ISO/DIS 23575

(Main)Ships and marine technology -- Marine securing devices for ro-ro cargoes

Ships and marine technology -- Marine securing devices for ro-ro cargoes

Titre manque

General Information

Standards Content (sample)

DRAFT INTERNATIONAL STANDARD

ISO/DIS 23575

ISO/TC 8/SC 4 Secretariat: SAC

Voting begins on: Voting terminates on:

2020-11-27 2021-02-19

Ships and marine technology — Marine securing devices

for ro-ro cargoes

ICS: 47.020.40

THIS DOCUMENT IS A DRAFT CIRCULATED

FOR COMMENT AND APPROVAL. IT IS

THEREFORE SUBJECT TO CHANGE AND MAY

NOT BE REFERRED TO AS AN INTERNATIONAL

STANDARD UNTIL PUBLISHED AS SUCH.

IN ADDITION TO THEIR EVALUATION AS

BEING ACCEPTABLE FOR INDUSTRIAL,

This document is circulated as received from the committee secretariat.

TECHNOLOGICAL, COMMERCIAL AND

USER PURPOSES, DRAFT INTERNATIONAL

STANDARDS MAY ON OCCASION HAVE TO

BE CONSIDERED IN THE LIGHT OF THEIR

POTENTIAL TO BECOME STANDARDS TO

WHICH REFERENCE MAY BE MADE IN

Reference number

NATIONAL REGULATIONS.

ISO/DIS 23575:2020(E)

RECIPIENTS OF THIS DRAFT ARE INVITED

TO SUBMIT, WITH THEIR COMMENTS,

NOTIFICATION OF ANY RELEVANT PATENT

RIGHTS OF WHICH THEY ARE AWARE AND TO

PROVIDE SUPPORTING DOCUMENTATION. ISO 2020

---------------------- Page: 1 ----------------------

ISO/DIS 23575:2020(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2020

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2020 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/DIS 23575:2020(E)

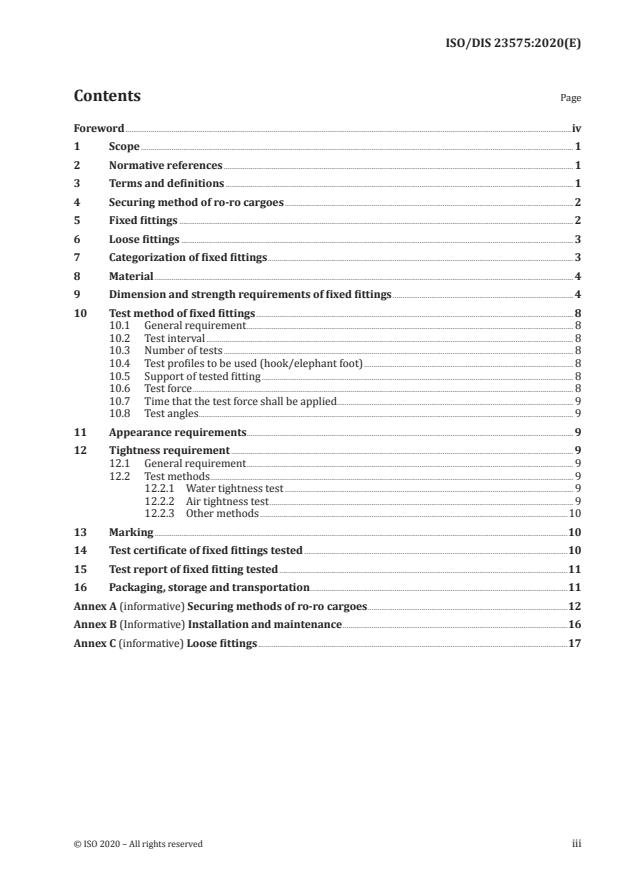

Contents Page

Foreword ........................................................................................................................................................................................................................................iv

1 Scope ................................................................................................................................................................................................................................. 1

2 Normative references ...................................................................................................................................................................................... 1

3 Terms and definitions ..................................................................................................................................................................................... 1

4 Securing method of ro-ro cargoes ...................................................................................................................................................... 2

5 Fixed fittings ............................................................................................................................................................................................................. 2

6 Loose fittings ............................................................................................................................................................................................................ 3

7 Categorization of fixed fittings ............................................................................................................................................................... 3

8 Material .......................................................................................................................................................................................................................... 4

9 Dimension and strength requirements of fixed fittings .............................................................................................. 4

10 Test method of fixed fittings ..................................................................................................................................................................... 8

10.1 General requirement .......................................................................................................................................................................... 8

10.2 Test interval ............................................................................................................................................................................................... 8

10.3 Number of tests ...................................................................................................................................................................................... 8

10.4 Test profiles to be used (hook/elephant foot) ............................................................................................................. 8

10.5 Support of tested fitting .................................................................................................................................................................. 8

10.6 Test force ...................................................................................................................................................................................................... 8

10.7 Time that the test force shall be applied ........................................................................................................................... 9

10.8 Test angles ................................................................................................................................................................................................... 9

11 Appearance requirements.......................................................................................................................................................................... 9

12 Tightness requirement .................................................................................................................................................................................. 9

12.1 General requirement .......................................................................................................................................................................... 9

12.2 Test methods ............................................................................................................................................................................................. 9

12.2.1 Water tightness test ...................................................................................................................................................... 9

12.2.2 Air tightness test .............................................................................................................................................................. 9

12.2.3 Other methods ................................................................................................................................................................10

13 Marking .......................................................................................................................................................................................................................10

14 Test certificate of fixed fittings tested .........................................................................................................................................10

15 Test report of fixed fitting tested ......................................................................................................................................................11

16 Packaging, storage and transportation ......................................................................................................................................11

Annex A (informative) Securing methods of ro-ro cargoes ........................................................................................................12

Annex B (Informative) Installation and maintenance .....................................................................................................................16

Annex C (informative) Loose fittings .................................................................................................................................................................17

© ISO 2020 – All rights reserved iii---------------------- Page: 3 ----------------------

ISO/DIS 23575:2020(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: www .iso .org/ iso/ foreword .html.This document was prepared by Technical Committee ISO/TC 8, Ships and marine technology,

Subcommittee SC 4, Outfitting and deck machinery.iv © ISO 2020 – All rights reserved

---------------------- Page: 4 ----------------------

DRAFT INTERNATIONAL STANDARD ISO/DIS 23575:2020(E)

Ships and marine technology — Marine securing devices

for ro-ro cargoes

1 Scope

This document specifies examples of types, dimensions and strength of devices for securing of ro-ro

cargoes in sea transportation. It may also be used as a reference for road vehicles secured on inland

vessels.2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 1461, Hot dip galvanized coatings on fabricated iron and steel articles — Specifications and test methods

ISO 2768-1, General tolerances — Part 1: Tolerances for linear and angular dimensions without individual

tolerance indicationsISO 5817, Welding — Fusion-welded joints in steel, nickel, titanium and their alloys (beam welding

excluded) — Quality levels for imperfectionsISO 7452, Hot-rolled steel plates — Tolerances on dimensions and shape

ISO 9001:2015, Quality management systems — Requirements

ISO 9013, Thermal cutting — Classification of thermal cuts — Geometrical product specification and

quality tolerancesISO 9367-1, Lashing and securing arrangements on road vehicles for sea transportation on Ro/Ro ships —

General requirements — Part 1: Commercial vehicles and combinations of vehicles, semi-trailers excluded

IMO resolution A.581(14), Guidelines for securing arrangements for transport of road vehicles on ro-ro ships

MSC 1/Circ.1353, Revised guidelines for the preparation of the cargo securing manual

3 Terms and definitionsFor the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IECElectropedia: available at http:// www .electropedia .org/— ISO Online browsing platform: available at https:// www .iso .org/ obp

3.1

ro-ro cargoes

all types of cargoes carried on board ro-ro vessels as road vehicles, roll trailers, etc

3.2fixed fittings

securing devices permanently installed in the vessel

© ISO 2020 – All rights reserved 1

---------------------- Page: 5 ----------------------

ISO/DIS 23575:2020(E)

3.3

loose fittings

securing devices not permanently installed in the vessel

3.4

MSL

Maximum Securing Load, in kN

the allowable load capacity for a device used to secure cargo to a ship

3.5

Proof Load, in kN

the test load during testing of securing devices.

3.6

MBL

Minimum Breaking Load, in kN

the tested minimum breaking strength of a securing device

3.7

α vertical lashing angle

angle between the lashing device and the horizontal plane, see Figure 1

3.8

β horizontal lashing angle

angle between the lashing device and the transverse direction on board the vessel, see Figure 1

Key1 vertical lashing angle α

2 horizontal lashing angle β

Figure 1 — Lashing angles

4 Securing method of ro-ro cargoes

Rules and guidelines on the securing of cargoes are found in IMO instrument as well as in the vessels

Cargo Securing Manual. For information typical securing methods for ro-ro cargoes are found in the

informative Annex A to this standard.5 Fixed fittings

5.1 The longitudinal distance of fixed fittings shall be not morethan 2,5 m, while the transverse

distance shall in general be between 2,8 m and 3 m.2 © ISO 2020 – All rights reserved

---------------------- Page: 6 ----------------------

ISO/DIS 23575:2020(E)

5.2 The MSL of fixed fittings shall in general be not less than 100 kN. The MSL of fixed fittings for the

vehicle with gross weight of less than 15 tons may be less than 100 kN after calculation proves it can

meet the requirement of securing safety.5.3 There shall be no sharp edge or sharp angle of the securing point within the area where road

vehicles run.5.4 Fixed fittings shall be marked according to Chapter 13. For information typical installation and

maintenance of fixed fittings for ro-ro cargoes are found in the informative Annex B to this standard.

6 Loose fittingsFor information typical loose fittings used for ro-ro cargoes are found in the informative Annex C to

this document.7 Categorization of fixed fittings

Categorization of fixed fittings is as shown in Table 1.

Table 1 — Categorization of fixed fittings

Type Code Name Illustration Remarks

Securing area where the

D-ringand

I11 deck is not required to be

clamp

flat for vehicle running.

Securing area where the

Flush Lashing deck is required to be flat

C21

Pot and watertight for vehicle

running.

Fixed

fittings

Securing area where the

Flush Lashing deck is required to be flat

C22

Pot and watertight for vehicle

running.

Securing area where the

Flush Lashing deck is required to be flat

C23

Hole and watertight for vehicle

running.

© ISO 2020 – All rights reserved 3

---------------------- Page: 7 ----------------------

ISO/DIS 23575:2020(E)

Table 1 (continued)

Type Code Name Illustration Remarks

Suitable for securing of

C24 Crinkle Bar

small vehicles

Raised Lashing Securing area not required

C25

Pot to be flat

Fixed

fittings

Securing area where

securing loads are large

Raised Lashing and close to the main

C26

Pot supporting structuresuch

as bulkheads, girders and

transverses

8 Material

The strength grade of materials of fixing fittings shall not be lower than that of the plate to which they

are welded, the low-temperature impact performance shall not be lower than the grade of the plate to

which they are welded.9 Dimension and strength requirements of fixed fittings

The dimension and strength requirements of fixed fittings are as shown in Figure 2~8 and Table 2~8.

Dimensions are in millimeters and strength in kN. The shown plate thickness t is the value, which

should meet the requirements of the classification society.Steel plate thickness should comply with ISO 7452 requirements; Flame cutting unmarked dimensional

tolerances shall comply with ISO 9013 class 2 requirements; Tolerances for linear and angular

dimensions without individual tolerance indications shall comply with ISO 2768-v.

Figure 2 — I11 D-rings and clamps4 © ISO 2020 – All rights reserved

---------------------- Page: 8 ----------------------

ISO/DIS 23575:2020(E)

Table 2 — Dimensions and strength of I11 D-rings and clamps

A B C D E T MSL Reference Mass

TYPE max max min min max min min max

(mm) (mm) (mm) (mm) (mm) (mm) (kN) (kg)

I11/40 15 16 40 50 25 6 40 0,5

I11/100 20 25 55 65 40 12 100 1,7

I11/180 25 30 60 75 45 14 180 2,7

Figure 3 — C21 flush lashing pot

Table 3 — Dimensions and strength of C21 flush lashing pot

A B C D E F G t MSL Reference Mass

TYPE abt max min min min abt min max

(mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (kN) (kg)

C21/100 240 16 27 186 35 65 115 12 100 8,2

C21/160 300 20 60 210 35 70 115 14 160 13,2

Figure 4 — C22 flush lashing pot

© ISO 2020 – All rights reserved 5

---------------------- Page: 9 ----------------------

ISO/DIS 23575:2020(E)

Table 4 — Dimensions and strength of C22 flush lashing pot

A B C D E F G H t MSL Reference Mass

TYPE abt max min min min abt abt min max

(mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm) (kN) (kg)

C22/100 240 16 27 186 35 65 57,5 78 12 100 7,3

C22/160 260 20 60 210 35 70 57,5 80 14 160 11,5

Key

1 deck.

Figure 5 — C23 flush lashing hole

Table 5 — Dimensions and strength of C23 flush lashing hole

A B C E t Dt MSL Reference Mass

TYPE abt min abt min min max

(mm) (mm) (mm) (mm) (mm) (mm) (kN) (kg)

C23/75 210 6 60 65 6~14 8 75 8,0

C23/100 210 6 60 65 6~14 13 100 8,0

key

1 deck.

Figure 6 — C24 crinkle bar

6 © ISO 2020 – All rights reserved

---------------------- Page: 10 ----------------------

ISO/DIS 23575:2020(E)

Table 6 — Dimensions and strength of C24 crinkle bar

L R H D MSL Reference Mass

TYPE abt min min max min max

(mm) (mm) (mm) (mm) (kN) (kg)

C24/20 290 23 30 13 20 0,4

C24/30 290 22 30 16 30 0,5

C24/100 400 25 40 25 100 1,7

Figure 7 — C25 raised lashing pot

Table 7 — Dimensions and strength of C25 raised lashing pot

A B D E G α MSL Reference Mass

TYPE abt max min min min max

min

(mm)

(mm) (mm) (mm) (mm) (mm) (mm) (kN) (kg)

C25/100 250 16 39 35 65 115 45° 100 5,1

C25/160 300 20 60 35 70 115 45° 160 11,4

Figure 8 — C26 raised lashing pot

© ISO 2020 – All rights reserved 7

---------------------- Page: 11 ----------------------

ISO/DIS 23575:2020(E)

Table 8 — Dimensions and strength of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.