ISO/DIS 22476-4.2

(Main)Geotechnical investigation and testing -- Field testing

Geotechnical investigation and testing -- Field testing

Reconnaissance et essais géotechniques -- Essais en place

General Information

Standards Content (sample)

DRAFT INTERNATIONAL STANDARD ISO/DIS 22476-4.2

ISO/TC 182/SC 1 Secretariat: DIN

Voting begins on: Voting terminates on:

2007-12-06 2008-02-06

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION • МЕЖДУНАРОДНАЯ ОРГАНИЗАЦИЯ ПО СТАНДАРТИЗАЦИИ • ORGANISATION INTERNATIONALE DE NORMALISATION

Geotechnical investigation and testing — Field testing —Part 4:

Ménard pressuremeter test

Reconnaissance et essais géotechniques — Essais en place —

Partie 4: Essai pressiométrique Ménard

ICS 93.020

ISO/CEN PARALLEL ENQUIRY

This draft International Standard is a draft standard developed within the European Committee for

Standardization (CEN) and processed under the CEN-lead mode of collaboration as defined in the

Vienna Agreement. The document has been transmitted by CEN to ISO for circulation for ISO member

body voting in parallel with CEN enquiry. Comments received from ISO member bodies, including those

from non-CEN members, will be considered by the appropriate CEN technical body. Should this DIS be

accepted, a final draft, established on the basis of comments received, will be submitted to a parallel two-

month FDIS vote in ISO and formal vote in CEN.In accordance with the provisions of Council Resolution 15/1993 this document is circulated in

the English language only.Conformément aux dispositions de la Résolution du Conseil 15/1993, ce document est distribué

en version anglaise seulement.To expedite distribution, this document is circulated as received from the committee secretariat.

ISO Central Secretariat work of editing and text composition will be undertaken at publication

stage.Pour accélérer la distribution, le présent document est distribué tel qu'il est parvenu du

secrétariat du comité. Le travail de rédaction et de composition de texte sera effectué au

Secrétariat central de l'ISO au stade de publication.THIS DOCUMENT IS A DRAFT CIRCULATED FOR COMMENT AND APPROVAL. IT IS THEREFORE SUBJECT TO CHANGE AND MAY NOT BE

REFERRED TO AS AN INTERNATIONAL STANDARD UNTIL PUBLISHED AS SUCH.IN ADDITION TO THEIR EVALUATION AS BEING ACCEPTABLE FOR INDUSTRIAL, TECHNOLOGICAL, COMMERCIAL AND USER PURPOSES, DRAFT

INTERNATIONAL STANDARDS MAY ON OCCASION HAVE TO BE CONSIDERED IN THE LIGHT OF THEIR POTENTIAL TO BECOME STANDARDS TO

WHICH REFERENCE MAY BE MADE IN NATIONAL REGULATIONS.RECIPIENTS OF THIS DRAFT ARE INVITED TO SUBMIT, WITH THEIR COMMENTS, NOTIFICATION OF ANY RELEVANT PATENT RIGHTS OF WHICH

THEY ARE AWARE AND TO PROVIDE SUPPORTING DOCUMENTATION.International Organization for Standardization, 2007

---------------------- Page: 1 ----------------------

ISO/DIS 22476-4.2

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall

not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the

unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

Copyright noticeThis ISO document is a Draft International Standard and is copyright-protected by ISO. Except as permitted

under the applicable laws of the user's country, neither this ISO draft nor any extract from it may be

reproduced, stored in a retrieval system or transmitted in any form or by any means, electronic, photocopying,

recording or otherwise, without prior written permission being secured.Requests for permission to reproduce should be addressed to either ISO at the address below or ISO's

member body in the country of the requester.ISO copyright office

Case postale 56 CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Reproduction may be subject to royalty payments or a licensing agreement.

Violators may be prosecuted.

ii ISO 2007 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/DIS 22476-4

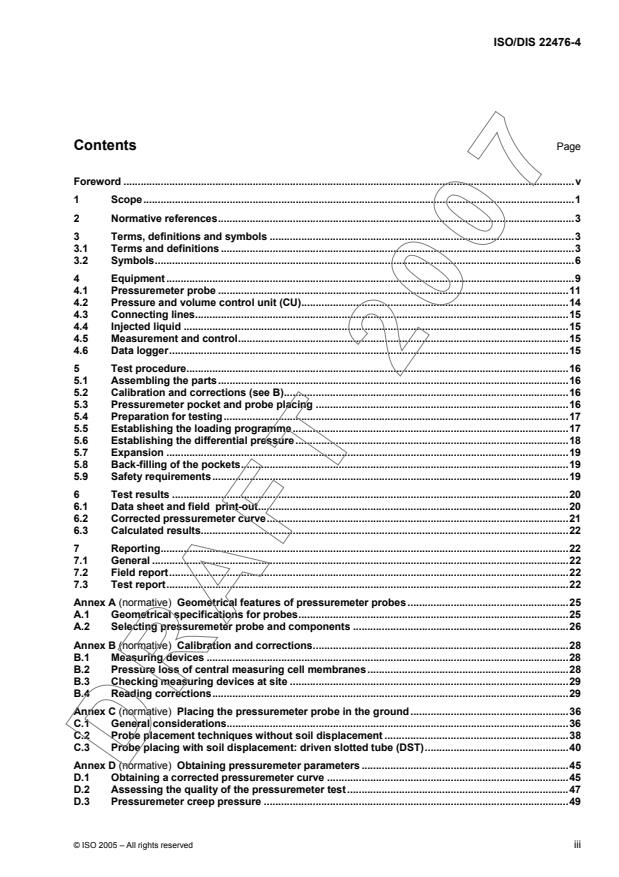

Contents Page

Foreword .............................................................................................................................................................v

1 Scope......................................................................................................................................................1

2 Normative references............................................................................................................................3

3 Terms, definitions and symbols ..........................................................................................................3

3.1 Terms and definitions ...........................................................................................................................3

3.2 Symbols..................................................................................................................................................6

4 Equipment..............................................................................................................................................9

4.1 Pressuremeter probe ..........................................................................................................................11

4.2 Pressure and volume control unit (CU).............................................................................................14

4.3 Connecting lines..................................................................................................................................15

4.4 Injected liquid ......................................................................................................................................15

4.5 Measurement and control...................................................................................................................15

4.6 Data logger...........................................................................................................................................15

5 Test procedure.....................................................................................................................................16

5.1 Assembling the parts..........................................................................................................................16

5.2 Calibration and corrections (see B)...................................................................................................16

5.3 Pressuremeter pocket and probe placing ........................................................................................16

5.4 Preparation for testing........................................................................................................................17

5.5 Establishing the loading programme................................................................................................17

5.6 Establishing the differential pressure...............................................................................................18

5.7 Expansion ............................................................................................................................................19

5.8 Back-filling of the pockets..................................................................................................................19

5.9 Safety requirements............................................................................................................................19

6 Test results ..........................................................................................................................................20

6.1 Data sheet and field print-out............................................................................................................20

6.2 Corrected pressuremeter curve.........................................................................................................21

6.3 Calculated results................................................................................................................................22

7 Reporting..............................................................................................................................................22

7.1 General .................................................................................................................................................22

7.2 Field report...........................................................................................................................................22

7.3 Test report............................................................................................................................................22

Annex A (normative) Geometrical features of pressuremeter probes ........................................................25

A.1 Geometrical specifications for probes..............................................................................................25

A.2 Selecting pressuremeter probe and components ...........................................................................26

Annex B (normative) Calibration and corrections.........................................................................................28

B.1 Measuring devices ..............................................................................................................................28

B.2 Pressure loss of central measuring cell membranes......................................................................28

B.3 Checking measuring devices at site .................................................................................................29

B.4 Reading corrections............................................................................................................................29

Annex C (normative) Placing the pressuremeter probe in the ground.......................................................36

C.1 General considerations.......................................................................................................................36

C.2 Probe placement techniques without soil displacement ................................................................38

C.3 Probe placing with soil displacement: driven slotted tube (DST)..................................................40

Annex D (normative) Obtaining pressuremeter parameters ........................................................................45

D.1 Obtaining a corrected pressuremeter curve ....................................................................................45

D.2 Assessing the quality of the pressuremeter test .............................................................................47

D.3 Pressuremeter creep pressure ..........................................................................................................49

© ISO 2005 – All rights reserved iiiDRAFT 2007

---------------------- Page: 3 ----------------------

ISO/DIS 22476-4

D.4 Pressuremeter limit pressure............................................................................................................ 50

D.5 Obtaining the Ménard pressuremeter modulus............................................................................... 51

D.6 Final check on pressuremeter parameters ...................................................................................... 53

Annex E (informative) Resolution, uncertainties and effects on results.................................................... 54

E.1 Resolution of the measuring devices............................................................................................... 54

E.2 Uncertainties of the measurements.................................................................................................. 54

Annex F (informative) Typical Forms .............................................................................................................. 56

Bibliography..................................................................................................................................................... 59

iv © ISO 2005 – All rights reservedDRAFT 2007

---------------------- Page: 4 ----------------------

ISO/DIS 22476-4

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

EN ISO 22476-4 was prepared by Technical Committee CEN/TC 341, Geotechnical investigation and testing

and by Technical Committee ISO/TC 182, Geotechnics, in collaboration.EN ISO 22476 consists of the following parts, under the general title Geotechnical investigation and testing —

Field testing:⎯ Part 1: Electrical cone penetration tests

⎯ Part 2: Dynamic probing

⎯ Part 3: Standard penetration test

⎯ Part 4:Menard pressuremeter test

⎯ Part 5: Flexible dilatometer test

⎯ Part 6: Self-boring pressuremeter test

⎯ Part 7: Borehole jack test

⎯ Part 8: Full displacement pressuremeter test

⎯ Part 9: Field vane test

⎯ Part 10: Weight sounding test

⎯ Part 11: Flat dilatometer test

⎯ Part 12: Mechanical cone penetration test

⎯ Part 13: Plate loading test

⎯ Part 14: Phicometer test

© ISO 2005 – All rights reserved v

DRAFT 2007

---------------------- Page: 5 ----------------------

ISO/DIS 22476-4

Geotechnical investigation and testing — Field testing —

Part 4:

Ménard pressuremeter test

1 Scope

This document deals with field testing using the Ménard pressuremeter test as part of geotechnical

investigation and testing according to EN 1997-1 and EN 1997-2.The present document describes the procedure for conducting a Ménard pressuremeter test in natural soils,

treated or untreated fills and in very hard soils, or soft rocks, either on land or off-shore.

The pressuremeter sounding results of this document are well suited to a quantitative determination of soil

strength and deformation parameters. Pressuremeters sounding results can yield lithological information.

They can also be combined with direct investigation (e;g; sampling according to EN ISO 22475-1) or

compared with other in situ tests (see EN 1997-2, 2.4.1.4(2) P, 4.1 (1) P and 4.2.3(2) P).

The Ménard pressuremeter test is performed by the radial expansion of a tricell probe placed in the ground

(see Figure 1). During the injection of the liquid volume in the probe, the inflation of the three cells first brings

the outer cover of the probe into contact with the borehole walls and then presses on them resulting in a soil

displacement. Pressure applied to, and the associated volume expansion of the probe are measured and

recorded so as to obtain the stress-strain relationship of the soil as tested.This Standard refers to a probe historically described as the 60 mm G type probe. This standard applies to

test depths limited to 50 m and test pressure limited to 5 MPa.NOTE 1 In the following instances: Ménard pressuremeter tests carried out at pressures above 5 MPa, Ménard

pressuremeter tests at depths exceeding 50m, Ménard pressuremeter tests carried out with E type probes, Full

displacement pressuremeter tests, the test procedures and the test interpretations are not necessarily covered by

this standard.NOTE 2 Ménard pressuremeter tests can be carried out with other diameter probes such as 44 mm and 76 mm probes.

NOTE 3 Ménard pressuremeter tests can be carried out with a pressure exceeding 5 MPa or at a depth exceeding

50 m. However the corresponding test procedure and test interpretation are not covered by this standard.

Two alternative methods of measurement are provided as follows:⎯ procedure A: data is recorded manually;

⎯ procedure B: data is recorded automatically.

© ISO 2005 – All rights reserved 1

DRAFT 2007

---------------------- Page: 6 ----------------------

ISO/DIS 22476-4

Key

1 Ground surface A – A axial section

2 Ground3 Borehole B - B cross section

4 Expanding pressuremeter probeFigure 1 — Principle of a pressuremeter test

© ISO 2005 – All rights reserved

DRAFT 2007

---------------------- Page: 7 ----------------------

ISO/DIS 22476-4

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.EN 1997-1, Eurocode 7: Ground investigation and testing – Part 1: General rules.

EN 1997-2, Eurocode 7: Ground investigation and testing – Part 2: Design assisted by laboratory and field

testing.ENV 13005:1999, Guide to the expression of uncertainty in measurement.

EN ISO 14688-1, Geotechnical investigation and testing – identification and classification of soil – Part 1:

identification and description.EN ISO 14689-1, Geotechnical investigation and testing – identification and classification of rock – Part 1:

identification and description.EN ISO 22475-1, Geotechnical investigation and testing – Sampling by drilling and excavationand ground

water measurements – Part 1: Technical principles for execution.EN ISO 10012, Measurement management systems – Requirements for measurement processes and

measuring equipment3 Terms, definitions and symbols

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply:

3.1.1

pressuremeter

the whole equipment which is used to carry out a Ménard pressuremeter test, excluding the means .

necessary to place the pressuremeter probe into the groundA pressuremeter includes a pressuremeter probe, a pressure and volume control unit, called CU, lines to

connect the probe to the CU and in the case of procedure B, a data logger which is either built into the CU or

linked to it.3.1.2 pressuremeter test pocket

A circular cylindrical cavity formed in the soil to receive a pressuremeter probe. The primary concern shall be

the quality of the pocket wall obtained, using the methods described in Annex C.3.1.3pressuremeter borehole

a borehole in which cylindrical pockets with circular cross sections are made in the ground, and into which the

pressuremeter probe is to be placed.3.1.4

pressuremeter test

the process during which a cylindrical probe is inflated in the ground and the resulting cavity expansion is

measured by volume as a function of time and pressure increments according to a defined programme (see

Figure 4)© ISO 2005 – All rights reserved 3

DRAFT 2007

---------------------- Page: 8 ----------------------

ISO/DIS 22476-4

3.1.5

pressuremeter sounding

the whole series of sequential operations necessary to perform Ménard pressuremeter testing at a given

location: i.e. forming pressuremeter pockets and performing pressuremeter tests in them

3.1.6pressuremeter pressure reading p

the pressure p as read at the CU elevation in the liquid circuit supplying the central measuring cell

3.1.7pressure loss

the pressure loss is the difference between the pressure inside the probe and the pressure applied to the

pocket wall.3.1.8

volume loss

the volume loss is the difference between the volume actually injected into the probe and the volume read on

the measuring device.3.1.9

raw pressuremeter curve

the raw pressuremeter curve is the graphical plot of the injected volumes recorded at time 60 s, V , versus

the applied pressure at each pressure hold, p3.1.10

corrected pressuremeter curve

the corrected pressuremeter curve is the graphical plot of the corrected volume V versus the corrected

pressure p (see Figure 5)3.1.11

Ménard creep

Ménard creep is defined as the difference in volumes recorded at 60 s and at 30 s at each pressure

hold: V – V = ∆V60 30 60/30

3.1.10

corrected Ménard creep curve

a graphical plot of the corrected Ménard creep versus the corrected applied pressure at each pressure hold

(see Figure 5)3.1.11

pressuremeter log

a graphical report of the results of the pressuremeter tests performed at a succession of depths in the same

pressuremeter borehole, together with all the information gathered during the drilling (see Figure 7)

3.1.12Ménard pressuremeter modulus E

E-modulus obtained from the section between (p V ) and (p V ) of the pressuremeter curve (see Figure 5

, ,1 1 2 2

and Annex D).

3.1.13

pressuremeter limit pressure p

by convention pressure at which the pressuremeter cavity has doubled its original volume, see Annex D

3.1.14pressuremeter creep pressure p

a pressure derived from the creep curve, as in Annex D

© ISO 2005 – All rights reserved

DRAFT 2007

---------------------- Page: 9 ----------------------

ISO/DIS 22476-4

3.1.15

operator

the qualified person who carries out the test

3.1.16

casing

lengths of tubing inserted into a borehole to prevent the hole caving in or to prevent the loss of flushing

medium to the surrounding formation© ISO 2005 – All rights reserved 5

DRAFT 2007

---------------------- Page: 10 ----------------------

ISO/DIS 22476-4

3.2 Symbols

For the purposes of this standard, the following symbols apply:

Table 1 — Symbols

Description Unit

Symbol

Apparatus volume loss coefficient

cm /MPa

d Outside diameter of the inner part of the probe with slotted tube Mm

Inside diameter of the calibration cylinder used for the volume loss calibration Mm

Outside diameter of the central measuring cell, including any additional Mmprotection such as a slotted tube

Drilling tool diameter Mm

Wall thickness of the calibration cylinder used for the volume loss calibration Mm

Length of the calibration cylinder used for the volume loss calibration MmLength of each guard cell Mm

l Length of each guard cell for a short central measuring cell pressuremeter Mm

probe

l Length of each guard cell for a long central measuring cell pressuremeter probe Mm

Length along the tube axis of the slotted section of the slotted tube MmLength of the central measuring cell of the probe, measured after fitting the Mm

membrane

l Length of the short central measuring cell after fitting the membrane Mm

l Length of the long central measuring cell after fitting the membrane Mm

Minimum value, strictly positive, of the m slopes

m i

cm /MPa

Slope of the corrected pressuremeter curve between the two points with

cm /MPa

coordinates (p , V ) and (p , V ).

i-1 i-1 i i

Pressure applied to the ground after correction MPa

Correction for membrane stiffness usually called pressure loss of the probe MPa

Pressure at the origin of the segment exhibiting the slope m MPa

p E

p Ultimate pressure loss of the probe MPa

Pressuremeter creep pressure MPa

Gas pressure applied by the control unit indicator to the guard cells of the MPa

pressuremeter probe

Hydrostatic pressure between the control unit indicator and the central MPa

measuring cell of the pressuremeter probe

p Gas pressure in the guard cells of the pressuremeter probe MPa

p Ménard pressuremeter limit pressure of the ground MPa

To be continued )

© ISO 2005 – All rights reserved

DRAFT 2007

---------------------- Page: 11 ----------------------

ISO/DIS 22476-4

Table 1 (continued)

Description Unit

Symbol

Ménard nett pressuremeter limit pressure of the ground MPa

p *

Ménard pressuremeter limit pressure as extrapolated by the hyperbolic best fit MPa

LMHmethod

Ménard pressuremeter limit pressure as extrapolated by the double hyperbolic MPa

LMDH

method

p Ménard pressuremeter limit pressure as extrapolated by the reciprocal curve MPa

LMRmethod

p Pressure loss of the central measuring cell membrane for a specific expansion. MPa

Pressure reading at the CU transducer elevation in the central measuring cell MPa

liquid circuitLiquid pressure in the central measuring cell of the pressuremeter probe MPa

Target pressure according to loading program MPa

p Corrected pressure at the origin of the pressuremeter modulus pressure range MPa

Corrected pressure at the end of the pressuremeter modulus pressure range MPaTime s

Time required for incrementing to the next pressure hold s

t Time the loading pressure level is held s

Pore water pressure in the ground at the depth of the test MPa

z Elevation, positively counted above datum m

Elevation of the pressure measuring device for the liquid injected in the m

measuring cell

z Elevation of the pressure measuring device for the gas injected in the guard m

cells of the pressuremeter probe

Elevation of the ground surface at the location of the pressuremeter sounding m

Elevation of the measuring cell centre during testing m

Elevation of the ground water table (or free water surface in a marine or river m

environment)CU Pressure and volume control unit ---

Type of pressuremeter probe where the three cells are formed by three ---

membranes in line

E Ménard pressuremeter modulus MPa

Type of pressuremeter probe where only the central measuring cell is formed ---

by a dedicated membrane (see Figure 2)

Coefficient of earth pressure at rest at the test depth ---

Value, after zeroing and data correction, of the volume injected in the central

measuring cell and measured 60 s after starting a pressure hold

To be continued

© ISO 2005 – All rights reserved 7

DRAFT 2007

---------------------- Page: 12 ----------------------

ISO/DIS 22476-4

Table 1 (continued)

Description Unit

Symbol

Original volume of the central measuring cell, including the slotted tube, if

applicable

Volume obtained in the volume loss calibration test (see Figure B.2)

value, after data correction, of the volume injected in the central measuring cell

for pressure p .V Value, after data correction, of the volume injected in the central measuring cell

when the original volume of the pressuremeter cavity has doubledV Volume injected in the probe as read on the CU, before data correction

Volume of the central measuring cell including the slotted tube cm

Corrected volume at the origin of the pressuremeter modulus pressure range

(see Figure 5)

V Corrected volume at the end of the pressuremeter modulus pressure range

V Volume injected in the central measuring cell as read 30 s after the beginning of

the pressure holdVolume injected in the central measuring cell as read 60 s after the beginning of

the pressure holdCoefficient used to determine the pressuremeter modulus pressure range. ---

Unit weight of soil at the time of testing.

γ KN/m

Unit weight of the liquid injected in the central measuring cell

γ KN/m

Unit weight of water

KN/m

Rate of change of pressure head of gas at p per metre depth m

ν Poisson’s ratio ---

Total vertical stress in the ground at test depth kPa

Total horizontal stress in the ground at test elevation kPa

Loading pressure increment MPa

Injected volume change from 30 s to 60 s after reaching the pressure hold - the

cm

Ménard creep

60/30

60 second injected volume change between successive pressure hold

60/60

© ISO 2005 – All rights reserved

DRAFT 2007

---------------------- Page: 13 ----------------------

ISO/DIS 22476-4

4 Equipment

The pressuremeter shown schematically on Figure 2 includes:

⎯ tri-cell probe;

⎯ string of rods to handle the probe;

⎯ control unit (CU);

⎯ lines connecting the control unit to the probe.

The control unit (CU) includes:

⎯ equipment to pressurize, and so to inflate the probe, and to maintain constant pressures as required

during the test;⎯ equipment to maintain an appropriate pressure difference between the central measuring cell and the

guard cells;⎯ device which permits the direct reading and in the case of procedure B the automatic recording of the

parameters to be measured: time, pressure and volume.The pressure measuring devices

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.