ISO 15002:2000

(Main)Flow-metering devices for connection to terminal units of medical gas pipeline systems

Flow-metering devices for connection to terminal units of medical gas pipeline systems

Dispositifs de mesure de débit pour raccordement aux prises murales des systèmes de distribution de gaz médicaux

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 15002

First edition

2000-12-01

Flow-metering devices for connection to

terminal units of medical gas pipeline

systems

Dispositifs de mesure de débit pour raccordement aux prises murales des

systèmes de distribution de gaz médicaux

Reference number

ISO 15002:2000(E)

©

ISO 2000

---------------------- Page: 1 ----------------------

ISO 15002:2000(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall not

be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In downloading this

file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat accepts no liability in this

area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation parameters

were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the unlikely event

that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2000

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means, electronic

or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or ISO's member body

in the country of the requester.

ISO copyright office

Case postale 56 � CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.ch

Web www.iso.ch

Printed in Switzerland

ii © ISO 2000 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 15002:2000(E)

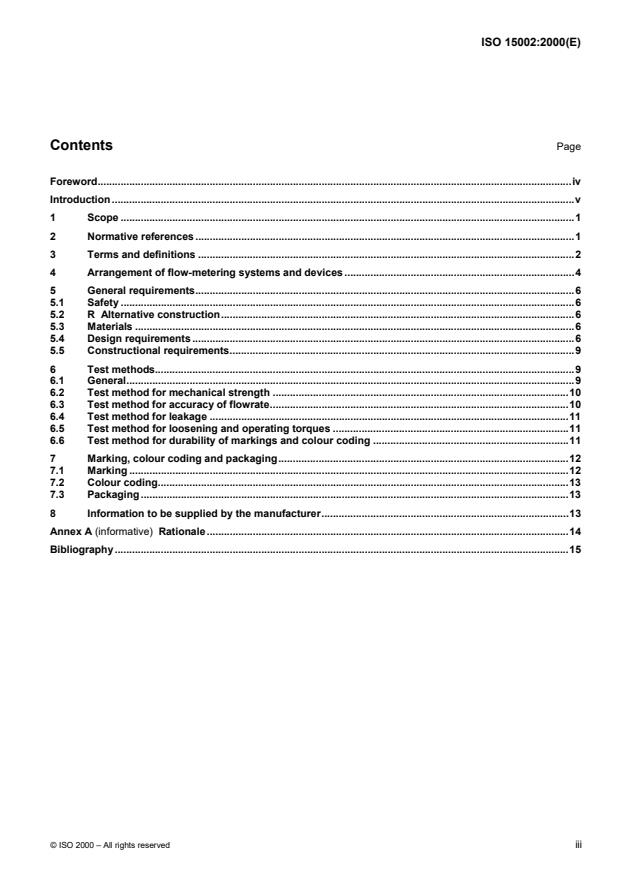

Contents Page

Foreword.iv

Introduction.v

1 Scope .1

2 Normative references .1

3 Terms and definitions .2

4 Arrangement of flow-metering systems and devices .4

5 General requirements.6

5.1 Safety .6

5.2 R Alternative construction.6

5.3 Materials .6

5.4 Design requirements .6

5.5 Constructional requirements.9

6 Test methods.9

6.1 General.9

6.2 Test method for mechanical strength .10

6.3 Test method for accuracy of flowrate.10

6.4 Test method for leakage .11

6.5 Test method for loosening and operating torques .11

6.6 Test method for durability of markings and colour coding .11

7 Marking, colour coding and packaging.12

7.1 Marking .12

7.2 Colour coding.13

7.3 Packaging.13

8 Information to be supplied by the manufacturer.13

Annex A (informative) Rationale.14

Bibliography.15

© ISO 2000 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 15002:2000(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies (ISO

member bodies). The work of preparing International Standards is normally carried out through ISO technical

committees. Each member body interested in a subject for which a technical committee has been established has

the right to be represented on that committee. International organizations, governmental and non-governmental, in

liaison with ISO, also take part in the work. ISO collaborates closely with the International Electrotechnical

Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 3.

Draft International Standards adopted by the technical committees are circulated to the member bodies for voting.

Publication as an International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this International Standard may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights.

International Standard ISO 15002 was prepared by Technical Committee ISO/TC 121, Anaesthetic and respiratory

equipment, Subcommittee SC 6, Medical gas systems.

Annex A of this International Standard is for information only.

iv © ISO 2000 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 15002:2000(E)

Introduction

This International Standard pays particular attention to:

� safety (mechanical strength, safe relief of excess pressure, resistance to ignition);

� gas specificity;

� cleanliness of materials;

� suitability of materials;

� accuracy;

� testing;

� identification;

� information supplied.

Throughout this International Standard, a subclause for which a rationale is provided in annex A is indicated by a

boldface capital R.

© ISO 2000 – All rights reserved v

---------------------- Page: 5 ----------------------

INTERNATIONAL STANDARD ISO 15002:2000(E)

Flow-metering devices for connection to terminal units of medical

gaspipelinesystems

1 Scope

1.1 This International Standard is applicable to:

� flow-metering devices which are connected, either directly or by means of flexible connecting assemblies, and

disconnected by the operator at terminal units of a medical gas pipeline system for measurement and delivery

of medical gases;

� flow-metering devices which are connected and disconnected by the operator at gas-specific connection points

of devices such as pressure regulators.

1.2 It applies only to flow-metering devices for the following medical gases:

� oxygen,

� nitrous oxide,

� air for breathing,

� carbon dioxide,

� helium,

� xenon,

� specified mixtures of the gases listed above,

� oxygen/nitrous oxide mixture 50/50 (% volume fraction).

1.3 This International Standard is not applicable to electrical or electronic flow-metering devices.

2 Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of

this International Standard. For dated references, subsequent amendments to, or revisions of, any of these

publications do not apply. However, parties to agreements based on this International Standard are encouraged to

investigate the possibility of applying the most recent editions of the normative documents indicated below. For

undated references, the latest edition of the normative document referred to applies. Members of ISO and IEC

maintain registers of currently valid International Standards.

ISO 32, Gas cylinders for medical use — Marking for identification of content.

ISO 5359, Low-pressure hose assemblies for use with medical gases.

© ISO 2000 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO 15002:2000(E)

ISO 9170-1, Terminal units for medical gas pipeline systems — Part 1: Terminal units for use with compressed

medical gases and vacuum.

ISO 11114-3:1997, Transportable gas cylinders — Compatibility of cylinder and valve materials with gas contents —

Part 3: Autogenous ignition test in oxygen atmosphere.

ISO 14971, Medical devices — Application of risk management to medical devices.

EN 12218, Rail systems for supporting medical equipment.

3 Terms and definitions

For the purposes of this International Standard, the following terms and definitions apply.

3.1

DISS connectors

diameter index safety system connectors

range of male and female components intended to maintain gas specificity by allocation of a set of different

diameters to the mating connectors for each particular gas

3.2

flow gauge

gauge which measures pressure differential and which is calibrated in units of flowrate

NOTE The flow gauge indicates flowrate by measuring the pressure upstream of a fixed orifice.

3.3

flowmeter

device that measures and indicates the flow of a specific gas

3.4

flow-metering device

device fitted with an inlet connector and an outlet connector and that incorporates one of the following:

a) a flowmeter and flow control valve

b) a flow gauge and a fixed orifice with a flow control valve

c) multiple fixed orifices with means of selection

3.5

gas-specific

having characteristics which prevent interchangeability and thereby allow assignment to one gas or vacuum service

only

3.6

gas-specific connection point

that part of the socket which is the receptor for a gas-specific probe

3.7

manufacturer

natural or legal person with responsibility for the design, manufacture, packaging and labelling of a device before it

is placed on the market under his own name, regardless of whether these operations are carried out by that person

himself or on his behalf by a third party

2 © ISO 2000 – All rights reserved

---------------------- Page: 7 ----------------------

ISO 15002:2000(E)

3.8

medical gas

any gas or mixture of gases intended for administration to patients for therapeutic, diagnostic or prophylactic

purposes, or for surgical tool applications

3.9

medical gas pipeline system

complete system which comprises a source of supply, a pipeline distribution system and terminal units at the points

where medical gases or vacuum may be used

3.10

medical gas supply system

medical gas pipeline system or any other installation having no permanent pipeline system but employing a medical

gas source complete with pressure regulator(s)

3.11

NIST connectors

non-interchangeable screw-threaded connectors

range of male and female components intended to maintain gas specificity by allocation of a set of different

diameters and a left-hand or right-hand screw thread to the mating components for each particular gas

3.12

placing on the market

the first making available, in return for payment or free of charge, of a device other than a device intended for

clinical investigation, with a view to distribution and/or use

3.13

probe

male component designed for acceptance by and retention in the socket

3.14

rated inlet pressure

p

1

maximum upstream pressure for which the flow-metering device is designed to operate

NOTE Unless otherwise specified, pressures in this International Standard are expressed as gauge pressures

(i.e. atmospheric pressure is defined as 0).

3.15

single fault condition

condition in which a single means for protection against a safety hazard in equipment is defective or a single

external abnormal condition is present

3.16

socket

that female part of a terminal unit which is either integral or attached to the base block by a gas-specific interface

and which contains the gas-specific connection point

3.17

terminal unit

outlet assembly (inlet for vacuum) in a medical gas supply system at which the operator makes connections and

disconnections

© ISO 2000 – All rights reserved 3

---------------------- Page: 8 ----------------------

ISO 15002:2000(E)

4 Arrangement of flow-metering systems and devices

4.1 Typical examples of flow-metering systems are shown in Figure 1.

a) Measuring tube with flow control valve downstream b) Measuring tube with flow control valve upstream

c) Paddle and a fixed orifice with flow control valve d) Paddle and a fixed orifice with flow control valve

downstream upstream

e) Flow gauge and a fixed orifice with flow control valve f) Multiple fixed orifices with selection knob

upstream

Figure 1 — Examples of flow-metering systems

Figure 1 a) shows a system which comprises a vertical measuring tube whose cross-section increases upwards

and in which a float is lifted by the action of the gas flow. The float settles at a height which is a function of the

flowrate, which is controlled by a flow control valve fitted downstream of the tube.

Figure 1 b) shows the same system as in a) with the flow control valve fitted upstream of the tube.

Figure 1 c) shows a system which comprises a paddle connected to a return spring which is located at the outlet of

a fixed orifice. The paddle is pushed by the action of the gas flow and settles at a position which is a function of the

flowrate, which is controlled by a flow control valve fitted downstream of the orifice.

Figure 1 d) shows the same system as in c) with the flow control valve fitted upstream of the orifice.

Figure 1 e) shows a system which comprises a pressure gauge measuring the pressure upstream of a fixed orifice.

The pressure is a function of the flowrate, which is controlled by a flow control valve fitted upstream of the pressure

gauge. The pressure gauge is calibrated in units of flowrate (flow gauge).

Figure 1 f) shows a system which comprises multiple fixed orifices. The change from the "off" position and from one

setting to another can be achieved, for example, by turning a knob.

4.2 Typical examples of flow-metering devices are shown in Figure 2.

4 © ISO 2000 – All rights reserved

---------------------- Page: 9 ----------------------

ISO 15002:2000(E)

a) Flow-metering device with a probe as inlet connector

b) Flow-metering device with a DISS or NIST nut and nipple as inlet connector

c) Flow-metering device with a hose and a probe as inlet connector

d) Flow-metering device with a hose and a DISS or NIST nut and nipple as inlet connector

Key

1 Flow control valve

2 Inlet connector

3 Outlet connector

4 Measuring tube

5Hose

Figure 2 — Typical examples of flow-metering devices

© ISO 2000 – All rights reserved 5

---------------------- Page: 10 ----------------------

ISO 15002:2000(E)

5 General requirements

5.1 Safety

Flow-metering devices shall, when transported, stored, installed, operated in normal use and maintained according

to the instructions of the manufacturer, cause no safety hazard which could be foreseen, using risk analysis

procedures in accordance with ISO 14971, which is connected with their intended application, in normal condition

and in single fault condition.

5.2 R Alternative construction

Flow-metering devices and components or parts thereof, using materials or having forms of construction different

from those detailed in clause 5 of this International Standard (except for dimensions and allocation of DISS and

NIST connectors and probes used as inlet connectors) shall be accepted if it can be demonstrated that an

equivalent degree of safety is obtained.

Such evidence shall be provided by the manufacturer.

5.3 Materials

5.3.1 The materials in contact with the gas shall be compatible with oxygen and the intended medical gas or gas

mixture in the temperature range specified in 5.3.2.

NOTE 1 Compatibility with oxygen involves both combustibility and ease of ignition. Materials which burn in air will burn

violently in pure oxygen. Many materials which do not burn in air will do so in pure oxygen, particularly under pressure. Similarly,

materials which can be ignited in air require lower ignition energies in oxygen. Many such materials may be ignited by friction at

a valve seat or by adiabatic compression produced when oxygen at high pressure is rapidly introduced into a system initially at

low pressure.

NOTE 2 Compatibility with oxygen includes resistance

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.