ASTM G180-13(2019)

(Test Method)Standard Test Method for Corrosion Inhibiting Admixtures for Steel in Concrete by Polarization Resistance in Cementitious Slurries

Standard Test Method for Corrosion Inhibiting Admixtures for Steel in Concrete by Polarization Resistance in Cementitious Slurries

SIGNIFICANCE AND USE

4.1 This test method provides a means for assessing corrosion-inhibiting concrete admixtures.

4.2 This test method is useful for development of admixtures intended to reduce corrosion of reinforcing steel in concrete.

4.3 This test method is useful in determining the corrosivity of admixtures toward steel reinforcing if the admixture sample is compared to a control without admixtures.

4.4 Good performance, a reduction in corrosion rate versus chloride alone by at least one order of magnitude in this test, is a strong indication that an admixture is a corrosion inhibitor. However, poor performance requires additional testing to determine if the admixture improves corrosion resistance.

4.5 This test method shall not be used to predict performance in the field.

4.6 The filtering process makes this test not suitable for the evaluation of emulsions.

SCOPE

1.1 This test method covers a procedure for determining the effects of chemical admixtures on the corrosion of metals in concrete. This test method can be used to evaluate materials intended to inhibit chloride-induced corrosion of steel in concrete. It can also be used to evaluate the corrosivity of admixtures by themselves or in a chloride environment. This test is not applicable for emulsions.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G180 − 13 (Reapproved 2019)

Standard Test Method for

Corrosion Inhibiting Admixtures for Steel in Concrete by

1

Polarization Resistance in Cementitious Slurries

This standard is issued under the fixed designation G180; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Measurements in Corrosion Testing

G5 Reference Test Method for Making Potentiodynamic

1.1 This test method covers a procedure for determining the

Anodic Polarization Measurements

effects of chemical admixtures on the corrosion of metals in

G59 Test Method for Conducting Potentiodynamic Polariza-

concrete. This test method can be used to evaluate materials

tion Resistance Measurements

intended to inhibit chloride-induced corrosion of steel in

G193 Terminology and Acronyms Relating to Corrosion

concrete. It can also be used to evaluate the corrosivity of

admixtures by themselves or in a chloride environment. This

3. Terminology

test is not applicable for emulsions.

3.1 Definitions—For definitions of terms used in this prac-

1.2 The values stated in SI units are to be regarded as

tice see Terminology G193.

standard. No other units of measurement are included in this

standard.

4. Significance and Use

1.3 This standard does not purport to address all of the

4.1 This test method provides a means for assessing

safety concerns, if any, associated with its use. It is the

corrosion-inhibiting concrete admixtures.

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

4.2 This test method is useful for development of admix-

mine the applicability of regulatory limitations prior to use.

tures intended to reduce corrosion of reinforcing steel in

1.4 This international standard was developed in accor-

concrete.

dance with internationally recognized principles on standard-

4.3 This test method is useful in determining the corrosivity

ization established in the Decision on Principles for the

of admixtures toward steel reinforcing if the admixture sample

Development of International Standards, Guides and Recom-

is compared to a control without admixtures.

mendations issued by the World Trade Organization Technical

4.4 Good performance, a reduction in corrosion rate versus

Barriers to Trade (TBT) Committee.

chloride alone by at least one order of magnitude in this test, is

2. Referenced Documents a strong indication that an admixture is a corrosion inhibitor.

2

However, poor performance requires additional testing to

2.1 ASTM Standards:

determine if the admixture improves corrosion resistance.

C150/C150M Specification for Portland Cement

C670 Practice for Preparing Precision and Bias Statements

4.5 This test method shall not be used to predict perfor-

for Test Methods for Construction Materials mance in the field.

D632 Specification for Sodium Chloride

4.6 The filtering process makes this test not suitable for the

E691 Practice for Conducting an Interlaboratory Study to

evaluation of emulsions.

Determine the Precision of a Test Method

G3 Practice for Conventions Applicable to Electrochemical

5. Apparatus

5.1 The test cell as described in Test Method G5.

1

This test method is under the jurisdiction of ASTM Committee G01 on

5.2 Potentiostat, as described inTest Method G5, capable of

Corrosion of Metals and is the direct responsibility of Subcommittee G01.14 on

varying potential at a constant scan rate and measuring the

Corrosion of Metals in Construction Materials.

Current edition approved July 15, 2019. Published July 2019. Originally resulting current.

approved in 2004. Last previous edition approved in 2013 as G180 – 13. DOI:

5.3 A method of recording the varying potential and result-

10.1520/G0180-13R19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or ing current is needed.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.4 Electrode holder such as described in Fig. 3 of Test

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Method G5.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

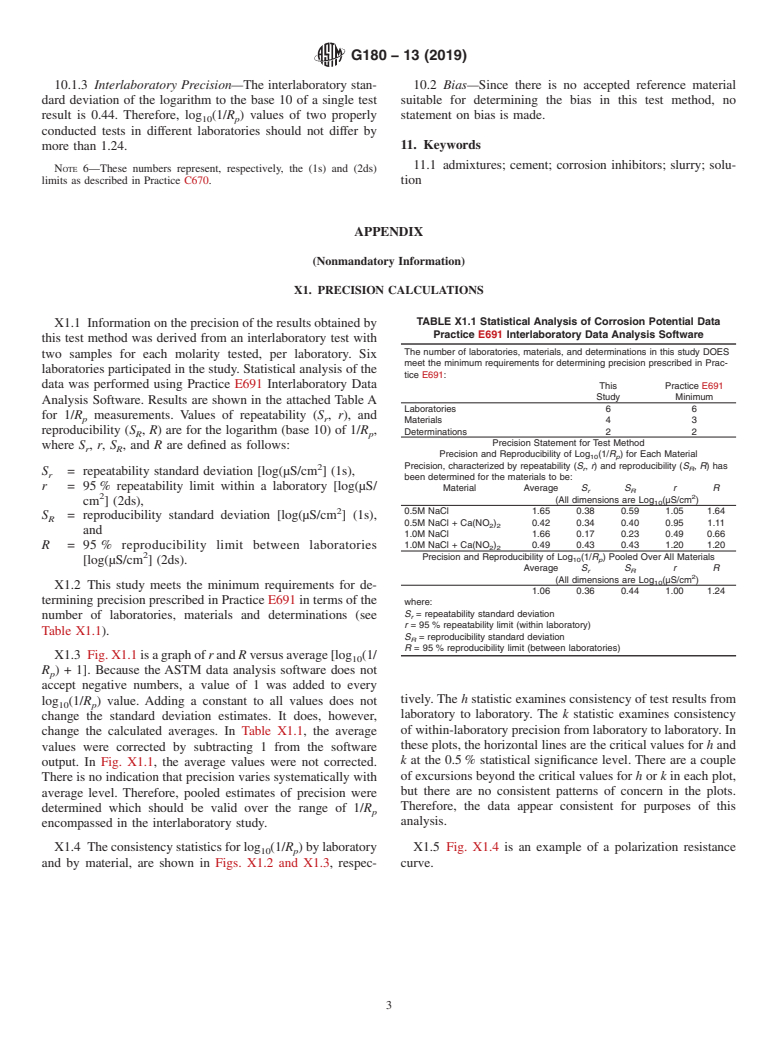

G180 − 13 (2019)

5.5 Electrodes: solution, and continue to stir and purge for a further 4 h.After

5.5.1 Workingelectrode,preparedfroma12.7mmlengthof 4 h, stop stirring and continue purging for a another 20 h.

9.5 mm diameter rod stock. Carbon steel C1215 should be

NOTE 3—The multi-laboratory test was run at the two different chloride

used.

levels to develop the pre

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: G180 − 13 G180 − 13 (Reapproved 2019)

Standard Test Method for

Corrosion Inhibiting Admixtures for Steel in Concrete by

1

Polarization Resistance in Cementitious Slurries

This standard is issued under the fixed designation G180; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a procedure for determining the effects of chemical admixtures on the corrosion of metals in

concrete. This test method can be used to evaluate materials intended to inhibit chloride-induced corrosion of steel in concrete. It

can also be used to evaluate the corrosivity of admixtures by themselves or in a chloride environment. This test is not applicable

for emulsions.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C150C150/C150M Specification for Portland Cement

C670 Practice for Preparing Precision and Bias Statements for Test Methods for Construction Materials

D632 Specification for Sodium Chloride

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

G3 Practice for Conventions Applicable to Electrochemical Measurements in Corrosion Testing

G5 Reference Test Method for Making Potentiodynamic Anodic Polarization Measurements

G59 Test Method for Conducting Potentiodynamic Polarization Resistance Measurements

G193 Terminology and Acronyms Relating to Corrosion

3. Terminology

3.1 Definitions—For definitions of terms used in this practice see Terminology G193.

4. Significance and Use

4.1 This test method provides a means for assessing corrosion-inhibiting concrete admixtures.

4.2 This test method is useful for development of admixtures intended to reduce corrosion of reinforcing steel in concrete.

4.3 This test method is useful in determining the corrosivity of admixtures toward steel reinforcing if the admixture sample is

compared to a control without admixtures.

4.4 Good performance, a reduction in corrosion rate versus chloride alone by at least one order of magnitude in this test, is a

strong indication that an admixture is a corrosion inhibitor. However, poor performance requires additional testing to determine

if the admixture improves corrosion resistance.

1

This test method is under the jurisdiction of ASTM Committee G01 on Corrosion of Metals and is the direct responsibility of Subcommittee G01.14 on Corrosion of

Metals in Construction Materials.

Current edition approved May 1, 2013July 15, 2019. Published May 2013July 2019. Originally approved in 2004. Last previous edition approved in 20072013 as

G180 – 07.G180 – 13. DOI: 10.1520/G0180-13.10.1520/G0180-13R19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G180 − 13 (2019)

4.5 This test method shall not be used to predict performance in the field.

4.6 The filtering process makes this test not suitable for the evaluation of emulsions.

5. Apparatus

5.1 The test cell as described in Test Method G5.

5.2 Potentiostat, as described in Test Method G5, capable of varying potential at a constant scan rate and measuring the resulting

current.

5.3 A method of recording the varying potential and resulting current is needed.

5.4 Electrode holder such as described in Fig. 3 of Test Method G5.

5.5 Electrode

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.