ISO 24322:2024

(Main)Timber structures — Methods of test for evaluation of long-term performance — Part 1: Wood-based products in bending

Timber structures — Methods of test for evaluation of long-term performance — Part 1: Wood-based products in bending

This document gives methods of determination of duration of load and creep factors under bending actions at ambient temperatures for a defined population of structural timber products such as solid timber, LVL, OSB, plywood, particleboard, I-beams calculated from test values. It presents methods for a) determining the duration of load and creep factors for new timber products, b) establishing whether a previously defined set of duration of load and creep factors can be applied to a tested product, and c) an optional method for establishment of sensitivity of duration of load and creep factors to changes in environmental conditions. NOTE 1 This document is intended to apply to wood-based products for which a duration of load factor or a creep factor is used in design. NOTE 2 The effect of elevated temperature on the duration of load factor and creep factor that is derived using these methods for use with timber products can need additional consideration.

Structures en bois — Méthodes d'essai pour l'évaluation du comportement à long terme — Partie 1: Produits à base de bois en flexion

General Information

Standards Content (Sample)

International

Standard

ISO 24322

First edition

Timber structures — Methods of

2024-01

test for evaluation of long-term

performance — Part 1: Wood-based

products in bending

Structures en bois — Méthodes d'essai pour l'évaluation du

comportement à long terme — Partie 1: Produits à base de bois

en flexion

Reference number

© ISO 2024

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

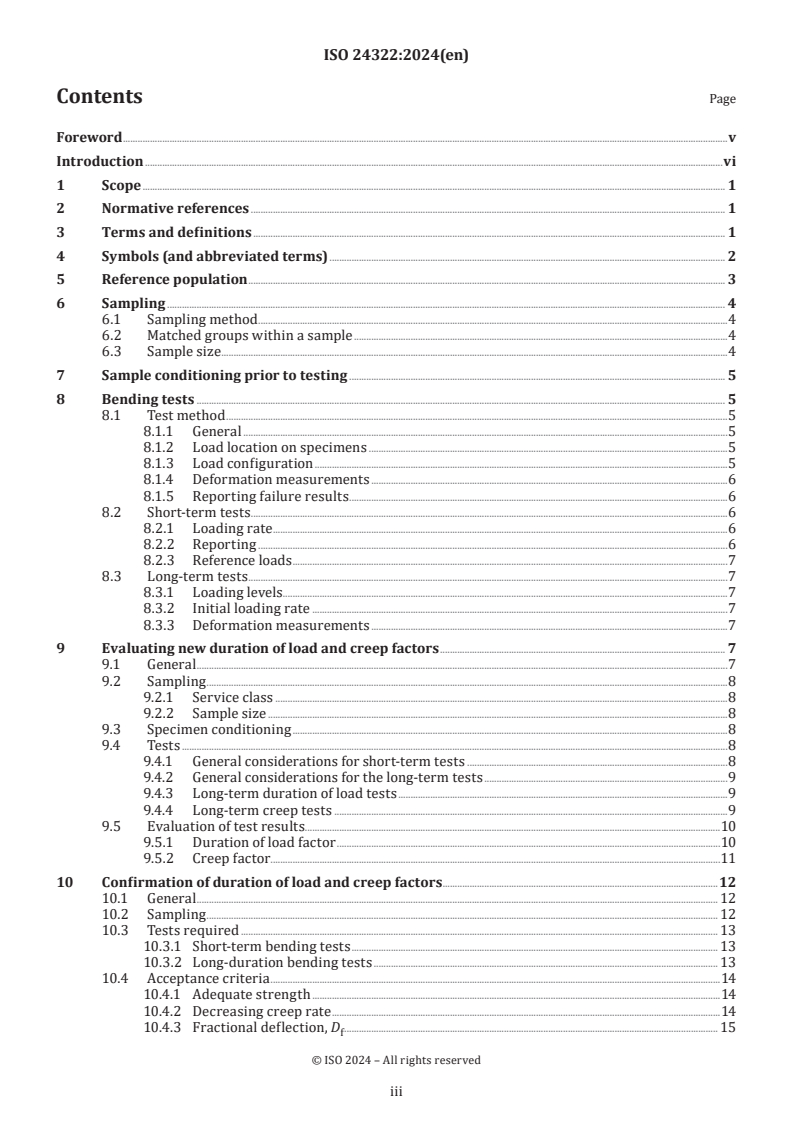

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Symbols (and abbreviated terms) . 2

5 Reference population . 3

6 Sampling . 4

6.1 Sampling method .4

6.2 Matched groups within a sample .4

6.3 Sample size .4

7 Sample conditioning prior to testing . 5

8 Bending tests . 5

8.1 Test method .5

8.1.1 General .5

8.1.2 Load location on specimens .5

8.1.3 Load configuration .5

8.1.4 Deformation measurements .6

8.1.5 Reporting failure results .6

8.2 Short-term tests . . .6

8.2.1 Loading rate .6

8.2.2 Reporting .6

8.2.3 Reference loads .7

8.3 Long-term tests .7

8.3.1 Loading levels.7

8.3.2 Initial loading rate .7

8.3.3 Deformation measurements .7

9 Evaluating new duration of load and creep factors . 7

9.1 General .7

9.2 Sampling .8

9.2.1 Service class .8

9.2.2 Sample size .8

9.3 Specimen conditioning .8

9.4 Tests .8

9.4.1 General considerations for short-term tests .8

9.4.2 General considerations for the long-term tests .9

9.4.3 Long-term duration of load tests .9

9.4.4 Long-term creep tests .9

9.5 Evaluation of test results.10

9.5.1 Duration of load factor .10

9.5.2 Creep factor.11

10 Confirmation of duration of load and creep factors .12

10.1 General . 12

10.2 Sampling . 12

10.3 Tests required . 13

10.3.1 Short-term bending tests . 13

10.3.2 Long-duration bending tests . 13

10.4 Acceptance criteria .14

10.4.1 Adequate strength .14

10.4.2 Decreasing creep rate .14

10.4.3 Fractional deflection, D . 15

f

iii

10.5 Retest option . 15

10.6 Acceptance criteria for retest at lower stress level . 15

10.6.1 Average fractional deflection .16

10.6.2 Average creep-recovery .16

10.6.3 Average residual strength and stiffness .16

10.7 Interpretation of retests .16

11 Test report .16

Annex A (informative) Sampling for tests on duration of load and creep .18

Annex B (informative) Testing for sensitivity of duration of load and creep factors to

environment . 19

Bibliography .20

iv

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out through

ISO technical committees. Each member body interested in a subject for which a technical committee

has been established has the right to be represented on that committee. International organizations,

governmental and non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely

with the International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are described

in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the different types

of ISO document should be noted. This document was drafted in accordance with the editorial rules of the

ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use of (a)

patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed patent

rights in respect thereof. As of the date of publication of this document, ISO had not received notice of (a)

patent(s) which may be required to implement this document. However, implementers are cautioned that

this may not represent the latest information, which may be obtained from the patent database available at

www.iso.org/patents. ISO shall not be held responsible for identifying any or all such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and expressions

related to conformity assessment, as well as information about ISO's adherence to the World Trade

Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www.iso.org/iso/foreword.html.

ISO 24322 was prepared by Technical Committee ISO/TC 165, Timber structures.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

v

Introduction

This document sets out a framework to establish the duration of load and creep characteristics of timber

structural products from test results on a sample drawn from a clearly defined reference population.

It is the intention that the document can be used on any structural product including but not limited to:

sawn timber, glulam, structural composite lumber, I-beams, wood-based panels, poles and round timber.

Whenever it is used, the document alerts the user to the basic requirements for the determination of

consistent characteristic values. It permits the characterisation of duration of load and creep behaviour

based on testing of commercial sized specimens.

vi

International Standard ISO 24322:2024(en)

Timber structures — Methods of test for evaluation of long-

term performance — Part 1: Wood-based products in bending

1 Scope

This document gives methods of determination of duration of load and creep factors under bending actions

at ambient temperatures for a defined population of structural timber products such as solid timber, LVL,

OSB, plywood, particleboard, I-beams calculated from test values.

It presents methods for

a) determining the duration of load and creep factors for new timber products,

b) establishing whether a previously defined set of duration of load and creep factors can be applied to a

tested product, and

c) an optional method for establishment of sensitivity of duration of load and creep factors to changes in

environmental conditions.

NOTE 1 This document is intended to apply to wood-based products for which a duration of load factor or a creep

factor is used in design.

NOTE 2 The effect of elevated temperature on the duration of load factor and creep factor that is derived using

these methods for use with timber products can need additional consideration.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content constitutes

requirements of this document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

ISO 12122-1, Structural timber — Determination of Characteristic values — Part 1: Basic principles

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1

characteristic value

value of a property taken to represent the property of a designated population using a process of sampling

Note 1 to entry: The sampling is as determined in accordance with ISO 12122-1.

3.2

creep

time-dependent increase of deformation of the material under a sustained load

3.3

duration of load

cumulative total time during which a load acts on a member

3.4

linear creep

time-dependent increase of deformation, which is linearly related to the load level

Note 1 to entry: Linear creep usually applies with low load levels.

3.5

non-linear creep

time-dependent increase of deformation, which is non-linearly related to the load level

Note 1 to entry: Non-linear creep usually applies with high load levels.

3.6

service class

class assigned to a structure based on the climatic conditions

Note 1 to entry: The service class system is mainly aimed at assigning strength values and for calculating deformations

under defined environmental conditions.

Note 2 to entry: The climatic conditions are according to EN 1995-1-1.

4 Symbols (and abbreviated terms)

Symbols defined in the relevant ISO product or test standard shall be used.

In addition, the following apply:

C is the average creep recovery within 30 days of unloading

R

F is the total force applied to the specimen

D is the fractional deflection after 90 days

f

F is the short term maximum load applied in a single short-term test, where the term is used in

max

a long-term test, it refers to the maximum load applied in the matched short-term test.

N number of specimen failures at the end of 90 days

N critical order statistic used to estimate the lower 5 % non-parametric tolerance limit based

c

on the number of specimens under long-term load

SC1 is service class 1

SC2 is service class 2

SC3 is service class 3

S is the stress level of a loading (%)

L

t is time after loading in a long-term test

t is time to failure in a long-term test

f

X is the 5 % point estimate of the capacity of a short-term test group

0,05

a is a deflection reading in a creep test

a is a deflection reading before a load is applied in a creep test

a is a deflection reading 1 min after the application of a load in a creep test

a is a deflection reading time, t, after the application of a load in a creep test

t

c is the intercept on a plot of log t versus S to evaluate the duration of load factor

10 L

e is the intercept of an S versus t plot (= c/m)

L

f is the slope of an S versus t plot (= 1/m)

L

f is the minimum applied bending stress

b

h is the depth of the specimen

k is duration of load factor after time, t

d,t

l is the test span in a bending test

l is the span of the deflection measurement yoke used in shear-free creep tests

m is the slope on a plot of log t versus S to evaluate the duration of load factor

10 L

w is the deformation in millimetres

Δ is the initial deflection measured 1 min after loading

a

Δ is the deflection measured 30 days after loading

Δ is the deflection measured 60 days after loading

Δ is the deflection measured 90 days after loading

Δ is the total creep deflection accumulated over the long-term load test

c

Δ is initial deflection gauge reading prior to loading

i

Δ is deflection gauge reading just prior to unloading

e

Δ is the total creep deflection recovered within 30 days after unloading

r

Δ is deflection gauge reading within 30 days after unloading

b

5 Reference population

The population to which the duration of load and creep factors apply shall be fully described. The description

shall reference all of the attributes that may affect either the strength or stiffness and restrict the pieces to

the grouping for which the characteristic value is required. These include but are not be limited to:

a) reference to the relevant product standard or manufacturing specification;

b) species or species grouping;

c) designation of grade of the product;

d) size or size range of the product;

e) moisture condition of the product at the commencement of the tests;

f) detail of any adhesives used in the product including method and time of curing;

g) treatment of the product; or

h) period in which the product was manufactured.

The reference population shall be a grouping from which it is possible to draw a representative sample, and

on which it is possible to perform tests on specimens to characterize the required properties.

Where the reference population includes a range of products (e.g. different thicknesses), the population may

be characterised by testing the extremes of the range. Where the results of the extremes are significantly

different, some other tests may be required to determine the nature of the variation within the range.

6 Sampling

6.1 Sampling method

The sampling method shall aim to produce a sample that is representative of the variants in the defined

reference population that may affect the tested properties. The sampling shall minimise selection bias, and

shall be appropriate to the purpose of the tests and the nature of the reference population.

The matched short-term and long-term specimens shall be clearly identified and marked so that the same

matched face is loaded in both long-term and short-term tests.

The sampling method shall be documented. The documentation shall include details of the steps taken

to ensure that each of the variants listed in the population as described in Clause 5 is included in the

representative sample.

6.2 Matched groups within a sample

Matched test representative groups are required for comparative short- and long-term tests.

Matching is a technique that attempts to subdivide the initial sample population into two or more separate

groups that possess near identical distributional form and scale for bending properties. Matching specimens

for the purposes of testing for this document should be done with care, considering errors introduced by the

process and the characteristics of the material under test.

Where two matched groups are required, specimens shall be matched in pairs (each specimen shall be

matched to another specimen and shall be marked to enable the pair of matched specimens to be identified.

Where three matched groups are required, specimens shall be matched in threes (each specimen shall be

matched to two other specimens and shall be marked to enable the three matched specimens to be identified.

The method of obtaining matched samples shall be documented.

The following methods of matching groups of specimens may be used:

a) Side matching for products with sufficient widths (e.g. panels, SCL)

b) End matching for width limited products (e.g. I-joists)

c) MOE matching for width and length limited products (e.g. solid timber)

6.3 Sample size

The sample shall be large enough to cover variants of the product that impact on the tested properties, and

give statistical significance to the result.

Minimum sample sizes for short-term and long-duration tests are detailed in Clauses 9 and 10.

Materials with larger assumed or assigned population coefficient of variation, C , of the tested properties,

V

should have a larger sample size.

Some product standards can define a minimum number of tests that shall be undertaken to determine

characteristic values to be used with described products.

NOTE Annex A gives some guidance on selecting sample size.

For some populations, a number of different sub-groups within the population may need to be sampled (e.g.

different cross-sectional sizes). In these cases, the size of each of the sub-groups can have to be sufficient to

allow meaningful pooling of the results as indicated in Annex A.

Where characteristic values are to support limit states (or LRFD) design, the sample size should be appropriate

th

for the statistical method selected to determine the 5 percentile value strength (full distribution or tail-

fit). However, where the data is used to support a full reliability design method, the sample size should be

appropriate to also enable the full statistical distribution of the property to be defined.

7 Sample conditioning prior to testing

Test specimens shall be conditioned prior to testing. The conditioning shall target moisture content that is

compatible with the definition of the population and with the moisture conditions at the commencement of

the long-duration tests specified in Clauses 9 and 10.

The test laboratory shall normally be maintained at the controlled environment, but when other conditions

apply, they shall be reported.

8 Bending tests

8.1 Test method

8.1.1 General

Subject to the requirements of 8.1.2 to 8.1.4, the test data shall be derived in accordance with an appropriate

test method for the properties and for the reference population.

For tests on some product types, discrimination of results on the basis of failure mode can be required

to ensure that the results are compatible with objectives of the test program and the property being

determined.

Test methods involve many variables that may affect results including loading configuration and rates,

specimen positioning and measurement methods. The selection of these variables shall be appropriate to

the objectives of the testing and may require some adjustments specified in 8.2.

8.1.2 Load location on specimens

The load locations on the bending test specimens shall be at random locations.

There should be no attempt to bias the test location.

NOTE A test at mid position of each specimen can be regarded as random position tests.

8.1.3 Load configuration

Tests shall be conducted using load points at 1/3 of the span as shown in Figure 1. Lateral restraints shall be

used when necessary to maintain lateral stability.

Test specimens shall be cut to length as shown in Figure 1. The test spans shall be appropriate for the

materials tested:

a) for members loaded in major axis bending (edgewise) the span is generally in the range 18 to 25 times

the depth (h),

b) for members loaded in minor axis bending (flatwise) the span shall be less than 48 times the depth (h)

and the specimen width shall not be less than 300 mm.,

The same span load positions and deformation measurement point and system shall be used for both short-

term and long-term tests.

Key

a

l Test span.

Figure 1 — Four-point bending test setup with apparent bending deflection measurement

Plates over supports to shall be of sufficient size to reduce crushing under a load of 0,5 of the average

maximum load to less than 0,5 % of the central deflection. (This aims to reduce overestimation of the

deflection measurements due to crushing under the loads and over the reactions.)

NOTE The expected length of bearing to satisfy this condition will be close to the depth of the member under test.

During the first static test, the deformation over the supports can be measured to verify that the condition has been

met.

8.1.4 Deformation measurements

The deformation measurement device shall have a resolution of 0,025 mm or 0,5 % of the deformation

reading near the end of the linear response, whichever is greater.

8.1.5 Reporting failure results

The results of a bending test shall be reported as the maximum load attained by the specimen.

8.2 Short-term tests

8.2.1 Loading rate

The loading rate used in short-term tests shall target failure in approximately 1 min. Failure load shall not

be reached in less than 10 s nor more than 10 min.

NOTE A loading rate of 0,003 × nominal thickness in mm/s is suitable for the testing.

8.2.2 Reporting

The results of each test shall include:

a) maximum load at failure;

b) moisture content of specimen;

c) orientation of the specimen;

d) time to failure.

8.2.3 Reference loads

The results of the short-term load tests give the reference load used to calculate the load levels to be used in

the long-term tests:

— For long-term tests in accordance with Clause 9, the reference load is the average of the maximum loads

from all of the short-term test specimens.

— For long-term tests in accordance with Clause 10, the reference load is the lower 5 % of the maximum

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...