ISO 1920-2:2005

(Main)Testing of concrete — Part 2: Properties of fresh concrete

Testing of concrete — Part 2: Properties of fresh concrete

ISO 1920-2:2005 specifies procedures for testing fresh concrete. It specifies the following test methods: determination of consistence (slump test, Vebe test, degree of compactability, flow table test and for high fluidity concrete, the slump-flow test), determination of fresh density and determination of air content by the pressure gauge method and by the water column method.

Essais du béton — Partie 2: Caractéristiques du béton frais

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 1920-2

First edition

2005-04-15

Testing of concrete —

Part 2:

Properties of fresh concrete

Essais du béton —

Partie 2: Caractéristiques du béton frais

Reference number

ISO 1920-2:2005(E)

©

ISO 2005

---------------------- Page: 1 ----------------------

ISO 1920-2:2005(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2005

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2005 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 1920-2:2005(E)

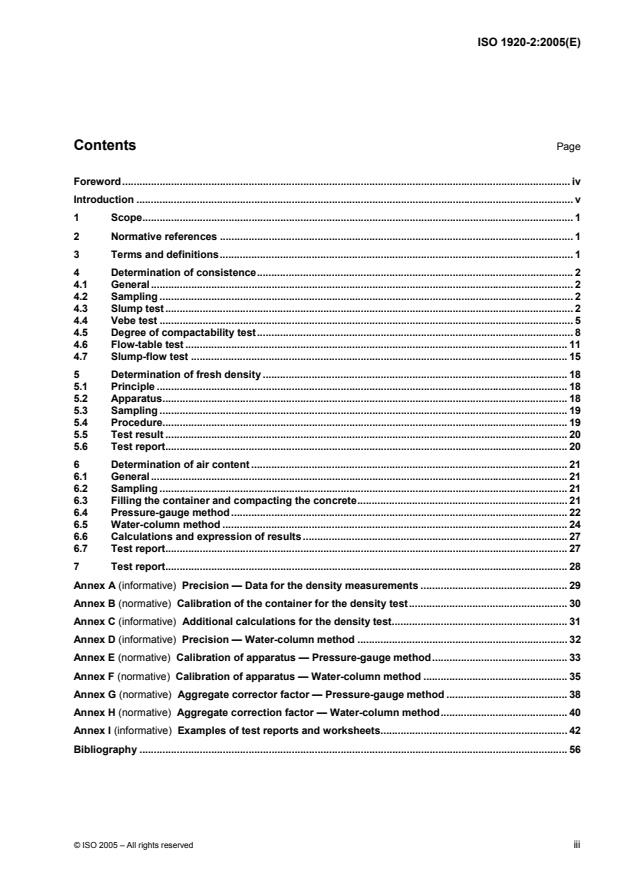

Contents Page

Foreword. iv

Introduction . v

1 Scope. 1

2 Normative references . 1

3 Terms and definitions. 1

4 Determination of consistence. 2

4.1 General. 2

4.2 Sampling . 2

4.3 Slump test. 2

4.4 Vebe test . 5

4.5 Degree of compactability test. 8

4.6 Flow-table test . 11

4.7 Slump-flow test . 15

5 Determination of fresh density . 18

5.1 Principle . 18

5.2 Apparatus. 18

5.3 Sampling . 19

5.4 Procedure. 19

5.5 Test result . 20

5.6 Test report. 20

6 Determination of air content . 21

6.1 General. 21

6.2 Sampling . 21

6.3 Filling the container and compacting the concrete. 21

6.4 Pressure-gauge method. 22

6.5 Water-column method . 24

6.6 Calculations and expression of results . 27

6.7 Test report. 27

7 Test report. 28

Annex A (informative) Precision — Data for the density measurements . 29

Annex B (normative) Calibration of the container for the density test. 30

Annex C (informative) Additional calculations for the density test. 31

Annex D (informative) Precision — Water-column method . 32

Annex E (normative) Calibration of apparatus — Pressure-gauge method. 33

Annex F (normative) Calibration of apparatus — Water-column method . 35

Annex G (normative) Aggregate corrector factor — Pressure-gauge method . 38

Annex H (normative) Aggregate correction factor — Water-column method. 40

Annex I (informative) Examples of test reports and worksheets. 42

Bibliography . 56

© ISO 2005 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 1920-2:2005(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 1920-2 was prepared by Technical Committee ISO/TC 71, Concrete, reinforced concrete and pre-

stressed concrete, Subcommittee SC 1, Test methods for concrete.

This first edition of ISO 1920-2 cancels and replaces the first edition of ISO 4109:1980, ISO 4110:1979,

ISO 4111:1979, ISO 4848:1980 and ISO 6276:1982, which have been technically revised.

ISO 1920 consists of the following parts, under the general title Testing of concrete:

Part 1: Sampling of fresh concrete

Part 2: Properties of fresh concrete

Part 3: Making and curing of test specimens

Part 4: Strength of hardened concrete

Part 5: Properties of hardened concrete other than strength

Part 6: Sampling, preparing and testing of concrete cores

Part 7: Non-destructive tests on hardened concrete

iv © ISO 2005 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 1920-2:2005(E)

Introduction

International Standards are widely adopted at the regional or national level and applied by manufacturers,

trade organizations, purchasers, consumers, testing laboratories, authorities and other interested parties.

Since these standards generally reflect the best experience of industry, researchers, consumers and

regulators worldwide and cover common needs in a variety of countries, they constitute one of the important

bases for the removal of technical barriers to trade. However, full adoption may not be practicable in all cases

for reasons such as regional or national security, protection of human health or safety, or protection of the

environment, or because of fundamental climatic, geographical or technological problems. As a consequence,

the corresponding technical deviations to ISO standards are permitted where required by national or regional

legislation or industry convention when adopting an International Standard.

Where such national deviations are required, it is important that they are clearly identified and the reasons for

the deviations stated. Depending of on the method of adoption of the International Standard, the deviations

will be noted in the national introduction, in the preface or foreword (for small numbers) or as a national annex

(for large numbers). See ISO/IEC Guide 21-1 for more information.

ISO/TC 71 has identified those items in this part of ISO 1920-2 that may be the subject of national or regional

deviations. The items are indicated in the text by the phrase “…except where the national annex to this part of

ISO 1920 requires…”.

© ISO 2005 – All rights reserved v

---------------------- Page: 5 ----------------------

INTERNATIONAL STANDARD ISO 1920-2:2005(E)

Testing of concrete —

Part 2:

Properties of fresh concrete

Caution — When cement is mixed with water, alkali is released. When sampling, prevent skin contact

with wet cement or concrete by wearing suitable protective clothing (gloves, footwear, safety glasses).

If wet cement or concrete enters the eye, immediately wash it out thoroughly with clean water and

seek medical treatment without delay. Wash wet concrete off the skin immediately.

Caution — The use of vibrating equipment, such as vibration tables, can cause damage to joints and

loss of sensation due to nerve damage. Moulds, density containers, etc. should be clamped to the

table and not held in position using one's hands while they are being vibrated.

1 Scope

This part of ISO 1920 specifies procedures for testing fresh concrete. It specifies the following test methods:

determination of consistence (slump test, Vebe test, degree of compactability, flow-table test and for

high-fluidity concrete, the slump-flow test), determination of fresh density and determination of air content by

the pressure-gauge method and by the water-column method.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 1101:1983, Technical drawing — Geometric tolerances — Tolerancing of form, orientation, location and

run-out — Generalities, definitions, symbols, indications on drawings

ISO 1920-1, Testing of concrete Part 1: Sampling of fresh concrete

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

fresh density

mass of a quantity of fully compacted fresh concrete divided by its volume

NOTE The fresh density is expressed in kilograms per cubic metre.

© ISO 2005 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO 1920-2:2005(E)

4 Determination of consistence

4.1 General

The consistence of the concrete is determined by one of the methods described below:

slump test (see 4.3);

Vebe test (see 4.4);

degree of compactability (see 4.5);

flow-table test. (see 4.6);

slump-flow test for high-fluidity concrete (see 4.7).

These methods are not applicable to foamed concrete, no-fines concrete or where the maximum aggregate

size exceeds 40 mm.

4.2 Sampling

Samples for the tests shall be obtained in accordance with ISO 1920-1. Each sample shall be remixed before

carrying out the tests.

4.3 Slump test

4.3.1 Principle

The fresh concrete is compacted into a mould in the shape of a frustum of a cone. When the cone is

withdrawn upwards, the distance the concrete has slumped provides a measure of the consistence of the

concrete.

The slump test is applicable to a range of consistence of concrete that corresponds to slumps of between

10 mm and 210 mm. Outside this range, the measurement of slump may be unsuitable and other methods of

determining the consistence should be considered.

If the slump continues to change over a period of 1 min after demoulding, this test is not suitable.

NOTE For high-fluidity concrete, the slump-flow test described in 4.7 is a more appropriate test.

4.3.2 Apparatus

Note the calibration requirements associated with each apparatus.

4.3.2.1 Mould, suitable of forming the test specimen, made of a metal not readily attacked by cement

paste and not thinner than 1,5 mm.

The mould may be made either with or without a seam. The interior of the mould shall be smooth and free

from projections such as protruding rivets and shall be free from dents. The mould shall be in the form of

hollow frustum of a cone and shall have the following internal dimensions:

diameter of base: 200 mm ± 2 mm;

diameter of top: 100 mm ± 2 mm;

height: 300 mm ± 2 mm.

2 © ISO 2005 – All rights reserved

---------------------- Page: 7 ----------------------

ISO 1920-2:2005(E)

The base and the top shall be open and parallel to each other and at right angles to the axis of the cone. The

mould shall be provided, on the upper portion, with two handles at two-thirds of the height, and at the bottom

with fixing clamps or foot pieces to hold it steady. A mould that can be clamped to the base is acceptable,

provided the clamping arrangement can be fully released without movement of the mould or interference with

the slumping concrete.

The mould shall be visually checked prior to each use to assure that it is clean and is not damaged or dented.

The cone shall be checked annually to ensure that its dimensions and conditions remain within tolerances.

4.3.2.2 Tamping rod, straight, made of steel, having a circular cross-section with a diameter of

16 mm ± 1 mm, 600 mm ± 5 mm in length, and with rounded ends. The rod may be extended with a handle of

plastic conduit, provided that the overall length does not exceed 1 000 mm.

The tamping rod shall be checked annually to ensure that its dimensions and conditions remain within

tolerances.

4.3.2.3 Funnel (optional), made of a non-absorbent material not readily attacked by cement paste.

The funnel shall consist of two co-axial conical frustums having a common diameter of 100 mm, the ends

being of greater diameter, one frustum to act as a filling funnel and the other as a collar to enable the funnel to

be located on the outer surface of the mould.

The funnel shall be checked annually to ensure that its dimensions and conditions remain within tolerances.

4.3.2.4 Rule, graduated from 0 mm to 300 mm, at intervals not exceeding 5 mm, with the zero point

being at the extreme end of the rule.

4.3.2.5 Base plate/surface, rigid, flat, non-absorbent and smooth plate or other surface on which to

place the mould.

4.3.2.6 Shovel, with a square blade.

4.3.2.7 Re-mixing tray, of rigid construction and made from a non-absorbent material not readily

attacked by cement paste.

It shall be of appropriate dimensions such that the concrete can be thoroughly remixed, using the square-

bladed shovel.

4.3.2.8 Scoop, with a width of approximately 100 mm.

4.3.2.9 Timer or other similar timing device, to allow time measurement to 1 s.

The watch shall be properly calibrated at the time of test.

4.3.2.10 Moist cloth.

4.3.3 Procedure

Dampen the mould and the base plate. Wipe any excessive water from the surfaces, using an absorbent

cloth. Place the mould on the horizontal base plate/surface. During filling, clamp or hold the mould firmly in

place by standing on the two foot pieces.

Immediately after obtaining the sample in accordance with 4.2, fill the mould in three layers, each

approximately one-third of the height of the mould when compacted. When adding the concrete, ensure that it

is distributed symmetrically around the mould. Tamp each layer with 25 strokes of the tamping rod. Uniformly

distribute the strokes over the cross-section of each layer. For the bottom layer, this will necessitate inclining

the rod slightly and positioning approximately half the strokes spirally toward the centre. Tamp the second

layer and the top layer each throughout its depth, so that the strokes just penetrate into the underlying layer.

In filling and tamping the top layer, heap the concrete above the mould before tamping is started.

© ISO 2005 – All rights reserved 3

---------------------- Page: 8 ----------------------

ISO 1920-2:2005(E)

If the tamping operation of the top layer results in subsidence of the concrete below the top edge of the mould,

add more concrete to keep an excess above the top of the mould at all times. Also ensure that the addition of

concrete to the top layer does not provide extra compaction of the concrete. After the top layer has been

tamped, scrape off the surface of the concrete level with the top of the mould by means of a sawing and rolling

motion of the tamping rod.

Remove spilled concrete from the base plate/surface. Remove the mould in 5 ± 2 s by a steady upward lift

with no lateral or torsional motion being imparted to the concrete. The lifting time may be shortened when

required by the national annex.

The entire operation from the start of the filling to the removal of the mould shall be carried out without

interruption and shall be completed within 180 s.

Immediately after removal of the mould, determine the slump, h, by measuring the difference between the

height of the mould and that of the highest point of the slumped test sample (see Figure 1), except where the

national annex to this part of ISO 1920 requires the measurement of the difference between the height of the

mould and the centre point or the average height of the slumped concrete. Measure to the nearest 10 mm,

except where the national annex to this part of ISO 1920 requires the measurement to the nearest 5 mm.

4.3.4 Test result

The test is valid only if it yields a true slump, this being a slump in which the concrete remains substantially

intact and symmetrical as shown in Figure 2 a). If a specimen shears, as shown in Figure 2 b), take another

sample and repeat the procedure.

Record the true slump, h, as shown in Figure 1 to the nearest 10 mm, or 5 mm when required by the national

annex.

If two consecutive tests show a portion of the concrete shearing off from the mass of the test specimen, report

the test as being invalid as the concrete lacks the necessary plasticity and cohesiveness for the slump test to

be suitable.

Figure 1 — Slump measurement

a) True slump b) Shear

Figure 2 — Forms of slump

4 © ISO 2005 – All rights reserved

---------------------- Page: 9 ----------------------

ISO 1920-2:2005(E)

4.3.5 Test report

In addition to the information required in Clause 7, the test report shall include the following:

a) the slump, if there is a true slump, measured to nearest 10 mm (or 5 mm when required by the national

annex), or;

b) a notation that the test gave a sheared slump.

4.4 Vebe test

4.4.1 Principle

The fresh concrete is compacted into a slump mould. The mould is lifted clear of the concrete and a

transparent disc is swung over the top of the concrete and carefully lowered until it comes in contact with the

concrete. The slump of the concrete is recorded. The vibrating table is started and the time taken for the lower

surface of the transparent disc to be fully in contact with concrete is measured.

If the Vebe time is less than 5 s or more than 30 s, the use of this test method to determine consistence may

be unsuitable and other methods should be considered for this purpose.

4.4.2 Apparatus

Note the calibration requirements associated with each apparatus.

4.4.2.1 Consistometer (Vebe meter), consisting of the following items and as shown in Figure 3:

a) container (Figure 3, item 1), cylindrical in shape, having an internal diameter of 240 mm ± 5 mm and a

height of 200 mm ± 2 mm, and made of a metal not readily attacked by cement paste. The thickness of

the wall shall be 3 mm and that of the base, 7,5 mm.

The container shall be watertight and of sufficient rigidity to retain its shape under rough usage. It shall be

fitted with handles and protected from corrosion. The container shall be provided with suitable foot pieces

to enable it to be securely clamped to the top of the vibrating table (Figure 3, item 7) by means of wing

nuts (Figure 3, item 8).

b) mould (Figure 3, item 2), as described in 4.3.2.1, except that the fixing clamps or foot pieces are not

required.

The mould shall be visually checked prior to each use to assure that it is clean and is not damaged or

dented.

c) disc (Figure 3, item 3), transparent, horizontal, attached to a rod (Figure 3, item 9) that slides vertically

through a guide sleeve (Figure 3, item 5) mounted on a swivel arm (Figure 3, item 13) and which can be

fixed in position by a screw (Figure 3, item 15).

The swivel arm also supports a funnel (Figure 3, item 4), the bottom of which coincides with the top of the

conical mould when the latter is positioned concentrically in the container. The swivel arm is located by a

holder (Figure 3, item 12) and can be fixed in position by a set-screw (Figure 3, item 6). When in the

appropriate position, the axes of the rod and of the funnel shall be coincident with the axis of the

container.

The transparent disc shall be 230 mm ± 2 mm in diameter and 10 mm ± 2 mm in thickness. A weight

(Figure 3, item 14) placed directly above the disc shall be provided such that the moving assembly

consisting of the rod, the disc and the weight has a mass of 2 750g ± 50 g. The rod shall be provided with

a scale graduated to at least 5 mm intervals to record the slump of the concrete.

© ISO 2005 – All rights reserved 5

---------------------- Page: 10 ----------------------

ISO 1920-2:2005(E)

d) vibrating table (Figure 3, item 7), 380 mm ± 3 mm in length and 260 mm ± 3 mm in width, supported on

four rubber shock absorbers.

A vibrator unit (Figure 3, item 11), carried on a base (Figure 3, item 10) resting on three rubber feet, shall

be securely fixed beneath it. The vibrator shall operate at a frequency of 55 Hz ± 5,5 Hz and the vertical

amplitude of the vibration of the table with the empty container on top of it shall be approximately

0,5 ± 0,02 mm.

The vibrating table shall be checked annually to ensure that the frequency and vertical amplitude remain

within tolerances.

All the elements of the vibration table shall be checked annually to ensure that their dimensions remain

within tolerances.

Dimensions in millimetres

Key

1 container 6 set-screw 11 vibrator unit

2 mould 7 vibrating table 12 holder

3 transparent disc 8 wing nuts 13 swivel arm

4 funnel 9 rod 14 weight

5 guide sleeve 10 base for vibrator 15 screw

Figure 3 — Consistometer (Vebe meter)

4.4.2.2 Tamping rod, straight, made of steel or other suitable metal, of circular cross-section, having a

diameter of 16 mm ± 1 mm, 600 mm ± 5 mm in length, and with rounded ends.

6 © ISO 2005 – All rights reserved

---------------------- Page: 11 ----------------------

ISO 1920-2:2005(E)

4.4.2.3 Stopwatch or clock, capable of recording time to an accuracy of 0,5 s.

4.4.2.4 Remixing container, of rigid construction, made from a non-absorbent material not readily

attacked by cement paste.

4.4.2.5 Scoop, with a width of approximately 100 mm.

4.4.2.6 Moist cloth.

4.4.3 Procedure

Place the Vebe meter (consistometer) on a rigid horizontal base free from extraneous vibration and shock.

Make sure that the container (Figure 3, item 1) is firmly fixed to the vibrating table (Figure 3, item 7) by means

of the wing nuts (Figure 3, item 8). Dampen the mould (Figure 3, item 2) and place it in the container. Swing

the funnel (Figure 3, item 4) into position over the mould and lower the funnel on the mould. Tighten the screw

(Figure 3, item 6) so that the mould cannot rise from the bottom of the container.

During the subsequent operations, ensure that the mould (Figure 3, item 2) does not rise or move until it is

raised and do not allow any concrete to fall into the container (Figure 3, item 1).

From the sample of concrete obtained in accordance with 4.2, immediately fill the mould in three layers, each

approximately one-third of the height of the mould when compacted. Tamp each layer with 25 strokes of the

tamping rod. Uniformly distribute the strokes over the cross-section of each layer. For the bottom layer, this

will necessitate inclining the rod slightly and positioning approximately half the strokes spirally toward the

centre. Tamp the second layer and the top layer each throughout its depth, so that the strokes just penetrate

into the underlying layer. In filling and tamping the top layer, heap the concrete above the mould before

tamping is started.

If necessary, add further concrete to maintain an excess above the top of the mould throughout the tamping

operation. After the top layer has been tamped, loosen the screw (Figure 3, item 6), raise and swing the funnel

(Figure 3, item 4) through 90° and tighten the screw (Figure 3, item 6).

Scrape off the concrete level with the top of the mould with a sawing and rolling motion of the tamping rod.

Remove the mould (Figure 3, item 2) from the concrete by raising it carefully in a vertical direction, using the

handles. The operation of raising the mould shall be performed in 5 s to 10 s by a steady upward lift with no

lateral or torsional motion being imparted to the concrete.

If the concrete shears [as shown in Figure 4 (b)], collapses [as shown in Figure 4 (c)], or slumps to the extent

that it touches the wall of the container (Figure 3, item 1), this information shall be recorded.

If the concrete has not slumped into contact with the wall of the container (Figure 3, item 1) and a true slump,

as shown in Figure 4 (a) has been obtained, the fact shall be recorded.

Swing the transparent disc (Figure 3, item 3) over the top of the concrete, tighten the screw (Figure 3, item 6),

loosen the screw (Figure 3, item 15) and very carefully lower the disc until it just comes in contact with the

concrete.

When the disc (Figure 3, item 3) just touches the highest point of the concrete without disturbing it, tighten the

screw (Figure 3, item 15). When there is a true slump, the value of the slump shall be read from the scale

(Figure 3, item 9) and the value recorded.

The screw (Figure 3, item 15) shall be loosened to allow the disc (Figure 3, item 3) to follow the concrete as it

settles under the subsequent vibration. Simultaneously, start the vibration of the table and the timer. Observe

through the transparent disc (Figure 3, item 3) how the concrete is being remoulded. As soon as the lower

surface of the disc is fully in contact with cement grout, stop the timer and switch off the vibrating table.

Record the time taken to the nearest second.

Complete the procedure within a period of 5 min from the start of filling.

© ISO 2005 – All rights reserved 7

---------------------- Page: 12 ----------------------

ISO 1920-2:2005(E)

The consistence of a concrete mix changes with time due to hydration of the cement and, possibly, loss of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.