ISO/TR 9212:2015

(Main)Hydrometry — Methods of measurement of bedload discharge

Hydrometry — Methods of measurement of bedload discharge

ISO/TR 9212:2015 reviews the current status of direct and indirect bedload-measurement techniques. The methods are mainly based on grain size distribution of the bedload, channel width, depth, and velocity of flow. This Technical Report outlines and explains several methods for direct and indirect measurement of bedload in streams, including various types of sampling devices. The purposes of measuring bedload-transport rates are to a) increase the accuracy of estimating total sediment load in rivers and deposition in reservoirs, b) gain knowledge of bedload transport that cannot be completely measured by conventional suspended-sediment collection methods, c) provide data to calibrate or verify theoretical transport models, and d) provide information needed in the design of river diversion and entrainment structures. NOTE The units of measurement used in this Technical Report are SI units.

Hydrométrie — Méthodes de mesurage du débit des matériaux charriés sur le fond

General Information

Relations

Overview

ISO/TR 9212:2015 - "Hydrometry - Methods of measurement of bedload discharge" is a Technical Report that reviews current direct and indirect bedload measurement techniques. It summarizes methods based on grain-size distribution, channel geometry (width, depth) and flow velocity, and explains sampling devices and strategies for determining bedload transport in rivers and streams. Units used in the report are SI units.

Key Topics

- Direct measurement methods

- Bedload samplers (basket/box, frame-and-net, pressure-difference types)

- Bedload traps (pit, trough, vortex-tube) for near-complete capture of moving bed material

- Requirements and characteristics of an ideal sampler; sampling procedures, identification, calculations and error considerations

- Indirect measurement methods

- Differential and volumetric measurements (deposition surveys)

- Dune-tracking techniques (moving-boat and in-situ echo sounder approaches)

- Tracers and bedload-surrogate monitoring technologies

- Remote sensing (LiDAR) and acoustic instruments including Acoustic Doppler Current Profiler (ADCP)

- Design and strategy

- Site selection guidance (reach vs cross-section), accounting for spatial and temporal variability

- Sampling strategy development tailored to local flow regimes and logistics

- Supporting content

- Procedures for sample processing and particle-size distribution measurement

- Annex on bedload-surrogate monitoring technologies and bibliography for further reading

Applications

ISO/TR 9212:2015 provides practical guidance for tasks where reliable bedload data are required:

- Improving estimates of total sediment load and reservoir deposition forecasting

- Supplementing suspended-sediment collection where bedload is not captured

- Providing calibration and verification data for sediment transport models

- Informing design of river engineering works (diversions, entrainment structures, channels, canals) to avoid unwanted bedload transfer

- Monitoring river-bed change, navigation channel maintenance and habitat assessments

Who should use this standard

- Hydrologists and hydrometrists

- River and coastal engineers

- Reservoir and dam designers

- Sediment transport researchers and modelers

- Environmental agencies and water-resource managers

- Consultants performing field sampling and instrument-based monitoring

Related Standards

- ISO 772 (Hydrometry - Vocabulary and symbols) is normatively referenced for terms and definitions.

- Document developed by ISO/TC 113 (Hydrometry), Subcommittee SC 6 (Sediment transport).

Keywords: ISO/TR 9212, hydrometry, bedload discharge, bedload measurement, sediment transport, bedload samplers, bedload traps, dune-tracking, LiDAR, acoustic instruments, ADCP, grain size distribution.

Standards Content (Sample)

TECHNICAL ISO/TR

REPORT 9212

Third edition

2015-06-01

Hydrometry — Methods of

measurement of bedload discharge

Hydrométrie — Méthodes de mesurage du débit des matériaux

charriés sur le fond

Reference number

©

ISO 2015

© ISO 2015, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2015 – All rights reserved

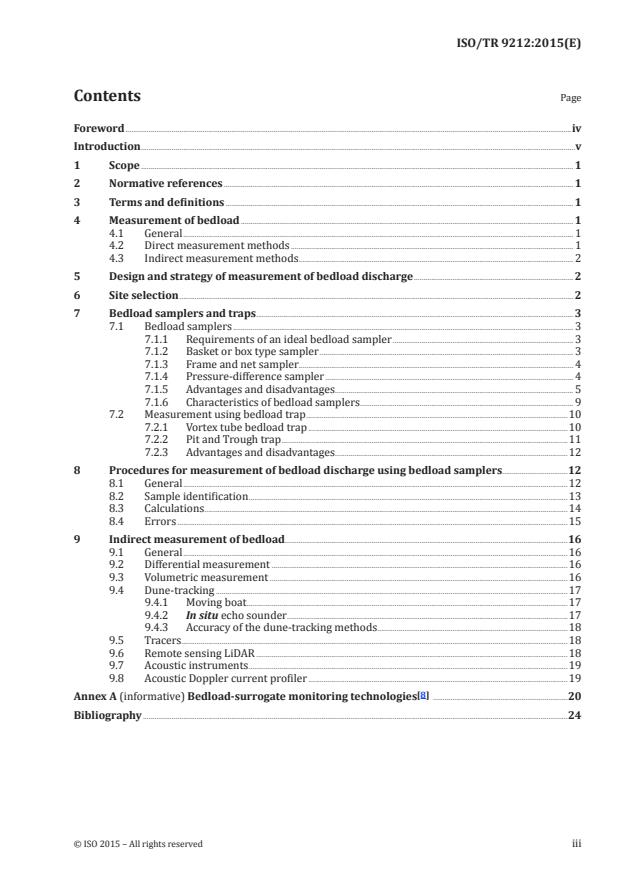

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Measurement of bedload . 1

4.1 General . 1

4.2 Direct measurement methods . 1

4.3 Indirect measurement methods . 2

5 Design and strategy of measurement of bedload discharge . 2

6 Site selection . 2

7 Bedload samplers and traps . 3

7.1 Bedload samplers . 3

7.1.1 Requirements of an ideal bedload sampler . 3

7.1.2 Basket or box type sampler . 3

7.1.3 Frame and net sampler. 4

7.1.4 Pressure-difference sampler . 4

7.1.5 Advantages and disadvantages . 5

7.1.6 Characteristics of bedload samplers . 9

7.2 Measurement using bedload trap .10

7.2.1 Vortex tube bedload trap .10

7.2.2 Pit and Trough trap .11

7.2.3 Advantages and disadvantages .12

8 Procedures for measurement of bedload discharge using bedload samplers .12

8.1 General .12

8.2 Sample identification .13

8.3 Calculations .14

8.4 Errors .15

9 Indirect measurement of bedload .16

9.1 General .16

9.2 Differential measurement .16

9.3 Volumetric measurement .16

9.4 Dune-tracking .17

9.4.1 Moving boat .17

9.4.2 In situ echo sounder . .17

9.4.3 Accuracy of the dune-tracking methods .18

9.5 Tracers.18

9.6 Remote sensing LiDAR .18

9.7 Acoustic instruments .19

9.8 Acoustic Doppler current profiler .19

[8]

Annex A (informative) Bedload-surrogate monitoring technologies .20

Bibliography .24

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical Barriers

to Trade (TBT) see the following URL: Foreword - Supplementary information.

The committee responsible for this document is ISO/TC 113, Hydrometry, Subcommittee SC 6, Sediment

transport.

This third edition cancels and replaces the second edition (ISO/TR 9212:2006), which has been

technically revised.

iv © ISO 2015 – All rights reserved

Introduction

The knowledge of the rate of sediment transport in a stream is essential in the solution of practically all

problems associated with the flow in alluvial channels. The problems include river management, such

as design and operation of flood control works, navigation channels and harbours, irrigation reservoirs

and canals, and hydroelectric installations. The bedload and suspended load broadly constitute total

sediment load. The bedload is the material transported on or near the bed by rolling or sliding (contact

load) and the material bouncing along the bed, or moving directly or indirectly by the impact of bouncing

particles (saltation load). Knowledge of the bedload-transport rate is necessary in designing reservoir

capacity because virtually 100 % of all bedload entering a reservoir accumulates there. Bedload should

not enter canals and distributaries and diversion structures should be designed to minimize the transfer

of bedload from rivers to canals.

The bedload-transport rate can be measured either as mass per unit time or volume per unit time. Volume

measurements should be converted to a mass rate. Measurements of mass rate of movement are made

during short time periods (seconds, minutes), whereas measurements of volume rates of movement are

measured over longer periods of time (hours, days). Regardless of whether the mass or volume rate is

measured, the average particle-size distribution of moving material should be determined. Knowledge

of particle-size distribution is needed to estimate the volume that the bedload material will occupy after

it has been deposited. Knowledge of particle-size distribution also assists in the estimation of bedload-

transport rates in other rivers transporting sediment.

The movement of bedload material is seldom uniform across the bed of a river. Depending upon the

river, hydraulic, and sediment properties (size and gradation), the bedload may move in various forms,

such as ripples, dunes, or narrow ribbons. Its downstream rate of movement is also extremely variable.

It is difficult to actually sample the rate of movement in a river cross-section or to determine and verify

theoretical methods of estimation.

TECHNICAL REPORT ISO/TR 9212:2015(E)

Hydrometry — Methods of measurement of bedload

discharge

1 Scope

This Technical Report reviews the current status of direct and indirect bedload-measurement

techniques. The methods are mainly based on grain size distribution of the bedload, channel width,

depth, and velocity of flow. This Technical Report outlines and explains several methods for direct and

indirect measurement of bedload in streams, including various types of sampling devices.

The purposes of measuring bedload-transport rates are to

a) increase the accuracy of estimating total sediment load in rivers and deposition in reservoirs,

b) gain knowledge of bedload transport that cannot be completely measured by conventional

suspended-sediment collection methods,

c) provide data to calibrate or verify theoretical transport models, and

d) provide information needed in the design of river diversion and entrainment structures.

NOTE The units of measurement used in this Technical Report are SI units.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 772, Hydrometry — Vocabulary and symbols

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 772 apply.

4 Measurement of bedload

4.1 General

Bedload can be measured by direct measuring bedload samplers or by indirect methods.

4.2 Direct measurement methods

a) Bedload samplers

In this method, a mechanical device or sampler is required for measuring the bedload-transport

rate. The bedload sampler is designed so that it can be placed directly on the channel bed in the flow,

to collect a sample of the bedload over a specific time interval. A sample thus obtained represents a

time-averaged mass per unit width per unit time.

b) Bedload trap

The best measurement of bedload would occur when all of the bedload moving through the river

cross was measured. Slot or pit samplers or traps meet this goal with near 100 % efficiencies.

4.3 Indirect measurement methods

All other methods of bedload measurement in which no mechanical device or bedload sampler is used,

are indirect methods. These include differential measurements of total and suspended-sediment loads,

periodic volumetric measurements of accumulated sediment depositions, dune tracking, tracers, remote

sensing, and acoustic measurements of moving sediment.

5 Design and strategy of measurement of bedload discharge

Measurement of bedload is difficult because it is highly variable in both space and time. Bedload generally

varies greatly both longitudinally along the channel and transversely across a cross section. These

variations are caused by several factors and are difficult to predict. The design of bedload sampling

needs to account for the spatial and temporal variability inherent in the processes of bedload transport.

Pit, vortex-tube, or other samplers that sample for long periods of time and encompass a significant

portion of the width of a stream cross section integrate the fluctuations in bedload-transport rate in

a cross section. In many instances, time, monetary constraints, or logistics precludes the use of these

types of samplers.

The use of portable samplers that essentially only collect samples at a point for short periods of time

is often the only practical way to collect samples of bedload. To effectively use portable samplers, the

number and location of the samples collected shall be carefully designed. Sufficient information about

the temporal and spatial variability is collected. To accomplish this task, information on the scales of

spatial and temporal variability is needed. To design an adequate sampling strategy, these time and

length scales shall be known at least approximately before the sampling procedure is defined.

Flow in many streams and rivers are not steady for periods of hours to days. For streams in which

variable flow is the norm, portable samplers will not be practical unless many flow events can be

sampled. No single sampling design can be used at all stations. A sampling design should be derived for

each site where bedload is to be sampled. Initial samples collected can provide information to serve as

a basis for developing the sampling plan.

6 Site selection

a) Depending upon the method of measurement, the site for conducting bedload measurements can

be either a river reach or a cross-section. The site should be relatively close to the geographical

location where bedload-transport rate information is needed. There should be no inflow or outflow

from the river between the measuring site and the site where bedload transport estimates will be

used.

b) When using a method such as dune-tracking, a straight reach where the channel width and depth

are fairly uniform throughout the reach is desirable. Flow through the reach should be uniform and

steady during the bedload-measurement period (see 9.4).

c) A single cross-section site should be selected if the method of measurement is by bedload sampler.

The channel width and mean depth of the cross-section site should be representative of the

average channel width and depth upstream and downstream. Ideally, a cross-section used for

bedload measurement by bedload sampler should be at the centre of a straight reach selected for

measurement of bedload by the dune-tracking method.

d) If it is not possible to place the cross-section site in the centre of an ideal straight, uniform reach,

then the cross-section should be located at least 10 to 20 channel widths downstream from any

2 © ISO 2015 – All rights reserved

bend in the channel. It should not be located at an excessively narrow section, such as might be

present at a bridge site, or at an excessively wide section.

7 Bedload samplers and traps

7.1 Bedload samplers

7.1.1 Requirements of an ideal bedload sampler

In order that the samples taken are truly representative of the bedload material of a river at the point of

sampling, the ideal bedload sampler should fulfil the following technical requirements.

a) It should be calibrated for bedload-sampler efficiency of specific sediment particle sizes.

b) It should be designed to minimize disturbances to normal bedload movement. In particular, local

erosion near the sampler mouth should be avoided so as to not form scour holes.

c) The lower edge of the sampler and nozzle should be in contact with the river bed.

d) The velocity of inflow at the mouth of the sampler should be as close as possible to the ambient

velocity of the stream at the sampling point, irrespective of what this velocity may be. This aspect

is very important if large sampling errors are to be avoided.

e) The mouth of the sampler should always face into the current and the sample should be taken

parallel to flow direction at the sampling point, into a specially designed chamber.

f) The mouth of the sampler should be outside the zone of the disturbances of the flow set up by the

body of the sampler and its operating gear and the flow lines should be as little disturbed as possible,

especially near the mouth.

g) The sampler should be able to collect only those particles moving as bedload, without contamination

by suspended sediment.

h) The sampler should be portable, yet sufficiently heavy to minimize deflection of the supporting

cable from the vertical due to current drag. A separate anchor is recommended for the sampler,

wherever possible.

i) The sampler should be simple in design and robust in construction and should require minimum

maintenance and care in operation.

j) It should be capable of collecting representative bedload samples under varying bed configurations.

k) The sampler should be designed for easy removal of the sampled material into a container for

transfer to a laboratory.

l) The volume of the sample collected should be sufficient for the determination of mass and particle-

size distribution.

m) The efficiency of the sampler should be independent of length of sampling over a reasonable time.

n) The efficiency of the sampler should be independent of the size of bedload particles and flow velocity.

7.1.2 Basket or box type sampler

This type of sampler consists of a basket or box, usually made of mesh material on all sides except the

front and bottom. The bottom may be solid or of loosely woven iron rings or steel mesh, to enable it to

conform to the irregular shape of the stream bed. The sampler is placed on the channel bed with the help

of a supporting frame and cables. A steering fin or vane(s) attached to the basket ensures positioning of

the instrument in the direction of the flow. The sediment is collected in the basket by causing a reduction

of the flow velocity and/or screening the sediment from flow for a measured time period.

Since a part of the bedload is dropped in front of the sampler, the efficiency of basket type samplers is

only about 45 %, for average sediment sizes varying from 10 mm to 50 mm. However, due to their large

capacity, basket type samplers are well suited for measuring of transport rate of large-sized sediment

[7]

.

7.1.3 Frame and net sampler

These are portable samplers consisting of a steel or aluminium frame and a trailing net for collecting

the sediment. The samplers can be used in small wadable streams. The samplers are anchored to the

streambed with steel rods driven through the frames. These samplers can be deployed for 1 h or more,

depending on the transport rate, so they can average out short-term temporal variations in transport

rates.

The sampler shown in Figure 1 was designed for use in small mountain streams. The frame, which was

fabricated from aluminium, 0,3 m wide, 0,2 m high, and 0,1 m deep. The netting, which extends about

1 m downstream from the frame, is sturdy nylon mesh with 3,5 mm openings. The sampler is able to

trap gravel particles as small as 4 mm and cobbles particles as large as 128 mm.

SCALE

APPROX. 0,3 m

Key

1 aluminium frame

2 bottom piece, bevelled

3 aluminium ground plate, inclined in front, with holes

4 adjustable nylon straps

5 slits at top and bottom on each side of the frame

6 smooth stakes, rolled steel

7 nylon netting

[2]

Figure 1 — Schematic diagram of a portable frame and net sampler

7.1.4 Pressure-difference sampler

This type of sampler is designed so that the velocity of water entering the sampler and the stream

velocity is approximately equal. Equalization of velocity is accomplished through creation of a pressure

drop at the exit due to a diverging configuration between the entrance and the exit. These are flow-

through samplers that trap coarse material behind baffles or in a mesh bag attached to the exit side or

in a specially designed chamber. The Scientific Research Institute of Hydrotechnics (SRIH) and Sphinx

samplers (see Figure 2 and Figure 5) are examples of samplers with internal baffles. The Arnhem, Helley-

Smith, US BLH-84, and US BL-84 are examples of mesh bag samplers (see Figure 3, Figure 4, Figure 6,

and Figure 7)

4 © ISO 2015 – All rights reserved

Key

1 transverse partitions

2 entrance

NOTE This is a pressure-difference bedload sampler. The SRIH sampler was the first of this type to be

developed. Such samplers can sample particles as small as fine sand to as large as 200 mm. Efficiencies are

extremely variable.

[10]

Figure 2 — Scientific Research Institute of Hydrotechnics (SRIH) sampler

7.1.5 Advantages and disadvantages

Portable samplers are generally inexpensive to acquire, but can be expensive to operate and suffer from

uncertain calibrations.

Dimensions in metres

Key

1 steering fin

2 entrance

3 rubber connection

4 mesh bag

NOTE This is a pressure-difference bedload sampler. The Arnhem or Dutch sampler comprises a rigid

rectangular entrance connected by a diverging rubber-neck to a basket of 0,2 mm to 0,3 mm mesh. Efficiencies

[13]

are variable, but generally about 70 % . It is suitable for collection of fine bedload material. The fine net of the

sampler can get clogged leading to a drop in efficiency of the sampler.

[14]

Figure 3 — Arnhem sampler

6 © ISO 2015 – All rights reserved

Dimensions in millimetres

Key

1 bag to tail attachment spring 6 rail attachment bolt

2 mesh polyester monofilament, 0,2 mm 7 hole for bag attachment spring

3 dot fastener 8 slot top rail to fit tail

4 aluminium alloy weld tail pieces except where side 9 aluminium tubing filled with lead after farming

rails join tail

5 sliding collar 10 tubing spacers, where necessary

NOTE This is a pressure-difference bedload sampler with a 76-mm square entrance nozzle and an area

[9]

expansion ratio of 3,22 . Field experiments indicate a nearly 100 % sampling efficiency for sizes from about

[6]

0,5 mm to 16 mm . Laboratory studies indicate that sampling efficiencies vary widely with particle size and

[11]

transport rate, ranging from 150 % for sand and small gravel and close to 100 % for coarse gravel .

[9]

Figure 4 — Helley-Smith bedload sampler

Dimensions in metres

NOTE This is a direct measurement sampler developed by Vinckers, Bijker and Schijft (see Reference [22]).

The hydraulic efficiency varies from about 1,09 for clear flow to about 1,0 for extreme conditions. Sampling

efficiency varies from about 93 % for particle sizes finer than 0,2 mm to about 85 % for sizes finer than about

0,09 mm.

[22]

Figure 5 — Sphinx sampler

NOTE The US BLH-84 is a hand-held 4,5 kg, wading type sampler used to collect bedload samples from a

stream of wading depth. The sampler consists of an expanding nozzle, a sampler bag, and a wading rod assembly.

Particle sizes less than 38 mm at mean velocities up to 3 m/s can be measured with this sampler. It was developed

by Reference [21]. Size of sampler: length: 711 mm, width: 140 mm, mass: 4,5 kg.

[5]

Figure 6 — US BLH-84 Wading type bedload sampler

8 © ISO 2015 – All rights reserved

NOTE The US BL-84 is a cable suspended 14,4 kg, sampler to collect bedload samples from a stream of any

depth. The sampler consists of an expanding nozzle mated to a frame, and a sampler bag. Particle sizes less than

38 mm at mean velocities up to 3 m/s can be measured with this sampler. It was developed by Reference [21]. Size

of sampler: length: 921 mm, width: 381 mm, mass: 14,4 kg.

[21]

Figure 7 — US BL-84 Cable suspended bedload sampler

7.1.6 Characteristics of bedload samplers

Since the sampling conditions encountered in streams vary widely, a single sampler for all conditions

cannot be recommended. Factors such as cost, availability, and specific requirements of the sampling

also influence the choice of the sampler to a great extent. Table 1, which summarizes the characteristics

of some commonly used samplers, can assist in the selection of a sampler in given conditions.

As the data obtained is affected by the sampling action and the mechanism of the sampler, any change

in the sampler would itself introduce a variable. Therefore, the results obtained from different samplers

might not be comparable.

Table 1 — Samplers commonly used for bedload measurement

Disturbance Acceptability to

Hydraulic Sampler

Type Description of flow various field

stability efficiency

characteristics conditions

Frame and Portable bedload trap with 0,3 m Near-bottom flow Anchored to Variable from −50 Suitable for sam-

net by 0,2 m opening and trailing velocity increases streambed. to +20 % pling coarse parti-

nylon net with 3,5 mm openings. by about 30 %. cles (greater than

4 mm) in streams

that are wadable at

high flow.

SRIH This is a pressure difference Efficiencies The sampler design

bedload sampler. extremely to measure parti-

variable cles as small as fine

sand or as large as

200 mm.

Table 1 (continued)

Disturbance Acceptability to

Hydraulic Sampler

Type Description of flow various field

stability efficiency

characteristics conditions

Arnhem Consists of a rigid rectangular Variable Variable About 70 % Generally

entrance connected by a diverg- restricted to

ing rubber neck to a basket of collection of fine

0,2 mm to 0,3 mm mesh fixed to bedload material

a large framework by springs in (2 mm); portable.

such a way that the entrance is

in contact with the bottom when

the sampler is lowered onto the

bed.

Helley - Tear-drop shaped, aluminium Intake Stable in Variable from Varying sizes, from

Smith tubing frame connecting expand- velocities are velocities about 100 % for hand-held wading

ing brass entrance to aluminium consistently higher up to gravel to more sampler to heavy

tailfins; aluminium tubing filled than ambient 3 m/s. than 150 % for sampler suspended

with lead for mass (weight); velocities. sand from cables; fairly

bedload particles are trapped in streamlined; port-

a polyester mesh bag attached able.

to exit.

Sphinx In this sampler the flow enters The hydraulic Sampling effi-

through a rectangular nozzle efficiency varies ciency varies

that gradually becomes circular, from about 1,09 for from about 93 %

then through a series of settling clear flow, to about for particle sizes

chambers, and then out a wide 1,0 for extreme finer than 0,2 mm

exit at the rear. conditions to about 85 % for

sizes finer than

about 0,09 mm

US BLH-84 The sampler is constructed of Mean veloc- Variable from The sampler design

wading type aluminium and is 711 mm long. ities up to near 100 % for enables collection

sampler Consists of an expanding nozzle, 3 m/s (this 11 mm to 32 mm of particle sizes

a sampler bag, and a wading rod velocity is particles to 125 % less than 38 mm at

assembly. The sampler has a higher than to 160% for finer mean velocities up

[10][11]

76-mm square entrance nozzle, safe wading particles to 3 m/s.

and nozzle and an area expan- velocities).

sion ratio (ratio of nozzle exit

area to entrance area) of 1:40. A

polyester mesh bag with mesh

openings of 0,25 mm is attached

to the rear of the nozzle assem-

bly with a rubber “O” ring.

US BL-84 The sampler consists of an Mean veloc- Variable from The sampler design

cable expanding nozzle mated to a ities up to near 100 % for enables collection

suspended frame, and a sampler bag. The 3 m/s. 11 mm to 32 mm of particle sizes up

sampler sampler has a 76-mm square particles to 125 % to 38 mm at mean

entrance nozzle and an area to 160% for finer velocities up to

[10][11]

expansion ratio of 1,40. The particles 3 m/s.

US BL-84 is constructed of

stainless steel and aluminium,

is equipped with tail fins, and is

921 mm long by 381 mm wide.

The sampler should be supported

by a steel cable and reel to be

lowered into a river or stream for

taking a bedload sample.

7.2 Measurement using bedload trap

7.2.1 Vortex tube bedload trap

The samplers consist of a 45 % diagonal slot in a concrete broad crested weir constructed across the

channel at the measurement site. A vortex is generated in the diagonal slot and from 5 % to 15 % of the

flow carries the bedload sediment to a trap on the side of the channel. The sediment is then weighed and

10 © ISO 2015 – All rights reserved

sampled and returned to the stream downstream of the weir (Robinson, 1962[18]; Milhous, 1973[15];

Tacconi and Billi, 1987[20]).

NOTE 1 This is a vortex tube bedload sampler designed by the Swiss Federal Institute of Technology Zurich.

The hydraulic tests showed that the principle of vortex tubes is suited for the extraction of transported sediment.

The results demonstrated extracting rates over 95 % under appropriate hydraulic conditions. The tube geometry

is dependent on sediment size, channel width, and economical aspects.

NOTE 2 Left: headrace channel (right) and residual flow reach (left), middle: types of the investigated vortex

tubes, right side: vortex tube cross-sections, arrows indicate the direction of flow.

Figure 8 — Vortex tube bedload trap

7.2.2 Pit and Trough trap

These samplers are used on small flashy streams where the bedload moves during a flood event. The

samplers are installed in the bed of the channel by burying the sampler so that the top is flush with

the surface of the bed. They consist of small containers that catch and retain all bedload sediment that

[10]

is transported to the sampler . The bedload is either removed and weighed after a flood event or

[13][16]

weighed continuously by a pressure pillow in the bottom of the trap . Another pit-type trap uses a

[6]

continuous conveyor belt, which carries the bedload to a weighing station on the stream bank .

Key

1 reinforced concrete outer box

2 steel inner box with slotted covers

3 pressure pillow

4 shelter for bubbler system

5 tubes from bubbler system to pillow

Figure 9 — Example of a pit and trough sediment trap that captures and weighs the sediment

transported as bedload during the measurement period (adapted from Reference [13] and

Reference [16])

7.2.3 Advantages and disadvantages

The bedload trap operates reliably on relatively small gravel-bed stream, but they are not portable and

the initial construction cost is high.

8 Procedures for measurement of bedload discharge using bedload samplers

8.1 General

Many problems in determining bedload discharge over the wide range of sediment and hydraulic

conditions found in nature have yet to be resolved. Among these problems, it should be noted that

a) quantification of physical relations is not complete enough to estimate the bedload discharge,

b) quantitative measurements are applicable only to specific site studies at the time of measurement,

and

c) direct measurement devices are useful for only a very limited range of sediment size and hydraulic

conditions.

As a result, no single apparatus or procedure has been universally accepted as completely adequate for

the determination of the bedload discharge over the wide range of sediment and hydraulic conditions

found in nature.

The type of sampler and the technique of sampling used will depend on a large number of factors namely,

stream velocity, depth, width, particle size, transport rate, channel stability, and bed configuration. The

transport rate of bedload not only changes from point to point in a cross-section but also exhibits widely

variable short-term and long-term fluctuations at a fixed point. These variations in the measurement of

12 © ISO 2015 – All rights reserved

bedload discharge mean that short-term measurements at a point are very likely to be non-representative

of the mean bedload discharge at that point. Therefore, each sampling point should be sampled many

times over an adequately long period in order to achieve any reasonable accuracy. The number of

sampling points in a cross-section is usually dependent on funding and manpower available. However, it

should be noted that the more points are sampled, the greater is the degree of accuracy.

The sampling time interval will be determined by the volume of bedload material in transport and the

capacity of the sampler used. Generally, the quantity of material collected should not exceed two-thirds

of the sampler capacity.

Among the potential problems inherent in the manual deployment of bedload samplers is the orientation

of the deployed bedload sampler with respect to flow direction, deployed sampler movement, and

inadvertent collection of bed material. A bedload sampler orientation other than directly upstream

may collect bedload from a stream section that is less than the nozzle’s width resulting in a systematic

negative bias in the capture of bedload.

Additionally, a bedload sampler that swings upstream as it is lowered to the bed can gouge into a bedform

and collect bed material that may be spuriously included in bedload. These problems tend to be most

[4]

prevalent in cable deployments. Use of a stayline and tetherline assembly minimizes or eliminates the

above-mentioned problems. This assembly enables the bedload sampler to be lowered vertically to the

bed and to be restrained from further movement.

Regardless of the method for deploying manual bedload samplers, without observing the bedload

sampler as it is deployed, one cannot be certain of the orientation or movement of the sampler once

on the bed, nor could one confirm or refute that the sampler collected bed material by gouging the

bed. When the deployed bedload sampler cannot be directly observed, affixing a video camera and

light source above and behind the bedload-sampler nozzle to provide video of bedload approaching the

nozzle can enable the operator to qualitatively assess of the reliability of the sample bedload collected.

8.2 Sample identification

In order to properly evaluate the bedload samples, the following items should be recorded on the

individual sampler container:

a) river name and location;

b) date of collection;

c) start time of collection;

d) cross-section location;

e) stationing on the cross section;

f) length of sampling time;

g) depth of water;

h) water temperature;

i) water discharge;

j) type of sampler used.

8.3 Calculations

The computation of bedload discharge from measurements made by direct methods employs the

Formula (1) which is applicable for all conditions for determining the total sediment discharge of a given

particle-size range:

TD= //eQ++QF−+QE1− eQ (1)

() ()

sM usM1 sM ts2

where

T is the total sediment discharge of the size range considered;

D is the discharge of the size range as measured with the bedload sampler; if the sampler

measures more than the bedload discharge, D includes some of the suspended-sediment

discharge; if the sampler measures only the bedload discharge, D = B (B being the bedload-

transport rate);

e is the efficiency of the bedload sampler in measuring the bedload discharge of the size

range;

Q is the measured suspended-sediment discharge of the size range. It equals the product of

sM

the total water discharge, a units-conversion constant, and the velocity-weighted mean

concentration in the sampled zone;

Q is the unmeasured suspended-sediment discharge of the size range at the depth between

usM1

the lowest point measured by the suspended-sediment sampler and the highest point meas-

ured by the bedload sampler. It equals the product of the water discharge at this depth, a

units-conversion constant, and the difference between the velocity-weighted mean concen-

trations in the sampled zone and at this depth;

F is the fraction of flow at the depth measured by the bedload sampler with respect to total

flow;

E is the efficiency of the bedload sampler in measuring the suspended-sediment discharge of

the size range that passes at the depth measured by the sampler;

Q is the total suspended-sediment discharge of the size range that passes at the depth meas-

ts2

ured by the bedload sampler.

Simplifications of Formula (1) can be made for different combinations of particle-size ranges (expressed

as bedload or suspended load), vertical distribution of the suspended-sediment concentration, and type

of bedload measuring apparatus. Table 2 shows the simplified formula for each combination of relevant

parameters.

14 © ISO 2015 – All rights reserved

Table 2 — Formulae for computing the total sediment discharge of a size range

Particle Type of Equivalent

size bedload

range measur-

Simplified formula

trans- ing

D/e Q Q F Q

sM usM1 ts2

ported appara-

a b

as tus

s W 0 Q 0 0 0 T = Q

sM sM

s Y (E/e) Q Q 0 F FQ T = Q

ts2 sM sM sM

s Z (E/e) Q Q 0 F FQ T = Q

ts2 sM sM sM

σ W 0 Q Q 0 0 T = Q + Q

sM usM1 sM usM1

c

σ Y (E/e) Q Q 0 F Q T = (D/e) + Q − FQ + (1 − E/e) Q

ts2 sM ts2 sM sM ts2

σ Z (E/e) Q Q Q F Q T = (D/e) + Q + Q − FQ + (1 − E/e)

ts2 sM usM1 ts2 sM usM1 sM

c

Q

ts2

β W B/e 0 0 0 0 T = (D/e)

β Y B/e 0 0 F 0 T = (D/e)

β Z B/e 0 0 F 0 T = (D/e)

β, s W B/e Q 0 0 0 T = (D/e) + Q

sM sM

β, s Y (B/e) + (E/e) Q 0 F FQ T = (D/e) + Q − (E/e) Q

sM sM sM ts2

Q

ts2

β, s Z (B/e) + (E/e) Q 0 F FQ T = (D/e) + Q − (E/e) Q

sM sM sM ts2

Q

ts2

β, σ W B/e Q Q 0 0 T = (D/e) + Q + Q

sM usM1 sM usM1

β, σ Y (B/e) + (E/e) Q 0 F Q T = (D/e) + Q − FQ + (1 − E/e) Q

sM ts2 sM sM ts2

Q

ts2

β, σ Z (B/e) + (E/e) Q Q F Q T = (D/e) + Q + Q − FQ + (1 − E/e)

sM usM1 ts2 sM usM1 sM

Q Q

ts2 ts2

a

β: bedload; s: suspended sediment having a uniform vertical distribution; σ: suspended sediment having a non-uniform

vertical distribution.

b

W: measures only bedload; Y: measures bedload plus suspended sediment in all of unsampled depth; Z: measures

bedload plus suspended sediment in part of unsampled depth.

c

Or Q + Q where Q is the unmeasured suspended-sediment discharge in unsampled depth.

sM usM usM

8.4 Errors

Bedload discharge is especially important during periods of extremely high discharge and in landscapes

of large topographical relief, where the river gradient is steep (such as in mountains). Measurement of

bedload is extremely difficult. Most bedload movement occurs during periods of high discharge on steep

gradients when the water level is high and the flow is extremely turbulent. Such conditions also cause

problems when making field measurements.

Despite many years of experimentation, sediment-monitoring agencies have so far been unable to devise

a standard sampler that can be used without elaborate field calibration or that can be used under a wide

range of bedload conditions.

Even with calibration, the measurement error can be very large because of the inherent hydraulic

characteristics of the samplers and the immense difficulty with representative sampling of the range of

sizes of particles in transit as bedload in many rivers.

Unless bedload is likely to be a major engineering concern (as in the filling of reservoirs), agencies should

not attempt to measure it as part of a routine sediment-monitoring programme. Where engineering

works demand knowledge of bedload, agencies shall acquire the sp

...

Frequently Asked Questions

ISO/TR 9212:2015 is a technical report published by the International Organization for Standardization (ISO). Its full title is "Hydrometry — Methods of measurement of bedload discharge". This standard covers: ISO/TR 9212:2015 reviews the current status of direct and indirect bedload-measurement techniques. The methods are mainly based on grain size distribution of the bedload, channel width, depth, and velocity of flow. This Technical Report outlines and explains several methods for direct and indirect measurement of bedload in streams, including various types of sampling devices. The purposes of measuring bedload-transport rates are to a) increase the accuracy of estimating total sediment load in rivers and deposition in reservoirs, b) gain knowledge of bedload transport that cannot be completely measured by conventional suspended-sediment collection methods, c) provide data to calibrate or verify theoretical transport models, and d) provide information needed in the design of river diversion and entrainment structures. NOTE The units of measurement used in this Technical Report are SI units.

ISO/TR 9212:2015 reviews the current status of direct and indirect bedload-measurement techniques. The methods are mainly based on grain size distribution of the bedload, channel width, depth, and velocity of flow. This Technical Report outlines and explains several methods for direct and indirect measurement of bedload in streams, including various types of sampling devices. The purposes of measuring bedload-transport rates are to a) increase the accuracy of estimating total sediment load in rivers and deposition in reservoirs, b) gain knowledge of bedload transport that cannot be completely measured by conventional suspended-sediment collection methods, c) provide data to calibrate or verify theoretical transport models, and d) provide information needed in the design of river diversion and entrainment structures. NOTE The units of measurement used in this Technical Report are SI units.

ISO/TR 9212:2015 is classified under the following ICS (International Classification for Standards) categories: 17.120.20 - Flow in open channels. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/TR 9212:2015 has the following relationships with other standards: It is inter standard links to ISO/TR 9212:2006. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase ISO/TR 9212:2015 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ISO standards.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...