ASTM B432-14

(Specification)Standard Specification for Copper and Copper Alloy Clad Steel Plate

Standard Specification for Copper and Copper Alloy Clad Steel Plate

ABSTRACT

This specification covers plates made of carbon steel or low-alloy steel base, to which a layer of copper or copper-base alloy cladding is integrally and continuously bonded on one or both sides. The material is generally intended for pressure vessel applications, but may be used in other structural applications where corrosion resistance or conductivity of the alloy is of prime importance. The steel shall be primarily made by the open-hearth, electric-furnace (with optional degassing and refining done separately), or basic-oxygen processes. Secondary processes may also be performed, whereby the steel made from the primary processes is remelted using, but not limited to, electroslag remelting or vacuum arc remelting. Materials shall be tested and shall conform to dimensional (thickness, flatness, and outside diameter), mechanical (tensile, shear and bond strengths), and chemical composition requirements. The manufacturer may rework defects in the cladding by repair welding provided specific requirements are met.

SCOPE

1.1 This specification establishes the requirements for plate of a carbon steel or low-alloy steel base to which is integrally and continuously bonded on one or both sides a layer of copper or copper-base alloy. The material is generally intended for pressure vessel use but may be used in other structural applications where corrosion resistance or conductivity of the alloy is of prime importance.

1.2 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B432 −14

Standard Specification for

1

Copper and Copper Alloy Clad Steel Plate

This standard is issued under the fixed designation B432; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

3

1. Scope* 2.2 ASME Code:

Boiler and Pressure Vessel Code, Section VIII

1.1 This specification establishes the requirements for plate

Boiler and Pressure Vessel Code, Section IX

of a carbon steel or low-alloy steel base to which is integrally

andcontinuouslybondedononeorbothsidesalayerofcopper

3. Terminology

or copper-base alloy. The material is generally intended for

pressure vessel use but may be used in other structural

3.1 For definitions of terms related to copper and copper

applications where corrosion resistance or conductivity of the

alloys, refer to Terminology B846.

alloy is of prime importance.

3.2 Definitions of Terms Specific to This Standard:

1.2 Units—The values stated in inch-pound units are to be

3.2.1 base metal (backing steel), n—component to which

regarded as standard. The values given in parentheses are

the cladding metal is applied, usually the greater percentage of

mathematical conversions to SI units that are provided for

the composite plate and usually consisting of carbon or

information only and are not considered standard.

low-alloy steel.

3.2.2 blind flange, n—same as a cover.

2. Referenced Documents

3.2.3 bonding, n—adhesion of one surface to another with-

2

2.1 ASTM Standards:

out the use of an adhesive as a bonding agent.

A6/A6M Specification for General Requirements for Rolled

3.2.4 cladding metal, n—the copper or copper-base alloy

Structural Steel Bars, Plates, Shapes, and Sheet Piling

component of the composite plate.

A20/A20M SpecificationforGeneralRequirementsforSteel

Plates for Pressure Vessels

3.2.5 cover, n—a component with similar features to a

A578/A578M Specification for Straight-Beam Ultrasonic

tubesheet which is used as a closure and which typically

Examination of Rolled Steel Plates for Special Applica-

requires surface machining over part of the face while main-

tions

taining minimum specified minimum thickness.

B96/B96M Specification for Copper-Silicon Alloy Plate,

3.2.6 double-clad, n—material is considered as double-clad

Sheet, Strip, and Rolled Bar for General Purposes and

whenbothsidesofthesteelbasemetalarecoveredwithcopper

Pressure Vessels

cladding.

B152/B152M Specification for Copper Sheet, Strip, Plate,

3.2.7 interface, n—of the clad product, is that region of the

and Rolled Bar

thickness in which the product transitions from essentially

B171/B171M Specification for Copper-Alloy Plate and

100 % base metal to 100 % cladding metal, also referred to as

Sheet for Pressure Vessels, Condensers, and Heat Ex-

the bond or bondzone.

changers

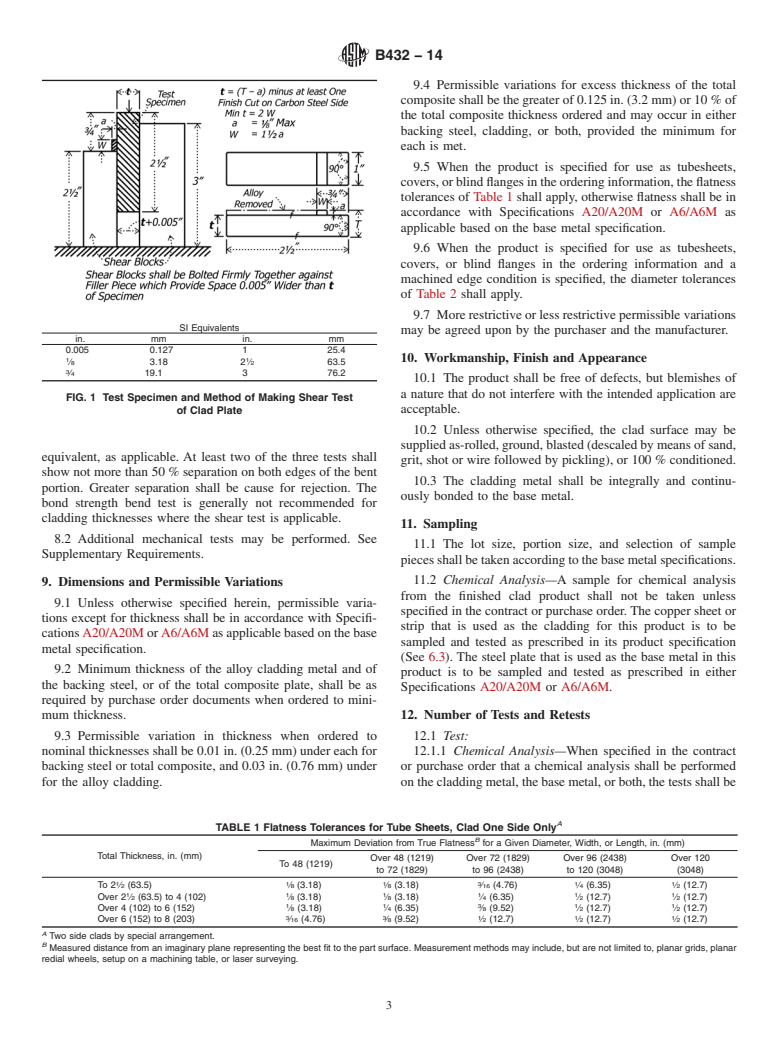

B846 Terminology for Copper and Copper Alloys 3.2.8 integrally and continuously bonded, adv—a condition

E29 Practice for Using Significant Digits in Test Data to in which the cladding metal and base metal are brought

Determine Conformance with Specifications together to form a metallurgical bond at essentially the entire

interfaceofthetwometalsbymeansotherthanthoseprocesses

that do not produce a homogeneous composite plate.

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

3.2.9 plate, n—the term plate as used in this specification

andCopperAlloysandisthedirectresponsibilityofSubcommitteeB05.01onPlate,

applies to material 0.188 in. (4.78 mm) and over in thickness,

Sheet, and Strip.

and over 10 in. (254 mm) in width.

Current edition approved Sept. 1, 2014. Published November 2014. Originally

approved in 1966. Last previous edition approved in 2009 as B432 – 09a. DOI:

10.1520/B0432-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from American Society of Mechanical Engineers (ASME), ASME

Standards volume information, refer to the standard’s Document Summary page on International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

the ASTM website. www.asme.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B432−14

3.2.10 single-clad, n—material is considered as single-clad 5.2.2 The cladding metal may be fabricated from multiple

when only one side of the steel base metal is covered with sheets or plates by edge butt welding prior to the cladding

copper cladding. operation.

5.2.3 The cladding thickness may con

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B432 − 09a B432 − 14

Standard Specification for

1

Copper and Copper Alloy Clad Steel Plate

This standard is issued under the fixed designation B432; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification establishes the requirements for plate of a carbon steel or low-alloy steel base to which is integrally and

continuously bonded on one or both sides a layer of copper or copper-base alloy. The material is generally intended for pressure

vessel use but may be used in other structural applications where corrosion resistance or conductivity of the alloy is of prime

importance.

1.2 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are

mathematical conversions to SI units that are provided for information only and are not considered standard.

2. Referenced Documents

2

2.1 ASTM Standards:

A6/A6M Specification for General Requirements for Rolled Structural Steel Bars, Plates, Shapes, and Sheet Piling

A20/A20M Specification for General Requirements for Steel Plates for Pressure Vessels

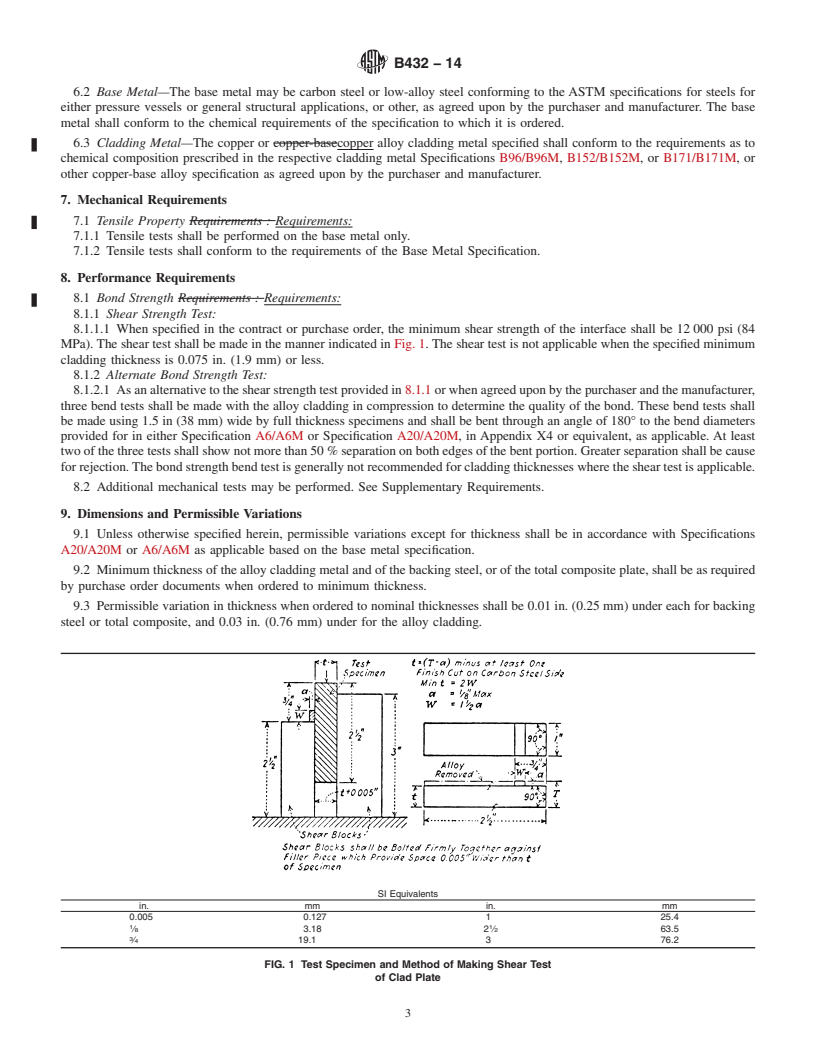

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A578/A578M Specification for Straight-Beam Ultrasonic Examination of Rolled Steel Plates for Special Applications

B96/B96M Specification for Copper-Silicon Alloy Plate, Sheet, Strip, and Rolled Bar for General Purposes and Pressure Vessels

B152/B152M Specification for Copper Sheet, Strip, Plate, and Rolled Bar

B171/B171M Specification for Copper-Alloy Plate and Sheet for Pressure Vessels, Condensers, and Heat Exchangers

B846 Terminology for Copper and Copper Alloys

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

3

2.2 ASME Code:

Boiler and Pressure Vessel Code, Section VIII

Boiler and Pressure Vessel Code, Section IX, Welding QualificationsIX

3. Terminology

3.1 For definitions of terms related to copper and copper alloys, refer to Terminology B846.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 base metal (backing steel), n—component to which the cladding metal is applied, usually the greater percentage of the

composite plate and usually consisting of carbon or low-alloy steel.

3.2.2 blind flange, n—same as a cover.

3.2.3 bonding, n—adhesion of one surface to another without the use of an adhesive as a bonding agent.

3.2.4 cladding metal, n—the copper or copper-base alloy component of the composite plate.

3.2.5 cover, n—a component with similar features to a tubesheet which is used as a closure and which typically requires surface

machining over part of the face while maintaining minimum specified minimum thickness.

3.2.6 double-clad, n—material is considered as double-clad when both sides of the steel base metal are covered with copper

cladding.

1

This specification is under the jurisdiction of ASTM Committee B05 on Copper and Copper Alloys and is the direct responsibility of Subcommittee B05.01 on Plate,

Sheet, and Strip.

Current edition approved Oct. 1, 2009Sept. 1, 2014. Published November 2009November 2014. Originally approved in 1966. Last previous edition approved in 2009 as

B432 – 09.B432 – 09a. DOI: 10.1520/B0432-09.10.1520/B0432-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American Society of Mechanical Engineers (ASME), ASME International Headquarters, ThreeTwo Park Ave., New York, NY 10016-5990,

http://www.asme.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B432 − 14

3.2.7 interface, n—of the clad product, is that region of the thickness in which the product transitions from essentially 100 %

base metal to 100 % cladding metal, also referred to as the bond or bondzone.

3.2.8 integrally and continuously bonded, adv—a condition in which the cladding metal and base metal are brought together to

form a metallurgical bond at essentially the entire interface of the two metals by means other than those processes that do

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.