the

else reaches a peak and declines rapidly with increase in water peak deceleration on impact. The circuitry is filtered electroni-

content slightly dry of optimum water content. This is gener- cally to remove unwanted frequencies and the peak decelera-

allybetween95and98 %maximumdrydensity(seeFig.1and tion is displayed in units of ten gravities (g) with the output

Fig.2).Afieldtarget strength in terms of IVmay bedesignated below units of ten gravities truncated.

D5874 − 02 (2007)

FIG. 2 Illustration of Target IV for Material With Pronounced

Peak

FIG. 3 Development of Force-Penetration from Deceleration Ver-

sus Time

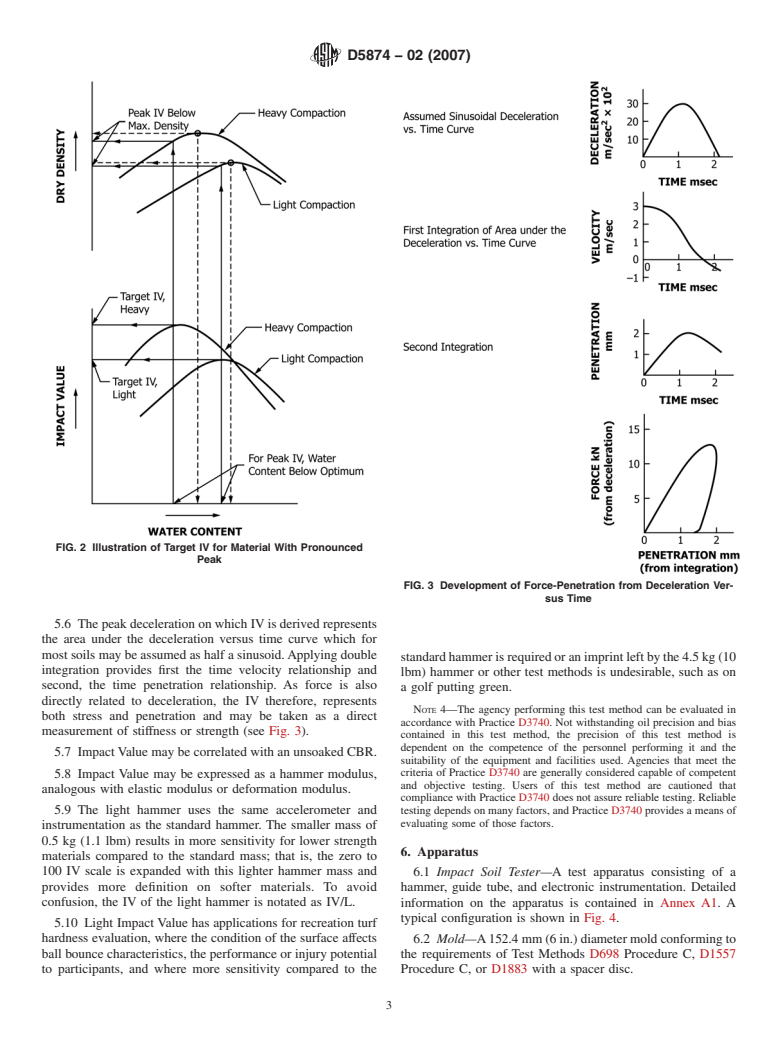

5.6 The peak deceleration on which IVis derived represents

the area under the deceleration versus time curve which for

most soils may be assumed as half a sinusoid.Applying double

standardhammerisrequiredoranimprintleftbythe4.5kg(10

integration provides first the time velocity relationship and

lbm) hammer or other test methods is undesirable, such as on

second, the time penetration relationship. As force is also

a golf putting green.

directly related to deceleration, the IV therefore, represents

NOTE 4—The agency performing this test method can be evaluated in

both stress and penetration and may be taken as a direct

accordance with Practice D3740. Not withstanding oil precision and bias

measurement of stiffness or strength (see Fig. 3).

contained in this test method, the precision of this test method is

dependent on the competence of the personnel performing it and the

5.7 Impact Value may be correlated with an unsoaked CBR.

suitability of the equipment and facilities used. Agencies that meet the

criteria of Practice D3740 are generally considered capable of competent

5.8 Impact Value may be expressed as a hammer modulus,

and objective testing. Users of this test method are cautioned that

analogous with elastic modulus or deformation modulus.

compliance with Practice D3740 does not assure reliable testing. Reliable

5.9 The light hammer uses the same accelerometer and testing depends on many factors, and Practice D3740 provides a means of

evaluating some of those factors.

instrumentation as the standard hammer. The smaller mass of

0.5 kg (1.1 lbm) results in more sensitivity for lower strength

6. Apparatus

materials compared to the standard mass; that is, the zero to

100 IV scale is expanded with this lighter hammer mass and 6.1 Impact Soil Tester—A test apparatus consisting of a

provides more definition on softer materials. To avoid

hammer, guide tube, and electronic instrumentation. Detailed

confusion, the IV of the light hammer is notated as IV/L. information on the apparatus is contained in Annex A1.A

typical configuration is shown in Fig. 4.

5.10 Light Impact Value has applications for recreation turf

hardness evaluation, where the condition of the surface affects 6.2 Mold—A152.4mm(6in.)diametermoldconformingto

ball bounce characteristics, the performance or injury potential the requirements of Test Methods D698 Procedure C, D1557

to participants, and where more sensitivity compared to the Procedure C, or D1883 with a spacer disc.

D5874 − 02 (2007)

NOTE 6—To avoid the possibility of damage to the electronics or the

hammer,theimpactsoiltestershouldnotbeuseddirectlyonhardsurfaces

suchasconcreteorotherwiseinsuchawayonmaterialsthatitwouldgive

results of more than 100 IV (1000 g ).

NOTE 7—The impact energy provided by the 4.5 kg hammer can cause

undesired damage to surfaces and materials such as brick or concrete

paving slabs or smoothly prepared turf surfaces.

7.2 Determine an IV as follows.

7.2.1 The peak deceleration that is the highest of the four

successive blows is taken as the IV. The maximum of the first

four blows has been found through experiment and practice to

be the simplest means by which to obtain consistent results.

Analysis of the blow count has shown that the first blow or two

may be considered as seating procedure as they create a

compacted wedge or hemisphere of soil that is subsequently

forced into the body of the soil causing an increase in

deceleration, that is, an increase in IV, as successive blows are

applied.Ingeneral,decelerationremainspracticallyunchanged

after the third or fourth blow with additional blows continuing

to produce a constant amount of penetration. If lower values

occur with subsequent blows, this is due apparently to the

hammer striking the sides of the indentation or by loose

material falling onto the strike surface causing a bias in this

direction.

7.2.2 Impact Values obtained from other blow counts, or an

average thereof, shall be reported accordingly in the report.

7.3 Field Procedure A—If necessary, prepare the surface of

the compacted or natural soil to be tested by lightly scuffing

with the foot to remove loose surface material. Before begin-

ning a test, ensure that the hammer strike face is clean of any

FIG. 4 Illustration (Cross Section) of a 4.5 kg Impact Soil Tester

soil build-up and that the guide tube is reasonably clean so as

with Hammer at Rest in the Guide Tube

not to restrict a free fall. Place the impact soil tester in position

with the guide tube base set on the ground. Steady the guide

6.2.1 Molds of other, typically larger, dimensions may be

tube to hold vertical in place, activate the instrumentation, and

used but must be reported accordingly in the report.

apply four free falling blows in succession from the set height

NOTE 5—For a particular material, the smaller 101.6 mm (4 in.) mold of drop. Take and record the highest value of the four blows as

may be used if it has been proven by a laboratory test comparison with the

the IV.

152.4 mm (6 in.) mold that there is no significant difference in the IV

results. N

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.