IEC 61058-1:2000/COR1:2009

(Corrigendum)Corrigendum 1 - Switches for appliances - Part 1: General requirements

Corrigendum 1 - Switches for appliances - Part 1: General requirements

Corrigendum 1 - Interrupteurs pour appareils - Partie 1: Règles générales

General Information

Relations

Standards Content (Sample)

IEC 61058-1

(Third edition – 2000)

Switches for appliances –

Part 1: General requirements

CORRIGENDUM 1

Corrections to IEC 61058-1:2000:

Table 15 – Electrical endurance tests for the different types of electronic switches with

or without electrical contact(s)

Replace Table 15 by the following new table:

January 2009

Table 15 – Electrical endurance tests for the different types of electronic switches with or without electrical contact(s)

Test conditions

Functional test (7.1.17.1) Simulated test (7.1.17.2) Specific test condition of

3)

Type of electronic switch

(Tables 17, 18) end application (7.1.17.3)

Complete Contacts only Complete Contacts only Complete Contacts only

switch switch switch

1)

SSD

TL1 TL3 TL4

without

TC5, TC6, TC8 --- TC5, TC6, TC8 --- TC5, TC6, TC8 ---

electrical

contact(s) TE1, TE3 TE1, TE3 TE1, TE3

a) Serial contact:

a) TL1

TL3, TC1, TC4

TC5, TC6, TC8

Serial contact: TE1 to TE3 Serial contact:

TL1 TE1, TE3 TL4

SSD with

2)

TC1, TC4 with TL2 (SSD short-circuited) TC7 with TL4

serial

TC5, TC6, TC8 TC5, TC8

TE1 to TE3 TE1 to TE3

b) Serial contact:

contact(s)

TE1, TE3 TE1, TE3

b) TL3

2) 2)

(SSD short-circuited) (SSD short-circuited)

TL3, TC1, TC7

TC5, TC6, TC8

TE1 to TE3

TE1, TE3

2)

(SSD short-circuited)

SSD with

Parallel contact: Parallel contact: Parallel contact:

parallel

TL1 TL3 TL4

TC1, TC4 with TL2 TL3, TC1, TC4 TC7 with TL4

contact(s)

TC5, TC6, TC8 TC5, TC6, TC8 TC5, TC8

TE1 to TE3 TE1 to TE3 TE1 to TE3

TE1, TE3 TE1, TE3 TE1, TE3

(SSD disconnected) (SSD disconnected) (SSD disconnected)

a) TL1 a) Serial contact:

TC5, TC6, TC8 TL3, TC1, TC4

Serial contact: TE1, TE3 TE1 to TE3 Serial contact:

2)

TC1, TC4 with TL2 (SSD short-circuited) TC7 with TL4

TE1 to TE3 TE1 to TE3

b) Serial contact:

b) TL3

SSD with 2) 2)

(SSD short-circuited) (SSD short-circuited)

TL1 TL4

TL3, TC1, TC7

serial and

TC5, TC6, TC8

TC5, TC6, TC8 TC5, TC8

TE1 to TE3

parallel

TE1, TE3

2)

TE1, TE3 TE1, TE3

contact(s) (SSD short-circuited)

a) and b) Parallel

Parallel contact: Parallel contact:

contact:

TC1, TC4 with TL2 TC7 with TL4

TL3, TC1, TC7

TE1 to TE3 TE1 to TE3

TE1 to TE3

(SSD disconnected) (SSD disconnected)

(SSD disconnected)

January 2009

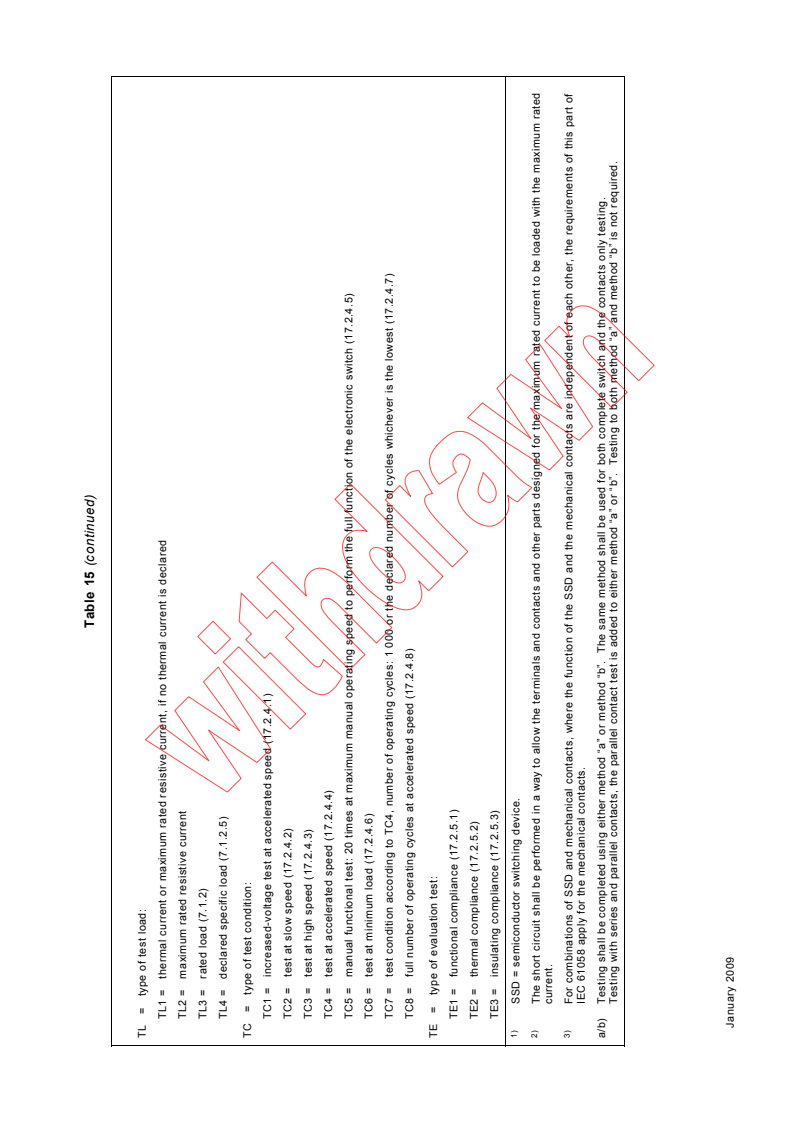

Table 15 (continued)

TL = type of test load:

TL1 = thermal current or maximum rated resistive current, if no thermal current is declared

TL2 = maximum rated resistive current

TL3 = rated load (7.1.2)

TL4 = declared specific load (7.1.2.5)

TC = type of test condition:

TC1 = increased-voltage test at accelerated speed (17.2.4.1)

TC2 = test at slow speed (17.2.4.2)

TC3 = test at high speed (17.2.4.3)

TC4 = test at accelerated speed (17.2.4.4)

TC5 = manual functional test: 20 times at maximum manual operating speed to perform the full function of the electronic switch (17.2.4.5)

TC6 = test at minimum load (17.2.4.6)

TC7 = test condition according to TC4, number of operating cycles: 1 000 or the declared number of cycles whichever is the lowest (17.2.4.7)

TC8 = full number of operating cycles at accelerated speed (17.2.4.8)

TE = type of evaluation test:

TE1 = functional compliance (17.2.5.1)

TE2 = thermal compliance (17.2.5.2)

TE3 = insulating compliance (17.2.5.3)

1)

SSD = semiconductor switching device.

2)

The short circuit shall be performed in a way to allow the terminals and contacts and other parts designed for the maximum rated current to be loaded with the maximum rated

current.

3)

For combinations of SSD and mechanical contacts, where the function of the SSD and the mechanical contacts are independent of each other, the requirements of this part of

IEC 61058 apply for the mechanical contacts.

a/b) Testing shall be completed using either method “a” or method “b”. The same method shall be used for both complete switch and the contacts only testing.

Testing with series and parallel contacts, the parallel contact test is added to either method “a” or “b”. Testing to both method “a” and method “b” is not required.

January 2009

17.2.4.8 Endurance test (TC8)

Replace the text of this subclause by the following:

Full number of operating cycles, the electrical conditions are those specified in table 15, at

accelerated speed.

Corrections to IEC 61058-1 Amendment 2:2007:

16 Heating

Replace the text

“Replace Subclause 16.2.2 by the following:”

by the following new text:

“Replace items a) to i)in Subclause 16.2.2 by the following:”

23 Abnormal operation and fault conditions for electronic switches

Add the following new text to the end of 23.1.1.2:

23.1.1.2.1 Switches for continuous duty, duty type S1, are loaded for 1 h with the conventional fusing

current for the fuse which in the installation will protect the switch.

For switches for short-time duty, duty type S2, the temperature is measured 2 min after the operation

of the switch.

For switches for intermittent periodic duty, duty type S3, the temperature is measured after steady

state has been reached, or after 4 h, whichever is the shorter time.

The conventional fusing currents to be used for these tests are specified in table 26:

Table 26 – Conventional fusing current versus rated current

Device Rated current Conventional

1)

fusing current

A A

Cord switches Up to and including 16 26

Independently mounted Up to and including 16 26

switches

Over 16 up to and including 32 51

Over 32 up to and including 63 101

1)

The values specified originate from IEC 60269-1.

23.1.1.2.2 Switches for continuous duty, duty type S1, are loaded in such a way that the current

through the switch measures 0,95 times the current with which the protecting device releases after

1 h

January 2009

For switches for short-time duty, duty type S2, the temperature is measured 2 min after the operation

of the switch.

For switches for intermittent periodic duty, duty type S3, the temperature is measured after steady

state has been reached, or after 4 h, whichever is the shorter time.

23.1.1.2.3 The fuses are replaced by links of negligible impedance and shall be loaded in such a

manner that the current through the links shall be 2,1 times the rated current of the fuse.

For switches for continuous duty, duty type S1, the temperature is measured after steady state has

been reached or after 30 min, whichever is the shorter time.

For switches for short-time duty, duty type S2, the temperature is measured 2 min after the operation

of the switch.

For switches for intermittent periodic duty, duty type S3, the temperature is measured after steady

state has been reached, or after 4 h, whichever is the shorter time.

23.1.1.2.4 The electronic cord switches and electronic independently mounted switches are loaded

either as described in 23.1.1.2.3 with incorporated fuse or as described in 23.1.1.2.2 with another

automatic protective device, choosing the test requiring the lowest load.

January 2009

IEC 61058-1

(Troisième édition – 2000)

Interrupteurs pour appareils –

Partie 1: Règles générales

CORRIGENDUM 1

Corrections à la CEI 61058-1:2000:

Tableau 15 – Essais d’endurance électrique pour les différents types d’interrupteurs

électroniques avec ou sans contacts électriques combinés

Remplacer le Tableau 15 par le nouveau tableau suivant :

Janvier 2009

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.