ISO 4365:2005

(Main)Liquid flow in open channels - Sediment in streams and canals - Determination of concentration, particle size distribution and relative density

Liquid flow in open channels - Sediment in streams and canals - Determination of concentration, particle size distribution and relative density

ISO 4365:2005 specifies methods for determining the concentration, particle-size distribution and relative density of sediment in streams and canals. The detailed methods of analysis are given for the following: determination of the suspended sediment concentration by evaporation and filtration; particle-size analysis of suspended sediment; determination of the bed-load and bed material sediment; determination of the relative density of sediment; determination of particle-size distribution characteristics.

Mesure de débit des liquides dans les canaux découverts — Sédiments dans les cours d'eau et dans les canaux — Détermination de la concentration, de la distribution granulométrique et de la densité relative

General Information

Relations

Overview

ISO 4365:2005 - "Liquid flow in open channels - Sediment in streams and canals - Determination of concentration, particle size distribution and relative density" specifies standardized laboratory and analytical methods for characterizing sediment in streams and canals. The standard defines procedures to determine suspended sediment concentration, particle‑size distribution (for suspended sediment, bed-load and bed material) and relative density of sediment. Detailed methods and laboratory procedures are provided in normative annexes (A–G).

Key Topics and Requirements

- Scope and definitions: Terms such as suspended load, bed-load, nominal/sieve/settlement diameters and relative density are defined in accordance with ISO vocabulary conventions.

- Sampling linkage: Suspended sediment sampling is referenced to ISO 4363; correct sampling is a prerequisite for analysis.

- Concentration methods:

- Evaporation method (Annex A) - mass determination after drying (suitable for coarser particles).

- Filtration methods (Annex B, C) - filter paper or glass‑fibre/Gooch/Coors/Alundum crucibles with vacuum filtration; annexes note advantages/limitations (e.g., potential loss of very fine particles).

- Hydrometer method - referenced for some sizing/concentration tasks (noted as temperature‑sensitive).

- Particle‑size analysis:

- Classification by size ranges: coarse (>0.25 mm), medium (0.062–0.25 mm), fine (<0.062 mm).

- Annex D: particle‑size distribution of suspended sediment.

- Annex E: particle‑size distribution for bed‑load and bed material.

- Methods include sieving for coarser fractions and sedimentation/hydrometer techniques for fines.

- Relative density: Determination procedures are given (Annex F) to support settling velocity and transport calculations.

- Data treatment: Expression of concentration (mass/volume or mass/mass), particle‑size distribution characteristics (Annex G), and SI units are required.

Applications and Practical Value

ISO 4365:2005 is used to produce consistent, comparable sediment characterization data for:

- River and canal engineering (sediment transport analysis, channel design)

- Reservoir and dredging planning (sediment yield and accumulation estimates)

- Erosion and catchment management (sediment budgets)

- Environmental monitoring and impact assessments (suspended sediment loads)

- Calibration and validation of sediment transport models

Accurate concentration, size distribution and relative density data enable reliable sediment load computations, settling velocity estimates and informed decisions on maintenance, mitigation and design.

Who Uses This Standard

- Hydrologists and hydrometric teams

- Civil and environmental engineers

- Sedimentologists and geomorphologists

- Water resource and reservoir managers

- Laboratory technicians performing sediment analysis

Related Standards

- ISO 4363 - Measurement of liquid flow in open channels - Methods for measurement of characteristics of suspended sediment

- ISO 4364 - Measurement of liquid flow in open channels - Bed material sampling

- ISO 772 - Hydrometric determinations - Vocabulary and symbols

Keywords: ISO 4365:2005, sediment concentration, particle-size distribution, relative density, suspended sediment, bed-load, filtration method, evaporation method, hydrometry, open channels.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 4365

Second edition

2005-02-01

Liquid flow in open channels — Sediment

in streams and canals — Determination

of concentration, particle size distribution

and relative density

Mesure de débit des liquides dans les canaux découverts — Sédiments

dans les cours d'eau et dans les canaux — Détermination de la

concentration, de la distribution granulométrique et de la densité

relative

Reference number

©

ISO 2005

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2005

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2005 – All rights reserved

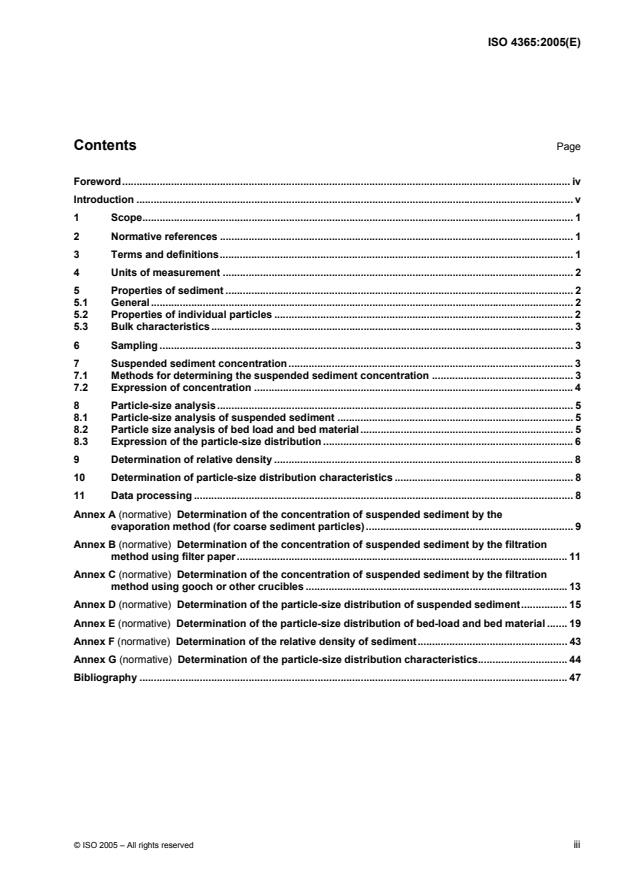

Contents Page

Foreword. iv

Introduction . v

1 Scope. 1

2 Normative references . 1

3 Terms and definitions. 1

4 Units of measurement . 2

5 Properties of sediment . 2

5.1 General. 2

5.2 Properties of individual particles . 2

5.3 Bulk characteristics. 3

6 Sampling . 3

7 Suspended sediment concentration. 3

7.1 Methods for determining the suspended sediment concentration . 3

7.2 Expression of concentration . 4

8 Particle-size analysis. 5

8.1 Particle-size analysis of suspended sediment . 5

8.2 Particle size analysis of bed load and bed material . 5

8.3 Expression of the particle-size distribution . 6

9 Determination of relative density . 8

10 Determination of particle-size distribution characteristics . 8

11 Data processing . 8

Annex A (normative) Determination of the concentration of suspended sediment by the

evaporation method (for coarse sediment particles). 9

Annex B (normative) Determination of the concentration of suspended sediment by the filtration

method using filter paper. 11

Annex C (normative) Determination of the concentration of suspended sediment by the filtration

method using gooch or other crucibles .13

Annex D (normative) Determination of the particle-size distribution of suspended sediment. 15

Annex E (normative) Determination of the particle-size distribution of bed-load and bed material . 19

Annex F (normative) Determination of the relative density of sediment. 43

Annex G (normative) Determination of the particle-size distribution characteristics. 44

Bibliography . 47

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 4365 was prepared by Technical Committee ISO/TC 113, Hydrometry, Subcommittee SC 6, Sediment

transport.

This second edition cancels and replaces the first edition (ISO 4365:1985), which has been technically

revised.

iv © ISO 2005 – All rights reserved

Introduction

In dealing with problems of sedimentation and sediment transport, knowledge of the concentration and the

characteristics of the sediment, such as particle size distribution and relative density, is of great importance.

For this purpose, sediment samples are collected by suitable samplers and analysed in a laboratory. The

results of the analysis are used in the calculation of sediment load, mean diameter and other characteristics.

INTERNATIONAL STANDARD ISO 4365:2005(E)

Liquid flow in open channels — Sediment in streams and

canals — Determination of concentration, particle size

distribution and relative density

1 Scope

This International Standard specifies methods for determining the concentration, particle-size distribution and

relative density of sediment in streams and canals.

NOTE The detailed methods of analysis are set out in the annexes. Annexes A, B and C deal with the determination

of the suspended sediment concentration by evaporation and filtration. Annexes D and E deal with the particle-size

analysis of suspended sediment and outline the procedures for the bed-load and bed material sediment, respectively.

Annex F deals with the determination of the relative density of sediment and Annex G with the determination of particle

size distribution characteristics.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 772, Hydrometric determinations — Vocabulary and symbols

ISO 4363, Measurement of liquid flow in open channels — Methods for measurement of characteristics of

suspended sediment

ISO 4364, Measurement of liquid flow in open channels — Bed material sampling

3 Terms and definitions

For the purpose of this document, the terms and definitions given in ISO 772 and the following apply.

3.1

bed-load

sediment in almost continuous contact with the bed, carried forward by rolling, sliding or hopping

3.2

bed material

sediment of which the stream bed in composed

3.3

bed material load

that part of the total sediment transported consisting of the bed material whose rate of movement is governed

by the transporting capacity of the channel

3.4

nominal diameter

diameter of a sphere of the same volume as the given particle

3.5

projected diameter

diameter of the smallest circle that encloses the projected image of a particle when viewed in the plane of

maximum stability

3.6

sediment concentration

ratio of the mass or volume of dry sediment in a water-sediment mixture to the total mass or volume of the

suspension

NOTE When reporting, it is necessary to mention whether mass concentration or volume concentration is reported.

3.7

sedimentation diameter

diameter of a sphere having the same relative density and terminal settling velocity as a given particle in the

same sedimentation fluid

3.8

sieve diameter

width of a square opening through which the given particles will just pass

3.9

relative density

ratio of the mass of a given volume of sediment to the mass of an equal volume of water

3.10

suspended load

that part of the total sediment transported which is maintained in suspension by turbulence in the flowing

water for considerable periods of time without contact with the streambed

NOTE The sediment moves practically with the same velocity as that of the flowing water. It is generally expressed

as a mass or volume per unit of time.

4 Units of measurement

The units of measurement used in this International Standard are those of the International System of Units

(SI).

5 Properties of sediment

5.1 General

The transport of sediment depends as much upon the properties of the sediment as upon the hydraulic

characteristics of the flow. The properties of sediment are defined by individual particle characteristics and

bulk characteristics.

5.2 Properties of individual particles

Sediment size is the most commonly used parameter to designate the properties of individual particles. While

the size of sediment and its packing directly affect the roughness of the bed, the settling velocity of the

particles characterizes their reaction to flow and governs the movement of the sediment. This, in turn,

depends upon the relative density, shape and size of the particle.

Since particles of natural sediment are of irregular shape, a single length or diameter has to be chosen to

characterize the size. Four such diameters, i.e. nominal diameter, projected diameter, sedimentation diameter

and sieve diameter, are used for different particle sizes or purposes (for example, sieve diameter for coarse

2 © ISO 2005 – All rights reserved

and medium particles, sedimentation diameter for fine particles that are not usually separated by sieves). The

nominal diameter has little significance in sediment transport, but is useful in the study of sedimentary

deposits.

5.3 Bulk characteristics

As sediments consist of large numbers of particles differing in size, shape, relative density, settling velocity,

etc., it is essential to find some parameters that can represent the characteristics of the group of particles as a

whole. Therefore, a sample of sediment is usually divided into class intervals according to characteristics

(size, settling velocity, etc.) and the percentage by mass of the total in each interval is determined for the

particular characteristic. Frequency distribution curves can be drawn from these data and the sediment

parameters (mean, standard deviation, etc.) determined.

6 Sampling

Samples of suspended sediment shall be collected as specified in ISO 4363.

7 Suspended sediment concentration

7.1 Methods for determining the suspended sediment concentration

7.1.1 General

Suspended sediment concentrations may be determined by the following methods:

a) evaporation method;

b) filtration method;

c) hydrometer method (also used for determining particle size).

NOTE Although the evaporation method [7.1.1 a)] requires less time, the filtration method [7.1.1 b)] has the

advantage that the fractions collected can be photographed on the filters and are available for further examination.

However, the filtration method is prone to greater loss of material, whereas in the evaporation method, the ratio of sample

mass to tare mass is small. Therefore, no hard and fast guidelines can be provided for the choice of method, and it is

necessary to judge each case on its merits.

7.1.2 Evaporation method

The evaporation method is specified in Annex A.

7.1.3 Filtration method

7.1.3.1 The filtration may be carried out using either a filter paper in a conical glass funnel or a glass-fibre

filter disc in a Coors or a Gooch crucible, or a fritted glass or an Alundum crucible, with the application of a

vacuum aspirator system to accelerate the passage of the filtrate.

The filtration method using a filter paper and a funnel is specified in Annex B.

7.1.3.2 Filter discs of glass fibre made without organic bindings, such as Whatman grade 934 AH or

1)

Gelman type A/E or Millipore type AP 40 or equivalent , can be used in a suitable filtration apparatus such as

25 ml to 40 ml capacity Coors or Gooch crucible with adapter.

The filtration method using a glass-fibre filter disk is specified in Annex C.

2)

7.1.3.3 A fritted glass crucible is made of Pyrex or other resistance glass, the base of the crucible is

fusion-fitted with a porous fritted disc insert.

The crucible is available in different porosity grades, such as coarse, medium and fine (of pore size 40 µm to

60 µm, 10 µm to 15 µm and 4 µm to 5,5 µm, respectively). The particular grade should be selected according

to the nature of the sample. The method using a fritted glass crucible is specified in Annex C.

3)

7.1.3.4 Filtering Alundum crucibles are similar in shape and size to Gooch or fritted glass crucibles, but

made of fused aluminium oxide.

They are made in three degrees of porosity (coarse, medium and fine) and in two types: plain and ignition.

The particular type and porosity are selected according to the nature of the sample and purpose of use.

The method of using Alundum crucibles is similar to that for using glass-fibre filter discs or fritted glass crucibles

(see Annex C). However, Alundum crucibles are used without the addition of a filtering medium.

The main advantages of using Alundum crucibles are the following.

a) The crucibles are light, which facilitates greater sensitivity in weighing operations.

b) The tare masses are less subject to change.

NOTE 1 For samples containing a significant quantity of very fine particles, the last two, viz. the fritted-glass and the

Alundum crucible method, are less accurate because of the loss of some of the particles during the filtration and the

washing stages.

NOTE 2 There are two other methods, in addition to those mentioned above, that have been used to determine

sediment concentration: the hydrometer method and a Gooch crucible with an asbestos layer as a filtering medium. The

hydrometer method, although rapid, is not accurate when the sediment concentration is not high or the particles settle

rapidly. Moreover, the hydrometer is usually calibrated for 19,4 °C and hence needs to be recalibrated for different

temperatures. The hydrometer method is specified in D.1.1. Regarding the use of the asbestos layer as a filtering medium

in Gooch crucibles, many countries no longer allow the use of asbestos. Moreover, the pore sizes of asbestos are

undefined as they depend on the thickness and uniformity of the layer. Some portion of the asbestos can get washed out

from the filtration layer, causing loss in accuracy.

7.2 Expression of concentration

The amount of suspended sediment shall be expressed as the mass or volume of dry sediment per unit mass

or volume of suspension (i.e. mass/volume or mass/mass etc.).

1) Whatman grade 934 AH, Gelman type A/E and Millipore AP 40 are examples of a suitable products available

commercially. This information is given for the convenience of users of ISO 4365 and does not constitute an endorsement

by ISO of this product.

2) Pyrex is an example of a suitable product available commercially. This information is given for the convenience of

users of ISO 4365 and does not constitute an endorsement by ISO of this product.

3) An Alundum crucible is an example of a suitable product available commercially. This information is given for the

convenience of users of ISO 4365 and does not constitute an endorsement by ISO of this product.

4 © ISO 2005 – All rights reserved

8 Particle-size analysis

8.1 Particle-size analysis of suspended sediment

For particle-size analysis, suspended sediment may be classified in terms of the diameter of the suspended

solids as follows:

a) coarse sediment: containing particles with a diameter greater than 0,25 mm;

b) medium sediment: containing particles with a diameter of 0,062 mm to 0,25 mm;

c) fine sediment: containing particles with a diameter less than 0,062 mm.

The methods for analysing suspended sediment of these classes are specified in Annex D.

NOTE In the case of suspended sediment, grading by particle size of the < 0,062 mm fraction is usually not carried

out because of the unimportance of accurately separating the small amount of solid particles that generally exist in

suspension. If, however, a more precise separation between the coarse and medium sediments is required, the procedure

specified in 8.2 for bed-load and bed material can be used. A particle-size analysis procedure for fine sediment is given in

E.3.5.

8.2 Particle-size analysis of bed-load and bed material

For the analysis of the bed-load or bed material for particle size distribution and mean diameter of samples,

they are classified broadly into those of diameter greater than, and those of diameter less than, 0,5 mm.

Classification of material into these two ranges is suitable for the computation of bed-load.

The methods for analysing bed-load and bed material are specified in Annex E.

The particle-size distribution of sediment may be determined by sieving (when particles are all coarse), by a

combination of sieving and settling velocity, or indirectly by measuring particle-settling velocities in a column of

liquid. It would be advantageous to use only one measure of diameter over the entire range of sizes for all

sediments, preferably the sedimentation diameter, but this is not practicable, since large particles will settle

very rapidly in the sedimentation liquid. This causes difficulties in dispersion, and would thus require larger

equipment. On the other hand, sieve dimensions and the quantity of material available will set a limitation on

the size of fine particles. Therefore, in practice, the coarser particles of suspended sediment (diameter greater

than 0,25 mm) and the coarser particles of bed-load and bed material (diameter greater than 0,5 mm) are

analysed by sieving and all the finer material by sedimentation techniques. This may result in a small abrupt

break in the particle size distribution curve, which may be adjusted by the use of the approximate relationship

among the diameters, as given in Equation (1):

D = 0,94 D = 0,67 D (1)

sd sa pd

where

D is the sedimentation diameter;

sd

D is the sieve diameter;

sa

D is the projected diameter.

pd

8.3 Expression of the particle-size distribution

8.3.1 Frequency-distribution tables

Frequency-distribution tables should be prepared from size analyses to present the data in an orderly form.

In order to draw up the frequency distribution, the total range of sizes (diameters in millimetres) is divided into

intervals, called “class intervals”, the number of which will depend on the classes into which the sample has

been divided. The percentage of the total mass of the sample falling within each one of these intervals is

tabulated. Thus, if an interval has limits of 0,10 mm and 0,08 mm, the percentage of the total mass of the sample

falling within this size range is tabulated and called the frequency of that particular class interval.

For the size distribution of coarser material, particularly for bed-load or bed material, the distribution is obtained

with unequal class intervals; but for the size distribution of suspended material, a class interval of 0,02 mm is

adopted over the range 0,062 mm to 0,50 mm. Particles larger than 0,50 mm and smaller than 0,062 mm are

broadly classified as “class > 0,50 mm” and “class < 0,062 mm”, respectively.

8.3.2 Graphical presentation

8.3.2.1 The data from a particle-size analysis may be presented in three different graphical forms:

a) as histograms;

b) as frequency polygons and frequency curves;

c) as cumulative curves or particle-size summation curves.

The simplest manner of depicting the results of a mechanical analysis is to prepare a histogram of the data.

The diameter, expressed in millimetres, is usually chosen as the independent variable, with the frequency as

the dependent variable. In general, the class intervals are the abscissa, and above each class, a vertical

rectangle of width equal to the class interval and height proportional to the frequency in the class, is drawn

(see Figure 1).

Key

X diameter, expressed in millimetres

Y frequency, expressed in mass percent

Figure 1 — Example of a histogram for the presentation of a particle-size distribution

6 © ISO 2005 – All rights reserved

8.3.2.2 In addition to the use of histograms as frequency diagrams, a common statistical device is to

indicate variations in frequency by means of a line diagram instead of rectangular blocks.

Such frequency diagrams are called frequency polygons (see Figure 2).

Key

X diameter, expressed in millimetres

Y frequency, expressed in mass percent

Figure 2 — Example of a frequency polygon for the presentation of a particle-size distribution

8.3.2.3 Cumulative frequency curves readily yield numerical values that serve to describe the properties

of the sample in terms of size distribution.

They are based on the frequency analysis of particle sizes, and drawn by choosing a size scale along the

horizontal axis, and a frequency scale from 0 % to 100 % along the vertical axis. Either an arithmetic or

logarithmic scale can be used for the size. However, the commonest approach is to use a logarithmic scale. In

practice, cumulative curves are constructed by plotting ordinates, which represent the total amount of material

larger or smaller than a given diameter. Two types of cumulative curves are possible: the “more than” curve

and the “less than” curve. Either may be used, as they provide the same type of information. Figure 3 gives an

example of a “more than” cumulative curve.

8.3.3 Basic distribution of bed material

The size distribution of bed material more or less follows logarithmic-normal, or lognormal, distribution, i.e. the

logarithm of the variable is distributed normally.

Differentiation of the cumulative distribution function leads to Equation (2):

2

1 (lg x− lgε )

PxdØx=−udu exp dlgx (2)

() () ()

σπ2

2σ

where, by definition,

mean (lg x) = lg ε (3)

2

variance (lg x) = mean lg x−=lgε σ (4)

()

Thus, the symbol ε does not denote the mean of the variable x; lg ε is defined as the mean of lg x.

NOTE The variable x in this case is D, the particle-size diameter.

Key

X diameter (logarithmic scale), expressed in millimetres

Y frequency, cumulative mass percent of particles with a diameter greater than the selected value

Figure 3 — Example of a cumulative frequency curve for the presentation of a particle-size distribution

9 Determination of relative density

The method for determining the relative density is specified in Annex F.

NOTE The density can be computed from a knowledge of the relative density.

10 Determination of particle-size distribution characteristics

The method for determining the particle-size distribution characteristics is specified in Annex G.

11 Data processing

For both manual and automatic data processing, systematic forms and procedures are required, depending on

the specific needs.

8 © ISO 2005 – All rights reserved

Annex A

(normative)

Determination of the concentration of suspended sediment

by the evaporation method

(for coarse sediment particles)

A.1 Procedure

A.1.1 Determine the volume and the total mass of the sample (sediment + water) plus bottle, with a capacity

usually not less than 1 l (except in some countries where a smaller sample size is used) to the nearest 0,5 g.

Record this mass as the gross mass.

A.1.2 Allow the sample to stand undisturbed so that the sediment settles out from the suspension. Decant

the sediment-free liquid after it appears to the eye to be clear.

A.1.3 Wash the remaining sediment from the bottle, by means of a stream of gravity-fed deionized or

distilled water from a wash-bottle, into a previously weighed dry evaporating dish. Loosen the sediment

adhering to the sides of the bottle by means of a rubber-tipped glass rod, ensuring that there is no loss of

material during this process.

Determine the mass of the empty bottle after drying, using the same balance, and record this as the tare

mass.

A.1.4 Dry the sample in the evaporating dish on a steam-bath or in a drying oven. If necessary, add

successive sample portions to the same dish after evaporation. The sample should be dried initially at 85 °C

to 95 °C to prevent splattering and loss of sample. After it appears dry, then heat the evaporated sample for at

least 1 h in an oven at 101 °C to 105 °C, cool the dish in a desiccator to balance temperature and weigh

quickly. Repeat the cycle of drying, cooling and weighing until a constant mass is obtained, i.e. until the loss of

mass is less than 1 mg. Otherwise, dry the evaporated sample overnight at 101 °C to 105 °C, cool the dish in

a desiccator to balance temperature and weigh the dish and contents quickly to the nearest 0,001 g.

A.2 Expression of results

Calculate the amount of suspended sediment, in accordance with Equation (A.1) to determine the mass

fraction, w , of the suspended solids or in accordance with Equation (A.2) to determine the concentration,

ss

C , of the suspended solids:

ss

mm−

w = (A.1)

ss

mm−

where

m is the tare mass, in grams, of the bottle;

m is the gross mass, in grams, of the bottle plus sample;

m is the mass, in grams, of the empty evaporating dish;

m is the mass, in grams, of the evaporating dish plus dried sediment.

mm−

C = (A.2)

ss

V

where V is the volume of the sample and the other variables are as given for Equation (A.1).

Express the result in appropriate units.

A.3 Limitations on the method

This method is satisfactory if dealing with coarse sediment particles. With finer-grained sediments, the settling

time increases until a point is reached at which the method becomes impractical. Also, it becomes undesirable

to decant liquid from a point close to the top of the deposited material, because of the danger of withdrawing

some of the extremely fine particles. The transfer of sediment to an evaporating dish becomes difficult owing

to the relatively large volume of water used for washing, which may necessitate another settling period. The

use of flocculating agents will reduce the settling time, but this introduces additional material and hence

requires a correction factor, which is difficult to assess with precision in routine estimates.

This method is not accurate enough for samples containing a high concentration of dissolved salt. The

dissolved salt contributes additional mass, which can be significant, especially for samples containing small

amounts of suspended sediment.

10 © ISO 2005 – All rights reserved

Annex B

(normative)

Determination of the concentration of suspended sediment

by the filtration method using filter paper

B.1 Procedure

B.1.1 Exclude large floating particles (floating plants, wastes, etc.) from the sample if their inclusion is not

desired. For better accuracy, choose a sample volume to yield between 25 mg and 200 mg dried sediment as

the final result. Determine the volume and the total mass of the sample (sediment + water) plus bottle to the

nearest 0,5 g. Record this mass as the gross mass.

B.1.2 Selection of filter paper: Acid-washed, hard-finished filter paper sufficiently retentive for fine particles,

like Whatman No. 42 filter paper (average pore size 1,1 µm) can be used. However, for a sample which does

not contain a significant quantity of fine particles, Whatman No. 40 or 41 filter paper (average pore size

2,4 µm and 4,1 µm, respectively), which are faster-speed filter papers can be used. If the filtrate looks turbid,

indicating fine particles passing through the Whatman No. 40 or 41 filter, then a Whatman No. 42 filter should

be used. The rate of filtration through No. 42 filter paper is slow and hence should not be used for gelatinous

sediment and need not be used for coarse sediment.

B.1.3 Dry the filter paper overnight in an oven at 101 °C to 105 °C, cool in a desiccator to bring it to room

temperature and weigh quickly (to avoid absorption of moisture from atmosphere) to the nearest 0,001 g.

Record this value as the tare mass of the filter paper.

Fit the filter paper into a funnel. To fit it properly, moisten it with a little water, press it down to the sides of the

funnel either with a clean forefinger or with a flattened glass rod. Place the funnel containing the properly fitted

filter paper in a funnel stand or support it vertically in some other way. Place a clean beaker or other

transparent container below the stem of the funnel to collect the filtrate.

B.1.4 Allow the sample to stand undisturbed for a period of time and then pour the top portion of the water-

sediment mixture into the funnel, allowing the water to percolate. To direct the water-sediment mixture into the

funnel, pour the mixture down a glass rod onto the filter paper, directing the liquid against the side of the filter

paper and not at the apex; the lower end of the glass rod should be very close to, but not quite touching, the

filter paper. The paper is never filled completely; the level of the liquid should come no closer than 5 mm to

10 mm to the edge of the paper.

Slowly pour most of the watery part of the sample onto the filter paper. Allow the water to percolate normally.

After the water has passed through the filter paper, wash the sediment adhering to the inside of the sample

bottle onto the filter paper by means of a jet of distilled (or deionized) water, from a wash bottle. If necessary,

loosen the firmly adhered sediment by means of a rubber-tipped glass rod.

Weigh the empty sample bottle after drying, and record this value as the tare mass.

B.1.5 To remove dissolved salt, if any, wash the contents on the filter paper with small portions of gravity-

fed deionized or distilled water from a wash bottle. Direct the water jet as near the top of the filter paper as

possible and then gradually towards apex of the cone. Let each portion of the wash water run through before

adding the next. Continue washing until about 5 ml of the wash water gives no opalescence with a drop or two

silver nitrate solution.

B.1.6 After all the water has passed through the filter paper, fold and place the paper in a dry evaporating

dish.

Dry the contents of the evaporating dish on a steam-bath or in a drying oven at about 85 °C to 95 °C until all

visible water is lost, then heat at 101 °C to 105 °C in an oven for overnight.

Remove the evaporating dish and its contents from the oven and place in a desiccator to cool to room

temperature.

Quickly weigh the filter paper with the dried sediment to the nearest 0,001 g, taking care that no sediment

particles are lost from the filter paper while taking it out of the evaporating dish and weighing. Record this

value as the gross mass of the filter paper plus dried sediment. Make a blank correction.

B.1.7 For the blank correction, fit another dried and weighed (initial mass) filter paper of the identical size in

a funnel. Pass the same volume of distilled water (as that of the sample volume) through it. Dry the filter paper

overnight at 101 °C to 105 °C, cool in a desiccator and weigh as described in B.1.6. Calculate any loss in

mass of the filter paper due to the passing of water through it from its initial mass minus final mass. Add the

value of the mass loss to the gross mass of the filter paper plus dried sediment as the blank correction.

B.2 Expression of results

Calculate the amount of suspended sediment, in accordance with Equation (B.1) to determine the mass

fraction, w , of the suspended solids or in accordance with Equation (B.2) to determine the concentration,

ss

C , of the suspended solids:

ss

()mm−+(mm−)

87 5 6

w = (B.1)

ss

mm−

where

m is the tare mass, in grams, of the bottle;

m is the gross mass, in grams, of the bottle plus test portion;

m is the initial mass of the dry filter paper used for blank correction purpose;

m is the final mass of the dried filter paper used for blank correction purpose;

m is the tare mass, in grams, of the dry filter paper used to filter the test portion;

m is the gross mass, in grams, of the filter paper with dried sediment.

mm−+mm−

( ) ( )

87 5 6

C = (B.2)

ss

V

where V is the volume of the sample and the remaining variables are the same as for Equation (B.1).

Express the result in the appropriate units.

B.3 Recommended precautions for this procedure.

B.3.1 If the water-sediment mixture is of such a large volume that all of it cannot be poured in at the start of

the filtration, it is necessary either to add it intermittently or to arrange the apparatus so that it filters

automatically. This may be accomplished by inverting the bottle containing the sample with its opening at the

desired water level in the filter.

B.3.2 For coarse sediment, allow the sample to stand undisturbed before filtration so that the sediment

settles out from the suspension. Decant off the sediment-free liquid portion after it appears to the eye to be

clear. Discard the decanted water and filter the settled sediment as in B.1.4. This will reduce filtration time. For

samples containing a significant proportion of fine particles or having a very small amount of sediment, the

entire sample should be filtered without sedimentation and decantation.

12 © ISO 2005 – All rights reserved

Annex C

(normative)

Determination of the concentration of suspended sediment

by the filtration method using a Gooch or other crucible

C.1 Procedure

C.1.1 For better accuracy, choose a sample volume to yield between 25 mg and 200 mg dried sediment.

Remove large floating particles (floating plants, wastes, etc.) if their inclusion is not desired in the final result.

Determine the volume and the total mass of the sample (sediment + water) plus bottle to the nearest 0,5 g.

Record this value as the gross mass.

C.1.2 Allow the sample to stand undisturbed for a period of time so that the sediment settles out from the

suspension. Decant as much of the sediment-free water as possible, if it appears to the eye to be clear,

without disturbing the sediment. Discard the decanted water.

Wash the remaining water-sediment mixture into a beaker, using distilled or deionized water. Loosen the

firmly adhered sediment particles, if any, by means of a rubber-tipped glass rod and transfer all the sediment

particles into the beaker.

Determine the mass of the dry, empty sample bottle to the nearest 0,5 g. Record this value as the tare mass

of the bottle.

NOTE Transferring samples to a bigger or secondary container can result in the loss of some of the sample.

C.1.3 Allow the sediment to settle in the beaker, then, if possible, decant again.

C.1.4 Prepare and insert the appropriate filtering medium. Insert a circular micro-fibre glass filter and pre-

filter disc firmly over the fritted base of the crucible. To prepare the glass-fibre filter disc, insert the disc with

wrinkled side up into a 25 ml to 40 ml capacity Coors or Gooch crucible with adapter.

If crucibles fitted with permanent porous plates, such as fritted glass or alundum crucibles, are used, then no

preparation of a filter-mat is required.

C.1.5 Apply a vacuum and wash the disc with three successive 20 ml volumes of distilled water. Continue

suction to remove all traces of water. Discard the washings. Remove the crucible and filter combination. Dry it

in an oven at 101 °C to 105 °C for 1 h. Cool in a desiccator to balance temperature, weigh quickly and

determine mass of the crucible. Repeat the cycle of drying, cooling and weighing until a constant mass is

obtained or until loss in mass is less than 1 mg between successive weighings. Record this value to the

nearest 0,001 g. Store the crucible with filter in a desiccator until needed.

C.1.6 Place the crucible with filter in position in the vacuum system and begin suction. If required, wet the

filter with a small volume of distilled water to seat it. Transfer the water-sediment mixture quantitatively from

the beaker into the crucible, wash the beaker with distilled or deionized water, and take all the particles with

washings into the crucible. Allow the mixture to filter.

To remove dissolved salts, if any, wash the contents of the crucible with small portions of distilled or deionized

water from a wash bottle. Let each portion of the wash-water run through before adding the next. Continue

washing until 5 ml of the wash water gives no opalescence with a drop or two silver nitrate solution.

C.1.7 When filtration is complete, dry the crucible and contents at 101 °C to 105 °C for at least 1 h. Cool in a

desiccator and weigh.

Repeat the cycle of drying, cooling in the desiccator and weighing until a constant mass is obtained. Weigh

the crucible and contents to the nearest 0,001 g.

Record this value as the gross mass of the crucible, filtering medium and dried sediment.

C.2 Expression of results

Calculate the amount of suspended sediment, in accordance with Equation (C.1) to determine the mass

fraction, w , of the suspended solids or in accordance with Equation (C.2) to determine the volume fraction,

ss

C , of the suspended solids:

ss

mm−

10 9

w = (C.1)

ss

mm−

where

m is the tare mass, in grams, of the bottle;

m is the gross mass, in grams, of the bottle plus sample;

m is the tare mass, in grams, of the crucible with filtering medium;

m is the gross mass, in grams, of the crucible with filtering medium and dried sediment.

mm−

10 9

C = (C.2)

ss

V

where V is the volume of the test portion and the remaining variables are as given for Equation (C.1).

Express the results in the appropriate units.

C.3 Recommended precautions for this procedure

For small amounts of solids or if the sample contains a significant proportion of fine particles that do not settle

quickly, the entire sample should be filtered without sedimentation.

14 © ISO 2005 – All rights reserved

Annex D

(normative)

Determination of the particle-size distribution of suspended sediment

D.1 High sediment concentrations

D.1.1 Estimation of total suspended load — Hydrometer method

D.1.1.1 General procedure

If the sediment concentration is high, the total suspended load can be measured with sufficient accuracy by

using a hydrometer. The main advantage of this method is rapidity.

After determining the mass and the volume of the sample, vigorously stir it for a few seconds in the original

container using a “figure-eight” motion in order to obtain a homogeneous mixture. Introduce the hydrometer

into the mixed sample immediately after stopping stirring and take the reading as soon as possible. The time

after which the reading should be taken is specified in Table D.1 and depends on the temperature of the

mixed sample.

Table D.1 — Time after which hydrometer readings are to be taken in relation

to temperature of the sample

Temperature Time

°C s

5 153

6 to 10 146

11 to 15 127

16 to 20 112

21 to 25 102

26 to 30 92

31 to 35 84

36 to 40 77

41 to 45 70

46 to 50 64

NOTE From the mass and volume of the sample, the total amount of suspended load and dissolved matter can be

computed from the density reading on the hydrometer.

D.1.1.2 Use of the hydrometer

A hydrometer is illustrated in Figure D.1. The depth to which the hydrometer is immersed gives the density of

the sediment mixture, including dissolved material. Before taking the hydrometric reading, the hydrometer

should be pushed down gently by about 1 mm or 2 mm and allowed to return slowly to the equilibrium

position.

As the hydrometer is usually calibrated for 19,4 °C, it should be calibrated in distilled water before use, and a

chart or temperature correction curve should be prepared for measurements at different temperatures.

The concentration, in grams per litre, of the to

...

Frequently Asked Questions

ISO 4365:2005 is a standard published by the International Organization for Standardization (ISO). Its full title is "Liquid flow in open channels - Sediment in streams and canals - Determination of concentration, particle size distribution and relative density". This standard covers: ISO 4365:2005 specifies methods for determining the concentration, particle-size distribution and relative density of sediment in streams and canals. The detailed methods of analysis are given for the following: determination of the suspended sediment concentration by evaporation and filtration; particle-size analysis of suspended sediment; determination of the bed-load and bed material sediment; determination of the relative density of sediment; determination of particle-size distribution characteristics.

ISO 4365:2005 specifies methods for determining the concentration, particle-size distribution and relative density of sediment in streams and canals. The detailed methods of analysis are given for the following: determination of the suspended sediment concentration by evaporation and filtration; particle-size analysis of suspended sediment; determination of the bed-load and bed material sediment; determination of the relative density of sediment; determination of particle-size distribution characteristics.

ISO 4365:2005 is classified under the following ICS (International Classification for Standards) categories: 17.120.20 - Flow in open channels. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 4365:2005 has the following relationships with other standards: It is inter standard links to ISO 4365:1985. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase ISO 4365:2005 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ISO standards.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...