ISO 13915:2023

(Main)Fine ceramics (advanced ceramics, advanced technical ceramics) — Test method for optical properties of ceramic phosphors for white light-emitting diodes with reference materials

Fine ceramics (advanced ceramics, advanced technical ceramics) — Test method for optical properties of ceramic phosphors for white light-emitting diodes with reference materials

This document specifies a substitution measurement method to measure internal quantum efficiency, external quantum efficiency and absorptance of ceramic phosphor powders, which are used in white light-emitting diodes (LEDs) and emit visible light when excited by UV or blue light. In this method, commercially available measurement equipment, such as a fluorescence spectrophotometer or a spectroradiometer equipped with a monochromatic light source as incident light, are used to measure fluorescence spectra for reference materials whose quantum efficiencies and absorptance have been determined using the methods in ISO 23946 and a phosphor material under test.

Titre manque

General Information

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 13915

First edition

2023-08

Fine ceramics (advanced ceramics,

advanced technical ceramics) — Test

method for optical properties of

ceramic phosphors for white light-

emitting diodes with reference

materials

Reference number

© ISO 2023

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

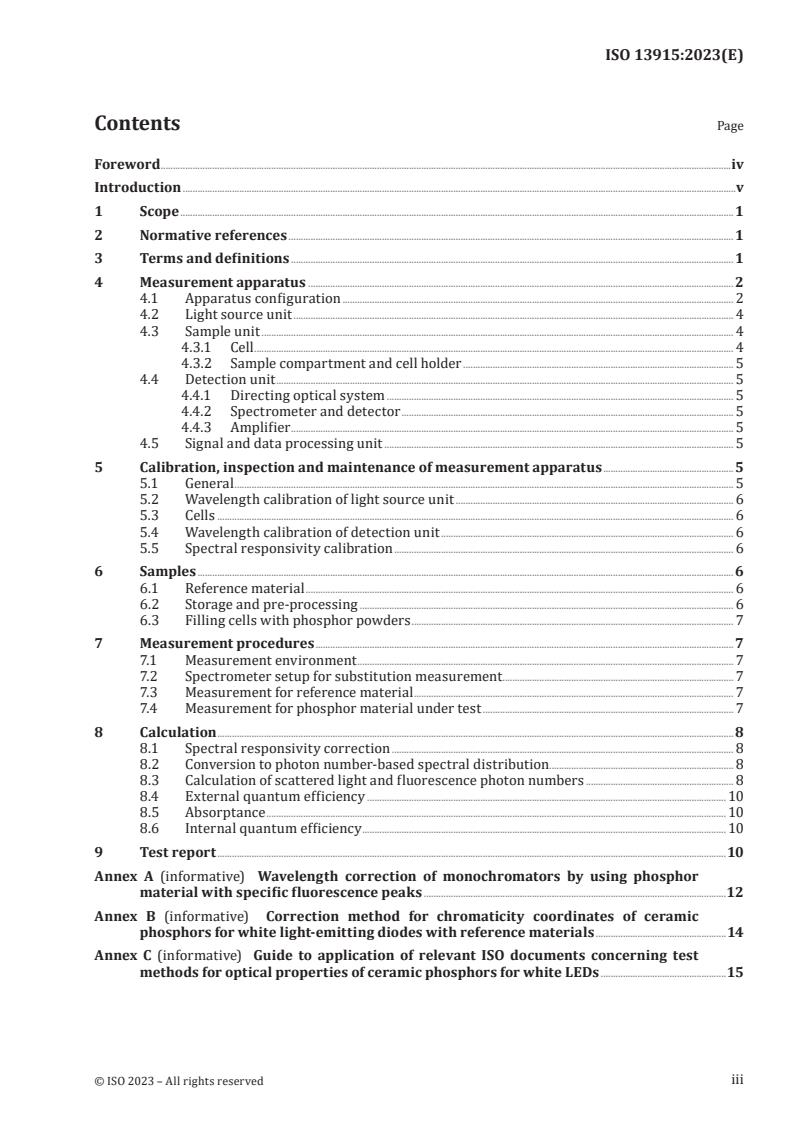

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Measurement apparatus . 2

4.1 Apparatus configuration . 2

4.2 Light source unit . 4

4.3 Sample unit . 4

4.3.1 Cell . 4

4.3.2 Sample compartment and cell holder . 5

4.4 Detection unit . 5

4.4.1 Directing optical system . 5

4.4.2 Spectrometer and detector . 5

4.4.3 Amplifier . 5

4.5 Signal and data processing unit . 5

5 Calibration, inspection and maintenance of measurement apparatus .5

5.1 General . 5

5.2 Wavelength calibration of light source unit . 6

5.3 Cells . 6

5.4 Wavelength calibration of detection unit . 6

5.5 Spectral responsivity calibration . 6

6 Samples . 6

6.1 Reference material . 6

6.2 Storage and pre-processing . 6

6.3 Filling cells with phosphor powders . 7

7 Measurement procedures .7

7.1 Measurement environment . 7

7.2 Spectrometer setup for substitution measurement . 7

7.3 Measurement for reference material . 7

7.4 Measurement for phosphor material under test . 7

8 Calculation . 8

8.1 Spectral responsivity correction . 8

8.2 Conversion to photon number-based spectral distribution. 8

8.3 Calculation of scattered light and fluorescence photon numbers . 8

8.4 External quantum efficiency . 10

8.5 Absorptance . 10

8.6 Internal quantum efficiency . 10

9 Test report .10

Annex A (informative) Wavelength correction of monochromators by using phosphor

material with specific fluorescence peaks .12

Annex B (informative) Correction method for chromaticity coordinates of ceramic

phosphors for white light-emitting diodes with reference materials .14

Annex C (informative) Guide to application of relevant ISO documents concerning test

methods for optical properties of ceramic phosphors for white LEDs .15

iii

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO document should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use

of (a) patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed

patent rights in respect thereof. As of the date of publication of this document, ISO had not received

notice of (a) patent(s) which may be required to implement this document. However, implementers are

cautioned that this may not represent the latest information, which may be obtained from the patent

database available at www.iso.org/patents. ISO shall not be held responsible for identifying any or all

such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 206, Fine ceramics.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

iv

Introduction

White light-emitting diode (LED)-based solid-state lighting (SSL) has been widely used for a variety of

applications as an alternative for incandescent and fluorescent lamps. Initially, white LEDs (comprising

blue LEDs and yellow phosphors) became popular as backlight sources for small-size liquid-crystal

displays (LCDs) used in mobile phones and digital cameras. These were followed by white LEDs

(consisting of blue LEDs combined with green and red phosphors) applied to backlight sources for large-

area LCDs. Subsequently, LED lamps were commercialised for general lighting, replacing conventional

luminaires and capitalising on their advantages, such as compactness, high luminous efficiency, high

brightness below 0 °C or higher ambient temperatures, long life and controllability of light intensity and

colour temperature.

The optical performance of a phosphor material for use in a white LED is one of the most important

factors influencing the performance of the white LED. Accordingly, it is of great importance not only

for researchers and manufacturers of phosphors for use in white LEDs but also for researchers and

manufacturers of white LED devices to evaluate optical properties of the phosphors in a well-established

manner. Photoluminescence quantum efficiency is one of the key optical parameters of phosphors for

use in white LEDs and has been measured extensively by using an integrating sphere-based absolute

method.

ISO 20351 was developed in accordance with the demand for standardizing the test method of internal

quantum efficiency of phosphors using an integrating sphere. This standard test method has the

advantage of a short measurement time and being available to those with no expertise in precise optical

measurement. Despite their importance in terms of the performance of ceramic phosphor products,

the external quantum efficiency and absorptance are out of the scope of ISO 20351 due to insufficient

understanding of the source of variation in these measurement values.

ISO 23946 was then developed to provide “integrating-sphere-free” absolute measurement methods for

the external quantum efficiency, internal quantum efficiency and absorptance for ceramic phosphors

for use in white LEDs using a gonio-spectrofluorometer. These goniometric measurement methods are

based on basic illumination theory and can give accurate values of quantum efficiencies and absorptance

for ceramic phosphors regardless of the spatial distribution of fluorescence or scattered light. While

the goniometric method is theoretically rigorous, it requires large and complicated equipment as well

as a long time to complete the measurement. Therefore, the application of ISO 23946 is assumed to be

limited to those who intend to determine the optical properties of phosphor materials to be utilized as

reference materials.

This document provides a simple measurement method for those who use a general-purpose instrument,

where a phosphor material with optical properties evaluated according to the methods in ISO 23946 is

used as a reference material.

In this document, measurement conditions and procedures that can affect the measurement values

are described in detail, helping those who address high-performance phosphors for competitive SSL

products to obtain appropriate information on their competitiveness.

This document can also be adopted for phosphors used in non-white LEDs, e.g. green, orange, pink and

purple.

Guide to application of relevant ISO documents concerning test methods for optical properties of

ceramic phosphors for white LEDs are presented in Annex C.

v

INTERNATIONAL STANDARD ISO 13915:2023(E)

Fine ceramics (advanced ceramics, advanced technical

ceramics) — Test method for optical properties of ceramic

phosphors for white light-emitting diodes with reference

materials

1 Scope

This document specifies a substitution measurement method to measure internal quantum efficiency,

external quantum efficiency and absorptance of ceramic phosphor powders, which are used in white

light-emitting diodes (LEDs) and emit visible light when excited by UV or blue light. In this method,

commercially available measurement equipment, such as a fluorescence spectrophotometer or a

spectroradiometer equipped with a monochromatic light source as incident light, are used to measure

fluorescence spectra for reference materials whose quantum efficiencies and absorptance have been

determined using the methods in ISO 23946 and a phosphor material under test.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 20351, Fine ceramics (advanced ceramics, advanced technical ceramics) — Absolute measurement of

internal quantum efficiency of phosphors for white light emitting diodes using an integrating sphere

ISO 23946, Fine ceramics (advanced ceramics, advanced technical ceramics) — Test methods for optical

properties of ceramic phosphors for white light-emitting diodes using a gonio-spectrofluorometer

ISO/CIE 11664-3, Colorimetry — Part 3: CIE tristimulus values

CIE S 017/E, International Lighting Vocabulary

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 20351, ISO 23946, CIE S 017/E,

ISO/CIE 11664-3 and the following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1

fluorescence spectrophotometer

apparatus measuring the fluorescence spectrum of a sample irradiated on its surface by monochromatic

light

4 Measurement apparatus

4.1 Apparatus configuration

The apparatus includes a light source unit, a sample unit, a detection unit and a signal/data processing

unit. Figure 1 and Figure 2 illustrate the typical configurations of a measurement apparatus.

The light source unit generates monochromatic excitation light and comprises a white light source,

a power supply for the white light source, a focusing optical system, a wavelength selection unit

(monochromator for the white light source) and an optical system for irradiation. A collimated laser

beam can also be used as the monochromatic light source.

The sample unit comprises a cell, a sample compartment and a cell holder.

The detection unit comprises a directing optical system for collecting light, a spectrometer, a detector

and an amplifier.

Key

A light source unit 1 light source

B sample unit 2 monochromator

C detection unit 3 optical system for irradiation

4 sample (cell)

5 directing optical system

6 spectrometer

7 detector

Figure 1 — Typical measurement apparatus configuration (fluorescence spectrophotometer

type)

Key

A light source unit 1 light source

B sample unit 2 monochromator

C detection unit 3 optical system for irradiation (optical fibre probe)

4 sample (cell)

5 directing optical system (optical fibre probe)

6 array spectrometer/spectroradiometer

Figure 2 — Typical measurement apparatus configuration (array spectrometer type)

The geometrical condition of the measurement is illustrated in Figure 3. When a substitution

measurement is performed with a certain fixed angle of incidence, an angle-adjustable optical system

for irradiating incident light onto the centre of a sample surface may be used. The propagation vector

of the optical radiation, whether emitted or reflected, is defined as the direction of observation and

should be located in or near the plane of incidence.

The angle of incidence θ (see Figure 3) should be configured with reference to the measurement

i

geometry applied when measuring the quantum efficiencies and absorptance of the reference material

in accordance with ISO 23946.

The angle of observation θ (see Figure 3) shall not be identical with or close to the angle of incidence θ

r i

to avoid specular reflection from the surface of a cell, a cover glass or a glass lid, as well as specular-like

directional scattering from the sample.

The following measurement geometries are typical configurations.

Geometry A θ = 0°, θ = 30°

i r

Geometry B θ = 30°, θ = 60°

i r

Geometry A is a vertical incidence configuration which is applicable to various sets of monochromatic

light sources and spectroradiometers. Geometry B is the basic configuration for commercially available

fluorescence spectrophotometers. Geometries other than these typical geometries are also possible.

A measurement apparatus with the sample unit comprising an integrating sphere, where the specific

angle of observation cannot be defined, is out of the scope of this document. The substitution

measurement can also be performed by an apparatus with an integrating sphere, which is described in

ISO 20351.

Key

angle of incidence

θ

i

angle of observation

θ

r

Figure 3 — Geometrical condition of substitution measurement

4.2 Light source unit

The spectral width of the excitation light is limited by the monochromator. The half-width of the

excitation light spectrum should be 15 nm or less.

The excitation light passes through an optical system for irradiation and irradiates a sample. One

example of an optical system for irradiation is focusing optics. The monochromated light from the exit

slit of the monochromator is collimated by the focusing optics to provide a circular, nearly circular or

oval-shaped beam of light onto the sample surface. An optical fibre probe can also be used as the optical

system for irradiation.

The optical system for irradiation should be designed to optimise the size of the illuminated area on the

sample for detecting scattered light and fluorescence efficiently.

4.3 Sample unit

4.3.1 Cell

The area of a sample shall be substantially larger than the area irradiated by the excitation light, and

the thickness of a sample in the incident plane shall be at least 2 mm.

A sample cell shall be made of a chemically and physically stable material which does not contaminate

the sample inside and can be used in conjunction with a cell holder. A rectangular cell, a flat plate cell

and a Petri dish can be used as a sample cell.

For normal incidence geometry (geometry A described in 4.1, for example), the surface of the powder

sample shall be exposed directly by the excitation light: i.e., it shall not be covered with any other

materials to prevent specular or diffuse reflection.

For geometries other than normal incidence (geometry B described in 4.1, for examp

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...