ISO 15364:2000

(Main)Ships and marine technology — Pressure/vacuum valves for cargo tanks

Ships and marine technology — Pressure/vacuum valves for cargo tanks

Navires et technologie maritime — Robinets à pression/à vide pour citernes de chargement

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 15364

First edition

2000-09-01

Ships and marine technology —

Pressure/vacuum valves for cargo tanks

Navires et technologie maritime — Robinets à pression/à vide pour

citernes de chargement

Reference number

ISO 15364:2000(E)

©

ISO 2000

---------------------- Page: 1 ----------------------

ISO 15364:2000(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall not

be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In downloading this

file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat accepts no liability in this

area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation parameters

were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the unlikely event

that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2000

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means, electronic

or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or ISO's member body

in the country of the requester.

ISO copyright office

Case postale 56 � CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.ch

Web www.iso.ch

Printed in Switzerland

ii © ISO 2000 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 15364:2000(E)

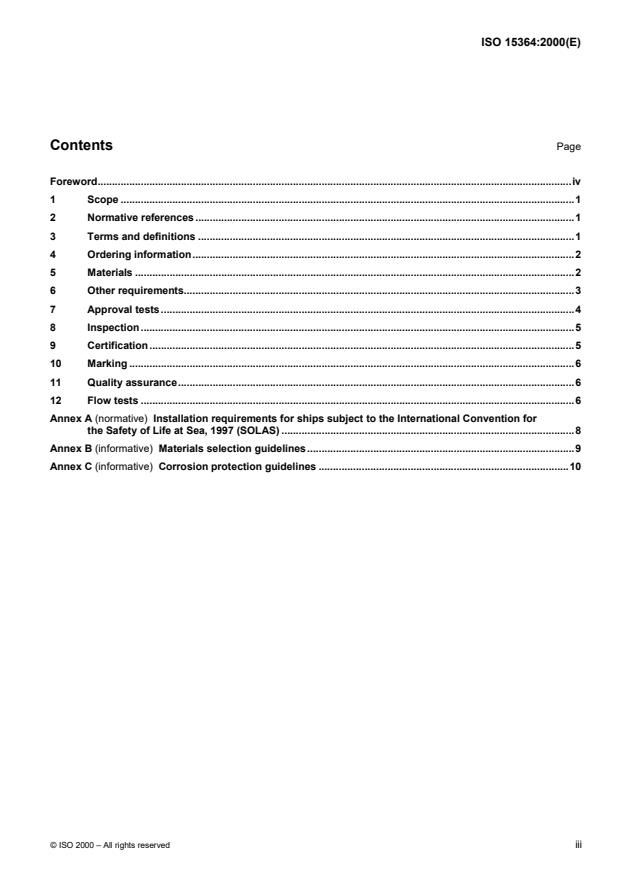

Contents Page

Foreword.iv

1 Scope .1

2 Normative references .1

3 Terms and definitions .1

4 Ordering information.2

5 Materials .2

6 Other requirements.3

7 Approval tests.4

8 Inspection.5

9 Certification.5

10 Marking .6

11 Quality assurance.6

12 Flow tests .6

Annex A (normative) Installation requirements for ships subject to the International Convention for

the Safety of Life at Sea, 1997 (SOLAS) .8

Annex B (informative) Materials selection guidelines.9

Annex C (informative) Corrosion protection guidelines .10

© ISO 2000 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 15364:2000(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies (ISO

member bodies). The work of preparing International Standards is normally carried out through ISO technical

committees. Each member body interested in a subject for which a technical committee has been established has

the right to be represented on that committee. International organizations, governmental and non-governmental, in

liaison with ISO, also take part in the work. ISO collaborates closely with the International Electrotechnical

Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 3.

Draft International Standards adopted by the technical committees are circulated to the member bodies for voting.

Publication as an International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this International Standard may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights.

International Standard ISO 15364 was prepared by Technical Committee ISO/TC 8, Ships and marine technology,

Subcommittee SC 3, Piping and machinery.

Annex A forms a normative part of this International Standard. Annexes B and C are for information only.

iv © ISO 2000 – All rights reserved

---------------------- Page: 4 ----------------------

INTERNATIONAL STANDARD ISO 15364:2000(E)

Ships and marine technology — Pressure/vacuum valves for cargo

tanks

1 Scope

This International Standard applies to pressure/vacuum relief valves protecting marine vessel systems, including

cargo tanks, that may be subject to gas/vapour pressure or vacuum outside the design parameters of the

system/tank. This standard specifies the minimum requirements for performance and testing of pressure/vacuum

relief valves, with emphasis on selection of materials, internal finish and surface requirements for pressure/vacuum

valves installed on cargo tanks in tankers (see annex A). This standard specifies design and in-service

performance criteria and operational testing and maintenance requirements. This standard does not address

devices to prevent the passage of flame. Advice on devices to prevent the passage of flame is found in the

International Maritime Organization (IMO) “International Convention on the Safety of Life at Sea, 1997” (SOLAS);

Chapter II-2, Regulation 59, and IMO Maritime Safety Committee (MSC) Circular No. 677 (MSC/Circ. 677)

“Revised Standards for the Design, Testing and Locating of Devices to Prevent the Passage of Flame into Cargo

Tanks in Tankers”.

2 Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of

this International Standard. For dated references, subsequent amendments to, or revisions of, any of these

publications do not apply. However, parties to agreements based on this International Standard are encouraged to

investigate the possibility of applying the most recent editions of the normative documents indicated below. For

undated references, the latest edition of the normative document referred to applies. Members of ISO and IEC

maintain registers of currently valid International Standards.

International Maritime Organization, Maritime Safety Committee Circular 677 (MSC/Circ. 677), “Revised Standards

for the Design, Testing and Locating of Devices to Prevent the Passage of Flame into Cargo Tanks in Tankers”.

International Maritime Organization, Assembly Resolution A.746(18), “Survey Guidelines under the Harmonized

System of Survey and Certification”.

International Maritime Organization, “International Convention on the Safety of Life at Sea, 1997” (SOLAS);

Chapter II-2, Regulation 59.

3 Terms and definitions

For the purposes of this International Standard, the following terms and definitions apply.

3.1

administration

the government of the state whose flag the ship is entitled to fly

3.2

flame arrester

device to prevent the passage of flame in accordance with a specified performance standard

NOTE Its flame-arresting element is based on the principle of quenching.

© ISO 2000 – All rights reserved 1

---------------------- Page: 5 ----------------------

ISO 15364:2000(E)

3.3

flame screen

device utilizing wire mesh to prevent the passage of unconfined flames in accordance with a specified performance

standard

3.4

passive flame stopper

device, such as a flame screen or a flame arrester, that operates passively to prevent the passage of unconfined

flames in accordance with a specified performance standard

3.5

high-velocity vent

device to prevent the passage of flame consisting of a mechanical valve which adjusts the opening available for

flow in accordance with the pressure at the inlet of the valve in such a way that the efflux velocity cannot be less

than 30 m/s (98 ft/sec) under all flow rates and the actual conditions of installation

3.6

pressure/vacuum valve

device to prevent the occurrence of over- or underpressure in a closed container

3.7

standard air

dry air at 21 °C(70 °F) and 1 013,25 hPa (29,92 inHg) pressure

3 3

NOTE This is substantially equivalent to air with a density of 1,2 kg/m (0,075 lb/ft ). The specific heat of dry air is

1 004,8 J/kg�K (0,24 btu/lb/°F).

3.8

third-party inspection body

an organization designated by the administration that is independent of the manufacturer and the user and that

performs or witnesses the tests and inspections provided for by this International Standard

4 Ordering information

Orders for devices under this specification shall include the following information, as applicable:

� Nominal pipe size, configuration of pipe, and pipe length.

� Molecular mass and specific heat ratio of each gas or vapour in the tank being protected, and maximum

explosive safe gap (MESG) value, if known.

� Inspections and tests other than those specified by this International Standard (see clause 8).

� Set opening points for pressure and vacuum.

� Anticipated ambient air temperature range.

� Materials of construction (see clause 5).

� Maximum flow rate for standard air and the design pressure drop for the piping system at that maximum flow

rate, and the maximum allowable tank pressure and tank vacuum.

5 Materials

5.1 The device housing, and other parts or bolting used for pressure retention, shall be constructed of materials

suitable for the intended service and listed in a recognized national or international standard.

2 © ISO 2000 – All rights reserved

---------------------- Page: 6 ----------------------

ISO 15364:2000(E)

5.1.1 Housings, discs, spindles, seats, springs, gaskets, seals, passive flame stoppers (when included in the

design) and all other integral parts, including parts with coatings to prevent corrosion, shall be made of materials

resistant to attack by seawater and the liquids and vapours contained in the tank being protected (see annex C).

5.1.2 Springs plated with corrosion-resistant material are not acceptable.

5.2 Non-metallic materials, other than gaskets and seals, shall not be used in the construction of pressure-

retaining components of the device.

5.2.1 Resilient seals may be installed only if the device is still capable of effectively performing its function when

the seals are partially or completely damaged or burned.

5.2.2 Non-metallic gaskets shall be made of non-combustible material suitable for the service intended.

5.3 Materials for connecting pressure/vacuum valves to their respective piping systems shall meet standards for

physical characteristics similar to those of the piping systems to which they are connected.

5.4 The materials of all parts not identified above shall be suitable for their intended purpose.

5.5 The possibility of galvanic corrosion shall be considered in the selection of materials.

6 Other requirements

6.1 Device housings shall be gastight in the primary pressure zone upstream of the main valve seat to prevent

the escape of vapours.

6.2 Housings, elements and seal gasket materials shall be capable of withstanding the maximum and minimum

pressures and temperatures to which the device may be exposed under normal operating conditions, and shall be

capable of withstanding the hydrostatic pressure test of 7.2.2.

6.3 Where welded construction is used for pressure-retaining components, welded-joint design details, welding

and non-destructive testing shall be in accordance with national or international standards. Welders and weld

procedures shall be qualified by a recognized organization to ensure consistent-quality production of weld joints

that are sound and of proper strength, in accordance with recognized national/international standards.

6.4 When pressure/vacuum relief valves are designed to allow for inspection, cleaning, repair or removal of

internal elements for replacement without removing the entire device from the system, the design shall not allow

the valve to be incorrectly reassembled following disassembly for inspection, cleaning or repair.

6.5 Pressure/vacuum valves shall be designed such that condensed vapour drains from the device and does not

impair the efficiency of the device. The design shall also prevent the accumulation of water inside the device and

subsequent blockage due to freezing.

Where the design does not permit complete drainage of condensed vapours through its connection to the tank, the

housing shall be fitted with a plugged drain opening on the side of the atmospheric outlet of not less than 13 mm

[1/2 inch nominal pipe size (NPS ½)]. The drain shall not allow vapour to escape unless the drain is equipped with

suitable means to prevent the passage of flame and meets all requirements for efflux velocity and direction.

6.6 All fastenings essential to the operation of the device shall be protected against loosening.

6.7 Devices shall be designed and constructed to minimize the effect of fouling under normal operating

conditions. The design shall be such that the device can be examined for any build-up of residue due to vapour

condensation that might impair the operation of the device. The manufacturer’s operating manual shall include

instructions on how to determine when cleaning is required and shall specify the method for cleaning (see

clause 9). For certain cargoes that crystallize, heating arrangements may be necessary.

© ISO 2000 – All rights reserved 3

---------------------- Page: 7 ----------------------

ISO 15364:2000(E)

6.8 Devices shall be capable of operating over the full range of ambient air temperatures anticipated. Devices

shall be capable of operating in freezing conditions (such as may cause blockage by freezing cargo vapours or by

icing in bad weather) and when covered by a layer of ice, the allowed thickness of which shall be stated by the

manufacturer in the operating manual. Devices shall also be capable of operating at whatever surface temperature

is developed by heating arrangements.

6.9 End-of-line devices shall be constructed to direct the efflux vertically upward under all flow rates intended by

the manufacturer.

6.10 A manual means shall be provided to verify that any valve lifts easily and cannot remain in the open position,

as per manufacturer’s instructions. The design shall be such that the device shall not be rendered inoperable due

to corrosion, residue build-up or icing, when maintenance is carried out in accordance with the manufacturer’s

requirements (see annex C).

6.11 Valve discs shall be guided by a suitable means to prevent binding and ensure proper self-closing (seating),

taking into account the possible build-up of condensed vapours passing through the valve during loading, when

maintenance is carried out in accordance with the manufacturer’s requirements.

Valve discs shall normally close against the valve seat by metal-to-metal contact. Resilient-seating seals may be

provided if the design is such that the disc closes tight against the seat in case the seals are destroyed, damaged

or otherwise carried away.

Valve discs may be solid or made hollow so that weight material may be added to vary the lifting pressure. If hollow

discs are employed, a watertight bolted cover shall be fitted to encase the weight material. The lifting pressure shall

not be varied by personnel other than the manufacturer without prior approval by the administration. A clear

indication, visible from the outside of the valve, shall be employed to indicate the position of the valve. If the lifting

pressure is varied, the marking required by clause 10 shall be updated.

6.12 Valves may be actuated by non-metallic diaphragms except where failure would result in unrestricted flow of

tank vapours to the atmosphere or in an increase in the pressure or vacuum at which the valve normally releases.

6.13 Relief pressure adjusting mechanisms shall be permanently secured by lockwire, locknuts or other suitable

means to prevent devices from becoming misadjusted due to handling, installation or vibration.

7 Approval tests

7.1 Type approval tests shall be conducted by a laboratory acceptable to the administration. The manufacturer,

in choosing a laboratory, shall ensure that the laboratory is qualified (by the administration or by a certifying entity

designated by the administration) to conduct the tests provided for by this International Standard and that the

laboratory has (or has access to) the apparatus, facilities, personnel and calibrated instruments that are necessary

for the tests. Alternatively, the tests provided for by this International Standard may be conducted by the

manufacturer when the tests are witnessed by a third-party inspection body designated by the administration who

can certify that the tests are conducted properly.

7.2 One device of each model and each size shall be tested. A change of design, material or construction that

affects the corrosion resistance, or any change that alters th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.