ISO/FDIS 3934

(Main)Rubber, vulcanized and thermoplastic -- Preformed gaskets used in buildings -- Classification, specifications and test methods

Rubber, vulcanized and thermoplastic -- Preformed gaskets used in buildings -- Classification, specifications and test methods

Caoutchouc vulcanisé et thermoplastique -- Profilés d'étanchéité utilisés dans le bâtiment -- Classification, spécifications et méthodes d'essai

General Information

RELATIONS

Standards Content (sample)

FINAL

INTERNATIONAL ISO/FDIS

DRAFT

STANDARD 3934

ISO/TC 45/SC 4

Rubber, vulcanized and

Secretariat: DSM

thermoplastic — Preformed gaskets

Voting begins on:

20210714 used in buildings — Classification,

specifications and test methods

Voting terminates on:

20210908

Caoutchouc vulcanisé et thermoplastique — Profilés d'étanchéité

utilisés dans le bâtiment — Classification, spécifications et méthodes

d'essai

RECIPIENTS OF THIS DRAFT ARE INVITED TO

SUBMIT, WITH THEIR COMMENTS, NOTIFICATION

OF ANY RELEVANT PATENT RIGHTS OF WHICH

THEY ARE AWARE AND TO PROVIDE SUPPOR TING

DOCUMENTATION.

IN ADDITION TO THEIR EVALUATION AS

Reference number

BEING ACCEPTABLE FOR INDUSTRIAL, TECHNO

ISO/FDIS 3934:2021(E)

LOGICAL, COMMERCIAL AND USER PURPOSES,

DRAFT INTERNATIONAL STANDARDS MAY ON

OCCASION HAVE TO BE CONSIDERED IN THE

LIGHT OF THEIR POTENTIAL TO BECOME STAN

DARDS TO WHICH REFERENCE MAY BE MADE IN

NATIONAL REGULATIONS. ISO 2021

---------------------- Page: 1 ----------------------

ISO/FDIS 3934:2021(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2021

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2021 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/FDIS 3934:2021(E)

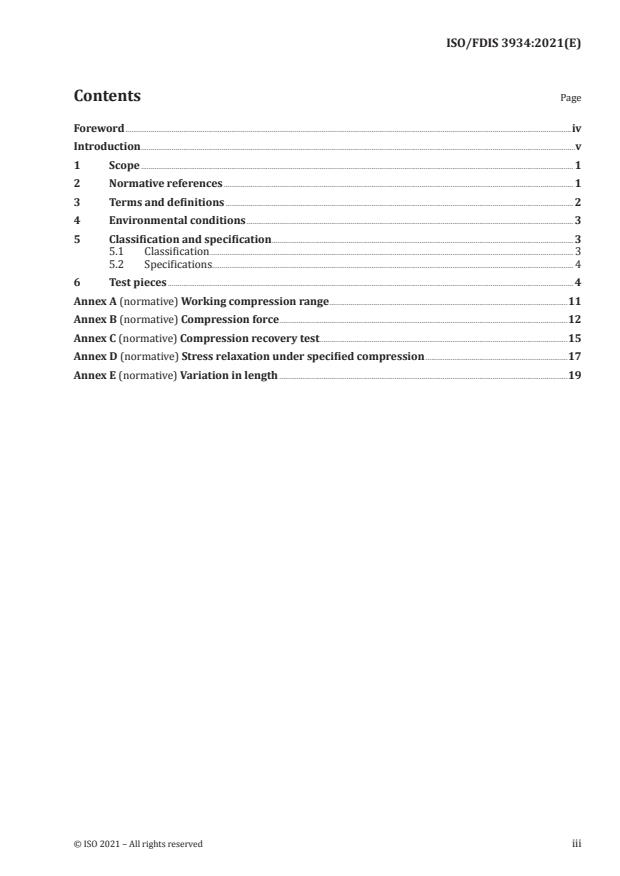

Contents Page

Foreword ........................................................................................................................................................................................................................................iv

Introduction ..................................................................................................................................................................................................................................v

1 Scope ................................................................................................................................................................................................................................. 1

2 Normative references ...................................................................................................................................................................................... 1

3 Terms and definitions ..................................................................................................................................................................................... 2

4 Environmental conditions .......................................................................................................................................................................... 3

5 Classification and specification ............................................................................................................................................................. 3

5.1 Classification ............................................................................................................................................................................................. 3

5.2 Specifications............................................................................................................................................................................................ 4

6 Test pieces ................................................................................................................................................................................................................... 4

Annex A (normative) Working compression range ............................................................................................................................11

Annex B (normative) Compression force ......................................................................................................................................................12

Annex C (normative) Compression recovery test .................................................................................................................................15

Annex D (normative) Stress relaxation under specified compression ..........................................................................17

Annex E (normative) Variation in length ......................................................................................................................................................19

© ISO 2021 – All rights reserved iii---------------------- Page: 3 ----------------------

ISO/FDIS 3934:2021(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and nongovernmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.This document was prepared by Technical Committee ISO/TC 45, Rubber and rubber products,

Subcommittee SC 4, Products (other than hoses).This third edition cancels and replaces the second edition (ISO 3934:2002), which has been technically

revised.The main changes to the previous edition are as follows:

— requirements on estimation of lifetime have been added;

— hardness tolerance has increased

— references have been updated.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.iv © ISO 2021 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/FDIS 3934:2021(E)

Introduction

Preformed gaskets used in buildings have conditions of use which differ depending on their function

and position in the building. When preparing this document, it was felt necessary to take into account

the various conditions to which the gaskets are subjected in order to define the material specifications.

The tests take into account the static and dynamic stresses to which the gaskets are subjected.

© ISO 2021 – All rights reserved v---------------------- Page: 5 ----------------------

FINAL DRAFT INTERNATIONAL STANDARD ISO/FDIS 3934:2021(E)

Rubber, vulcanized and thermoplastic — Preformed

gaskets used in buildings — Classification, specifications

and test methods

WARNING — Persons using this document should be familiar with normal laboratory practice.

This document does not purport to address all of the safety problems, if any, associated with

its use. It is the responsibility of the user of this document to establish appropriate safety and

health practices and to determine the applicability of any national regulatory conditions.

1 ScopeThis document specifies a system of classification of materials used in preformed gaskets for buildings.

It applies to the following products:a) gaskets for use round the inside of door or window casings, i.e. weatherstripping (dynamic gaskets);

b) gaskets for glazing (static gaskets);c) gaskets for use round infilling;

d) gaskets for use between facade parts;

e) gaskets for use between masonry walls.

In addition to specifying the characteristics required for the constituent materials, some functional

tests on the gaskets themselves are specified. The corresponding test procedures are given in Annexes A

to E.This document applies to preformed gaskets made from vulcanized or thermoplastic rubber. It also

applies to preformed gaskets made of cellular rubber designed for use at temperatures between −20 °C

and +55 °C (thermal conditions category P ) and between −40 °C and +70 °C (thermal conditions

category P ) (see Clause 4).2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 37, Rubber, vulcanized or thermoplastic — Determination of tensile stress-strain properties

ISO 484, Rubber, vulcanized or thermoplastic — Determination of hardness — Part 4: Indentation

hardness by durometer method (Shore hardness)ISO 105A02, Textiles — Tests for colour fastness — Part A02: Grey scale for assessing change in colour

ISO 188:2011, Rubber, vulcanized or thermoplastic — Accelerated ageing and heat resistance tests

ISO 812, Rubber, vulcanized or thermoplastic — Determination of low-temperature brittleness

ISO 8151, Rubber, vulcanized or thermoplastic — Determination of compression set — Part 1: At ambient

or elevated temperaturesISO 8152, Rubber, vulcanized or thermoplastic — Determination of compression set — Part 2: At low

temperatures© ISO 2021 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO/FDIS 3934:2021(E)

ISO 14311, Rubber, vulcanized or thermoplastic — Resistance to ozone cracking — Part 1: Static and

dynamic strain testingISO 2285:2019, Rubber, vulcanized or thermoplastic — Determination of tension set under constant

elongation, and of tension set, elongation and creep under constant tensile loadISO 33841:2019, Rubber, vulcanized or thermoplastic — Determination of stress relaxation in

compression — Part 1: Testing at constant temperatureISO 48922, Plastics — Methods of exposure to laboratory light sources — Part 2: Xenon-arc lamps

ISO 11346, Rubber, vulcanized or thermoplastic — Estimation of life-time and maximum temperature of

use3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp— IEC Electropedia: available at http:// www .electropedia .org/

3.1

compression force

force needed to compress a test piece through its working range to its minimum width (3.3)

3.2compression recovery

ability of a gasket to recover its shape after being compressed through its working range

3.3minimum width

lower limit of the working compression range (3.7)

Note 1 to entry: For a glazing gasket, the minimum width is the sum of the gaps between the glass and the

frame on each side of the glass. For weatherstripping, it is the gap between the door or window and the casing,

measured at the hinge side.Note 2 to entry: It is recommended that the minimum width of weatherstripping and the minimum clearance

between glazing and frame for a glazing gasket be agreed by consultation between designer, manufacturer and

user3.4

sample

complete batch of test material (gaskets) as supplied by the manufacturer for test purposes and from

which test pieces are cut3.5

stress relaxation

timedependent decrease in stress at a constant deformation

3.6

weathering resistance

resistance to combined detrimental influences of the outdoor environment (e.g. sunlight, ozone, oxygen,

humidity, temperature) on a material2 © ISO 2021 – All rights reserved

---------------------- Page: 7 ----------------------

ISO/FDIS 3934:2021(E)

3.7

working compression range

range, stated by the manufacturer, through which the gasket performs its function of being compressed

or otherwise deformed when used in any particular productNote 1 to entry: See Annex A.

EXAMPLE For a gasket of free height (3.8) 7,5 mm, the manufacturer states a working range of 3 mm to

6 mm.3.8

free height

height of a gasket measured without causing any significant deformation

Note 1 to entry: See Figure 1.

Figure 1 — Example of measurement of free height

4 Environmental conditions

The conditions to which gaskets may be subjected in the working environment are divided into the

following categories:a) Thermal conditions (depending on the climate and the position in the construction)

— P : temperature of preformed gasket −20 °C to +55 °C— P : temperature of preformed gasket –20 °C to +85 °C

— P : temperature of preformed gasket –40 °C to +70 °C

— P : temperature of preformed gasket –40 °C to +100 °C

b) Mechanical conditions

— X: static uses (see Table 1), i.e. between fixed elements

— Y: dynamic uses (see Table 1), i.e. between moving elements

c) Weathering

— R : protected from solar radiation

— R : exposed to solar radiation

5 Classification and specification

5.1 Classification

From the results of the tests carried out in accordance with this document, the classification of a

particular type of gasket shall be determined using Table 1. The numbers from Table 1, taken in the

order given, form the classification code for that gasket, viz:© ISO 2021 – All rights reserved 3

---------------------- Page: 8 ----------------------

ISO/FDIS 3934:2021(E)

— A: type of gasket

— B: working compression range

— C: compression force

— D: working temperature range

— E: compression recovery

— F: stress relaxation

— G: weathering resistance

Figure 2 gives a typical example of a classification code.

5.2 Specifications

The characteristics for the different classification criteria shall meet the requirements specified in

Tables 2 to 9.6 Test pieces

Test pieces shall be prepared in accordance with the relevant standard test method or the relevant

annex of this document and, whenever possible, shall be cut from the gasket to be tested.

Failing this, they shall be taken from extruded ribbon (2 mm thick, 30 mm in width) or from

appropriately dimensioned test slabs prepared from the same batch of material used to produce the

gaskets being assessed and obtained under conditions that have been shown by experience to give

comparable results.If measurements are made on test pieces not conforming to the standard referenced in Tables 2 to 9

(e.g. part of a gasket), the results can be different and the requirements to be met shall be s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.