ISO/TR 17252:2008

(Main)Fire tests — Applicability of reaction to fire tests to fire modelling and fire safety engineering

Fire tests — Applicability of reaction to fire tests to fire modelling and fire safety engineering

ISO/TR 17252 gives guidelines on the applicability of the existing reaction to fire tests to fire safety engineering and fire modelling. It also gives general guidance on the type of data needed for fire safety engineering calculations and for fire modelling.

Essais au feu — Applicabilité des résultats de l'essai de réaction au feu aux techniques de modélisation et de sécurité contre l'incendie

General Information

Relations

Buy Standard

Standards Content (Sample)

TECHNICAL ISO/TR

REPORT 17252

First edition

2008-12-15

Fire tests — Applicability of reaction to

fire tests to fire modelling and fire safety

engineering

Essais au feu — Applicabilité des résultats de l'essai de réaction au feu

aux techniques de modélisation et de sécurité contre l'incendie

Reference number

ISO/TR 17252:2008(E)

©

ISO 2008

---------------------- Page: 1 ----------------------

ISO/TR 17252:2008(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe’s licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe’s licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

COPYRIGHT PROTECTED DOCUMENT

© ISO 2008

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO’s member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2008 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/TR 17252:2008(E)

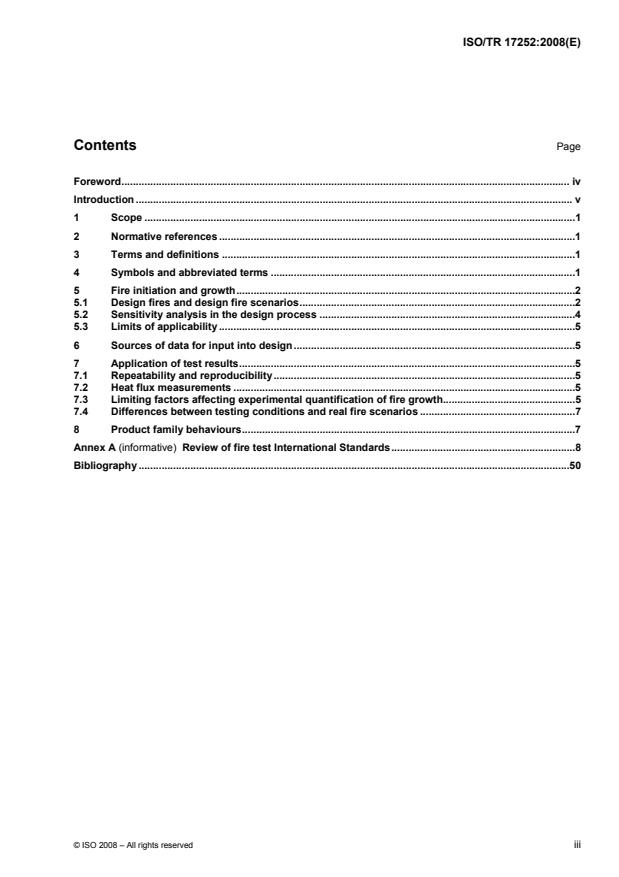

Contents Page

Foreword. iv

Introduction . v

1 Scope .1

2 Normative references .1

3 Terms and definitions .1

4 Symbols and abbreviated terms .1

5 Fire initiation and growth.2

5.1 Design fires and design fire scenarios.2

5.2 Sensitivity analysis in the design process .4

5.3 Limits of applicability .5

6 Sources of data for input into design.5

7 Application of test results.5

7.1 Repeatability and reproducibility.5

7.2 Heat flux measurements .5

7.3 Limiting factors affecting experimental quantification of fire growth.5

7.4 Differences between testing conditions and real fire scenarios .7

8 Product family behaviours.7

Annex A (informative) Review of fire test International Standards.8

Bibliography .50

© ISO 2008 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO/TR 17252:2008(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

In exceptional circumstances, when a technical committee has collected data of a different kind from that

which is normally published as an International Standard (“state of the art”, for example), it may decide by a

simple majority vote of its participating members to publish a Technical Report. A Technical Report is entirely

informative in nature and does not have to be reviewed until the data it provides are considered to be no

longer valid or useful.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO/TR 17252 was prepared by Technical Committee ISO/TC 92, Fire safety, Subcommittee SC 1, Fire

initiation and growth.

iv © ISO 2008 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/TR 17252:2008(E)

Introduction

There is a current trend towards performance-based approaches in national building regulations. This trend

has seen rapid advancement internationally in the development of fire safety engineering (FSE). This has

been supported by the application of fire modelling over the last five years, as marked by the publication of

ISO/TR 13387-1, ISO/TR 13387-2, ISO/TR 13387-3, ISO/TR 13387-4, ISO/TR 13387-5, ISO/TR 13387-6,

ISO/TR 13387-7 and ISO/TR 13387-8. The development of ISO/TR 13387-1, ISO/TR 13387-2,

ISO/TR 13387-3, ISO/TR 13387-4, ISO/TR 13387-5, ISO/TR 13387-6, ISO/TR 13387-7 and ISO/TR 13387-8,

as well as activities carried out nationally, have clearly identified that there are inconsistencies between the

requirements of FSE (including the application of fire modelling) and the data reported from standard tests and

ad hoc experiments.

This Technical Report is intended to assist in the development of an internationally consistent approach to the

support of FSE by giving guidance on appropriate fire test methods that, where possible, have the primary

function of fire safety regulations for the use of construction products.

It examines all of the current reaction to fire test methods and provides information to support the use of the

data that the tests provide for FSE and fire modelling.

© ISO 2008 – All rights reserved v

---------------------- Page: 5 ----------------------

TECHNICAL REPORT ISO/TR 17252:2008(E)

Fire tests — Applicability of reaction to fire tests to fire

modelling and fire safety engineering

1 Scope

This Technical Report gives guidelines on the applicability of the current reaction to fire tests to fire safety

engineering (FSE) and fire modelling. It also gives general guidance on the type of data needed for FSE

calculations and fire modelling.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 13943, Fire safety — Vocabulary

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 13943 and the following apply.

3.1

design fire

quantitative description of assumed fire characteristics within the design fire scenario

3.2

design fire scenario

specific fire scenario on which an analysis will be conducted

3.3

fire scenario

qualitative description of the course of a fire with time, identifying key events that characterize the fire and

differentiate it from other possible fires

4 Symbols and abbreviated terms

FSE Fire safety engineering

Q is the heat release rate (MW)

Q is the reference heat release rate, often taken to be 1 MW

0

t is the characteristic time to reach heat release rate, Q (s)

g 0

© ISO 2008 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO/TR 17252:2008(E)

5 Fire initiation and growth

5.1 Design fires and design fire scenarios

5.1.1 Background

5.1.1.1 Design fire scenarios are at the core of the FSE methodology described in all parts of

ISO/TR 13387. An additional series of International Standards, ISO 16734, ISO 16736, ISO 16737 and

ISO TS 16732, extend and implement these concepts.

The methodology is based upon analysing particular design fire scenarios and then drawing inferences from

the results with regard to the adequacy of the proposed fire safety system to meet the performance criteria

that have been defined. Identification of the appropriate scenarios requiring analysis is crucial to the fulfilment

of fire safety performance objectives for buildings.

The characterization of a design fire scenario for analysis purposes should involve a description of such things

as fire initiation, growth and extinction of fire, together with the likely smoke and fire spread routes under a

defined set of conditions. This might include consideration of such conditions as diverse combinations of

outcomes or events of different fire safety subsystems [see ISO/TR 13387 (all parts)], different internal

ventilation conditions and different external environmental conditions. The consequences of each design fire

scenario need to be considered. It is important to realize that smouldering fires may have the potential to

cause a large number of fatalities in certain occupancies such as residential buildings.

5.1.1.2 Examples of typical design fire scenarios include:

⎯ room fire (corner, ceiling, wall, floor);

⎯ fire in stairwells;

⎯ single burning item fire (furniture, wastepaper basket, fittings);

⎯ developing fire (smoke extraction);

⎯ cable tray or duct fire;

⎯ roof fire (underside);

⎯ cavity fire (wall, façade, plenum);

⎯ fire in underground transportation system;

⎯ arson:

1) internal,

2) external;

⎯ fire in neighbouring building;

⎯ fire in external fuel package(s);

⎯ fire on roof;

⎯ fire on façade;

⎯ subterranean fire;

2 © ISO 2008 – All rights reserved

---------------------- Page: 7 ----------------------

ISO/TR 17252:2008(E)

⎯ forest fire or wildfire;

⎯ fire in tunnel(s).

5.1.1.3 Following identification of the relevant design fire scenarios, it is necessary to describe the

assumed characteristics of the fire on which the design will be based. These fire characteristics are defined as

the design fire and usually require quantification of the following variables with respect to time:

⎯ heat release rate [HRR (peak, mean, etc.)];

⎯ toxic species production rate;

⎯ smoke production rate (SPR);

⎯ fire size (including flame length);

⎯ time to key events such as flashover;

⎯ other factors such as temperature, emissivity and location.

5.1.1.4 The fire characteristics listed above are influenced by a number of factors, which include:

⎯ internal ventilation conditions (e.g. building air handling system);

⎯ external environmental conditions;

⎯ type, size and location(s) of ignition source;

⎯ distribution and type(s) of fuel;

⎯ fire load density;

⎯ geometry of enclosure;

⎯ ignitability of fuel;

⎯ rate of heat release characteristics;

⎯ ventilation [status of doors and/or windows (open or closed)];

⎯ external heat flux;

⎯ exposed surface area.

Additionally, events can modify the design fire and these are typically accounted for in an FSE approach to

design. For example, the breakage of a window will alter the ventilation conditions and will influence the

design fire. The incorporation of active fire protection measures into a design will also impact upon the design

fire. It is therefore important that the effects of suppression systems, smoke control systems and intervention

by the fire service be considered when appropriate.

5.1.2 Design fire types

For design purposes, an exponential or power-law rate of fire growth is often used. The most commonly used

relationship is the t-squared fire growth rate given by Equation (1):

2

QQ= t /t (1)

()

0g

© ISO 2008 – All rights reserved 3

---------------------- Page: 8 ----------------------

ISO/TR 17252:2008(E)

where the growth time, t , is the time to reach heat release rate, Q .

g 0

In addition, when the fuel package for a particular design fire scenario is well defined and unlikely to change

significantly during the life of the building, the actual burning characteristics of the fuel package can be used

as the design fire. In such cases, oxygen consumption calorimetry, for example ISO 9705, is useful for

providing quantitative data.

In some cases, it is now possible to predict the fire growth behaviour using calculation and modelling

methods. For such approaches, the validation and verification of the approach will be an important

consideration and will be very dependent upon the quality and reliability of the input data, whether it is

generated from test methods or material data.

The concept of the reference scenario is not particularly new, but has gained prominence recently with the

new developments within Europe. A reference scenario is basically intended to be representative of the

application of products in buildings on an experimental scale. It should be representative of a specific hazard

scenario and as such, needs to be fully defined in terms of the physical geometry of the space, the properties

of the boundaries, the locations of openings and the fire source. Products can be performance tested within

an appropriate reference scenario and in some cases, it could be argued that this type of test is the only

means of producing reliable performance data. Examples of reference scenarios include the room corner test,

a façade test, a horizontal duct test, a stairwell test and a roof test.

5.2 Sensitivity analysis in the design process

5.2.1 The design fire characteristics will have a major impact upon many aspects of the design since they

form the input into many of the deterministic quantitative design calculations carried out in FSE design. A

sensitivity analysis can be defined as the calculation of changes in outputs for variations in an input parameter

of interest. It may be possible to deal with the uncertainties associated with the deterministic design by taking

a conservative approach. However, the judgement of conservatism is very subjective. A worst-case design fire

in terms of maximum size or growth rate will typically also be the worst case for:

⎯ effect of smoke control system;

⎯ effect of suppression systems on fire growth;

⎯ time to structural failure;

⎯ time and extent of fire spread within and from enclosure;

⎯ fire service extinguishing capacity.

5.2.2 However, the same design fire may represent the best-case test for:

⎯ time of activation of alarm system;

⎯ time of activation of smoke control systems;

⎯ time of activation of smoke and fire barriers;

⎯ time of activation of suppression systems.

A sensitivity study should, therefore, be carried out on the consequences of the choice of design fire on the

different parts of the quantitative assessment.

The objective of a sensitivity study is to establish the impact on the output parameter(s) caused by variation(s)

in the input parameter(s); it is not intended to check the accuracy of the results.

If a single assumption is shown to be critical to the design and potentially the level of safety, consideration

should be given to providing a degree of redundancy in the design or to carrying out a probabilistic study.

4 © ISO 2008 – All rights reserved

---------------------- Page: 9 ----------------------

ISO/TR 17252:2008(E)

5.3 Limits of applicability

Empirically-based calculation methods and other types of approach to FSE design are generally assumed to

be adequate provided that the approaches are used within their stated limits of applicability. However, if an

approach is used outside of its limits of applicability, it is important that it be assessed on a theoretical basis

and/or by comparison with experimental data. In such cases, it is usual to include some suitable safety factors

in the analysis.

6 Sources of data for input into design

A systematic review of the current ISO/TC 92 reaction to fire test methods has been carried out. The outcome

is summarized in Annex A in standardized tabular templates that make the extraction of the key information

clear and simple to retrieve. This summary information should make the task of the application of test data

within design approaches more robust as the limitations of the test methods and data are more visible to the

user.

Summary sheets for the following International Standards are included in Annex A:

ISO 1182 ISO 9705

ISO 1716 ISO 11925-2

ISO 5657 ISO 13784-1

ISO 5658-2 ISO 13784-2

ISO 5658-4 ISO 13785-1

ISO 5660-1 ISO 13785-2

ISO 5660-2 ISO/TR 14696

ISO 9239-1

7 Application of test results

7.1 Repeatability and reproducibility

Information associated with the repeatability and reproducibility of test data is determined through inter-

laboratory trials in accordance with ISO 5725 (all parts). However, the repeatability and reproducibility data

relate only to the specific version of the test method and protocols that were used in the trial. If the test

method is subsequently updated, then the repeatability and reproducibility data may only be considered to be,

at best, indicative of performance. Therefore, in cases where the repeatability and reproducibility are important

parameters in relation to the specific application of the test data, efforts should be made in establishing the

relevance to the particular version of the test method used to generate the test data.

7.2 Heat flux measurements

Many of the reaction to fire test methods use heat flux meters to calibrate and/or set the incident radiant heat

flux to the surface of the test specimens. The methodology for calibrating these gauges is provided in

ISO 14934 (all parts). It is important to understand that whilst ISO 14934 provides for traceability of the

calibrations to a primary calibration standard, the accuracy and relevance of the measurements should be

carefully considered, especially if the values are to be used as input data for mathematical modelling and/or

as part of an FSE design. In particular, consideration should be given to characterization of the radiative and

convective contributions to the heat transfer and the importance of spectral characteristics.

7.3 Limiting factors affecting experimental quantification of fire growth

7.3.1 General

Fire tests do not typically simulate all aspects of a real fire. Typically, they have been designed to assess

product or material characteristics in a well-defined methodology to enable direct comparison of fire

performance parameters. The fire performance parameters that are measured are considered to be relevant

© ISO 2008 – All rights reserved 5

---------------------- Page: 10 ----------------------

ISO/TR 17252:2008(E)

to particular fire hazards and as such should be useable within modelling methods to predict larger scale

and/or real-scale fire growth.

7.3.2 Heat release rate

Data from the cone calorimeter may be used to predict the heat release rate from lining products. However,

selection of the incident radiant heat flux levels appropriate to a specific scenario will require consideration. In

addition, for scenarios or orientations for which the conditions are vitiated, e.g. ceiling fires, the heat release

rates resulting from the cone calorimeter tests will tend to be overestimated. However, the resulting smoke

production rates will tend to be underestimated. Below concentrations of 15 % oxygen, the smoke yield tends

to increase significantly.

Results from large-scale experimental fire test data may be used as a direct source of heat release data for

fire models provided that the limitations of the tests are considered. Much information is available on burning

rates for single items under free-burning or well-ventilated conditions in large enclosures. However,

consideration should be given to inclusion, or not, of the effects of:

⎯ radiative feedback from the hot smoke layer or from enclosure surface(s);

⎯ limited supply of oxygen due to ventilation conditions or flames becoming immersed in the layer of

combustion products;

⎯ interaction between objects, in particular, their orientation and storage configuration.

7.3.3 Smoke production rate

As a large-scale fire develops and becomes more complex, the correlation between optical density of smoke

in the small-scale and large-scale tests tends to break down. This is because the ventilation conditions and

heat transfer can have a major impact on the smoke production.

NOTE None of the ISO/TC 92/SC 1 fire test methods provides any quantification of the irritancy of smoke.

7.3.4 Flame spread

Simply, flame spread can be divided into two categories:

⎯ opposed flow or counter-current flame spread;

⎯ wind-aided or concurrent flame spread.

In terms of direct measurements, the ISO/TC 92/SC 1 test methods relate predominantly to opposed-flow

flame spread under a well-defined externally applied radiant heat exposure.

7.3.5 Ignition

Ignition of a solid material or product is generally the point at which the flow of volatiles from the surface is

sufficient to enable a flame to persist. This is the starting point of any of the fire test methods that have been

developed in ISO/TC 92/SC 1. Some of the test methods can be used to attempt to quantify the ignition

characteristics of the material or product, whilst others simply ensure that the incident heat flux is sufficient to

cause ignition for many materials or products. Whichever case is relevant, it is important that the externally

applied heat flux and the external conditions be well characterized (e.g. ventilation conditions). This is

certainly believed to be the case for the smaller scale test methods such as the cone calorimeter, however,

the ignition sources are far less well characterized in relation to the large-scale test methods, such as the

ISO 9705 test.

6 © ISO 2008 – All rights reserved

---------------------- Page: 11 ----------------------

ISO/TR 17252:2008(E)

7.4 Differences between testing conditions and real fire scenarios

There can be significant differences between testing conditions and real fire scenarios. Some of the most

obvious differences are itemized below, however, it should be realized that this list is not exhaustive.

⎯ Conditioning

Fire test specimens are generally “conditioned” prior to the test. This means that the specimens are kept

in a constant environment of temperature and humidity for the period of time required to produce constant

mass. That is, the moisture content and any other properties that may vary depending upon the humidity

and temperature have stabilized. These conditions are unlikely to reproduce realistic conditions, but do

seek to maintain a constant basis from which to compare the fire performance of different products.

⎯ Ageing effects

Typically, specimens for fire tests are delivered from the manufacturer’s production line to the test

laboratory. It is unusual, but not impossible, for any account to be taken of factors such as washing,

durability, UV light stability, humidity, leaching of additives, wear and weathering. Clearly these factors

may have some influence upon the performance of materials and products during their lifetime, but the

importance of any influence will depend upon the type of product.

⎯ Mounting and fixing

The performance of a product within a test is dependent upon the mounting and fixing arrangements used

in the test and their relationship to the realistic applications of the products. Factors that should be

considered when carrying out tests include types of substrate, presence or absence of an air gap directly

behind the product, the location and type of joints, edge details and fixing details.

⎯ Thermal attack

The thermal attack in terms of the imposed heat flux to the specimen surface in a test is reasonably well

characterized. As already mentioned, the thermal attack is better defined in some of the test methods

than in others, and the significant challenge rests with the fire safety engineer to determine how relevant

the test results and conditions are in relation to the problem that should be solved.

8 Product family behaviours

There are some product family behaviours that are important to recognize and that will provide a significant

challenge to some types of mathematical modelling approaches. These behaviours include melting, shrinking,

slumping, dripping, spalling, charring, delaminating and intumescing. It may be the case that some of these

types of behaviour can only be accommodated through empirical models in the short term, but it is clearly for

the fire safety engineer to judge the relevance of these behaviours within the context of the design.

The importance of these behaviours, in particular test methods, is discussed in Annex A. In general, the

effects of softening and melting are most apparent in tests where the specimen is in vertical orientation. As a

result of movement of the specimen from its test position, the data produced is of limited validity.

The collapse of a thermoplastic foamed product or the expansion of an intumescent product in any test

orientation changes the position of the product surface in relation to the heat source and it needs to be

considered in any use of the data.

© ISO 2008 – All rights reserved 7

---------------------- Page: 12 ----------------------

ISO/TR 17252:2008(E)

Annex A

(informative)

Review of fire test International Standards

A.1 Summary sheet for ISO 1182

1 International Standard ISO 1182

2 Scope

Method of test for determining the non-combustibility performance, under specified conditions, of

homogeneous building products and substantial components of non-homogeneous building products.

3 Application

The test method is used for selection of construction products which, whilst not completely inert, produce

only a very limited amount of heat and flame when exposed to temperatures of approximately 750 °C.

4 Other related standards: none.

5 Summary test information

Thermal exposure Radiant Flame Other

Vertical tube furnace

6 Description

The test apparatus consists of a furnace comprising essentially a refractory tube surrounded by a heating

coil and enclosed in an insulated surround. A cone-shaped airflow stabilizer is attached to the base of the

furnace and a draught shield to its top. The furnace is stabilized at 750 °C before test, thereafter the

corresponding power input is kept constant throughout the test. A small cylindrical shaped specimen is

placed in the centre of the furnace.

7 Duration of exposure

The test is carried out until final temperature equilibrium has been reached in the furnace, or for 60 min.

8 Specimen details

General application Homogeneous building products and substantial components of non-homogeneous

building products, as defined in the standard (i.e. ISO 1182).

Height of specimen

(50 ± 3) mm, if the thickness of the material is different from (50 ± 3) mm, specimens

of height (50 ± 3) mm are made by using a sufficient number of layers of the material

and/or by adjustment of the material thickness.

Specimen diameter

(45, +0, –2) mm

Specimen The layers of the material occupy a horizontal position in the specimen and are held

preparation together firmly, without compression, by means of two fine steel wires to prevent air

gaps between layers.

Specimen Temp. Humidity Other

conditioning

To constant mass, followed by a drying procedure.

(23 ± 2) °C (50 ± 5) %

8 © ISO 2008 – All rights reserved

---------------------- Page: 13 ----------------------

ISO/TR 17252:2008(E)

Burning Dripping Flowing Falling debris Delamination Other

characteristics droplets

considered

(yes or no) No No No No

Number of tests Five tests

required and criteria

for tests

...

TECHNICAL ISO/TR

REPORT 17252

First edition

2008-##-##

Fire tests — Applicability of reaction to

fire tests to fire modelling and fire safety

engineering

Essais au feu — Applicabilité des résultats de l'essai de réaction au feu

aux techniques de modélisation et de sécurité contre l'incendie

PROOF/ÉPREUVE

Reference number

ISO/TR 17252:2008(E)

©

ISO 2008

---------------------- Page: 1 ----------------------

ISO/TR 17252:2008(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe’s licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe’s licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

COPYRIGHT PROTECTED DOCUMENT

© ISO 2008

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO’s member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii PROOF/ÉPREUVE © ISO 2008 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/TR 17252:2008(E)

Contents Page

Foreword. iv

Introduction . v

1 Scope .1

2 Normative references .1

3 Terms and definitions .1

4 Symbols and abbreviated terms .1

5 Fire initiation and growth.2

5.1 Design fires and design fire scenarios.2

5.2 Sensitivity analysis in the design process .4

5.3 Limits of applicability .5

6 Sources of data for input into design.5

7 Application of test results.5

7.1 Repeatability and reproducibility.5

7.2 Heat flux measurements .5

7.3 Limiting factors affecting experimental quantification of fire growth.5

7.4 Differences between testing conditions and real fire scenarios .7

8 Product family behaviours.7

Annex A (informative) Review of fire test International Standards.8

Bibliography .50

© ISO 2008 – All rights reserved PROOF/ÉPREUVE iii

---------------------- Page: 3 ----------------------

ISO/TR 17252:2008(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

In exceptional circumstances, when a technical committee has collected data of a different kind from that

which is normally published as an International Standard (“state of the art”, for example), it may decide by a

simple majority vote of its participating members to publish a Technical Report. A Technical Report is entirely

informative in nature and does not have to be reviewed until the data it provides are considered to be no

longer valid or useful.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO/TR 17252 was prepared by Technical Committee ISO/TC 92, Fire safety, Subcommittee SC 1, Fire

initiation and growth.

iv PROOF/ÉPREUVE © ISO 2008 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/TR 17252:2008(E)

Introduction

There is a current trend towards performance-based approaches in national building regulations. This trend

has seen rapid advancement internationally in the development of fire safety engineering (FSE). This has

been supported by the application of fire modelling over the last five years, as marked by the publication of

ISO/TR 13387-1, ISO/TR 13387-2, ISO/TR 13387-3, ISO/TR 13387-4, ISO/TR 13387-5, ISO/TR 13387-6,

ISO/TR 13387-7 and ISO/TR 13387-8. The development of ISO/TR 13387-1, ISO/TR 13387-2,

ISO/TR 13387-3, ISO/TR 13387-4, ISO/TR 13387-5, ISO/TR 13387-6, ISO/TR 13387-7 and ISO/TR 13387-8,

as well as activities carried out nationally, have clearly identified that there are inconsistencies between the

requirements of FSE (including the application of fire modelling) and the data reported from standard tests and

ad hoc experiments.

This Technical Report is intended to assist in the development of an internationally consistent approach to the

support of FSE by giving guidance on appropriate fire test methods that, where possible, have the primary

function of fire safety regulations for the use of construction products.

It examines all of the current reactions to fire test methods and provides information to support the use of the

data that the tests provide for FSE and fire modelling.

© ISO 2008 – All rights reserved PROOF/ÉPREUVE v

---------------------- Page: 5 ----------------------

TECHNICAL REPORT ISO/TR 17252:2008(E)

Fire tests — Applicability of reaction to fire tests to fire

modelling and fire safety engineering

1 Scope

This Technical Report gives guidelines on the applicability of the current reaction to fire tests, to fire safety

engineering (FSE) and fire modelling. It also gives general guidance on the type of data needed for FSE

calculations and fire modelling.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 13943, Fire safety — Vocabulary

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 13943 and the following apply.

3.1

design fire

quantitative description of assumed fire characteristics within the design fire scenario

3.2

design fire scenario

specific fire scenario on which an analysis will be conducted

3.3

fire scenario

qualitative description of the course of a fire with time, identifying key events that characterize the fire and

differentiate it from other possible fires

4 Symbols and abbreviated terms

FSE Fire safety engineering

Q is the heat release rate (MW)

Q is the reference heat release rate, often taken to be 1 MW

0

t is the characteristic time to reach heat release rate, Q (s)

g 0

© ISO 2008 – All rights reserved PROOF/ÉPREUVE 1

---------------------- Page: 6 ----------------------

ISO/TR 17252:2008(E)

5 Fire initiation and growth

5.1 Design fires and design fire scenarios

5.1.1 Background

5.1.1.1 Design fire scenarios are at the core of the FSE methodology described in all parts of

ISO/TR 13387. An additional series of International Standards, ISO 16734, ISO 16736, ISO 16737 and

ISO TS 16732, extend and implement these concepts.

The methodology is based upon analysing particular design fire scenarios and then drawing inferences from

the results with regard to the adequacy of the proposed fire safety system to meet the performance criteria

that have been defined. Identification of the appropriate scenarios requiring analysis is crucial to the fulfilment

of fire safety performance objectives for buildings.

The characterization of a design fire scenario for analysis purposes should involve a description of such things

as fire initiation, growth and extinction of fire, together with the likely smoke and fire spread routes under a

defined set of conditions. This might include consideration of such conditions as diverse combinations of

outcomes or events of different fire safety subsystems [see ISO/TR 13387 (all parts)], different internal

ventilation conditions and different external environmental conditions. The consequences of each design fire

scenario need to be considered. It is important to realize that smouldering fires may have the potential to

cause a large number of fatalities in certain occupancies such as residential buildings.

5.1.1.2 Examples of typical design fire scenarios include:

⎯ room fire (corner, ceiling, wall, floor);

⎯ fire in stairwells;

⎯ single burning item fire (furniture, wastepaper basket, fittings);

⎯ developing fire (smoke extraction);

⎯ cable tray or duct fire;

⎯ roof fire (underside);

⎯ cavity fire (wall, façade, plenum);

⎯ fire in underground transportation system;

⎯ arson:

1) internal,

2) external;

⎯ fire in neighbouring building;

⎯ fire in external fuel package(s);

⎯ fire on roof;

⎯ fire on façade;

⎯ subterranean fire;

2 PROOF/ÉPREUVE © ISO 2008 – All rights reserved

---------------------- Page: 7 ----------------------

ISO/TR 17252:2008(E)

⎯ forest fire or wildfire;

⎯ fire in tunnel(s).

5.1.1.3 Following identification of the relevant design fire scenarios, it is necessary to describe the

assumed characteristics of the fire on which the design will be based. These fire characteristics are defined as

the design fire and usually require quantification of the following variables with respect to time:

⎯ heat release rate [HRR (peak, mean, etc.)];

⎯ toxic species production rate;

⎯ smoke production rate (SPR);

⎯ fire size (including flame length);

⎯ time to key events such as flashover;

⎯ other factors such as temperature, emissivity and location.

5.1.1.4 The fire characteristics listed above are influenced by a number of factors, which include:

⎯ internal ventilation conditions (e.g. building air handling system);

⎯ external environmental conditions;

⎯ type, size and location(s) of ignition source;

⎯ distribution and type(s) of fuel;

⎯ fire load density;

⎯ geometry of enclosure;

⎯ ignitability of fuel;

⎯ rate of heat release characteristics;

⎯ ventilation [status of doors and/or windows (open or closed)];

⎯ external heat flux;

⎯ exposed surface area.

Additionally, events can modify the design fire and these are typically accounted for in an FSE approach to

design. For example, the breakage of a window will alter the ventilation conditions and will influence the

design fire. The incorporation of active fire protection measures into a design will also impact upon the design

fire. It is therefore important that the effects of suppression systems, smoke control systems and intervention

by the fire service be considered when appropriate.

5.1.2 Design fire types

For design purposes, an exponential or power-law rate of fire growth is often used. The most commonly used

relationship is the t-squared fire growth rate given by Equation (1):

2

QQ= t /t (1)

()

0g

© ISO 2008 – All rights reserved PROOF/ÉPREUVE 3

---------------------- Page: 8 ----------------------

ISO/TR 17252:2008(E)

where the growth time, t , is the time to reach heat release rate, Q .

g 0

In addition, when the fuel package for a particular design fire scenario is well defined and unlikely to change

significantly during the life of the building, the actual burning characteristics of the fuel package can be used

as the design fire. In such cases, oxygen consumption calorimetry, for example ISO 9705, is useful for

providing quantitative data.

In some cases, it is now possible to predict the fire growth behaviour using calculation and modelling

methods. For such approaches, the validation and verification of the approach will be an important

consideration and will be very dependent upon the quality and reliability of the input data, whether it is

generated from test methods or material data.

The concept of the reference scenario is not particularly new, but has gained prominence recently with the

new developments within Europe. A reference scenario is basically intended to be representative of the

application of products in buildings on an experimental scale. It should be representative of a specific hazard

scenario and as such, needs to be fully defined in terms of the physical geometry of the space, the properties

of the boundaries, the locations of openings and the fire source. Products can be performance tested within

an appropriate reference scenario and in some cases, it could be argued that this type of test is the only

means of producing reliable performance data. Examples of reference scenarios include the room corner test,

a façade test, a horizontal duct test, a stairwell test and a roof test.

5.2 Sensitivity analysis in the design process

5.2.1 The design fire characteristics will have a major impact upon many aspects of the design since they

form the input into many of the deterministic quantitative design calculations carried out in FSE design. A

sensitivity analysis can be defined as the calculation of changes in outputs for variations in an input parameter

of interest. It may be possible to deal with the uncertainties associated with the deterministic design by taking

a conservative approach. However, the judgement of conservatism is very subjective. A worst-case design fire

in terms of maximum size or growth rate will typically also be the worst case for:

⎯ effect of smoke control system;

⎯ effect of suppression systems on fire growth;

⎯ time to structural failure;

⎯ time and extent of fire spread within and from enclosure;

⎯ fire service extinguishing capacity.

5.2.2 However, the same design fire may represent the best-case test for:

⎯ time of activation of alarm system;

⎯ time of activation of smoke control systems;

⎯ time of activation of smoke and fire barriers;

⎯ time of activation of suppression systems.

A sensitivity study should, therefore, be carried out on the consequences of the choice of design fire on the

different parts of the quantitative assessment.

The objective of a sensitivity study is to establish the impact on the output parameter(s) caused by variation(s)

in the input parameter(s); it is not intended to check the accuracy of the results.

If a single assumption is shown to be critical to the design and potentially the level of safety, consideration

should be given to providing a degree of redundancy in the design or to carrying out a probabilistic study.

4 PROOF/ÉPREUVE © ISO 2008 – All rights reserved

---------------------- Page: 9 ----------------------

ISO/TR 17252:2008(E)

5.3 Limits of applicability

Empirically-based calculation methods and other types of approach to FSE design are generally assumed to

be adequate provided that the approaches are used within their stated limits of applicability. However, if an

approach is used outside of its limits of applicability, it is important that it be assessed on a theoretical basis

and/or by comparison with experimental data. In such cases, it is usual to include some suitable safety factors

in the analysis.

6 Sources of data for input into design

A systematic review of the current ISO/TC 92 reaction to fire test methods has been carried out. The outcome

is summarized in Annex A in standardized tabular templates that make the extraction of the key information

clear and simple to retrieve. This summary information should make the task of the application of test data

within design approaches more robust as the limitations of the test methods and data are more visible to the

user.

Summary sheets for the following International Standards are included in Annex A:

ISO 1182 ISO 9705

ISO 1716 ISO 11925-2

ISO 5657 ISO 13784-1

ISO 5658-2 ISO 13784-2

ISO 5658-4 ISO 13785-1

ISO 5660-1 ISO 13785-2

ISO 5660-2 ISO/TR 14696

ISO 9239-1

7 Application of test results

7.1 Repeatability and reproducibility

Information associated with the repeatability and reproducibility of test data is determined through inter-

laboratory trials in accordance with ISO 5725 (all parts). However, the repeatability and reproducibility data

relate only to the specific version of the test method and protocols that were used in the trial. If the test

method is subsequently updated, then the repeatability and reproducibility data may only be considered to be,

at best, indicative of performance. Therefore, in cases where the repeatability and reproducibility are important

parameters in relation to the specific application of the test data, efforts should be made in establishing the

relevance to the particular version of the test method used to generate the test data.

7.2 Heat flux measurements

Many of the reaction to fire test methods use heat flux meters to calibrate and/or set the incident radiant heat

flux to the surface of the test specimens. The methodology for calibrating these gauges is provided in

ISO 14934 (all parts). It is important to understand that whilst ISO 14934 provides for traceability of the

calibrations to a primary calibration standard, the accuracy and relevance of the measurements should be

carefully considered, especially if the values are to be used as input data for mathematical modelling and/or

as part of an FSE design. In particular, consideration should be given to characterization of the radiative and

convective contributions to the heat transfer and the importance of spectral characteristics.

7.3 Limiting factors affecting experimental quantification of fire growth

7.3.1 General

Fire tests do not typically simulate all aspects of a real fire. Typically, they have been designed to assess

product or material characteristics in a well-defined methodology to enable direct comparison of fire

performance parameters. The fire performance parameters that are measured are considered to be relevant

© ISO 2008 – All rights reserved PROOF/ÉPREUVE 5

---------------------- Page: 10 ----------------------

ISO/TR 17252:2008(E)

to particular fire hazards and as such should be useable within modelling methods to predict larger scale

and/or real-scale fire growth.

7.3.2 Heat release rate

Data from the cone calorimeter may be used to predict the heat release rate from lining products. However,

selection of the incident radiant heat flux levels appropriate to a specific scenario will require consideration. In

addition, for scenarios or orientations for which the conditions are vitiated, e.g. ceiling fires, the heat release

rates resulting from the cone calorimeter tests will tend to be overestimated. However, the resulting smoke

production rates will tend to be underestimated. Below concentrations of 15 % oxygen, the smoke yield tends

to increase significantly.

Results from large-scale experimental fire test data may be used as a direct source of heat release data for

fire models provided that the limitations of the tests are considered. Much information is available on burning

rates for single items under free-burning or well-ventilated conditions in large enclosures. However,

consideration should be given to inclusion, or not, of the effects of:

⎯ radiative feedback from the hot smoke layer or from enclosure surface(s);

⎯ limited supply of oxygen due to ventilation conditions or flames becoming immersed in the layer of

combustion products;

⎯ interaction between objects, in particular, their orientation and storage configuration.

7.3.3 Smoke production rate

As a large-scale fire develops and becomes more complex, the correlation between optical density of smoke

in the small-scale and large-scale tests tends to break down. This is because the ventilation conditions and

heat transfer can have a major impact on the smoke production.

NOTE None of the ISO/TC 92/SC 1 fire test methods provides any quantification of the irritancy of smoke.

7.3.4 Flame spread

Simply, flame spread can be divided into two categories:

⎯ opposed flow or counter-current flame spread;

⎯ wind-aided or concurrent flame spread.

In terms of direct measurements, the ISO/TC 92/SC 1 test methods relate predominantly to opposed-flow

flame spread under a well-defined externally applied radiant heat exposure.

7.3.5 Ignition

Ignition of a solid material or product is generally the point at which the flow of volatiles from the surface is

sufficient to enable a flame to persist. This is the starting point of any of the fire test methods that have been

developed in ISO/TC 92/SC 1. Some of the test methods can be used to attempt to quantify the ignition

characteristics of the material or product, whilst others simply ensure that the incident heat flux is sufficient to

cause ignition for many materials or products. Whichever case is relevant, it is important that the externally

applied heat flux and the external conditions be well characterized (e.g. ventilation conditions). This is

certainly believed to be the case for the smaller scale test methods such as the cone calorimeter, however,

the ignition sources are far less well characterized in relation to the large-scale test methods, such as the

ISO 9705 test.

6 PROOF/ÉPREUVE © ISO 2008 – All rights reserved

---------------------- Page: 11 ----------------------

ISO/TR 17252:2008(E)

7.4 Differences between testing conditions and real fire scenarios

There can be significant differences between testing conditions and real fire scenarios. Some of the most

obvious differences are itemized below, however, it should be realized that this list is not exhaustive.

⎯ Conditioning

Fire test specimens are generally “conditioned” prior to the test. This means that the specimens are kept

in a constant environment of temperature and humidity for the period of time required to produce constant

mass. That is, the moisture content and any other properties that may vary depending upon the humidity

and temperature have stabilized. These conditions are unlikely to reproduce realistic conditions, but do

seek to maintain a constant basis from which to compare the fire performance of different products.

⎯ Ageing effects

Typically, specimens for fire tests are delivered from the manufacturer’s production line to the test

laboratory. It is unusual, but not impossible, for any account to be taken of factors such as washing,

durability, UV light stability, humidity, leaching of additives, wear and weathering. Clearly these factors

may have some influence upon the performance of materials and products during their lifetime, but the

importance of any influence will depend upon the type of product.

⎯ Mounting and fixing

The performance of a product within a test is dependent upon the mounting and fixing arrangements used

in the test and their relationship to the realistic applications of the products. Factors that should be

considered when carrying out tests include types of substrate, presence or absence of an air gap directly

behind the product, the location and type of joints, edge details and fixing details.

⎯ Thermal attack

The thermal attack in terms of the imposed heat flux to the specimen surface in a test is reasonably well

characterized. As already mentioned, the thermal attack is better defined in some of the test methods

than in others, and the significant challenge rests with the fire safety engineer to determine how relevant

the test results and conditions are in relation to the problem that should be solved.

8 Product family behaviours

There are some product family behaviours that are important to recognize and that will provide a significant

challenge to some types of mathematical modelling approaches. These behaviours include melting, shrinking,

slumping, dripping, spalling, charring, delaminating and intumescing. It may be the case that some of these

types of behaviour can only be accommodated through empirical models in the short term, but it is clearly for

the fire safety engineer to judge the relevance of these behaviours within the context of the design.

The importance of these behaviours, in particular test methods, is discussed in Annex A. In general, the

effects of softening and melting are most apparent in tests where the specimen is in vertical orientation. As a

result of movement of the specimen from its test position, the data produced is of limited validity.

The collapse of a thermoplastic foamed product or the expansion of an intumescent product in any test

orientation changes the position of the product surface in relation to the heat source and it needs to be

considered in any use of the data.

© ISO 2008 – All rights reserved PROOF/ÉPREUVE 7

---------------------- Page: 12 ----------------------

ISO/TR 17252:2008(E)

Annex A

(informative)

Review of fire test International Standards

A.1 Summary sheet for ISO 1182

1 International Standard ISO 1182

2 Scope

Method of test for determining the non-combustibility performance, under specified conditions, of

homogeneous building products and substantial components of non-homogeneous building products.

3 Application

The test method is used for selection of construction products which, whilst not completely inert, produce

only a very limited amount of heat and flame when exposed to temperatures of approximately 750 °C.

4 Other related standards: none.

5 Summary test information

Thermal exposure Radiant Flame Other

Vertical tube furnace

6 Description

The test apparatus consists of a furnace comprising essentially a refractory tube surrounded by a heating

coil and enclosed in an insulated surround. A cone-shaped airflow stabilizer is attached to the base of the

furnace and a draught shield to its top. The furnace is stabilized at 750 °C before test, thereafter the

corresponding power input is kept constant throughout the test. A small cylindrical shaped specimen is

placed in the centre of the furnace.

7 Duration of exposure

The test is carried out until final temperature equilibrium has been reached in the furnace, or for 60 min.

8 Specimen details

General application Homogeneous building products and substantial components of non-homogeneous

building products, as defined in the standard (i.e. ISO 1182).

Height of specimen

(50 ± 3) mm, if the thickness of the material is different from (50 ± 3) mm, specimens

of height (50 ± 3) mm are made by using a sufficient number of layers of the material

and/or by adjustment of the material thickness.

Specimen diameter

(45, +0, –2) mm

Specimen The layers of the material occupy a horizontal position in the specimen and are held

preparation together firmly, without compression, by means of two fine steel wires to prevent air

gaps between layers.

Specimen Temp. Humidity Other

conditioning

To constant mass, followed by a drying procedure.

(23 ± 2) °C (50 ± 5) %

8 PROOF/ÉPREUVE © ISO 2008 – All rights reserved

---------------------- Page: 13 ----------------------

ISO/TR 17252:2008(E)

Burning Dripping Flowin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.