ISO/IEC 11694-4:2001

(Main)Identification cards - Optical memory cards - Linear recording method - Part 4: Logical data structures

Identification cards - Optical memory cards - Linear recording method - Part 4: Logical data structures

Cartes d'identification — Cartes à mémoire optique — Méthode d'enregistrement linéaire — Partie 4: Structures de données logiques

General Information

Relations

Frequently Asked Questions

ISO/IEC 11694-4:2001 is a standard published by the International Organization for Standardization (ISO). Its full title is "Identification cards - Optical memory cards - Linear recording method - Part 4: Logical data structures". This standard covers: Identification cards - Optical memory cards - Linear recording method - Part 4: Logical data structures

Identification cards - Optical memory cards - Linear recording method - Part 4: Logical data structures

ISO/IEC 11694-4:2001 is classified under the following ICS (International Classification for Standards) categories: 35.240.15 - Identification cards. Chip cards. Biometrics. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/IEC 11694-4:2001 has the following relationships with other standards: It is inter standard links to ISO/IEC 11694-4:1996, ISO/IEC 11694-4:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase ISO/IEC 11694-4:2001 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ISO standards.

Standards Content (Sample)

INTERNATIONAL ISO/IEC

STANDARD 11694-4

Second edition

2001-10-15

Identification cards — Optical memory

cards — Linear recording method —

Part 4:

Logical data structures

Cartes d'identification — Cartes à mémoire optique — Méthode

d'enregistrement linéaire —

Partie 4: Structures de données logiques

Reference number

©

ISO/IEC 2001

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall not

be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In downloading this

file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat accepts no liability in this

area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation parameters

were optimized for printing. Every care has been taken to ensure that the file is suiTable for use by ISO member bodies. In the unlikely event

that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO/IEC 2001

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means, electronic

or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or ISO's member body

in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.ch

Web www.iso.ch

Printed in Switzerland

ii © ISO/IEC 2001 – All rights reserved

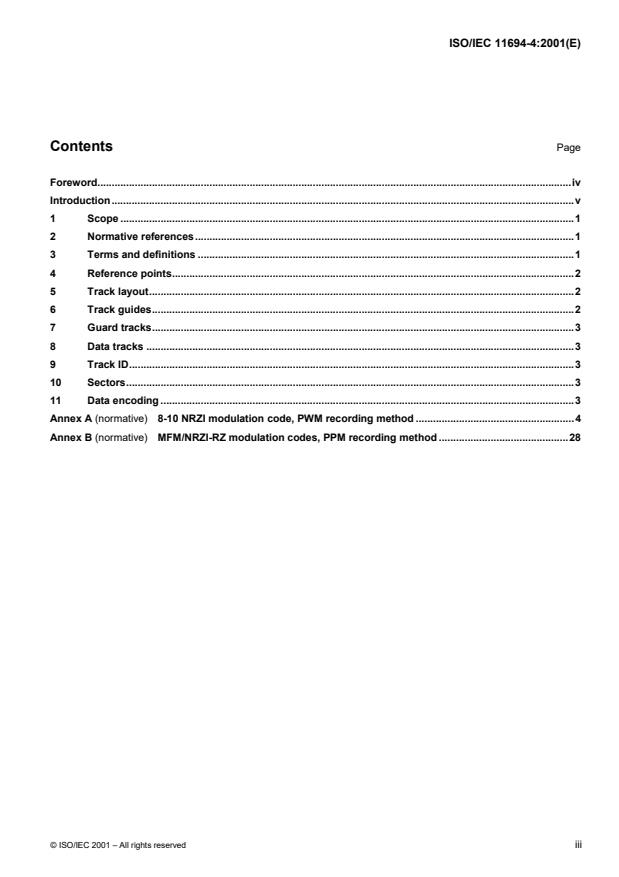

Contents Page

Foreword.iv

Introduction.v

1 Scope .1

2 Normative references.1

3 Terms and definitions .1

4 Reference points.2

5 Track layout.2

6 Track guides.2

7 Guard tracks.3

8 Data tracks .3

9 Track ID.3

10 Sectors.3

11 Data encoding .3

Annex A (normative) 8-10 NRZI modulation code, PWM recording method .4

Annex B (normative) MFM/NRZI-RZ modulation codes, PPM recording method .28

© ISO/IEC 2001 – All rights reserved iii

Foreword

ISO (the International Organization for Standardization) and IEC (the International Electrotechnical Commission)

form the specialized system for worldwide standardization. National bodies that are members of ISO or IEC

participate in the development of International Standards through technical committees established by the

respective organization to deal with particular fields of technical activity. ISO and IEC technical committees

collaborate in fields of mutual interest. Other international organizations, governmental and non-governmental, in

liaison with ISO and IEC, also take part in the work.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 3.

In the field of information technology, ISO and IEC have established a joint technical committee, ISO/IEC JTC 1.

Draft International Standards adopted by the joint technical committee are circulated to national bodies for voting.

Publication as an International Standard requires approval by at least 75 % of the national bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this part of ISO/IEC 11694 may be the subject of

patent rights. ISO and IEC shall not be held responsible for identifying any or all such patent rights.

International Standard ISO/IEC 11694-4 was prepared by Joint Technical Committee ISO/IEC JTC 1, Information

technology, Subcommittee SC 17, Identification cards and related devices.

This second edition cancels and replaces the first edition (ISO/IEC 11694-4:1996), which has been technically

revised.

ISO/IEC 11694 consists of the following parts, under the general title Identification cards — Optical memory cards

— Linear recording method:

Part 1: Physical characteristics

Part 2: Dimensions and location of the accessible optical area

Part 3: Optical properties and characteristics

Part 4: Logical data structures

Annexes A and B form a normative part of this part of ISO/IEC 11694.

iv © ISO/IEC 2001 – All rights reserved

Introduction

This part of ISO/IEC 11694 is one of a series of standards describing the parameters for optical memory cards and

the use of such cards for the storage and interchange of digital data.

The standards recognize the existence of different methods for recording and reading information on optical

memory cards, the characteristics of which are specific to the recording method employed. In general, these

different recording methods will not be compatible with each other. Therefore, the standards are structured to

accommodate the inclusion of existing and future recording methods in a consistent manner.

This part of ISO/IEC 11694 is specific to optical memory cards using the linear recording method. Characteristics

which apply to other specific recording methods shall be found in separate standards documents.

This part of ISO/IEC 11694 defines the logical data structures and the extent of compliance with, addition to, and/or

deviation from the relevant base document ISO/IEC 11693.

© ISO/IEC 2001 – All rights reserved v

INTERNATIONAL STANDARD ISO/IEC 11694-4:2001(E)

Identification cards — Optical memory cards — Linear recording

method —

Part 4:

Logical data structures

1 Scope

This part of ISO/IEC 11694 specifies the logical data structures for optical memory cards necessary to allow

compatibility and interchange between systems using the linear recording method.

2 Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of

this part of ISO/IEC 11694. For dated references, subsequent amendments to, or revisions of, any of these

publications do not apply. However, parties to agreements based on this part of ISO/IEC 11694 are encouraged to

investigate the possibility of applying the most recent editions of the normative documents indicated below. For

undated references, the latest edition of the normative document referred to applies. Members of ISO and IEC

maintain registers of currently valid International Standards.

ISO/IEC 11693:2000, Identification cards — Optical memory cards — General characteristics

ISO/IEC 11694-1:2000, Identification cards — Optical memory cards — Linear recording method — Part 1:

Physical characteristics

ISO/IEC 11694-2:2000, Identification cards — Optical memory cards — Linear recording method — Part 2:

Dimensions and location of the accessible optical area

ISO/IEC 11694-3:2001, Identification cards — Optical memory cards — Linear recording method — Part 3: Optical

properties and characteristics

3 Terms and definitions

For the purposes of this part of ISO/IEC 11694, the terms and definitions given in ISO/IEC 11693,

ISO/IEC 11694-1, ISO/IEC 11694-2, ISO/IEC 11694-3 and the following apply.

3.1

data bit

area which represents data on an optical memory card; mark which has a different reflectivity and/or phase

difference from the background reflectivity

NOTE One mark can define one or two data transitions dependent on the modulation method selected.

© ISO/IEC 2001 – All rights reserved 1

3.2

data track

area located between adjacent track guides where data are written and/or read

3.3

error correction code (ECC)

code designed to correct certain kinds of errors in data

3.4

error detection and correction (EDAC)

family of methods in which redundancy is added to a message block, at the time the message block is recorded, in

known fashion; upon read back, a decoder removes the redundancy and uses the redundant information to detect

and correct erroneous channel symbols

3.5

modulation code

system for coding which transforms information bits into some physical representation for recording onto the optical

memory card

3.6

pitch

distance between corresponding points on adjacent data spots

3.7

sector

minimum unit of data that can be accessed on a card for any read and/or write command

4 Reference points

The reference track and reference edges defined in ISO/IEC 11694-2 apply unless otherwise specified.

4.1 First data bit

The first data bit shall be located on the reference track and is part of the track ID. The location may vary

dependent on the track layout selected. See annex A or annex B.

5 Track layout

Track layout information shall be preformatted on cards during manufacture and/or written to cards prior to use.

The total number of tracks may vary dependent on the application requirements; however, in all cases, tracks shall

be arranged in order, and numbered sequentially, beginning with the reference track. See annex A or annex B for

actual track layouts and numbering sequences.

5.1 Track layout options

See annex A or annex B for information concerning data structures that support the optional card layouts described

in ISO/IEC 11694-2.

6 Track guides

Track guides shall be uniformly spaced across the card and shall extend the length of the accessible optical area.

The accumulated tolerances across the width of all track guides shall be less than or equal to 0,01 % at 25 °C. See

annex A or annex B for specific dimensions.

2 © ISO/IEC 2001 – All rights reserved

7 Guard tracks

There shall be 20 guard tracks, ten located directly above and ten directly below the user data area to enable the

optics to locate the user data tracks and prevent the optical head from overrunning the accessible optical area if

auto-tracking is lost.

Guard tracks may contain data relating to card type, physical data format, specific application and/or card drive

autodiagnosis and calibration. See annex A or annex B.

8 Data tracks

Written and/or preformatted data shall be located within data tracks and centred between adjacent track guides to a

tolerance of ± 0,5µm in the y-axis. See annex A or annex B.

9 Track ID

Written and/or preformatted track ID shall identify the physical address of each data track. See annex A or annex B

for specific configuration and location.

10 Sectors

Sectors are defined by the amount of user data in bytes and the number of sectors which can be written to a single

data track. See annex A or annex B for specific types/sizes.

All sectors within a given track shall be identical in type and partially written tracks shall only be appended with

sectors of the same type as those previously written on the track unless otherwise specified in annex A or annex B.

NOTE Sector types/sizes have been defined to maximize the efficiency of data storage on a track and may vary by

modulation code.

11 Data encoding

To encode data requires the use of a modulation code. See annex A or annex B for acceptable modulation codes.

NOTE The user data on any single optical card shall only be encoded using one modulation code.

© ISO/IEC 2001 – All rights reserved 3

Annex A

(normative)

8-10 NRZI modulation code, PWM recording method

A.1 Scope

This annex defines the logical data structures specific to optical cards using a pulse width modulation recording

method and an 8-10 NRZI modulation code.

A.2 Terms and definitions

For the purposes of this annex, the following terms and definitions apply.

A.2.1

carrier/burst modulation code

form of FM modulation code which makes 1,0 information correspond to a different frequency

A.2.2

NRZI

non-return-to-zero-inverse; a specific modulation method to make 1 corresponding to inverse and 0 to non-inverse

A.2.3

Reed-Solomon code

byte error detection and/or correction code which is generally used in optical and magnetic storage

A.3 Reference points

The first bottom guard track (LPT9) is the reference track and shall be located 5,4 mm ± 0,3 mm from the horizontal

reference edge.

NOTE This dimension is tighter yet still falls within the tolerance range specified by dimension D of ISO/IEC 11694-2.

A.3.1 First data bit

The first data bit closest to the left edge of the card shall be located at 12,50 mm ± 0,40 mm in the x-axis. The

distance between the first data bit closest to the left edge of the card and the first data bit closest to the right edge

of the card shall be 60,6 mm ± 0,1 mm in the x-axis.

A.4 Track layout

Tracks shall be arranged in order beginning with the reference track and shall be numbered sequentially beginning

with track -10, the reference track.

4 © ISO/IEC 2001 – All rights reserved

Track Description Track No. Hex

Guard track LPT9 (first bottom)

-10 FFF6

:: :

:: :

Guard track LPT0(last bottom) -1 FFFF

First user data track 0 0000

::

::

Last user data track n

Guard track UPT0 (first top) n+1

::

::

Guard track UPT9 (last top) n+10

NOTE Because the total number of tracks may vary dependent on the application requirements, the last user data track

and the top guard tracks are expressed in parametric form.

A.5 Track layout examples

This section provides information concerning data structures that support the optional card layouts described in

ISO/IEC 11694-2.

A.5.1 Cards with moderate data capacity

This layout shall contain 2520 data tracks, of which 2500 shall be user data tracks. Tracks shall be numbered

sequentially beginning with track -10, the reference track.

NOTE This layout supports the inclusion of a magnetic stripe and/or signature panel.

A.5.2 Cards with small data capacity

This layout shall contain 1128 data tracks, of which 1108 shall be user data tracks. Tracks shall be numbered

sequentially beginning with track -10, the reference track.

NOTE This layout supports the inclusion of a magnetic stripe, IC chip with contacts, embossing and/or signature panel.

A.5.3 Cards with maximum data capacity

This layout shall contain 3593 data tracks, of which 3573 shall be user data tracks. Tracks shall be numbered

sequentially beginning with track −10, the reference track.

NOTE This layout supports the inclusion of a magnetic stripe and/or signature panel.

A.6 Track guides

The width of the track guides shall be 2,3µm ± 0,3µm. The distance from the centre of one track guide to the

centre of an adjacent track guide shall be 12,0µm ± 0,2µm.

No track guides shall have any breaks exceeding 180µm.

© ISO/IEC 2001 – All rights reserved 5

A.7 Guard tracks

All guard tracks shall contain preformatted track-ID and card-type data and/or card-ID field data. Cards shall not be

issued with these tracks left blank nor shall these tracks be made available to the application for writing.

Each guard track shall contain two track ID areas, one to the left, the other to the right of the card-type data and/or

card-ID field. See A.10.

NOTE It is expected that card drive units will have the ability to read guard tracks whether preformatted with card-type data

or pre-recorded with card-ID field data.

A.7.1 Card-type data

Card-type data are pre-set indicia that denote the physical data format, the number and location of tracks and/or a

specific type application. There shall be two blocks per track each containing the same card-type pattern repeated

eight times. See Figure A.1 and Table A1.

Card-type data shall be preformatted using a carrier/burst modulation code. These tracks shall not be made

available to the application for writing nor shall cards be issued with these tracks left blank.

The carrier/burst pattern shall consist of an L-pattern (denotes 0 data) and an S-pattern (denotes 1 data), the only

difference between patterns being the pattern-pitch. The L-pattern pitch shall be 240µm ± 5µm and the S-pattern

pitch shall be 120µm ± 5µm. See A.12.2, Figure A.1 and Table A.1.

The length, or x-axis dimension, of preformatted data bits shall be 6,0µm ± 0,6µm; the width, or y-axis dimension,

shall be 2,5µm ± 0,5µm; the bit pitch shall be 12,0µm ± 0,3µm.SeeFigure A.1.

The distance between the first data bit of the left track ID closest to the left edge of the card and the first data bit of

the card type pattern closest to the left edge of the card shall be 14,9 mm ± 0,1 mm in the x-axis.

A.7.2 Unique card identification (ID) field

For those applications requiring unique card serialization, guard tracks LPT1 (track -2) and LPT0 (track -1) shall be

used as a card-ID field. If using this option, information related to the application and other issuer information may

be included in these tracks along with the card serialization data.

Card-ID field data shall be pre-recorded during the manufacturing process. These tracks shall not be made

available to the application for writing nor shall cards be issued with these tracks left blank.

There are two types of card identification (ID) field data described in A.7.2.1.1 (card-type 0 to 14) and A.7.2.1.2

(card-type 15).

A.7.2.1 Content

Figure A.2 shows the structure and data content of the card-ID field. Data shall be pre-recorded using a type-2

sector as defined in A.11.1 and Table A.2. The same information shall be repeated in each sector of each track,

that is four times in two tracks.

NOTE 1 It is not permissible to set all data fields to 0FF hex.

NOTE 2 If no components of the card-ID field are used, these two tracks must be preformatted with card-type data. See

A.7.1.

Field components are described in both A.7.2.1.1 and A.7.2.1.2.

6 © ISO/IEC 2001 – All rights reserved

A.7.2.1.1 Card-type 0 to 14

Application identifier (AID): The AID shall consist of 16 bytes of alpha/numeric data, which data shall be

agreed to by the card manufacturer and card issuer. If the AID is not implemented, these 16 bytes shall be

set to 0FF hex.

NOTE Card manufacturers shall have the responsibility to manage the information to ensure AID's are not duplicated

between different card issuers.

Unique identifier (UID): The UID shall consist of six bytes, one byte containing the card manufacturer

identifier (CMID), and five bytes containing a unique card identifier (UCID). If the UID is not implemented,

these six bytes shall be set to 0FF hex.

NOTE 1 The card manufacturer shall have the responsibility to ensure only one UID is contained in their card products.

NOTE 2 Since different card manufacturers can use the same UCID, it is recommended that the entire UID (CMID +

UCID) be used.

Number of issuer data bytes (NID): The NID shall consist of two bytes which specify the number of bytes

used in the ISSUER portion of the card-ID field. If the NID is not implemented, these two bytes shall be set to

0FF hex.

Optional issuer data (ISSUER): The ISSUER shall consist of 488 bytes and shall be reserved for the

exclusive use of the card issuer. Any unused bytes in this area shall be set to 0FF hex.

NOTE Since card-ID field data are pre-recorded, the ISSUER data must be pre-recorded at the time of card

manufacture.

A.7.2.1.2 Card-type 15

Application identifier (AID): Same with A.7.2.1.1.

Unique identifier (UID): Same with A.7.2.1.1.

Number of issuer data bytes (NID): Same with A.7.2.1.1.

Format identifier (FID): The FID shall consist of six bytes of alpha/numeric data, which specify the format

classification. "SIOC01" shall be recorded for the current international standard.

Card type (CTYPE): The CTYPE shall be one byte data which is same with the card-type data. In this case,

it shall be 0F hex.

Track pitch (PITCH): The PITCH shall be one byte data, which is ten-times value of track pitch. For 12 µm

track pitch, it shall be 78 hex.

Number of user track (NUMBER): The NUMBER shall consist of two bytes which specify the user track

number in the card. It shall be recorded the most significant byte first.

Mediatype(MTYPE): The MTYPE shall be one byte which specifies the media type which is under control

of the card manufacturer.

Contacts for IC chip (CONTACT): The CONTACT shall be one byte which specifies the presence/absence

of contacts for IC chip. This byte is optional, and 0FF hex shall be recorded in no use.

00 hex : No IC contacts

10 hex : Contacts on the same side with AOA (Accessible Optical Area)

© ISO/IEC 2001 – All rights reserved 7

20 hex : Contacts on the opposite side with AOA

others : Reserved

Contactless IC chip (CLIC): The CLIC shall be one byte which specifies the presence/absence of

contactless IC chip. This byte is optional, and 0FF hex shall be recorded in no use.

00 hex : No IC chip

10 hex : Includes inductive coupling IC chip

20 hex : Includes capacitive coupling IC chip

others : Reserved

Magneticstripe(MS): The MS shall be one byte which specifies the presence/absence of magnetic stripe.

This byte is optional, and 0FF hex shall be recorded in no use.

00 hex : No magnetic stripe

10 hex : Magnetic stripe on the same side with AOA

20 hex : Magnetic stripe on the opposite side with AOA

30 hex : Magnetic stripe on both sides

others : Reserved

Embossing (EMBOSS): The EMBOSS shall be one byte which specifies the presence/absence of

embossing. This byte is optional, and 0FF hex shall be recorded in no use.

00 hex : No embossing

10 hex : With embossing

others : Reserved

Optional issuer data (ISSUER): The ISSUER shall consist of 472 bytes and shall be reserved for the

exclusive use of the card issuer. Any unused bytes in this area shall be set to 0FF hex.

NOTE Since card-ID field data are pre-recorded, the ISSUER data must be pre-recorded at the time of card

manufacture.

A.8 Data tracks

Each data track can contain a maximum of 60,7 mm of written and/or preformatted data, including the gaps

between sectors.

A.8.1 Data bits

Use of the 8-10 NRZI modulation code requires that written and/or preformatted data bits consist of four different

sizes. The length, or x-axis dimension, shall be 3,0µm ± 0,6µm, 6,0µm ± 0,6µm, 9,0µm ± 0,6µm or

12,0µm ± 0,6µm; the width, or y-axis dimension, shall be 2,5µm ± 0,5µm.

The minimum distance from the centre of one data bit to the centre of an adjacent data bit shall be

6,0µm ± 0,3µm.

8 © ISO/IEC 2001 – All rights reserved

A.9 Track components

A.9.1 Preamble (PRE)

A series of 60 consecutive bits laid out from the left edge direction of the card. The PRE bit-pattern shall be

1010101010. or 0101010101. See Figure A.3.

NOTE The PRE generates the data clock required by the card drive's phase-lock-loop (PLL) circuit when an optical card is

read from left to right.

A.9.2 Sync marker

A specific 10-bit pattern which does not show up as a read-output signal when the 8-10 NRZI modulation code is

implemented on the track ID and/or user data.

NOTE When asynchronization occurs during reading, data can be re-synchronized after sensing successive sync markers.

The sync marker shall be set on the border of the data matrix, created when implementing the Reed-Solomon

code, to divide the user data into multiple blocks. See Figure A.4.

The first sync marker from the left edge of the card, in every sector and in both track ID's, shall be 1100010001

prior to NRZI modulation. All other sync markers shall be either 1100010001 or 0100010001 prior to NRZI

modulation.

Thus all written sync markers shall become either 1000011110 or 0111100001 after NRZI modulation.

A.9.3 Post-amble (PST)

A series of 60 consecutive bits laid out from the left edge direction of the card. The PST bit-pattern shall be

0101010101. or 1010101010. See Figure A.3.

NOTE The PST generates the data clock required by the card drive's PLL circuit when an optical card is read from right to

left.

A.10 Track ID

Track ID shall be preformatted at the right and left side of each data track. See Figures A.3 and A.5.

NOTE The structure allows the track ID to be read from either direction, that is from left to right or right to left.

A.10.1 Content

The track ID shall consist of 75 bytes of information and the length shall be 2,25 mm ± 0,02 mm. The track ID shall

consist of the PRE, sync markers, track numbers, ECC and the PST. See A.12.3 and Figure A.3.

The track number itself shall be repeated twice per track ID with the most significant bit (MSB) positioned closest to

the left edge of the card.

A.11 Sectors

Every sector shall contain a PRE, sync markers, user data, ECC and a PST and shall be separated from adjoining

sectors by a gap, that is an unrecorded area. See Figures A.4 and A.5.

User data shall be written within a sector and arranged from left to right regardless of the writing direction

implemented.

© ISO/IEC 2001 – All rights reserved 9

NOTE Sectors can be written in either direction, that is, from left to right, the forward direction, or from right to left, the

reverse direction.

The accumulated tolerances across any sector shall be less than ± 3 % of the sector length.

A.11.1 Types of sectors

Sector types shall be as defined in Figure A.6 and Table A.2.

NOTE The sector lengths shown in Figure A.6 are the maximum allowed when taking into consideration up to a 3 %

deviation in the velocity of the card drive mechanism which is anticipated in the actual use of optical card systems.

All sectors, regardless of sector type, shall be located relative to the first bit position of the left track ID. The MSB

shall always be placed at the edge of each sector closest the left edge of the card.

A.12 Data encoding

This section describes the method for encoding and storing data on optical cards using the various sector types.

A.12.1 Modulated data

All track ID's and user data along with their associated ECC shall be modulated using the 8-10 NRZI modulation

code. See Figures A.7, A.8, A.9 and Table A.3.

NOTE When encoding, ten bits are assigned to every eight bits of actual data using the 8-10 modulation table. When

reading, the original eight bits are retrieved/demodulated from the corresponding 10-bit data pattern.

A.12.2 Carrier/burst modulation code

All card-type data shall be preformatted using the carrier/burst modulation code. See A.7.1, Figure A.1 and

Table A.1.

NOTE In the read mode, this modulation code permits card-type information found in the guard tracks to be demodulated

with software, eliminating the influence from the variable velocity, if any, of the optical card drive.

A.12.3 Error correction code

Each track ID and every sector of written data shall be encoded using the Reed-Solomon ECC generated by the

following generator polynomial:

3 2

G(x) = (X - α )(X- α )(X- α)(X-1)

where

8 4 3 2

x +x +x +x +1 = 0

α is a primitive element of GF (2 ).

The Reed-Solomon code arranges every track ID and every sector of user data into a matrix as shown in

Figure A.10 and then applies the ECC based on the generator polynomial, resulting in the addition of four parity

bytes to the matrix.

EXAMPLE 1 Track ID are encoded using a C1 (6,2), C2 (5,1) Reed-Solomon code. As a result, 28 parity bytes are added to

the original two bytes which make up the track ID.

EXAMPLE 2 Encoding a sector type 7 using the Reed-Solomon ECC.

10 © ISO/IEC 2001 – All rights reserved

Write 16 bytes of data containing the following integer values in hexadecimal:

00 01 02 03 04 05 06 07 08 09 0A 0B 0C 0D 0E 0F

Arranging the bytes into an 8 × 2 matrix, the data becomes:

00 01 02 03 04 05 06 07

08 09 0A 0B 0C 0D 0E 0F

Encoding each row of the matrix using the generator polynomial G(x), the above matrix becomes:

00 01 02 03 04 05 06 07 2C 84 05 AD

08 09 0A 0B 0C 0D 0E 0F D8 4E 65 F3

Encoding each column of this matrix using the generator polynomial G(x), the matrix becomes:

00 01 02 03 04 05 06 07 2C 84 05 AD

08 09 0A 0B 0C 0D 0E 0F D8 4E 65 F3

78 14 A0 CC D5 B9 0D 61 EE FB DB CE

AD CC 6F 0E 34 55 F6 97 18 91 77 FE

E7 4D AE 04 75 DF 3C 96 67 8F E8 00

3A 9D 69 CE 9C 3B CF 68 65 2F 24 6E

A.13 Measurement

NOTE 1 The reading/writing test conditions outlined in ISO/IEC 11694-3 apply unless otherwise specified when observing

the optical characteristics.

NOTE 2 An Optical Specialties, Inc. Video Linewidth System, VLS-I is used for physical measurements. This information is

given for the convenience of users of this part of ISO/IEC 11694 and does not constitute an endorsement by ISO and IEC of the

product named. Equivalent products may be used if they can be shown to lead to the same results.

A.13.1 Track guide measurement

The measurement of the track guide pitch and width shall be performed in the nine areas shown in Figure A.11.

Each area shall consist of ten tracks and the average value at each of the nine areas shall fall within the specified

range.

A.13.2 Track ID measurement

The measurement of the track ID data bit size, bit pitch and the length of the track ID shall be performed in the six

areas designated by D and E in Figure A.11. Each area shall consist of ten tracks and the average value at each of

the six areas shall fall within the specified range.

© ISO/IEC 2001 – All rights reserved 11

A.13.3 Guard track measurement

The measurement of the guard track data bit size, bit pitch and the carrier pattern pitch shall be performed in two

tracks each in the areas designated A and C in Figure A.11. The average value of a minimum of ten measurements

taken at each location shall fall within the specified range.

A.13.4 Preformatted data characteristics

The following characteristics shall be achieved when scanning a preformatted portion of the accessible optical area

containing a card-type carrier/burst pattern. See Figure A.1.

To achieve the expected results, tests shall be conducted using a beam diameter of 2,5µm and a media linear

velocity of 480 mm/s ± 3%.

A.13.4.1 The low frequency recovery value shall be greater than or equal to 0,9. See ISO/IEC 11694-3.

A.13.4.2 The amplitude comparison value shall be greater than or equal to 0,8. See ISO/IEC 11694-3.

A.13.4.3 The signal overlap (S ) divided by the high frequency amplitude (A ) shall be greater than or equal to

O HF

0,8. See ISO/IEC 11694-3.

A.13.5 Written data measurement

The measurement of the written data bit and the bit pitch shall be determined using the wave shape of the read out

signal using a beam diameter of 2,5µm, a read power of 0,1 mW ± 5 % and a media linear velocity of

480 mm/s ± 0,5 %.

The bit size shall be measured at the half value point and the bit pitch at the peak point of the read signal. The

average value of a minimum of ten measurements shall fall within the specified range.

A.13.6 Written data characteristics

The following characteristics shall be achieved when scanning a written portion of the accessible optical area

containing high frequency data (80 kHz), and low frequency data (20 kHz).

To achieve the expected results, tests shall be conducted using a beam diameter of 2,5µm and a media linear

velocity of 480 mm/s ± 3 %. The write power shall be 18 mW ± 5 %. A pulse width of 3,5µs at 80 kHz, and 22µs at

20 kHz shall be used.

A.13.6.1 The low frequency recovery value shall be greater than or equal to 0,9. See ISO/IEC 11694-3.

A.13.6.2 The amplitude comparison value shall be greater than or equal to 0,8. See ISO/IEC 11694-3.

A.13.6.3 The signal overlap (S ) divided by the high frequency amplitude (A ) shall be greater than or equal to

O HF

0,8. See ISO/IEC 11694-3.

A.13.6.4 The carrier-to-noise ratio (C/N) shall be greater than or equal to 40 dB when measured across a

bandwidth 1 kHz at a carrier frequency of 80 kHz.

12 © ISO/IEC 2001 – All rights reserved

UPT9

10 Upper guard tracks

UPT0

User data tracks

LPT0

10 Lower guard tracks

LPT9

Left track ID Card-type data and/or Right track ID

Card-ID field data

NOTE LPT9 is the reference track as described in ISO/IEC 11694-2.

(a) Guard track layout

(1) (2) (3)

„„„„ „„„„ „„„„ „„„„ „„„„ „„„„ „„„„ „„„„ „„„„

(240µm) (120 µm)

L L S SSS

L S

For pattern length see Table A.1

Dimensions in micrometres

(1) (2) (3)

2,5 2,5

66 66

36 36

S=120 L = 240

(b) Example of card-type pattern (P11) - See Table A.1

NOTE Drawings not to scale.

Figure A.1 - Guard track structure

© ISO/IEC 2001 – All rights reserved 13

Top

LPT0

TrK ID Gap Sector 0 Gap Sector 1 Gap Trk ID

Track (-1)

LPT1

TrK ID Gap Sector 0 Gap Sector 1 Gap Trk ID

Track (-2)

AID UID NID ISSUER

16 bytes 2bytes 488 bytes

CMID UCID

1byte 5bytes

-- For card-type 0 to 14 --

AID UID NID ISSUER

16 bytes 2 bytes 16 bytes 472 bytes

CMID UCID

1byte 5bytes

FID CTYPE PITCH NUMBER MTYPE CONTACT CLIC MS EMBOSS

6bytes 1byte 1byte 2bytes 2bytes 1byte 1byte 1byte 1byte

(optional) (optional) (optional) (optional)

-- For card-type 15 --

NOTE Type-2 sectors shall be used for card-ID field data.

(a) Structure of each sector in the card-ID field

Figure A.2 - Structure and content of the card ID field

14 © ISO/IEC 2001 – All rights reserved

Length Field Name Description Control Remarks

16 AID Application identifier Mfg/Isr

1 CMID Card manufacturer identifier Std

For all card-types

5 UCID Unique card identifier Mfg

2 NID Number of issuer data bytes Isr

488 ISSUER Reserved for issuer data Isr For card-type 0 to 14

6 FID Format identifier Std

1CTYPE Cardtype Std

1PITCH Trackpitch Std

2 NUMBER Number of user track Mfg

2 MTYPE Media type Mfg

For card-type 15

1 CONTACT Presence/absence of contacts for IC chip Mfg

(optional)

1 CLIC Presence/absence of contactless IC chip Mfg

(optional)

1 MS Presence/absence of magnetic stripe Mfg

(optional)

1 EMBOSS Presence/absence of embossing Mfg

(optional)

472 ISSUER Reserved for issuer data Isr

Note 1 Length values are in bytes.

Note 2 Mfg are fields assigned/controlled by each individual card manufacturer.

Note 3 Isr are fields assigned/controlled by each individual card issuer.

Note 4 Std are fields assigned/controlled by the appropriate ISO/IEC standards body.

Note 5 If CONTACT/CLIC/MS/EMBOSS are not in use, they shall be filled with 0FF hex.

(b) Content of the card-ID field

Figure A.2 - Structure and content of the card-ID field

© ISO/IEC 2001 – All rights reserved 15

Left edge Right edge

PRE PST PRE PST

1010101010 1010101010 1010101010 1010101010

ECC ECC ECC ECC

or or or or

280 bits 280 bits 280 bits 280 bits

0101010101 0101010101 0101010101 0101010101

60 bits 60 bits 60 bits 60 bits

NOTE Each sync pattern is 10 bits set to 1000011110 or 0111100001.

Figure A.3 - Track ID format

Left edge

PRE Sync Block 1 Sync Block 2 Sync Block 3 Sync Sync Block m Sync PST

NOTE m denotes m in Table A.2.

Figure A.4 - Format of a sector

Left edge

Track ID Gap Sector 1 Gap Sector 2 Gap Gap Sector n Gap Track ID

NOTE n denotes n in Table A.2.

Figure A.5 - Format of a data track

16 © ISO/IEC 2001 – All rights reserved

SYNC

Track Number, 20 bits

SYNC

Track Number, 20 bits

SYNC

GAP

SYNC

Track Number, 20 bits

SYNC

Track Number, 20 bits

SYNC

Dimensions in millimetres

3,51 53,64

Type 0

(1,20)

2,25

9,51 41,58 (7,26)

Type 1

2,25 2,25

(2,82)

5,07 23,82 2,82

Type 2

2,25

2,79 (0,42)

13,38 0,54

Type 3

2,25

2,25

3,03 (0,66)

8,46 0,78

Type 4

2,25

2,25

3,81 5,28

(1,38)

Type 5

2,25

2,25

3,21 3,66 0,96 (0,66)

Type 6

2,25

2,25

2,91 2,82 0,66 (0,42)

Type 7

(12,50) 56,10 2,25 (12,50)

Reference edge of card Right edge of card

NOTE Drawing not to scale.

Figure A.6 - Sector layout by type

© ISO/IEC 2001 – All rights reserved 17

Dataword

Q'

8-10 Modulation

conversion table

Q

One symbol delay

Codeword

EXAMPLE

Dataword

Sync (Q’=-1) FF (Q’=-1)

FF (Q’=1)

Qoutput -1

1-1

-1

Codeword

01 000 100 010 111 101 010 111 110 101 0

Modulated

waveform

NOTE 1 The 8-10 modulation conversion table is shown in Table A.3.

NOTE 2 The codeword is selected by the dataword and Q'. Q' is the Q output of the previous codeword.

NOTE 3 The modulated waveform is made from the codeword stream according to the NRZI rule.

Figure A.7 - 8-10 modulation method

18 © ISO/IEC 2001 – All rights reserved

ECC encoding:

04 E2 46 A0 99 99

3C D7 C5 2E 54 54

D8 E1 B5 8C DE DE

FD F6 66 6D 9A 9A

1D 22 50 6F 89 89

8-10 modulation plus sync markers:

0101001001 1111011101 xxxxxecc00 xxxxxecc01 xxxxxecc02 xxxxxecc03

xxxxxecc04 xxxxxecc05 xxxxxecc06 xxxxxecc07 xxxxxecc08 xxxxxecc09

xxxxxecc10 xxxxxecc11 xxxxxecc12 xxxxxecc13 xxxxxecc14 xxxxxecc15

xxxxxecc16 xxxxxecc17 xxxxxecc18 xxxxxecc19 xxxxxecc20 xxxxxecc21

xxxxxecc22 xxxxxecc23 xxxxxecc24 xxxxxecc25 xxxxxecc26 xxxxxecc27

xxxxxsyncx 0101001001 1111011101 xxxxxecc00 xxxxxecc01 xxxxxecc02

xxxxxecc03 xxxxxecc04 xxxxxecc05 xxxxxecc06 xxxxxecc07 xxxxxecc08

xxxxxecc09 xxxxxecc10 xxxxxecc11 xxxxxecc12 xxxxxecc13 xxxxxecc14

xxxxxecc15 xxxxxecc16 xxxxxecc17 xxxxxecc18 xxxxxecc19 xxxxxecc20

xxxxxecc21 xxxxxecc22 xxxxxecc23 xxxxxecc24 xxxxxecc25 xxxxxecc26

xxxxxecc27 xxxxxsyncx

NRZI conversion plus PRE, sync and PST patterns:

1010101010 1010101010 1010101010 1010101010 1010101010 1010101010

xxxxxsyncx xxxtr#high xxxxtr#low xxxxxxnrzi xxxxxxnrzi xxxxxxnrzi

xxxxxxnrzi xxxxxxnrzi xxxxxxnrzi xxxxxxnrzi xxxxxxnrzi xxxxxxnrzi

xxxxxxnrzi xxxxxxnrzi xxxxxxnrzi xxxxxxnrzi xxxxxxnrzi xxxxxxnrzi

xxxxxxnrzi xxxxxxnrzi xxxxxxnrzi xxxxxxnrzi xxxxxxnrzi xxxxxxnrzi

xxxxxxnrzi xxxxxxnrzi xxxxxxnrzi xxxxxxnrzi xxxxxxnrzi xxxxxxnrzi

xxxxxxnrzi xxxxxsyncx xxxtr#high xxxxtr#low xxxxxxnrzi xxxxxxnrzi

xxxxxxnrzi xxxxxxnrzi xxxxxxnrzi xxxxxxnrzi xxxxxxnrzi xxxxxxnrzi

xxxxxxnrzi xxxxxxnrzi xxxxxxnrzi xxxxxxnrzi xxxxxxnrzi xxxxxxnrzi

xxxxxxnrzi xxxxxxnrzi xxxxxxnrzi xxxxxxnrzi xxxxxxnrzi xxxxxxnrzi

xxxxxxnrzi xxxxxxnrzi xxxxxxnrzi xxxxxxnrzi xxxxxxnrzi xxxxxxnrzi

xxxxxxnrzi xxxxxxnrzi xxxxxsyncx 0101010101 0101010101 0101010101

0101010101 0101010101 0101010101

Figure A.8 - Example of modulation code using the track ID # 1250 (04E2 hex)

© ISO/IEC 2001 – All rights reserved 19

ECC encoding:

D00 D01 D02 D03 D04 D05 D06 D07 | E00 E01 E02 E03

D08 D09 D10 D11 D12 D13 D14 D15 | E04 E05 E06 E07

D16 D17 D18 D19 D20 D21 D22 D23 | E08 E09 E10 E11

D24 D25 D26 D27 D28 D29 D30 D31 | E12 E13 E14 E15

D32 D33 D34 D35 D36 D37 D38 D39 | E16 E17 E18 E19

D40 D41 D42 D43 D44 D45 D46 D47 | E20 E21 E22 E23

D48 D49 D50 D51 D52 D53 D54 D55 | E24 E25 E26 E27

D56 D57 D58 D59 D60 D61 D62 D63 | E28 E29 E30 E31

E32 E33 E34 E35 E36 E37 E38 E39 E40 E41 E42 E43

E44 E45 E46 E47 E48 E49 E50 E51 E52 E53 E54 E55

E56 E57 E58 E59 E60 E61 E62 E63 E64 E65 E66 E67

E68 E69 E70 E71 E72 E73 E74 E75 E76 E77 E78 E79

8-10 modulation plus sync markers:

MD00 MD01 MD02 MD03 MD04 MD05 MD06 MD07 | ME00 ME01 ME02 ME03 SYNC

MD08 MD09 MD10 MD11 MD12 MD13 MD14 MD15 | ME04 ME05 ME06 ME07 SYNC

MD16 MD17 MD18 MD19 MD20 MD21 MD22 MD23 | ME08 ME09 ME10 ME11 SYNC

MD24 MD25 MD26 MD27 MD28 MD29 MD30 MD31 | ME12 ME13 ME14 ME15 SYNC

MD32 MD33 MD34 MD35 MD36 MD37 MD38 MD39 | ME16 ME17 ME18 ME19 SYNC

MD40 MD41 MD42 MD43 MD44 MD45 MD46 MD47 | ME20 ME21 ME22 ME23 SYNC

MD48 MD49 MD50 MD51 MD52 MD53 MD54 MD55 | ME24 ME25 ME26 ME27 SYNC

MD56 MD57 MD58 MD59 MD60 MD61 MD62 MD63 | ME28 ME29 ME30 ME31 SYNC

ME32 ME33 ME34 ME35 ME36 ME37 ME38 ME39 ME40 ME41 ME42 ME43 SYNC

ME44 ME45 ME46 ME47 ME48 ME49 ME50 ME51 ME52 ME53 ME54 ME55 SYNC

ME56 ME57 ME58 ME59 ME60 ME61 ME62 ME63 ME64 ME65 ME66 ME67 SYNC

ME68 ME69 ME70 ME71 ME72 ME73 ME74 ME75 ME76 ME77 ME78 ME79 SYNC

NRZI conversion plus PRE, sync, PST patterns:

PRE1 PRE2 PRE3 PRE4 PRE5 PRE6 SYNC MD00 MD01 MD02 MD03 MD04 MD05

MD06 MD07 ME00 ME01 ME02 ME03 SYNC MD08 MD09 MD10 MD11 MD12 MD13

MD14 MD15 ME04 ME05 ME06 ME07 SYNC MD16 MD17 MD18 MD19 MD20 MD21

MD22 MD23 ME08 ME09 ME10 ME11 SYNC MD24 MD25 MD26 MD27 MD28 MD29

MD30 MD31 ME12 ME13 ME14 ME15 SYNC MD32 MD33 MD34 MD35 MD36 MD37

MD38 MD39 ME16 ME17 ME18 ME19 SYNC MD40 MD41 MD42 MD43 MD44 MD45

MD46 MD47 ME20 ME21 ME22 ME23 SYNC MD48 MD49 MD50 MD51 MD52 MD53

MD54 MD55 ME24 ME25 ME26 ME27 SYNC MD56 MD57 MD58 MD59 MD60 MD61

MD62 MD63 ME28 ME29 ME30 ME31 SYNC ME32 ME33 ME34 ME35 ME36 ME37

ME38 ME39 ME40 ME41 ME42 ME43 SYNC ME44 ME45 ME46 ME47 ME48 ME49

ME50 ME51 ME52 ME53 ME54 ME55 SYNC ME56 ME57 ME58 ME59 ME60 ME61

ME62 ME63 ME64 ME65 ME66 ME67 SYNC ME68 ME69 ME70 ME71 ME72 ME73

ME74 ME75 ME76 ME77 ME78 ME79 SYNC PRE1 PRE2 PRE3 PRE4 PRE5 PRE6

* MDxx, MExx : 10 bits

Figure A.9 - Example of modulation code using a sector type 5

20 © ISO/IEC 2001 – All rights reserved

4 Parity bytes

C1 direction

Left edge

User bytes

4 Parity bytes

(a) Sector layout with ECC applied

Type User bytes Parity bytes Structure of ECC in bytes

Per sector Per sector (direction) (direction)

Sector type 0 1368 312 C1(40,36) C2(42,38)

Sector type 1 1024 272 C1(36,32) C2(36,32)

Sector type 2 512 208 C1(20,16) C2(36,32)

Sector type 3 256 144 C1(20,16) C2(20,16)

Sector type 4 128 112 C1(12,8) C2(20,16)

Sector type 5 64 80 C1(12,8) C2(12,8)

Sector type 6 32 64 C1(12,8) C2(8,4)

Sector type 7 16 56 C1(12,8) C2(6,2)

(b) Content of sector with ECC applied

Structure of ECC

Type Bytes Per ID Parity bytes

(direction) (direction)

per ID

Track ID 2 28 C1(6,2) C2(5,1)

(c) Content of track ID with ECC applied

Figure A.10 - ECC matrix

© ISO/IEC 2001 – All rights reserved 21

C2 direction

Dimensions in millimetres

DE

Top

X

C X X

Accessible optical area

X

B X

X

X

A X X

NOTE 1 Drawing not to scale.

NOTE 2 A designates the lower guard track area.

NOTE 3 B designates the center region of the user data track area.

NOTE 4 C designates the upper guard track area.

NOTE 5 B and C shall vary according to card type.

NOTE 6 D designates the left track ID area.

NOTE 7 E designates the right track ID area.

Figure A.11 - Measurement points

22 © ISO/IEC 2001 – All rights reserved

---------------------- Pa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...