ISO 18901:2002

(Main)Imaging materials — Processed silver-gelatin type black-and-white films — Specifications for stability

Imaging materials — Processed silver-gelatin type black-and-white films — Specifications for stability

This International Standard establishes the specifications for photographic films intended for the storage of records. It is applicable specifically to films with a base of safety cellulose ester or polyester having silver-gelatin emulsions, processed to produce a black-and-white silver image by negative or full-reversal processing. It applies to film processed by a monobath, which includes thiosulfate as the fixing agent, followed by a conventional wash. It also is applicable to silver films given a stabilizing treatment by partial or full conversion to silver sulfide, silver selenide or gold. This International Standard is applicable to films having ultrasonic or dielectric (induction heated) splices. It does not cover films with splices made by means of adhesive tape or solvent-type spIices. NOTE Solvent-type splices are suspect since they may retain traces of residual solvents containing peroxide which can pose some risk of oxidative attach on the silver image. This International Standard is not applicable to films with chromogenic black-and-white images, colour images of any type, nor to films with a magnetic recording track. It does not apply to films with silver images produced by dry or thermal processing or by diffusion-reversal processing, nor to films that have been processed by a monobath using a means other than a thiosulfate-type fixing solution. It is not applicable to films where the silver salts are removed by means other than thiosulfate solutions. This International Standard is not applicable to films to which lacquers have been applied.

Matériaux pour l'image — Films noir et blanc de type gélatino-argentique traités — Spécifications relatives à la stabilité

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 18901

First edition

2002-02-15

Imaging materials — Processed silver-

gelatin type black-and-white films —

Specifications for stability

Matériaux pour l'image — Film noir et blanc de type gélatino-argentique

traité — Spécifications relatives à la stabilité

Reference number

ISO 18901:2002(E)

©

ISO 2002

---------------------- Page: 1 ----------------------

ISO 18901:2002(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall not

be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In downloading this

file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat accepts no liability in this

area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation parameters

were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the unlikely event

that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2002

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means, electronic

or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or ISO's member body

in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.ch

Web www.iso.ch

Printed in Switzerland

ii © ISO 2002 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 18901:2002(E)

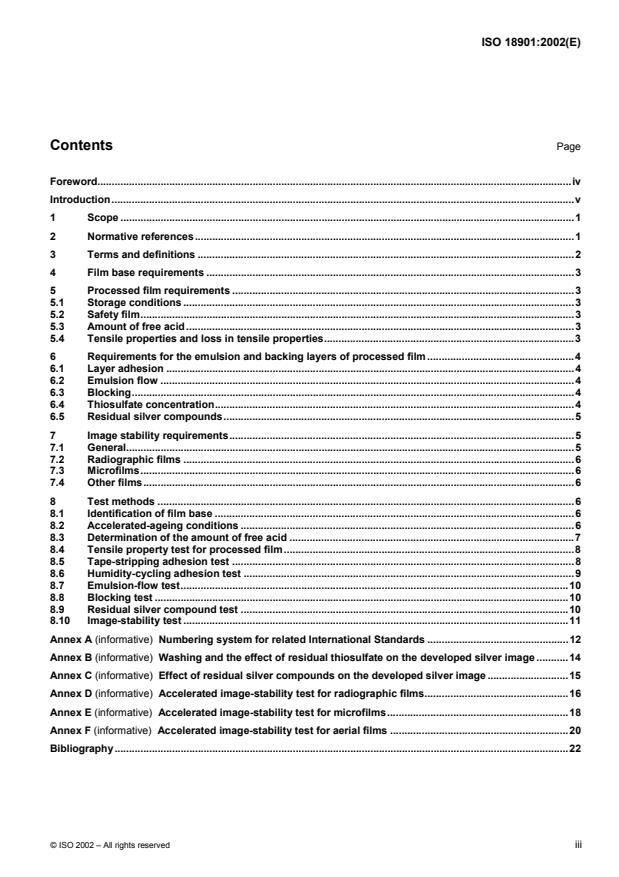

Contents Page

Foreword.iv

Introduction.v

1 Scope .1

2 Normative references.1

3 Terms and definitions .2

4 Film base requirements .3

5 Processed film requirements .3

5.1 Storage conditions .3

5.2 Safety film.3

5.3 Amount of free acid.3

5.4 Tensile properties and loss in tensile properties.3

6 Requirements for the emulsion and backing layers of processed film .4

6.1 Layer adhesion .4

6.2 Emulsion flow .4

6.3 Blocking.4

6.4 Thiosulfate concentration.4

6.5 Residual silver compounds.5

7 Image stability requirements.5

7.1 General.5

7.2 Radiographic films .6

7.3 Microfilms.6

7.4 Other films.6

8 Test methods .6

8.1 Identification of film base .6

8.2 Accelerated-ageing conditions .6

8.3 Determination of the amount of free acid .7

8.4 Tensile property test for processed film.8

8.5 Tape-stripping adhesion test .8

8.6 Humidity-cycling adhesion test .9

8.7 Emulsion-flow test.10

8.8 Blocking test .10

8.9 Residual silver compound test .10

8.10 Image-stability test .11

Annex A (informative) Numbering system for related International Standards .12

Annex B (informative) Washing and the effect of residual thiosulfate on the developed silver image .14

Annex C (informative) Effect of residual silver compounds on the developed silver image .15

Annex D (informative) Accelerated image-stability test for radiographic films.16

Annex E (informative) Accelerated image-stability test for microfilms.18

Annex F (informative) Accelerated image-stability test for aerial films .20

Bibliography.22

© ISO 2002 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 18901:2002(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies (ISO

member bodies). The work of preparing International Standards is normally carried out through ISO technical

committees. Each member body interested in a subject for which a technical committee has been established has

the right to be represented on that committee. International organizations, governmental and non-governmental, in

liaison with ISO, also take part in the work. ISO collaborates closely with the International Electrotechnical

Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 3.

The main task of technical committees is to prepare International Standards. Draft International Standards adopted

by the technical committees are circulated to the member bodies for voting. Publication as an International

Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this International Standard may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 18901 was prepared by Technical Committee ISO/TC 42, Photography.

This first edition cancels and replaces the second edition of ISO 10602, of which it constitutes a technical revision.

This International Standard is one of a series of International Standards dealing with the physical properties and

stability of imaging materials. To facilitiate identification of these International Standards, they are assigned a

number within the block from 18900 to 18999 (see annex A).

Annexes A to F of this International Standard are for information only.

iv © ISO 2002 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 18901:2002(E)

Introduction

Since 1930, great advances have been made in the use of photographic films for the preservation of records. The

preservation of film records by governments, banks, insurance companies, industry and other enterprises has been

stimulated by a recognition of the economies in storage space, organization, accessibility and ease of reproduction

that result from the use of film records.

During the early development period of the art of copying documents, 35-mm nitrate motion-picture film was

sometimes used. This material is highly flammable and is not a safety film as specified in ISO 18906. Nitrate film is

not acceptable for any record film. The manufacture of nitrate film declined after World War II and was discontinued

in most countries in the 1950s.

From about 1908 to 1956, the only safety type film bases in commercial use were cellulose acetate, cellulose

acetate propionate and cellulose acetate butyrate. The useful life of these cellulose-ester type bases is somewhat

conjectural because of limited practical experience. However, the results of laboratory incubation tests indicate a

useful life of at least 100 years when cellulose-ester base films are stored under recommended conditions (see [1],

[2], [3], [4] in the bibliography).

A second type of polymer safety film base was introduced commercially in 1956. This is a polyester class material

whose chemical name is polyethylene terephthalate. [Another type of polyester base, known as polyethylene

naphthalate, has been used for APS (Advanced Photo System) type films since 1996.] Polyester base has several

advantages over cellulose-ester base, including greater strength, stiffness, tear resistance and dimensional stability

which are important in many photographic applications (see [5], [6] in the bibliography). Accelerated ageing tests

supplemented by 35 years of practical experience indicate a potential useful life of 500 years.

This International Standard provides image stability predictions for three classes of black and white films in terms of

LE (life expectancy) ratings. These three classes are radiographic films, microfilms and all other films. Two or three

LE ratings are given for each of these film classes, depending on their residual thiosulfate concentrations.

Studies on the stability of silver-gelatin-type films have investigated the effect of residual hypo on the image

permanence of radiographic films, microfilms and aerial films (see [7], [8], [9] respectively in the bibliography). This

work suggested modifications to the residual hypo limits and a more quantitative image-stability test was included

in the first edition of ISO 10602. Residual hypo limits and image-stability tests are now included for all film

categories.

This International Standard identifies certain hazards to permanence attributable to the chemical or physical

characteristics of processed film and gives methods of evaluating them. Some of these are inherent film

characteristics, some are related to the chemical processing procedure and some are influenced by both factors.

However, storage conditions also can have a pronounced influence on film permanence. The essential

requirements for longevity are proper storage temperature and humidity as well as protection from the hazards of

fire, water, fungus, and atmospheric pollutants. Proper storage conditions are specified in ISO 18902 and

ISO 18911.

© ISO 2002 – All rights reserved v

---------------------- Page: 5 ----------------------

INTERNATIONAL STANDARD ISO 18901:2002(E)

Imaging materials — Processed silver-gelatin type black-and-white

films — Specifications for stability

1 Scope

This International Standard establishes the specifications for photographic films intended for the storage of records.

It is applicable specifically to films with a base of safety cellulose ester or polyester having silver-gelatin emulsions,

processed to produce a black-and-white silver image by negative or full-reversal processing. It applies to film

processed by a monobath, which includes thiosulfate as the fixing agent, followed by a conventional wash. It also is

applicable to silver films given a stabilizing treatment by partial or full conversion to silver sulfide, silver selenide or

gold.

This International Standard is applicable to films having ultrasonic or dielectric (induction heated) splices. It does

not cover films with splices made by means of adhesive tape or solvent-type spIices.

NOTE Solvent-type splices are suspect since they may retain traces of residual solvents containing peroxide which can

pose some risk of oxidative attack on the silver image.

This International Standard is not applicable to films with chromogenic black-and-white images, colour images of

any type, nor to films with a magnetic recording track. It does not apply to films with silver images produced by dry

or thermal processing or by diffusion-reversal processing, nor to films that have been processed by a monobath

using a means other than a thiosulfate-type fixing solution. It is not applicable to films where the silver salts are

removed by means other than thiosulfate solutions (see [10] in the bibliography).

This International Standard is not applicable to films to which lacquers have been applied.

2 Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of

this International Standard. For dated references, subsequent amendments to, or revisions of, any of these

publications do not apply. However, parties to agreements based on this International Standard are encouraged to

investigate the possibility of applying the most recent editions of the normative documents indicated below. For

undated references, the latest edition of the normative document referred to applies. Members of ISO and IEC

maintain registers of currently valid International Standards.

ISO 5-2:2001, Photography — Density measurements — Part 2: Geometric conditions for transmission density

ISO 5-3:1995, Photography — Density measurements — Part 3: Spectral conditions

ISO 527-3:1995, Plastics — Determination of tensile properties — Part 3: Test conditions for films and sheets

ISO 18902:2001, Imaging materials — Processed photographic films, plates and papers — Filing enclosures and

storage containers

ISO 18906:2000, Imaging materials — Photographic films — Specifications for safety film

© ISO 2002 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO 18901:2002(E)

ISO 18911:2000, Imaging materials — Processed safety photographic films — Storage practices

ISO 18917:1999, Photography — Determination of residual thiosulfate and other related chemicals in processed

photographic materials — Methods using iodine-amylose, methylene blue and silver sulfide

3 Terms and definitions

For the purposes of this International Standard, the following terms and definitions apply.

3.1

archival medium

recording material that can be expected to retain information for ever, so that such information can be retrieved

without significant loss when properly stored

NOTE There is, however, no such material and it is not a term to be used in International Standards or system

specifications.

3.2

emulsion layer(s)

image or image-forming layer(s) of photographic films, papers and plates

3.3

extended-term storage conditions

storage conditions suitable for the preservation of recorded information having permanent value

3.4

film base

plastic support for the emulsion and backing layers

3.4.1

cellulose-ester base

base for record materials composed mainly of the cellulose esters of acetic, propionic, or butyric acids, or mixtures

thereof

3.4.2

polyester base

base for recording materials composed mainly of a polymer of ethylene glycol and terephthalic acid (also referred

to as polyethylene terephthalate), or a polymer of ethylene glycol and 2,6 naphthalene dicarboxylic acid (also

referred to as polyethylene naphthalate)

3.5

full-reversal processing

reversal photographic processing that consists of development, bleach, clear, reexposing and second

development, followed by fixing and washing

3.6

life expectancy

LE

length of time that information is predicted to be acceptable in a system after dark storage at 21 °C and 50 % RH

3.7

LE designation

rating for the “life expectancy” of recording materials and associated retrieval systems

NOTE The number following the LE symbol is a prediction of the minimum life expectancy in years for which information

can be retrieved without significant loss when stored at 21 °C and 50 % RH, e.g., LE-100 indicates that information can be

retrieved after at least 100 years of storage.

2 © ISO 2002 – All rights reserved

---------------------- Page: 7 ----------------------

ISO 18901:2002(E)

3.8

medium-term storage conditions

storage conditions suitable for the preservation of recorded information for a minimum of 10 years

3.9

non-curl backing layer

layer, usually made of gelatin, applied to the side of the photographic film base opposite that of the emulsion layer,

for the purpose of preventing curl

NOTE 1 It is comparable to the emulsion layer in thickness and is not removed in processing.

NOTE 2 Antihalation or other layers removed in processing are excluded from this definition.

3.10

safety photographic film

photographic film which passes the ignition-time test and the burning-time test defined in ISO 18906

4 Film base requirements

The base used for record films, as specified in this International Standard, shall be of a safety polyester or a

cellulose-ester type and can be identified by the method described in 8.1.

Some films on a cellulose-ester-type base can have a maximum LE rating of 100. Some films on a polyester base

can have a maximum LE rating of 500.

NOTE These limitations are based on historical experiences as discussed in the Introduction.

5 Processed film requirements

5.1 Storage conditions

Films shall be stored under the conditions specified in ISO 18902 and ISO 18911.

5.2 Safety film

Film shall meet the requirements specified in ISO 18906.

5.3 Amount of free acid

The cellulose-ester base shall not have an amount of free acid greater than the equivalent of 0,1 ml of 0,1 mol/l

sodium hydroxide solution per gram of film. The amount of free acidity shall be measured in accordance with 8.3.

NOTE The degradation of cellulose-ester base is autocatalytic and proceeds rapidly when the free acid is greater than

0,5 ml of 0,1 mol/l.

The volume of 0,1 mol/l sodium hydroxide equivalent to the amount of free acid of the processed film shall not

increase by more than 0,5 ml/l over its original value after the accelerated ageing described in 8.2.

5.4 Tensile properties and loss in tensile properties

Film specimens shall be processed and dried under the conditions used for film records.

Processed films shall be tested for tensile properties as described in 8.4 and shall have a tensile stress and

elongation at break as specified in Table 1 (unheated film). The loss in tensile properties after accelerated ageing

as described in 8.2 shall not exceed the percentage specified in Table 1 (heated film).

© ISO 2002 – All rights reserved 3

---------------------- Page: 8 ----------------------

ISO 18901:2002(E)

Table 1 — Limits for tensile properties and loss in tensile properties on ageing

Film type Tensile stress at break Elongation at break

Unheated film

Minimum permissible tensile properties:

a

Cellulose-ester base 80 MPa 15 %

Polyester base 140 MPa 75 %

Heated film

Maximum permissible loss in tensile properties

compared with unheated film:

Cellulose-ester base 15 % 30 %

Polyester base 15 % 30 %

a 6 2

1 MPa = 10 N/m

6 Requirements for the emulsion and backing layers of processed film

6.1 Layer adhesion

6.1.1 Tape-stripping adhesion

Processed film shall not show any removal of emulsion layer or backing layer when tested as described in 8.5.

6.1.2 Humidity-cycling adhesion

The emulsion layer or backing layer of processed film shall not show separation or cracking that can impair its

intended use when tested as described in 8.6.

6.2 Emulsion flow

Processed film shall not show any visual evidence of emulsion flow (caused by partial emulsion remelting) as a

result of accelerated ageing of the processed film. Emulsion flow shall be determined as described in 8.7, when the

accelerated ageing is performed as described in 8.2.

6.3 Blocking

Processed film shall show no evidence of blocking (sticking), delamination or surface damage when tested as

described in 8.8. A slight sticking of the film specimens that does not result in physical damage or a change in the

gloss of the surface shall be acceptable.

6.4 Thiosulfate concentration

Films shall be fixed in solutions containing either sodium thiosulfate (hypo) or ammonium thiosulfate (see [10] in the

bibliography). Hypo-eliminating agents containing oxidizing agents such as peroxides or hypochlorites shall not be

used.

NOTE Hypo-eliminating agents contain chemicals, usually strong oxidizing agents, which decompose thiosulfate (see

annex B). These are to be distinguished from hypo-clearing baths, which are high ionic strength salt solutions. These facilitate

the washing of thiosulfate from the film, but do not chemically alter the thiosulfate.

4 © ISO 2002 – All rights reserved

---------------------- Page: 9 ----------------------

ISO 18901:2002(E)

After processing, the film shall not contain a greater concentration of residual thiosulfate calculated as thiosulfate

2−

ions (S O ) than that specified in Table 2 when determined by one of the test methods described in ISO 18917.

2 3

NOTE Three methods for measuring residual thiosulfate-based chemicals in film are described in ISO 18917. All three

2 2−

methods are considered to be sufficiently reliable to report thiosulfate concentrations at the level of 0,014 g/m of S O . The

2 3

2

methylene blue method is considered to be reliable for thiosulfate concentrations of 0,007 g/m . The methylene blue and iodine

amylose methods measure thiosulfate ions only. They are to be run within two weeks of processing. The silver sulfide

densitometric test method measures polythionate decomposition products and other residual chemicals in addition to thiosulfate.

The method may be run more than two weeks after processing. To determine thiosulfate levels accurately with this method, a

calibration curve for the particular film is necessary.

The analysis for thiosulfate shall be made on a film specimen from a clear area and shall be made within two

weeks after processing (see annex B). The test method does not measure any change in the specimen between

the time of processing and the time of analysis, but is used to judge the keeping of the film following the time of the

test.

6.5 Residual silver compounds

Processed film shall not show more than an increase of 0,02 in Status A blue density when tested in accordance

with 8.9 (see annex C).

Table 2 — Limits for thiosulfate concentration

Maximum permissible concentration

b, c, d, e

a of thiosulfate

Film type Film classification

2

g/m

Radiographic films LE-10 0,100

LE-100 0,050

LE-500 0,020

Microfilms LE-100 0,030

LE-500 0,014

Other films LE-10 0,100

LE-100 0,050

LE-500 0,014

a

LE-500 film only applies to polyester-base film.

b

Values are for each side of the film that has a photographic layer or a non-curl backing layer.

c

The concentration of thiosulfate is expressed in grams per square metre, which conforms to SI units.

d

Very low concentrations of thiosulfate due to excessive washing may cause the silver image to be more susceptible to

oxidative attack. These concentrations may be below the detection limits of ISO 18917.

e 2 2

0,010 g/m = 1µg/cm

7 Image stability requirements

7.1 General

The specifications and test methods for image stability vary for different product types.

ISO visual diffuse density or Status A blue density shall be measured on a densitometer which has geometric

conformance to ISO 5-2 and spectral conformance to ISO 5-3. Processed film specimens shall be incubated as

described in 8.10.3.

© ISO 2002 – All rights reserved 5

---------------------- Page: 10 ----------------------

ISO 18901:2002(E)

7.2 Radiographic films

An area of unexposed processed film shall be tested. The Status A blue density change of the unexposed area

shall be no greater than 0,05 density units after incubation. This requirement shall apply to LE-10, LE-100 and

LE-500 films.

7.3 Microfilms

An area of minimum density and another area having a visual diffuse density of 1,2 ± 0,1 on the processed film

specimen shall be tested.

Neither the minimum-density area nor the high-density area shall change by more than ± 0,1 visual diffuse density

units after incubation.

7.4 Other films

A minimum-density area and a 1,0 ± 0,1 Status A blue-density patch of processed film shall be tested. Neither the

minimum-density area nor the high-density patch shall change by more than ± 0,1 Status A blue density units after

incubation. This requirement shall apply to LE-10, LE-100 and LE-500 films.

8 Test methods

8.1 Identification of film base

Remove all emulsion and backing layers from a specimen of unknown film, either by scraping or by the use of

enzyme solution. Then remove all sublayers by scraping.

Prepare a specimen of the base material by scuffing the surface with a suitable tool, such as a razor blade. The

general procedure is to move the scuffing device back and forth over the specimen manually while exerting a very

slight pressure. This removes the top layer of the base as a very fine dust. Carefully brush this into a mortar.

Mix the specimen with about 100 times its mass of potassium bromide, previously ground to about 75 µm. Prepare

a strip or pellet as described in [11] in the bibliography.

Obtain an infrared (IR) absorption curve from the prepared pellet by means of an infrared-absorption spectrometer.

By comparing the IR absorption curve for the unknown with curves for known polymers, the identity of the unknown

can be established (see [12] in the bibliography).

NOTE It is difficult, although not impossible, to distinguish between cellulose acetate, cellulose-acetate propionate and

cellulose-acetate butyrate bases by this method, but such separation is not necessary for the purpose of this International

Standard.

8.2 Accelerated-ageing conditions

Processed film shall be subjected to accelerated-ageing conditions to meet the requirements for an increase in the

amount of free acid, loss in tensile properties and emulsion flow.

Test specimens shall be conditioned at (23 ± 1) °C and (50 ± 2) % RH for at least 15 h. After conditioning, place the

specimens in a moisture-proof envelope and heat-seal the envelope. To prevent sticking between adjacent

specimens, it may be necessary to interleave them with polytetrafluoroethylene or uncoated polyester. Ensure a

high ratio of film to air volume by squeezing out excess air prior to heat-sealing. Use a separate envelope for each

film specimen. Double bagging is recommended to reduce any effect of pinholes in the envelopes. Heat the

envelopes in an oven for 72 h at (100 ± 2) °C.

NOTE 1 A suitable moisture-proof envelope is a metal-foil bag that is coated on the inside with polyethylene for heat-sealing.

6 © ISO 2002 – All rights reserved

---------------------- Page: 11 ----------------------

ISO 18901:2002(E)

NOTE 2 Incubation is accomplished in a closed environment to prevent escape of any acid that may be produced during

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.