ISO 15364:2007

(Main)Ships and marine technology — Pressure/vacuum valves for cargo tanks

Ships and marine technology — Pressure/vacuum valves for cargo tanks

ISO 15364:2007 applies to pressure-vacuum relief valves protecting marine vessel systems, including cargo tanks, which may be subject to gas/vapour pressure or vacuum beyond the design parameters of the system/tank. ISO 15364:2007 specifies the minimum requirements for performance and testing of pressure-vacuum relief valves, with emphasis on selection of materials, internal finish and surface requirements for pressure-vacuum valves installed on cargo tanks in tankers (see Annex A). It specifies design and in-service performance criteria, operational testing and maintenance requirements. Certification to ISO 15364:2007 does not imply suitability for any given installation; it indicates that certain minimum requirements have been considered and that information necessary for determination of suitability is provided to the buyer of the equipment.

Navires et technologie maritime — Robinets à pression/à vide pour citernes de chargement

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 15364

Second edition

2007-12-15

Ships and marine technology —

Pressure/vacuum valves for cargo tanks

Navires et technologie maritime — Robinets à pression/à vide pour

citernes de chargement

Reference number

ISO 15364:2007(E)

©

ISO 2007

---------------------- Page: 1 ----------------------

ISO 15364:2007(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

COPYRIGHT PROTECTED DOCUMENT

© ISO 2007

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2007 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 15364:2007(E)

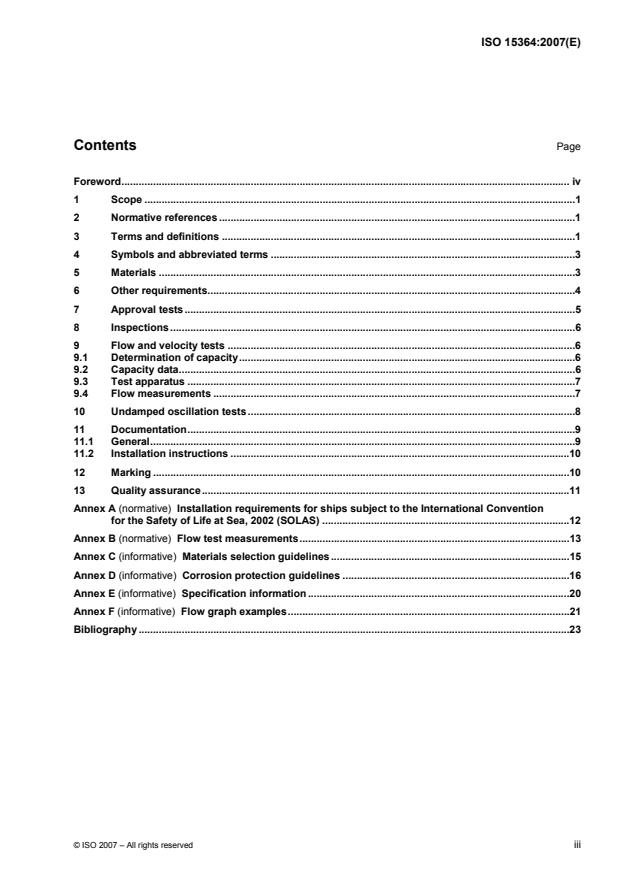

Contents Page

Foreword. iv

1 Scope .1

2 Normative references .1

3 Terms and definitions .1

4 Symbols and abbreviated terms .3

5 Materials .3

6 Other requirements.4

7 Approval tests.5

8 Inspections .6

9 Flow and velocity tests .6

9.1 Determination of capacity.6

9.2 Capacity data.6

9.3 Test apparatus .7

9.4 Flow measurements .7

10 Undamped oscillation tests.8

11 Documentation.9

11.1 General.9

11.2 Installation instructions .10

12 Marking .10

13 Quality assurance.11

Annex A (normative) Installation requirements for ships subject to the International Convention

for the Safety of Life at Sea, 2002 (SOLAS) .12

Annex B (normative) Flow test measurements.13

Annex C (informative) Materials selection guidelines.15

Annex D (informative) Corrosion protection guidelines .16

Annex E (informative) Specification information .20

Annex F (informative) Flow graph examples.21

Bibliography .23

© ISO 2007 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 15364:2007(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 15364 was prepared by Technical Committee ISO/TC 8, Ships and marine technology, Subcommittee

SC 3, Piping and machinery.

This second edition cancels and replaces the first edition (ISO 15364:2000) which has been technically

revised.

iv © ISO 2007 – All rights reserved

---------------------- Page: 4 ----------------------

INTERNATIONAL STANDARD ISO 15364:2007(E)

Ships and marine technology — Pressure/vacuum valves for

cargo tanks

1 Scope

This international standard applies to pressure-vacuum relief valves protecting marine vessel systems,

including cargo tanks, which may be subject to gas/vapour pressure or vacuum beyond the design parameters

of the system/tank. This International Standard specifies the minimum requirements for performance and

testing of pressure-vacuum relief valves, with emphasis on selection of materials, internal finish and surface

requirements for pressure-vacuum valves installed on cargo tanks in tankers (see Annex A). This International

Standard specifies design and in-service performance criteria, operational testing and maintenance

requirements. Certification to this International Standard does not imply suitability for any given installation; it

indicates that certain minimum requirements have been considered and that information necessary for

determination of suitability is provided to the buyer of the equipment.

This International Standard does not cover all test procedures for devices that prevent the passage of flame,

such as flame arresters. Such devices may be used in conjunction with pressure/vacuum valves.

NOTE Additional information for devices to prevent the passage of flame is found in the International Maritime

Organization (IMO) “International Convention for the Safety of Life at Sea, 2002” (SOLAS), Chapter II-2, Regulation 4, and

IMO Maritime Safety Committee (MSC) Circular No. 677 (MSC/Circ. 677), “Revised Standards for the Design, Testing and

Locating of Devices to Prevent the Passage of Flame into Cargo Tanks in Tankers”, as amended by IMO MSC/Circ. 1009.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

International Maritime Organization, Assembly Resolution A.746(18), Survey Guidelines under the

Harmonized System of Survey and Certification

International Maritime Organization, International Convention for the Safety of Life at Sea, 2002 (SOLAS),

Chapter II-2, Regulation 4

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

administration

government of the state whose flag the ship is entitled to fly

3.2

flame arrester

device to prevent the passage of flame, designed and tested in accordance with a specified performance

standard

NOTE Its flame-arresting unit is based on the principle of quenching.

© ISO 2007 – All rights reserved 1

---------------------- Page: 5 ----------------------

ISO 15364:2007(E)

3.3

full opening valve

design that opens fully at the set pressure

3.4

high velocity vent

device to prevent the passage of flame, consisting of a mechanical valve which adjusts the opening available

for flow in accordance with the pressure at the inlet of the valve in such a way that the efflux velocity cannot

be less than 30 m/s (98 ft/sec)

3.5

maximum experimental safe gap

MESG

property of the respective gas mixture being the maximum clearance of the joint between two parts of the

interior chamber of a test apparatus which, when the internal gas mixture is ignited and under specified

conditions, prevents ignition of the external gas mixture through a 25 mm (10 in) long joint, for all

concentrations of the tested gas or vapour in air

[1]

NOTE IEC 60079-1 standardizes the test apparatus and the test method.

3.6

maximum intended pressure drop

largest pressure drop generated over a valve for which the test laboratory verifies the corresponding flow

capacity

3.7

modulating valve

design that opens proportionally with rise in pressure

3.8

pressure/vacuum valve

device designed to maintain pressure and vacuum in a closed container within preset limits

3.9

standard air

dry air at 21 °C (70 °F) and 1 013,25 hPa (29,92 in Hg) pressure

3 3

NOTE This is substantially equivalent to a density of 1,2 kg/m (0,075 lb/ft). Specific heat of dry

. .

air = 1 004,8 J/(kg K) [0,24 Btu/(lb °R].

3.10

third party inspection body

organization designated by the administration which is independent from the manufacturer or user and which

performs or witnesses the tests and inspections provided for by this International Standard

3.11

transition point valve

design where the valve characteristics change from modulating to full opening at a particular pressure

3.12

verified drawings and diagrams

drawings and diagrams certified to be authentic and complete by the test laboratory issuing the test report in

accordance with this International Standard

3.13

verified flow chart

pressure versus flow volume presented in a chart certified by the test laboratory issuing the test report in

accordance with this International Standard

2 © ISO 2007 – All rights reserved

---------------------- Page: 6 ----------------------

ISO 15364:2007(E)

4 Symbols and abbreviated terms

D nominal pipe diameter at device connection

D minimum diameter of the piping between the device and the tank allowed for non-oscillating

min

performance

L maximum length of the piping between the device and the tank allowed for non-oscillating

max

performance

L pipe length between test tank and the device for flow testing

1

L pipe length between test tank and the device during non-oscillation testing

2

P pressure drop over the valve corresponding to the minimum flow required to keep the valve partially

closing

open with no contact between the disc and the seat

P maximum pressure drop corresponding to the maximum flow volume (Q )

max 3

P set pressure, expressed as the calculated force applied to the disc versus the area on which tank

set

pressure is applied

P pressure at which a transition point valve changes from modulating to full opening

1-tpv

Q flow volume needed to open the valve

1-fov

Q flow volume needed for the valve to remain fully open

2

Q flow volume needed to maintain the valve fully open at P

2-fov set

Q flow volume needed to open the valve

1-mv

Q flow volume needed to maintain the valve fully open

2-mv

Q flow volume at which a transition point valve changes from modulating to full opening

1-tpv

Q flow volume needed to maintain a transition point valve fully open at P

2-tpv 1-tpv

Q flow volume corresponding to the maximum intended pressure drop over the valve

3

Q minimum flow required to keep the valve partially open with no contact between the disc and the seat

close

V minimum volume of the tank allowed for non-oscillating performance

min

5 Materials

5.1 The device housing, and other parts or bolting used for pressure retention, shall be constructed of

materials suitable for the intended service and listed in a recognised national/international standard.

Housings, discs, spindles, seats, springs, gaskets, seals, flame arresters (when included in the design) and all

other integral parts, including parts with coatings to prevent corrosion, shall be made of materials resistant to

attack by sea water and the liquids and vapours contained in the tank being protected (see Annex C).

Springs plated with corrosion resistant material are not acceptable.

5.2 Non-metallic materials, other than gaskets, seals and diaphragms as allowed by 6.11, shall not be used

in the construction of pressure retaining components of the device.

Resilient seals may be installed only if the device is still capable of effectively performing its flame arresting

function when the seals are partially or completely damaged or burned.

Non-metallic gaskets shall be made of non-combustible material and suitable for the service intended.

© ISO 2007 – All rights reserved 3

---------------------- Page: 7 ----------------------

ISO 15364:2007(E)

5.3 Materials for connecting pressure-vacuum valves to their respective piping systems should meet

standards for physical characteristics similar to those of the piping systems to which they are connected.

5.4 The possibility of galvanic corrosion shall be considered in the selection of materials (see Annex C for

additional considerations).

5.5 The verified drawings shall include a complete bill of materials showing conformity with this clause and

any other material requirements listed in Clause 6.

6 Other requirements

6.1 The maximum gas leakage rate shall be provided and expressed as the volume in standard air that may

leak from the valve at 80 % of the nominal setting.

6.2 Housings, elements, and seal gasket materials shall be capable of withstanding the maximum and

minimum pressures and temperatures to which the device may be exposed under normal operating

conditions.

6.3 Where welded construction is used for pressure retaining components, welded joint design details,

welding and non-destructive testing shall be in accordance with national or international standards. Welders

and weld procedures shall be qualified by a recognised organization to ensure consistent quality production of

weld joints that are sound and of proper strength, in accordance with recognised national/international

standards.

6.4 End-of-line pressure-vacuum valves shall be designed such that condensed vapour and water in the

pressure-retaining zone drain from the device into the tank and do not impair the efficiency of the device. The

design shall also prevent the accumulation of water inside the device and subsequent blockage due to

freezing. Internal components, channels and inner walls to be drained shall be sloped.

6.5 All fasteners essential to the operation of the device shall be protected against loosening.

6.6 Devices shall be designed and constructed to minimize the effect of fouling under normal operating

conditions. The design shall be such that the device can be examined for any build-up of residue due to

vapour condensation. For certain cargoes that crystallize, heating arrangements may be necessary.

6.7 Devices shall be capable of operating over the full range of ambient air temperatures anticipated.

Devices shall be capable of operating in freezing conditions (such as may cause blockage by freezing cargo

vapours or by icing in bad weather) and when covered by a layer of ice, the allowed thickness of which shall

be stated by the manufacturer in the instruction manual. Devices shall also be capable of operating at

whatever surface temperature is developed by heating arrangements.

6.8 End-of-line devices are required to direct the efflux vertically upward (see SOLAS 2002, Ch. II-2

Regulation 4, 5.3.4.1.1.2) and the minimum average velocity of air through a cross section of the valve’s outlet

to atmosphere shall not be less than 30 m/s for all flow rates.

6.9 A manual means shall be provided to verify that any valve disc and other moving elements lift freely and

fully and cannot remain in the open position. The design shall be such that the device is verified not to be

inoperable due to corrosion, residue build-up or icing, when the aforementioned manual means is used in

combination with the manufacturer’s requirements for visual inspection.

6.10 Valve discs and other moving parts shall be guided by a suitable means to prevent binding and ensure

proper self-closing (seating), taking into account the possible build-up of condensed vapours passing through

the valve during loading, when maintenance is carried out in accordance with the manufacturer’s

requirements. Valve discs shall normally close against the valve seat by metal to metal contact. Resilient

seating seals may be provided if the design is such that the disc closes tight against the seat in case the seals

are destroyed, damaged or are otherwise carried away.

4 © ISO 2007 – All rights reserved

---------------------- Page: 8 ----------------------

ISO 15364:2007(E)

Valve discs may be solid or made hollow so that weight material may be added to vary the lifting pressure. If

hollow discs are employed, a watertight bolted cover shall be fitted to encase the weight material. The set

pressure shall not be varied by personnel other than the manufacturer without prior approval by the

Administration. A clear indication, visible from the outside of the valve, shall be employed to indicate the

position of the valve disc(s). The indicator shall be visible from below and from the side of the valve at deck

level.

6.11 Valves may be actuated by non-metallic diaphragms except where failure would result in unrestricted

flow of tank vapours to the atmosphere or in an increase in the pressure or vacuum at which the valve

normally releases.

6.12 Relief pressure adjusting mechanisms shall be permanently secured by lockwire, locknuts or other

suitable means to prevent devices from becoming misadjusted due to handling, installation or vibration.

7 Approval tests

7.1 Type approval tests shall be conducted by a laboratory acceptable to the administration. The

manufacturer, in choosing a laboratory, shall ensure that the laboratory is qualified (by the administration or by

a certifying entity designated by the administration) to conduct the tests provided for by this International

Standard, and that the laboratory has (or has access to) the apparatus, facilities, personnel and calibrated

instruments necessary for the tests. Alternatively, the tests provided for by this International Standard may be

conducted by the manufacturer when the tests are witnessed by a third party inspection body designated by

the administration, who can certify that the tests are conducted properly.

7.2 One of each model device and each size shall be tested. A change of material that negatively affects

the corrosion resistance shall be considered a change of model for the purpose of this paragraph. A change of

design or construction shall be considered a change of model for the purpose of this paragraph. Each size of

each model should be submitted for type approval. Devices should have the same dimensions and most

unfavourable clearances expected in the production model. If a device is modified during the test programme,

or at a later date, such that the function of the valve or its performance characteristics are affected, the

administration shall be informed and an acceptable test related to the modified part required by a third party

inspection body.

A corrosion test shall be conducted. In this test, a complete device, including a section of pipe similar to that to

which it will be fitted, shall be exposed to a 5 % sodium chloride solution spray at a temperature of 25 °C

(77 °F) for a period of 240 h, and allowed to dry for 48 h. Following this exposure, all movable parts shall

operate properly and there shall be no corrosion deposits that cannot be washed off.

The pressure retaining boundary of the device shall be subjected to a hydrostatic pressure test of at least

1)

150 % of maximum rated pressure or a minimum pressure of 3 450 hPa gauge (50 psig) , whichever is

greater, for 10 min without rupturing, leaking or showing permanent distortion. For the purposes of this test,

the disc may be gagged or blocked.

Performance characteristics as declared by the manufacturer, such as flow rates under both positive and

negative pressure, operating sensitivity, flow resistance and velocity, shall be verified by laboratory tests.

An external ice test shall be conducted to verify the allowable accumulation of an external layer of ice at which

the valve will still operate. In this test, a complete device, including a section of the pipe similar to which the

device will be fitted, shall be exposed to a temperature of −10 °C (14 °F) for a period of 24 h. Following this

initial exposure, 1 l (1,7 pints) of water at no more than 2 °C (35,6 °F) shall be sprayed every 10 min on to the

outside of the valve until the specified ice thickness is achieved. Proper operation of the valve shall be

verified.

2

1) 1 psig = 1 lbf/in gauge.

© ISO 2007 – All rights reserved 5

---------------------- Page: 9 ----------------------

ISO 15364:2007(E)

7.3 A test report for each prototype shall be prepared by the laboratory. This shall include:

⎯ verified detail drawings of the device and its components;

⎯ the types of test conducted and results obtained, with such recorded data to allow verification of the tests;

⎯ specific advice on approved attachments;

⎯ drawings of the test rig, to include a description of the inlet and outlet piping attached;

⎯ a record of all markings found on the tested device;

⎯ an instruction manual (provided by manufacturer);

⎯ a report number.

8 Inspections

8.1 The manufacturer shall afford the purchaser’s representative all reasonable facilities necessary to

satisfy him that the material is being furnished in accordance with this International Standard. Inspection by

the purchaser shall not interfere unnecessarily with the manufacturer’s operations. All examinations and

inspections shall be made at the place of manufacture, unless otherwise agreed upon.

8.2 Each finished device shall be visually and dimensionally checked to ensure that the device complies

with this International Standard, including the specification information in Annex E, the certification and the

markings in Clause 12. Special attention shall be given to the adequacy of welds and the proper fit-up of

joints.

8.3 Each finished device shall be leakage tested using air to verify the maximum leakage rate specified

according to 6.1.

9 Flow and velocity tests

9.1 Determination of capacity

The capacity of pressure/vacuum valves shall be established by flow testing at least one production model of

every type and size of venting device under the conditions listed in 9.2 to 9.4.

9.2 Capacity data

The following requirements shall be met when establishing capacity data:

⎯ the pipes, as well as the connections between the pipes and the device, shall be without obstructions

causing additional turbulence;

⎯ the nominal diameter of the test pipe shall be of the same or larger size as the device being tested;

⎯ all pressure measuring points shall be arranged normal to the pipe axis and shall not influence the flow;

⎯ the test medium shall be air at ambient conditions; ambient pressure and temperature shall be recorded

to convert flow rate to normal conditions;

⎯ all measuring instruments shall be calibrated.

6 © ISO 2007 – All rights reserved

---------------------- Page: 10 ----------------------

ISO 15364:2007(E)

9.3 Test apparatus

The test apparatus is shown in Figure 1. The dimensions of the tank (key 3) shall be sufficient to allow a mean

flow velocity of less than 0,5 m/s in the tank. All tank pressure data shall be recorded under these conditions.

The test pipe L shall have a length of no more than 10 × D and no less than 1,5 × D of the test specimen.

1

The tank penetration should be at a location of the tank where it is essentially flat and the rounding of the

penetration shall be in accordance with a recognised national or international standard to provide uniform

pressure drop influence.

Vacuum valves shall have the flow direction reversed.

CAUTION — It should be observed that the blower or fan may cause oscillation in the system if the fan

wings are not aligned or damaged. This should be avoided.

9.4 Flow measurements

9.4.1 Flow measurements for pressure/vacuum valves shall be made using the lowest and highest setting

for the specific model. Flow charts for in-between settings may be interpolated.

NOTE If the setting can be changed without making any changes to the form and shape of the valve housing and the

physical appearance of any component (e.g. by changing the magnet power, spring compression, etc.), this does not

constitute a change of model. The spring wire diameter need not be taken into consideration.

9.4.2 The pressure at which the valve opens shall be established using a flow rate resulting in a pressure

2

rise no greater than 0,01 N/mm /min (10 kPa/min or 0,295 3 in Hg). The set-pressure is designated as P

set

which shall be within ± 3 % of the calculated set-pressure expressed as the correlation between the closing

force and the area of the disc against which tank pressure is projected.

9.4.3 Depending on valve type, the flow measurement shall consist of the steps described in Annex B.

See Annex F for corresponding examples of flow diagrams.

For high velocity vents, during each of the measuring periods in accordance with Annex B, the average

velocity of air through a cross section of the valve’s outlet to atmosphere shall be recorded.

9.4.4 Flow graphs shall be drawn showing the readings from the steps described by Annex B, and in the

appropriate format given in Annex F.

9.4.5 Flow testing shall be conducted adhering to the test rig provided in Figure 1. All instrumentation shall

be calibrated and have an uncertainty of no more than ± 5 %.

Key

1 blower or fan 4 pressure measuring device

2 flowmeter 5 pressure/vacuum valve

3 tank L length of connection pipe

1

Figure 1 — Flow test rig

© ISO 2007 – All rights reserved 7

---------------------- Page: 11 ----------------------

ISO 15364:2007(E)

10 Undamped oscillation tests

High velocity vents shall be tested for undamped oscillations. The test apparatus is shown in Figure 2. All

instrumentation shall be calibrated.

This test shall be carried out with the lowest and the highest opening setting available for the particular model

without a change of setting constituting a modification as defined in the note in 9.4.1.

The length and diameter of the pipe, L , and the volume of the tank shall be requested by the manufacturer.

2

The tests shall be carried out for 3 min each at ten about-equally spaced flow rates starting at 0,2 × Q and

close

using this rate as the step width (maximum flow in this test: 2 × Q ).

close

NOTE Some valve designs will perform open/close cycles that wi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.