ISO/IEC 15486:1998

(Main)Information technology — Data interchange on 130 mm optical disk cartridges of type WORM (Write Once Read Many) using irreversible effects — Capacity: 2,6 Gbytes per cartridge

Information technology — Data interchange on 130 mm optical disk cartridges of type WORM (Write Once Read Many) using irreversible effects — Capacity: 2,6 Gbytes per cartridge

Technologies de l'information — Échange de données sur cartouches de disque optique de 130 mm de type WORM utilisant des effets irréversibles — Capacité: 2,6 Gbytes par cartouche

General Information

Standards Content (Sample)

INTERNATIONAL

STANDARD

First edition

1998-05- 15

Information technology - Data interchange

on 130 mm optical disk cartridges of type

WORM (Write Once Read Many) using

- Capacity: 2,6 Gbytes

irreversible effects

per cartridge

Technologies de I’informa tion - khange de donrkes sur cartouches de

disque optique de 130 mm de type WORM utilisant des effets

irr&ersibles - Capacitk: 2,6 Gbytes par cartouche

---------------------- Page: 1 ----------------------

PSO/IEC 15486:1998 (E)

Contents

1

Section 1 - General

1

1 Scope

2 Conformance

2.1 Optical Disk Cartridge (ODC)

2.2 Generating system

2.3 Receiving system

2.4 Compatibility statement

1

3 Normative reference

2

4 Definitions

2

4.1 band

2

4.2 case

2

4.3 clamping zone

2

4.4 control track

2

4.5 Cyclic Redundancy Check (CRC)

2

4.6 defect management:

3

4.7 disk reference plane

1

4.8 entrance surface

2

4.9 Error Correction Code (ECC)

2

4.10 format

2

4.11 hub

2

4.12 interleaving

2

4.13 land and groove

2

4.14 logical track

2

4.15 mark

2

4.16 mark edge

2

4.17 mark edge recording

2

4.18 optical disk

2

4.19 optical disk cartridge (ODC)

2

4.20 physical track

2

4.21 polarization

2

4.22 pre-recorded mark

2

4.23 read power

2

4.24 recording layer

2

4.25 Reed-Solomon code

3

4.26 space

3

4.27 spindle

3

4.28 substrate:

3

4.29 track pitch

3

4.30 write-inhibit hole

3

4.31 zone

0 ISO/IEC 1998

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced

or utilized in any form or by any means, electronic or mechanical, including photocopying and microfilm,

without permission in writing from the publisher.

ISO/IEC Copyright Office * Case Postale 56 * CH-1211 Geneve 20 * Switzerland

Printed in Switzerland

11

---------------------- Page: 2 ----------------------

ISO/IEC15486:1998 (E)

OISO/IEC

3

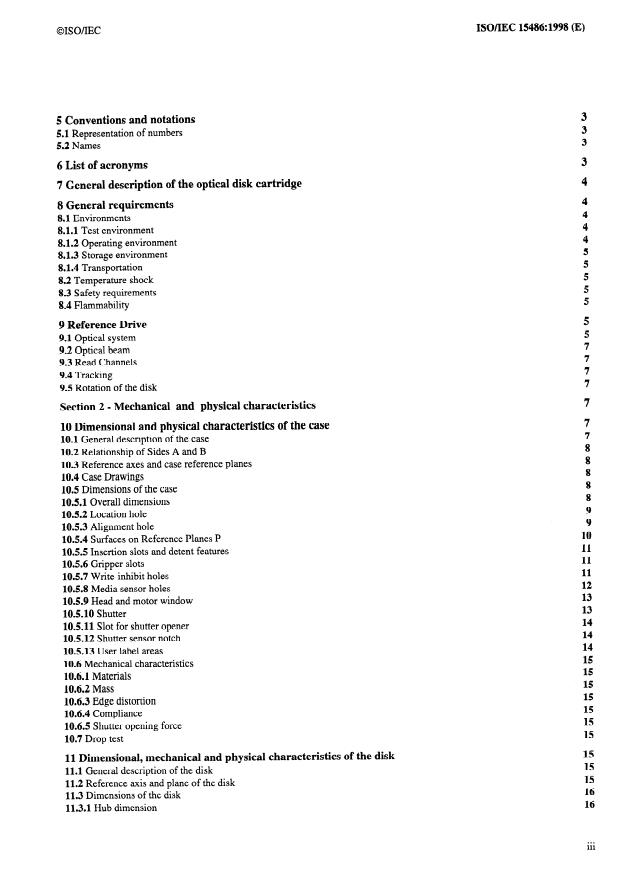

5 Conventions and notations

3

5.1 Representation of numbers

3

5.2 Names

3

6 List of acronyms

7 General description of the optical disk cartridge

8 General requirements

8.1 Environments

8.1.1 Test environment

8.1.2 Operating environment

8.1.3 Storage environment

8.1.4 Transportation

8.2 Temperature shock

8.3 Safety requirements

8.4 Flammability

9 Reference Drive

9.1 Optical system

9.2 Optical beam

9.3 Read Channels

9.4 Tracking

9.5 Rotation of the disk

7

Section 2 - Mechanical and physical characteristics

7

10 Dimensional and physical characteristics of the case

7

10.1 General description of the case

8

10.2 Relationship of Sides A and B

8

10.3 Reference axes and case reference planes

8

10.4 Case Drawings

8

10.5 Dimensions of the case

8

10.5.1 Overall dimensions

9

10.5.2 Location hole

9

10.5.3 Alignment hole

10

10.5.4 Surfaces on Reference Planes P

11

10.5.5 Insertion slots and detent features

11

10.5.6 Gripper slots

11

10.5.7 Write-inhibit holes

12

10.5.8 Media sensor holes

13

10.5.9 Head and motor window

13

10.5.10 Shutter

14

10.5.11 Slot for shutter opener

14

10.5.12 Shutter sensor notch

14

10.5.13 User label areas

15

10.6 Mechanical characteristics

15

10.6.1 Materials

15

10.6.2 Mass

15

10.6.3 Edge distortion

15

10.6.4 Compliance

15

10.6.5 Shutter opening force

15

10.7 Drop test

15

11 Dimensional, mechanical and physical characteristics of the disk

15

11.1 General description of the disk

15

11.2 Reference axis and plane of the disk

16

11.3 Dimensions of the disk

16

11.3.1 Hub dimension

. . .

111

---------------------- Page: 3 ----------------------

OISO/IEC

ISO/IEC 15486: 1998 (E)

17

11.4 Mechanical characteristics

17

11.4.1 Material

17

11.4.2 Mass

17

11.4.3 Moment of inertia

17

11.4.4 Imbalance

17

11.4.5 Axial deflection

17

11.4.6 Axial acceleration

18

11.4.7 Radial runout

18

11.4.8 Radial acceleration

18

11.4.9 Tilt

18

11.5 Optical characteristics

18

11.5.1 Index of refraction

18

11.5.2 Thickness

18

11.5.3 Birefringence

18

11.5.4 Vertical Birefringence

19

11.5.5 Reflectance

19

12 Interface between cartridge and drive

19

12.1 Clamping method

19

12.2 Clamping force

19

12.3 Capture cylinder

20

12.4 Disk position in the operating condition

35

Section 3 - Format of information

35

13 Track geometry

35

13.1 Track shape

35

13.2 Direction of track spiral

35

13.3 Track pitch

35

13.4 Logical track number

35

13.5 Physical track number

35

14 Track format

35

14.1 Physical track layout

35

14.2 Logical track layout

36

14.3 Radial alignment

36

14.4 Sector number

36

15 Sector format

36

15.1 Sector layout

36

15.2 Sector Mark

37

15.3 VFO fields

38

15.4 Address Mark (AM)

38

15.5 ID fields

38

15.6 Postamble (PA)

39

15.7 Gap

39

15.8 Flag

39

15.9 Auto Laser Power Control (ALPC)

39

15.10 Sync

39

15.11 Data field

40

15.11.1 User data bytes

40

15.11.2 CRC and ECC bytes

40

15.11.3 Bytes for Defect Management Pointers (DMP)

40

15.11.4 Resync bytes

40

15.12 Buffer field

40

16 Recording Code

41

17 Formatted Zone

41

17.1 General description of the Formatted Zone

1v

---------------------- Page: 4 ----------------------

ISO/IEC 15486:1998 (E)

OISO/IEC

41

17.2 Division of the Formatted Zone

43

17.2.1 Lead-in Zone

43

17.2.2 Manufacturer Zones

44

17.2.3 User Zone

44

17.2.4 Reflective Zone

44

17.2.5 Control Track Zones

44

17.3 Control Track PEP Zone

44

17.3.1 Recording in the PEP Zone

45

17.3.2 Format of the tracks of the PEP Zone

49

17.4 Control Track SFP Zones

49

17.4.1 Duplicate of the PEP information

49

17.4.2 Media information

51

17.4.3 System Information

52

18 Layout of the User Zone

52

18.1 General description of the User Zone

52

18.2 Divisions of the User Zone

52

18.2.1 Reserved Area Use

53

18.3 User Area

54

18.4 Defect Management Areas (DMAs)

55

18.5 Disk Structure Table (DST)

56

18.6 Write Once Read Many (WORM) Zone

57

18.6.1 Location

57

18.6.2 Partitioning

57

19 Defect Management for WORM Media

57

19.1 Initialization of the disk

57

19.2 Defect Management Pointers

58

19.3 Write procedure

58

19.3.1 Read Procedure

60

Section 4 - Characteristics of embossed information

60

20 Method of testing

60

20.1 Environment

60

20.2 Use of the Reference Drive

60

20.2.1 Optics and mechanics

60

20.2.2 Read power

60

20.2.3 Read Channels

60

20.2.4 Tracking

60

20.3 Definition of signals

62

21 Signal from grooves

62

21.1 Cross-track signal

62

21.2 Push-pull signal

62

21.3 Divided push-pull signal

63

21.4 Phase depth

63

21.5 Track location

63

22 Signals from Headers

63

22.1 Sector Mark Signals

63

22.2 VFO signals

63

22.3 Address Mark, ID and PA signals

64

22.4 Timing jitter

64

23 Signals from embossed Recording fields

64

23.1 Signal amplitude

64

23.2 Modulation method offset

64

23.3 Timing Jitter

65

23.4 Byte Errors

V

---------------------- Page: 5 ----------------------

OISO/IEC

ISO/IEC 15486: 1998 (E)

65

24 Signals from Control Track PEP marks

66

Section 5 - Characteristics of the recording layer

66

25 Method of testing

66

25.1 Environment

66

25.2 Reference Drive

66

25.2.1 Optics and mechanics

66

25.2.2 Read power

66

25.2.3 Read Channel

66

25.2.4 Tracking

66

25.2.5 Signal detection for testing purposes

66

25.3 Write conditions

66

25.3.1 Write pulse and power

67

25.3.2 Pulse power determination

67

25.3.3 Media power sensitivity

67

25.4 Definition of signals

68

26 Imbalance of difference signal

68

27 Write characteristics

68

27.1 Resolution

68

27.2 Narrow-band signal-to-noise ratio

69

27.3 Cross-talk ratio

69

27.3.1 WORM track test method

69

27.4 Timing Jitter

69

27.5 Media thermal interaction

70

Section 6 - Characteristics of user data

70

28 Method of testing

70

28.1 Environment

70

28.2 Reference Drive

70

28.2.1 Optics and mechanics

70

28.2.2 Read power

70

28.2.3 Read amplifiers

70

28.2.4 Mark Quality

71

28.2.5 Channel bit clock

71

28.2.6 Binary-to-digital converters

71

28.2.7 Error correction

71

28.2.8 Tracking

71

29 Minimum quality of a sector

71

29.1 Headers

71

29.1.1 Sector Mark

71

29.1.2 ID fields

71

29.2 User-written data

71

29.2.1 Recording field

71

29.2.2 Byte errors

71

29.2.3 Modulation method offset

71

29.2.4 Timing jitter

71

30 Data interchange requirements

72

30.1 Tracking

72

30.2 User-written data

72

30.3 Quality of disk

Annexes

73

A - Air cleanliness class 100 000

Vi

---------------------- Page: 6 ----------------------

ISO/IEC 15486:1998 (E)

OISO/IEC

74

B- Edge distortion test

76

C- Compliance test

78

D- Test method for measuring the adsorbent force of the hub

80

I

E CRC for ID fields

81

F- Interleave, CRC, ECC, Resync for the Data Field

85

G- Determination of Resync pattern

90

H- Read Channel for measuring NBSNR and jitter

91

measuring procedure

Timing jitter

J-

92

K - Definition of write pulse shape

L - Implementation Independent Mark Quality Determination (IIMQD) for the interchange of recorded

93

media

96

M - Requirements for interchange

98

N - Measurement implementation for Cross-track signal

99

P - Values to be implemented in existing and future standards

100

Q - Office environment

101

R - Derivation of the operating climatic environment

106

S - Transportation

107

T - Sector retirement guidelines

108

U - Track deviation measurement

112

V - Measure of the vertical birefringence of the substrate

114

W - Laser Power Calibration for evaluation of media power sensitivity

vii

---------------------- Page: 7 ----------------------

OISO/IEC

ISO/IEC 15486:1998 (E)

Foreword

IS0 (the International Organization for Standardization) and IEC (the International Electrotechnical Commission) form the

specialized system for worldwide standardization. National bodies that are members of IS0 or IEC participate in the

development of International Standards through technical committees established by the respective organization to deal with

particular fields of technical activity. IS0 and IEC technical committees collaborate in fields of mutual interest. Other

international organizations, governmental and non-governmental, in liaison with IS0 and IEC, also take part in the work.

In the field of information technology, IS0 and IEC have established a joint technical committee, ISO/IEC JTC 1. Draft

International Standards adopted by the joint technical committee are circulated to national bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the national bodies casting a vote.

International Standard ISO/IEC 15486 was prepared by ECMA (as ECMA-238) and was adopted, under a special “fast-track

procedure ”, by Joint Technical Committee ISO/IEC JTC 1, Information technology, in parallel with its approval by national

bodies of IS0 and IEC.

Annexes A to N form an integral part of this International Standard. Annexes P to W are for information only.

. . .

Vlll

---------------------- Page: 8 ----------------------

ISO/IEC 15486:1998 (E)

INTERNATIONAL STANDARD 0 ISO/IEC

Data interchange on 130 mm optical disk cartridges of

Information technology -

type WORM. (Write Once Read Many) using irreversible effects - Capacity:

2,6 Gbytes per cartridge

Section 1 - General

1 Scope

This International Standard specifies the characteristics of a 130 mm optical disk cartridge (ODC) of Type WORM (Write

Once Read Many) with a capacity of 2,6 Gbytes. Type WORM ODCs use writing effects that are inherently irreversible.

Written marks cannot be erased and attempted modification of the written marks are detectable.

This International Standard specifies

-

the conditions for conformance testing and the Reference Drive;

-

the environments in which the cartridges are to be operated and stored;

-

the mechanical, physical and dimensional characteristics of the cartridge, so as to provide mechanical interchange ability

between data processing systems;

-

the format of the information on the disk, both embossed and user-written, including the physical disposition of the tracks

and sectors, the error correction codes, the modulation methods used;

-

the characteristics of the embossed information on the disk;

-

the recording characteristics of the disk, enabling processing systems to write data onto the disk;

-

the minimum quality of user-written data on the disk, enabling data processing systems to read data from the disk.

This International Standard provides for interchange between optical disk drives. Together with a standard for volume and file

structure it provides for full data interchange between data processing systems.

2 Conformance

21 . Optical Disk Cartridge (ODC)

An Optical Disk Cartridge shall be in conformance with this International Standard if it meets the mandatory requirements

specified herein. A claim of conformance shall state that the ODC is of Type WORM.

22 . Generating system

A generating system shall be in conformance with this International Standard if the ODC it generates is in accordance with 2.1.

23 . Receiving system

A receiving system shall be in conformance with this International Standard if it is able to handle an ODC according to 2.1

24 . Compatibility statement

A claim of conformance by a generating or receiving system with this International Standard shall include a statement listing

any other International Optical Disk Cartridge standard(s) supported by the system for which conformance is claimed. This

statement shall specify the number of the standard(s), including, where appropriate, the ODC Type(s), or the Types of side,

and whether support includes reading only or both reading and writing.

3 Normative reference

The following standard contains provisions which, through reference in this text, constitute provisions of this International

Standard. At the time of publication, the edition indicated was valid. All standards are subject to revision, and parties to

agreements based on this International Standard are encouraged to investigate the possibility of applying the most recent

edition of the standard indicated below. Members of IEC and IS0 maintain registers of currently valid International Standards.

Safety of information technology equipment.

IEC 950: 1991,

---------------------- Page: 9 ----------------------

OISOLIEC

ISO/IEC 15486:1998 (E)

4 Definitions

For the purposes of this International Standard, the following definitions apply.

41 0 band: An annular area within the user zone on the disk having a constant clock frequency.

42 l case: The housing for an optical disk, that protects the disk and facilitates disk interchange.

clamping zone: The annular part of the disk within which the clamping force is applied by the clamping device.

43 l

44 0 control track: A track containing the information on media parameters and format necessary for writing, reading and

erasing (read/write disks only) the remaining tracks on the optical disk.

45 0 method for detecting errors in data.

Cyclic Redundancy Check (CRC): A

46 0 defect management: A method for handling the defective areas on the disk.

47 l disk reference plane: A plane defined by the perfectly flat annular surface of an ideal spindle onto which the

clamping zone of the disk is clamped, and which is normal to the axis of rotation.

entrance surface: The surface of the disk on to which the optical beam first impinges.

48 0

kinds of errors in data.

49 0 Error Correction Code (ECC): A n error-detecting code designed to correct certain

format: The arrangement or layout of information on the disk.

4.10

to provide radial centring and

4.11 hub: The central feature on the disk which interacts with the spindle of the disk drive

the clamping force.

4.12 interleaving: The process of allocating the physical sequence of units of data so as to render the data more immune

to burst errors.

any information, and used to

4.13 land and groove: A trench-like feature of the disk, applied before the recording of

define the track location. The groove is located nearer to the entrance surface than the land with which it is paired to

form a track.

4.14 logical track: 17 consecutive sectors in one or more physical tracks. The first sector of each logical track is assigned

sector number 0.

4.15 mark: A feature of the recording layer which may take the form of a crystalline region a pit, or any other type or

form that can be sensed as a reflectivity change by the optical system. The pattern of marks represents the data on the

disk.

Note - Subdivisions of a sector which are named “mark” are not marks in the sense of this definition

mark edge: The transition between a region with a mark and one without a mark or vice versa, along the track.

4.16

4.17 mark edge recording: A recording method which uses a mark edge to represent a Channel bit.

optical disk: A disk that will accept and retain information in the form of marks in a recording layer, that can be read

4.18

with an optical beam.

4.19 optical disk cartridge (ODC): A device consisting of a case containing an optical disk.

4.20 physical track: The path which is followed by the focus of the optical beam during one revolution of the disk. This

path is not directly addressable.

4.21 polarization: The direction of polarization of an optical beam is the direction of the electric vector of the beam.

Note - The plane of polarization is the plane containing the electric vector and the direction of propagation of the beam. The polarization is right-handed

when, to an observer looking in the direction of propagation of the beam, the end-point of the electric vector would appear to describe an ellipse in the

clockwise sense.

4.22 pre-recorded mark: An unalterable mark recorded or embossed onto the disk prior to customer use.

4.23 read power: The read power is the optical power, incident at the entrance surface of the disk, used when reading.

Note - It is specified as a maximum power that may be used without damage to the written data. Lower power may be used providing that the signal-to-noise

ratio and other requirements of this International Standard are met.

4.24 recording layer: A layer of the disk on, or in, which data is written during manufacture and/or use.

Reed-Solomon code: An error detection and/or correction code which is particularly suited to the correction of

4.25

errors which occur in bursts or are strongly correlated.

---------------------- Page: 10 ----------------------

OISO/IEC ISO/IEC 15486:1998 (E)

4.26 space: The area between marks along the track.

4.27 spindle: The part of the disk drive which contacts the disk and/or hub.

4.28 substrate: A transparent layer of the disk, provided for mechanical support of the recording layer, through which the

optical beam accesses the recording layer.

track pitch: The distance between adjacent track centrelines, measured in a radial direction.

4.29

4.30 write-inhibit hole: A hole in the case which, when detected by the drive to be open, inhibits write operations.

zone: An annular area of the disk.

4.31

5 Conventions and notations

51 l Representation of numbers

- A measured value is rounded off to the least significant digit of the corresponding specified value. It implies that a specified

value of 1,26 with a positive tolerance of +O,Ol, and a negative tolerance of -0,02 allows a range of measured values from

1,235 to 1,275.

- Letters and digits in parentheses represent numbers in hexadecimal notation.

The setting of a bit is denoted by ZERO or ONE.

-

- Numbers in binary notation and bit combinations are represented by strings of digits 0 and 1.

- Numbers in binary notation and bit combinations are shown with the most significant bit to the left.

- Negative values of numbers in binary notation are given in TWO ’s complement.

In each field the data is recorded so that the most significant byte (byte 0) is recorded first. Within each byte the least

-

significant bit is numbered 0 and is recorded last, the most significant bit (numbered 7 in an 8-bit byte) is recorded first.

This order of recording applies also to the data input of the Error Detection and Correction circuits and their output.

52 0 Names

The names of entities, e.g. specific tracks, fields, etc., are given with a capital initial.

6 List of acronvms

aI

ALPC Auto Laser Power Control

Address Mark

Cyclic Redundancy Code

CRC

DMA Defect Management Area

DMP Defect Management Pointers

DST Disk Structure Table

ECC Error Correction Code

Error Detection And Correction Code

EDAC

ID Identifier

LBA Logical Block Address

LSB Least Significant Byte

Magneto-Optical

MO

MSB Most Significant Byte

ODC Optical Disk Cartridge

PA Postamble

Primary Defect List

PDL

PRA Primary Reserved Area

PEP Phase-Encoded Part of the Control Tracks

Run Length Limited (code)

=w,v

Reed-Solomon (code)

R-S

Rewritable

R-ULDC Reed-Solomon Long Distance Code

SCSI Small Computer System Interface

Secondary Defect List

SDL

SFP Standard Formatted Part of the Control Tracks

---------------------- Page: 11 ----------------------

ISO/IEC 15486: 1998 (E) OISO/IEC

SM Sector Mark

SRA Secondary Reserved Area

Time Interval Analyzer

TIA

VFO Variable Frequency Oscillator

wo Write Once

WORM Write Once Read Many

ZCAV Zoned Constant Angular Velocity

7 General description of the optical disk cartridge

The optical disk cartridge which is the subject of this International Standard consists of a case containing an optical disk.

The case is a protectiv -e enclosure for the disk. It has access windows covered by a shutter. The windows are automatically

when the cartridge is inserted into it.

uncovered the drive

by

The optical disk consists of two sides assembled together with their recording layers on the inside.

The optical disk is recordable on both sides. Data is written onto the disk with a focused optical beam as marks in the recording

layer using irreversible effects, such that the marks cannot be erased or transformed back into an unrecorded state. The marks

can be formed by either a phase transformation process, an ablative process, or any other irreversible process. The data are read

by detecting the intensity modulation of the reflected beam caused by the difference of reflectivity of the recorded marks and

the unrecorded regions. The beam accesses the recording layer through the transparent substrate of the disk.

8 General requirements

81 0 Environments

8.1.1 Test environment

The test environment is the environment where the air immediately surrounding the optical disk cartridge has the following

properties:

temperature : 23 “C ~fi 2 “C

relative humidity : 45 % to 55 %

atmospheric pressure :60kPato 106kPa

air cleanliness : Class 100 000 (see annex A)

No condensation on or in the optical disk cartridge shall occur. Before testing, the optical disk cartridge shall be conditioned in

this environment for 48 h minimum. It is recommended that, before testing, the entrance surface of the disk be cleaned

according to the instructions of the manufacturer of the disk.

Unless otherwise stated, all tests and measurements shall be made in this test environment.

Operating environment

8.1.2

This International Standard requires that an optical disk cartridge which meets all requirements of this International Standard in

the specified test environment provides data interchange over the specified ranges of environmental parameters in the operating

environment (See also annex Q).

The operating environment is the environment where the air imediakly surrounding the optical disk car&idge has the

following properties:

temperature : 5 “C to 55 “C

relative humidity : 3 % to 85 %

absolute humidity : 1 g/m3 to 30 g/m3

atmospheric pressure : 60 kPa to 106 kPa

temperature gradient : lO ”C/hmax.

relative humidity gradient : 10 %/h max.

air cleanliness : office environment (see Q. 1)

---------------------- Page: 12 ----------------------

OISOKIEC ISO/IEC 15486: 1998 (E)

No condensation on or in the optical disk cartridge shall occur. If an optical disk cartridge has been exposed to conditions

outside those specified in this clause, it shall be acclimatized in an allowed operating environment for at least 2 hours before

use. (See also annex R).

8.1.3 Storage environment

The optical disk cartridge without any protective enclosure shall not be stored in an environment outside the range allowed for

storage. The storage environment is defined as an environment where the air immediately surrounding the optical disk cartridge

has the following properties:

temperature : -10 “C to 55 “C

relative humidity : 3 % to 90 %

absolute humidity : 1 g/m3 to 30 g/m3

atmospheric pressure : 60kPato 106kPa

temperature gradient : 15 “C/h max.

relative humidity gradient : 10 %/h max.

: Office environment (see Q.1)

air cleanliness

No condensation on or in the optical disk cartridge shall occur.

8.1.4 Transportation

This International Standard does not specify requirements for transportation; guidance is given in annex S.

82 l Temperature shock

The optical disk cartridge shall withstand a temperature shock of up to 20 “C when inserted into, or removed from, the drive.

Safety requirements

83 0

The cartridge shall satisfy the safety requirements of IEC 950, when used in the intended manner or in any foreseeable use in an

information processing system.

Flammability

84 .

The cartridge and its components shall be made from materials that comply with the flammability class for HB materials, or

better, as specified in IEC 950.

9 Reference Drive

The Reference Drive is a drive several critical components of which have well defined properties and which is used to test the

write and read parameters of the disk for conformance to this International Standard. The critical components vary from test to

test. This clause gives an outline of all components; components critical for tests in specific clauses are specified in those

clauses.

Optical system

91 .

The basic set-up of the optical system of the Reference Drive used for measuring the write and read parameters is shown in

figure 1. Different components and locations of components are permitted, provided that the performance remains the same as

that of the set-up in figure 1. The optical system shall be such that the detected light reflected from the entrance surface of the

disk is minimized so as not to influence the accuracy of the measurements.

---------------------- Page: 13 ----------------------

OISO/IEC

ISO/IEC 15486: 1998 (E)

r-----------------------------------------------------------------------------------------------------------------------------------------------------

I

Ch.2

I

I 0

I

K2

I

I

I

Ch.1

-0

,

1 I

F G

950041-A

A Laser diode H Optional half-wave plate

B Collimator lens II

Tracking signals from photodiode K,

1’ 2

C Optional shaping prism J Polarizing beam splitter

Ch.1 Channel 1 Photodiodes for Channels 1 and 2

K ,K

2

Ch.2 Channel 2 K1 Split photodiode

D Beam splitter d.c.-coupled amplifiers

L3,L2

E Polarizing beam splitter Ai Tracking Channel (see 20.3)

F Objective lens N Phase retarder

G Optical disk

Figure 1 - Optical system of the Reference Drive

In the absence of polarization changes in the disk, the polarizing beam splitter J shall be aligned to make the signal of detector

K1 equal to that of detector K2. The direction of polarization in this case is called the neutral direction. The phase retarder N

shall be adjusted such that the optical system does not have more than 2,5” phase retardation between the neutral polarization

and the polarization perpendicular to it. This position of the retarder is called the neutral position.

The phase retarder can be used for the measurement of the narrow-band signal-to-noise ratio (see 27.2 ).

The beam splitter J shall have a p-s intensity reflectance ratio of at least 100.

The beam splitter E shall have an intensity reflectance Rp from F to H of nominally 0,30 for the neutral polarization direction.

The reflectance R, for the polarization perpendicular to the neutral direction shall be nominally 0,95. The actual value of R,

shall not be smaller than 0,90.

The imbalance of the difference signal is specified for a beam splitter with nominal reflectance. If the measurement is made on

a drive with reflectance ’s Rp’ and R,’ for beam splitter E, then the measured imbalance shall be multiplied by

RsR’

P

S

RPg

6

to make it correspond to the nominal beam splitter E.

---------------------- Page: 14 ----------------------

OISO/IEC ISO/IEC 15486: 1998 (E)

The output of Channel 1 is the sum of the currents through photodiodes Kl and K2 , and is used for reading embossed marks

and the user-written marks. The output of Channel 2 is the difference between photo-diode currents.

92 0 Optical beam

The focused optical beam used for writing and reading data shall have the following properties:

+lO nm

Wavelength ( h )

685 nm

a>

-10 nm

Wavelength ( h) divided by the numerical

W

aperture of the objective lens (NA) h/NA=1,245~m~O,OlQ~m

Filling D/W of the aperture of the

C)

objective lens 0,85 & 0,05

Variance of the wavefront of the

d)

optical beam near the recording layer 0 to h2/ 330

Polarization Linear - parallel to the groove

e>

Extinction ratio 0,Ol max.

f>

The optical power and pulse width for writing and reading shall be as specified in later clauses of this International

g>

Standard.

D is the diameter of the lens aperture and W is the beam diameter of the Gaussian beam where the intensity is l/e2 of the

maximum intensity.

The extinction ratio is the ratio of the minimum over the maximum power observed behind a linear polarizer in the optical

beam, which is rotated over at least 180 ”.

93 . Read Channels

Channel 1 shall be provided to generate signals from the marks in the recording layer. Unless ot

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.