ISO/DIS 22477-1

(Main)Geotechnical investigation and testing -- Testing of geotechnical structures

Geotechnical investigation and testing -- Testing of geotechnical structures

Reconnaissance et essais géotechniques -- Essais de structures géotechniques

General Information

Standards Content (sample)

DRAFT INTERNATIONAL STANDARD ISO/DIS 22477-1

ISO/TC 182/SC 1 Secretariat: DIN

Voting begins on Voting terminates on

2005-12-22 2006-05-22

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION • МЕЖДУНАРОДНАЯ ОРГАНИЗАЦИЯ ПО СТАНДАРТИЗАЦИИ • ORGANISATION INTERNATIONALE DE NORMALISATION

Geotechnical investigation and testing — Testing of geotechnicalstructures —

Part 1:

Pile load test by static axially loaded compression

Reconnaissance et essais géotechniques — Essais de structures géotechniques —

Partie 1: Essai de charge statique axiale en compression

ICS 93.020

ISO/CEN PARALLEL ENQUIRY

This draft International Standard is a draft standard developed within the European Committee for

Standardization (CEN) and processed under the CEN-lead mode of collaboration as defined in the

Vienna Agreement. The document has been transmitted by CEN to ISO for circulation for ISO

member body voting in parallel with CEN enquiry. Comments received from ISO member bodies,

including those from non-CEN members, will be considered by the appropriate CEN technical body.

Should this DIS be accepted, a final draft, established on the basis of comments received, will be

submitted to a parallel two-month FDIS vote in ISO and formal vote in CEN.In accordance with the provisions of Council Resolution 15/1993 this document is circulated

in the English language only.Conformément aux dispositions de la Résolution du Conseil 15/1993, ce document est

distribué en version anglaise seulement.To expedite distribution, this document is circulated as received from the committee

secretariat. ISO Central Secretariat work of editing and text composition will be undertaken at

publication stage.Pour accélérer la distribution, le présent document est distribué tel qu'il est parvenu du

secrétariat du comité. Le travail de rédaction et de composition de texte sera effectué au

Secrétariat central de l'ISO au stade de publication.THIS DOCUMENT IS A DRAFT CIRCULATED FOR COMMENT AND APPROVAL. IT IS THEREFORE SUBJECT TO CHANGE AND MAY NOT BE REFERRED TO

AS AN INTERNATIONAL STANDARD UNTIL PUBLISHED AS SUCH.IN ADDITION TO THEIR EVALUATION AS BEING ACCEPTABLE FOR INDUSTRIAL, TECHNOLOGICAL, COMMERCIAL AND USER PURPOSES, DRAFT

INTERNATIONAL STANDARDS MAY ON OCCASION HAVE TO BE CONSIDERED IN THE LIGHT OF THEIR POTENTIAL TO BECOME STANDARDS TO WHICH

REFERENCE MAY BE MADE IN NATIONAL REGULATIONS.© International Organization for Standardization, 2005

---------------------- Page: 1 ----------------------

ISO/DIS 22477-1

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall not

be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In downloading

this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat accepts no liability in

this area.Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the

unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

Copyright noticeThis ISO document is a Draft International Standard and is copyright-protected by ISO. Except as permitted

under the applicable laws of the user’s country, neither this ISO draft nor any extract from it may be reproduced,

stored in a retrieval system or transmitted in any form or by any means, electronic, photocopying, recording or

otherwise, without prior written permission being secured.Requests for permission to reproduce should be addressed to either ISO at the address below or ISO’s member

body in the country of the requester.ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Reproduction may be subject to royalty payments or a licensing agreement.

Violators may be prosecuted.

ii © ISO 2005 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/DIS 22477-1

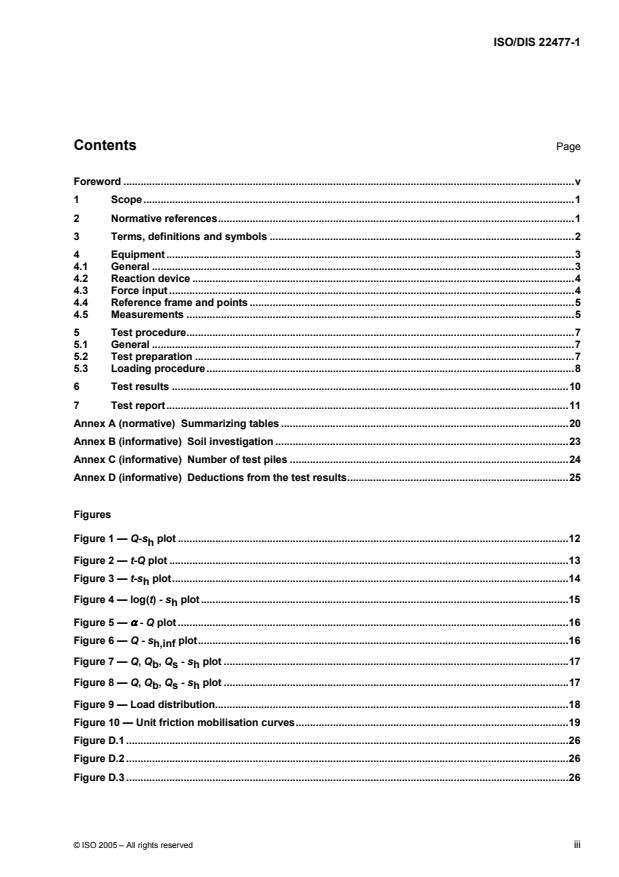

Contents Page

Foreword .............................................................................................................................................................v

1 Scope......................................................................................................................................................1

2 Normative references............................................................................................................................1

3 Terms, definitions and symbols ..........................................................................................................2

4 Equipment ..............................................................................................................................................3

4.1 General ...................................................................................................................................................3

4.2 Reaction device .....................................................................................................................................4

4.3 Force input .............................................................................................................................................4

4.4 Reference frame and points .................................................................................................................5

4.5 Measurements .......................................................................................................................................5

5 Test procedure.......................................................................................................................................7

5.1 General ...................................................................................................................................................7

5.2 Test preparation ....................................................................................................................................7

5.3 Loading procedure................................................................................................................................8

6 Test results ..........................................................................................................................................10

7 Test report............................................................................................................................................11

Annex A (normative) Summarizing tables ....................................................................................................20

Annex B (informative) Soil investigation ......................................................................................................23

Annex C (informative) Number of test piles .................................................................................................24

Annex D (informative) Deductions from the test results.............................................................................25

FiguresFigure 1 — Q-s plot ........................................................................................................................................12

Figure 2 — t-Q plot ...........................................................................................................................................13

Figure 3 — t-s plot..........................................................................................................................................14

Figure 4 — log(t) - s plot................................................................................................................................15

Figure 5 — α - Q plot ........................................................................................................................................16

Figure 6 — Q - s plot.................................................................................................................................16

h,infFigure 7 — Q, Q , Q - s plot ........................................................................................................................17

b s hFigure 8 — Q, Q , Q - s plot ........................................................................................................................17

b s hFigure 9 — Load distribution...........................................................................................................................18

Figure 10 — Unit friction mobilisation curves...............................................................................................19

Figure D.1 ..........................................................................................................................................................26

Figure D.2 ..........................................................................................................................................................26

Figure D.3 ..........................................................................................................................................................26

© ISO 2005 – All rights reserved iii---------------------- Page: 3 ----------------------

ISO/DIS 22477-1

Tables

Table A.1 — Equipment................................................................................................................................... 20

Table A.2 — Test procedure ........................................................................................................................... 21

iv © ISO 2005 – All rights reserved---------------------- Page: 4 ----------------------

ISO/DIS 22477-1

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

ISO 22477-1 was prepared by Technical Committee ISO/TC 182, Geotechnics, Subcommittee SC 1, and by

Technical Committee CEN/TC 341, Geotechnical investigation and testing in collaboration.

ISO 22477 consists of the following parts, under the general title Geotechnical investigation and testing —

Testing of geotechnical structures:⎯ Part 1: Pile load test by static axially loaded compression

⎯ Part 2: Pile load test by static axially loaded tension (in preparation)

⎯ Part 3: Pile load test by static transversally loaded tension (in preparation)

⎯ Part 4: Pile load test by dynamic axially loaded compression test (in preparation)

⎯ Part 5: Testing of anchorages⎯ Part 6: Testing of nailing (in preparation)

⎯ Part 7: Testing of reinforced fill (in preparation)

© ISO 2005 – All rights reserved v

---------------------- Page: 5 ----------------------

DRAFT INTERNATIONAL STANDARD ISO/DIS 22477-1

Geotechnical investigation and testing — Testing of

geotechnical structures — Part 1: Pile load test by static axially

loaded compression

1 Scope

This Standard establishes the specifications for the execution of static pile load tests in which a single pile is

subjected to an axial static load in compression in order to define its load-displacement behaviour.

The provisions of EN 22477-1 apply to vertical piles as well as raking piles.All types of piles are covered by this standard.

The tests considered in this Standard are limited to maintained load tests.

EN 22477-1 shall be used in conjunction with EN 1997-1. Numerical values of partial factors for limit states

and of correlation factors to derive characteristic values from static pile load tests to be taken into account in

design are provided in EN 1997-1. Guidance on analysis of the load testing results is given in the informative

Annex D.This Standard provides specifications for:

a) Investigation tests, whereby the pile is loaded up to failure or close to failure ;

b) Control tests, whereby the pile is loaded up to a specified load in excess of the SLS design action.

2 Normative referencesThe following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.EN 1990:2002, Eurocode 0 : Basis of structural design

EN 1997-1, Eurocode 7 : Geotechnical Design - Part 1 : General rules

EN 1536:1999, Execution of special geotechnical work - Bored piles

EN 10002-2, Metallic materials – Tensile testing – Part 2 : Verification of the force measuring system of the

tensile testing machinesEN 12699:2000, Execution of special geotechnical work - Displacement piles

prEN 14199:2001, Execution of special geotechnical work – Micropiles

© ISO 2005 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO/DIS 22477-1

3 Terms, definitions and symbols

For the purposes of this document, the terms and definitions given in EN 1990 and the following apply.

Terms, definitions and symbols specific for EN 22477-1-1 are given hereunder.3.1

Q : pile load

the load applied to the head of the pile during the test

3.2

∆Q : load increment

an increment of load added or removed during the course of the test

3.3

max

the predefined maximum load to be applied for the test

3.4

c;u

ultimate total pile (bearing) resistance in compression : the load per pile required to produce a condition of

failure in the ground or in the pileNOTE Following 7.6.1.1 of EN 1997-1, the compressive resistance failure corresponds to the state in which the pile

foundation displaces significantly with negligible increase of resistance. In case that it is difficult to define an ultimate limit

state from a load settlement plot showing a continuous curvature, a settlement of the pile top equal to 10 % of the pile

base diameter should be adopted as the “failure” criterion.3.5

b;u

ultimate pile base resistance

3.6

s;u

ultimate pile shaft resistance

3.7

s;u

ultimate unit shaft resistance

3.8

b;u

ultimate unit base resistance

3.9

yield resistance:

a) a critical experimental load beyond which the rate of axial displacement takes place with a notably

increased incrementb) the load at which the rate of settlement increases without any significant increase in load

3.10α : yield factor

the ratio of the increase in pile head displacement and the log of time during a specified time interval (usually

the last 30 min of a load step)2 © ISO 2005 – All rights reserved

---------------------- Page: 7 ----------------------

ISO/DIS 22477-1

3.11

s , s : settlement

h b

the axial displacement of pile head or pile base respectively

3.12

D : equivalent pile base diameter

for noncircular pile sections with A being the area of the relevant pile base, the equivalent diameter equals

( 4 /π ). A3.13

preliminary pile

a pile installed before the commencement of the main piling works or a specific part of the works for the

purpose of establishing the suitability of the chosen type of pile and for confirming its design, dimensions and

bearing resistance (EN 1536:1999)3.14

trial pile

pile installed to assess the practicability and suitability of the construction method for a particular application

(EN 1536:1999)3.15

working pile

pile for the foundation of a structure (EN 1536:1999)

3.16

test pile

pile to which loads are applied to determine the resistance deformation characteristics of the pile and the

surrounding ground (EN 1536:1999)NOTE The test pile can be a preliminary pile, a trial pile or a working pile.

3.17

static pile load test

loading test where a pile is subjected to chosen axial and/or lateral forces at the pile had for the analysis of its

capacity3.18

maintained pile load test

static loading test in which a test pile has loads applied in incremental stages, each of which is held constant

for a certain period or until pile motion has virtually ceased or has reached a prescribed limit (ML-test)

(EN 1536:1999)4 Equipment

4.1 General

For guidance, the most relevant specifications related to the equipment, as detailed hereunder, are

summarised in Table A.1.The selection of the equipment shall take into account the aim of the test, the ground conditions and the

execution of the test.© ISO 2005 – All rights reserved 3

---------------------- Page: 8 ----------------------

ISO/DIS 22477-1

4.2 Reaction device

The reaction device for pile compressive loads can be :

⎯ dead load (kentledge);

⎯ ground anchorages either by tension piles or ground anchors;

⎯ a structure over the test pile (e. g. for jacked underpinning piles);

⎯ the test pile itself where the load is applied at depth by one or more hydraulic jacks which are cast into the

pile for bi-directional pile loading.Dead load should not be used for tests of raking piles, unless particular measures are carefully considered

with respect to the stability and displacements of the kentledge system.For all these reaction systems the clear distance between the test pile and the nearest edge of the kentledge

support or the anchorage shall be at least 2,5 m or 3 D , whichever is the greatest. These requirements might

be more severe for test piles that act predominantly through skin friction or when using ground anchors as a

reaction device.The reaction system shall be designed for the maximum test load Q in accordance with the relevant

maxEuropean standards.

To avoid uplift or instability of the kentledge, the dead load should be in excess of the maximum test load

Q by at least 10 %.max

Working piles may be used as reaction piles, provided that their structural resistance is sufficient and there is

no detrimental effect on their ability to perform as part of the structureReaction piles and anchors should be arranged symmetrically around the test pile. In cases of non-

symmetrical reaction systems measures shall be taken to avoid excessive rotation and/or translation of the

reaction system.4.3 Force input

Unless otherwise required by the design, one or more hydraulic jacks shall be used to apply the load on the

test pile.NOTE 1 For top-down loading the hydraulic jack is seated on top of the pile between the reaction assembly and the

pile head.NOTE 2 For bi-directional loading the hydraulic jack is cast into the pile to apply an axial load in two opposite directions.

The jacking force and stroke of the jack shall be matched to Q and to the expected deformations (pile head

maxdisplacement and those of the reaction system under load). A minimum stroke of 150 mm and 15 % D is

recommended.It shall be possible to decrease or increase the load fluently without any shocks or vibrations and to maintain

the load at any required value. For investigation tests an automatic and continuous electric or hydraulic control

and regulation of the jack force should be used. For control tests a hand pump control and regulation may be

used.To safeguard the test, it should be possible to repair the equipment without excessive loss of load on the pile.

The accuracy of the force regulation shall by in accordance to the test purpose. It should allow the load Q to

be applied and maintained during each load step within the following relative variation:

4 © ISO 2005 – All rights reserved---------------------- Page: 9 ----------------------

ISO/DIS 22477-1

⎯ For investigation tests : ± 0,5 % of Q and ± 1,0 % of Q

max

⎯ For control tests : ± 3 % of Q

NOTE More severe requirements may be required for time dependent analysis of the test results.

4.4 Reference frame and pointsThe displacements of the pile head can be measured either by dial gauges or transducers, supported from

reference beams or alternatively, the displacements may be measured independently from reference beams

by advanced levelling methods such as electronic optical devices.It is recommended to use reference beams supported independently from the test pile. Alternatively, beams

may be fixed on the pile head. In this case the displacements of the pile head or the beams should be

measured from independent reference marks.The clear distance between the supporting ends of the reference beams (or alternatively the reference marks)

and the test pile and reaction piles or the nearest edge of the kentledge support shall be at least 2,5 m or

3 × D, whichever is the greatest.One end of each reference beam should be free to slide.

4.5 Measurements

4.5.1 Measurement of pile head displacements

The pile head displacements shall be measured with at least three displacement transducers or dial gauges

supported from reference beams.The overall accuracy of the measured pile head displacement shall be of MAX (0,1 mm; 0,2 % of the read out

value) or better. Therefore dial gauges or transducers shall enable readings to be made to an accuracy of at

least 0,01 mm.The dial gauges or transducers should also have a sufficient measuring range, in order to avoid readjustment

during testing.The pile head displacements may be measured by alternative techniques (e.g. optical levelling) which are

independent from the reference beam.The optical levelling measurements shall be controlled by reference to one or more fixed reference points.

When relevant, complementary optical levelling of at least one point fixed to the test pile head shall be

provided, as a control of the transducers or dial gauges measurements.The potential transversal displacement of the test pile under axial load should be checked by two dial gauges

or transducers with the same accuracy as above, positioned in orthogonal directions and fixed on reference

beams. Alternatively, horizontal pile head displacements can be obtained from horizontal survey.

The displacements of the reference beams should be checked by optical levelling at least at the end of each

load step.To safeguard against sudden failure of the supports, the corner points of a kentledge, or the anchor heads

should be included in the levelling checks.4.5.2 Measurement of pile load

Load measurement can be obtained from a load cell (load cells) or from the pressure of the jack or jack

system, by means of suitable calibrated pressure gauges.© ISO 2005 – All rights reserved 5

---------------------- Page: 10 ----------------------

ISO/DIS 22477-1

The load measurement devices shall be calibrated in accordance with EN 10002–2 by a certified institute.

For investigation tests, the accuracy of the load measurement should be 1 % or less.

For control tests, the accuracy of the load measurement should be 3 % or less.When a load cell is used, it shall have been calibrated within a period of 12 months before the test.

When the load is measured from the jack pressure, the calibration of the entire jack system

(jack + pump + pressure gauges) shall be executed within a period of 1 month before the test.

4.5.3 Pile instrumentationThe load distribution along the pile shaft may be determined by means of direct or indirect measurement of

the force at cross sections of the pile at various depths.The following measurement devices may be used:

⎯ removable extensometer;

⎯ telltales;

⎯ strain gauges or strain gauge devices;

⎯ vibrating wire strain gauge;

⎯ load cell at the pile base or within the pile shaft;

⎯ hydraulic jacks at the base of the pile or built-in in the shaft of the pile.

The depth, the number of measuring levels, the number of devices at each level, should take into account the

ground conditions, the type and the size of the test pile and the aim of the test.

Removable extensometers should be installed in the centre of smaller diameter piles (shaft diameter < 0,5 m),

or in diametrically opposed pairs for larger diameter piles (shaft diameter > 0,5 m), and this for each depth to

be measured.Strain gauges or strain gauge devices should be fixed to the reinforcement bars rods or embedded in the

concrete of concrete piles or attached to the walls of steel piles at least in diametrically opposed pairs for each

depth to be measured.The cross section A and the deformation properties of the pile material (modulus of elasticity) shall be

determined.For reinforced concrete piles, a composite composed deformation modulus shall be applied comprising the

concrete, the reinforcement and embedded parts. The effective deformation modulus of the pile shaft should

be determined directly by :⎯ laboratory testing on a piece of pile made and conserved under the same conditions as the tested pile;

⎯ in situ measurement of the pile deformation on the free upper part of the pile at a level below the pile

head where uniform stress distribution can be presumed.For steel piles, the manufacturer’s information or common methods may be used to determine the deformation

modulus.6 © ISO 2005 – All rights reserved

---------------------- Page: 11 ----------------------

ISO/DIS 22477-1

5 Test procedure

5.1 General

For guidance, the most relevant specifications related to the test procedure, as detailed hereunder, are

summarised in Table A.2.5.2 Test preparation

5.2.1 Protections

Throughout the test period all measuring equipment shall be protected from weather (direct sunlight, wind,

rain) and other disturbances.NOTE It is essential to protect the gauges and reference beam from direct sunlight as the temperature variations can

hugely influence the test results even for short duration tests.For investigation test, the complete testing set-up should be covered and the use of a tent or similar is

recommended. For tests of short duration or for control tests, protective covers for the measuring devices and

the reference system are sufficient.All components, cables and measuring devices embedded in or arranged outside the pile shall be protected

against damage during all stages of construction and testing. This includes in particular adequate insulation of

electric gauges and cables against water and cement laitance as well as mechanical protection against

damage during the concreting and trimming of the pile, the preparation of the pile head and the setting up of

the test installation and devices of the test.Any other site activities that may influence the measurements, for example vibrations by nearby traffic or by

ongoing pile driving, shall be avoided.5.2.2 Construction of a test pile

Test piles should be constructed in a similar manner as working piles (same installation method, machinery

and materials). They shall be designed to resist the maximum load to be applied during the test , so extra

reinforcement and concrete of increased strength are permitted.However their possible influence on the pile’s behaviour shall be assessed.

The influence of pile instrumentation on the pile construction and integrity shall be minimised.

Particular care should be given to the supervision and the monitoring of the installation of the test piles and

the elaboration of adequate piling records. The record shall include precise data on pile tip level, the piling

tools and equipment, the pile geometry, the materials used, the construction method and the monitoring

during the construction (details of the energy required during driving, drilling, and so forth at various depths,

concrete consumption, etc.), and of any particular problem encountered. Guidance on the various items to be

monitored and recorded is given in 7.9 of EN 1997-1 and in the respective European piling execution codes.

Test piles should be of the same diameter D as the working piles. Load tests on smaller diameter test piles

may be considered following the specifications and restrictions specified in 7.6.2.2 of EN 1997-1.

5.2.3 Test dateBetween the installation of the test pile and the beginning of the load test, adequate time shall be allowed to

ensure that the required strength of the pile material is achieved and the ground has had sufficient time to

recover from the process of pile installation and dissipation of pore-water pressures. The required waiting

period may be assessed by measurements of e.g. excess pore pressure and soil strength evolution.

The following time periods between installation and testing of a pile are recommended:

© ISO 2005 – All rights reserved 7---------------------- Page: 12 ----------------------

ISO/DIS 22477-1

⎯ for investigation tests: minimum 7 days in non-cohesive soils, and minimum 3 weeks (bored piles) or

5 weeks (driven piles) in cohesive soils;⎯ for control tests: minimum 5 days in non-cohesive soils, an

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.