ISO/TS 16878:2010

(Main)Direct reduced iron and hot briquetted iron — Determination of metallic iron — Iron(III) chloride titrimetric method

Direct reduced iron and hot briquetted iron — Determination of metallic iron — Iron(III) chloride titrimetric method

ISO/TS 16878:2010 specifies an iron(III) chloride titrimetric method for the determination of the mass fraction of metallic iron in hot briquetted iron (HBI) and direct reduced iron (DRI). This method cannot be used for referee purposes.

Minerais de fer préréduits et fer briqueté à chaud — Dosage du fer métallique — Méthode titrimétrique au chlorure de fer(III)

General Information

Relations

Standards Content (Sample)

TECHNICAL ISO/TS

SPECIFICATION 16878

First edition

2010-12-01

Direct reduced iron and hot briquetted

iron — Determination of metallic iron —

Iron(III) chloride titrimetric method

Minerais de fer préréduits et fer briqueté à chaud — Dosage du fer

métallique — Méthode titrimétrique au chlorure de fer(III)

Reference number

ISO/TS 16878:2010(E)

©

ISO 2010

---------------------- Page: 1 ----------------------

ISO/TS 16878:2010(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

COPYRIGHT PROTECTED DOCUMENT

© ISO 2010

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2010 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/TS 16878:2010(E)

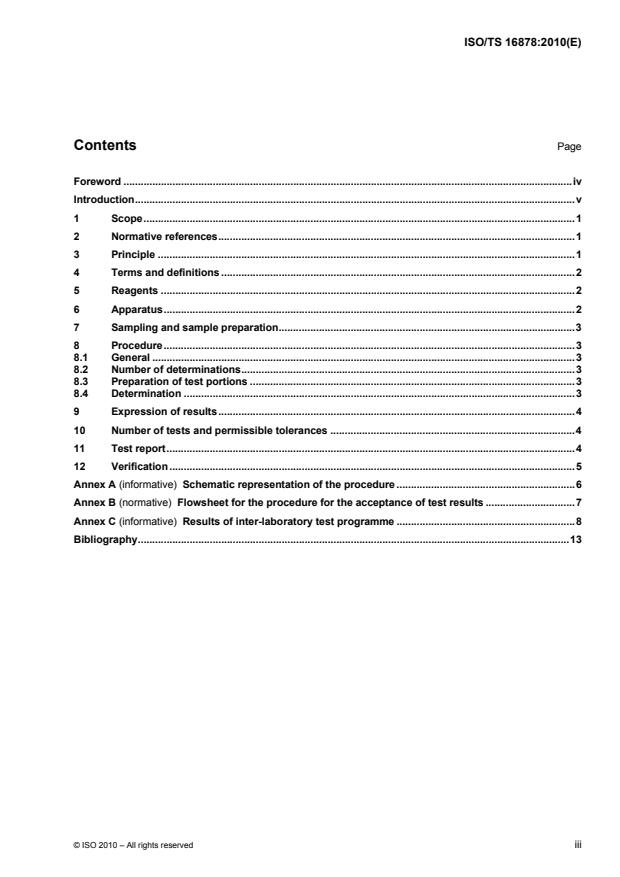

Contents Page

Foreword .iv

Introduction.v

1 Scope.1

2 Normative references.1

3 Principle.1

4 Terms and definitions .2

5 Reagents .2

6 Apparatus.2

7 Sampling and sample preparation.3

8 Procedure.3

8.1 General .3

8.2 Number of determinations.3

8.3 Preparation of test portions .3

8.4 Determination .3

9 Expression of results.4

10 Number of tests and permissible tolerances .4

11 Test report.4

12 Verification.5

Annex A (informative) Schematic representation of the procedure .6

Annex B (normative) Flowsheet for the procedure for the acceptance of test results .7

Annex C (informative) Results of inter-laboratory test programme .8

Bibliography.13

© ISO 2010 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO/TS 16878:2010(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

In other circumstances, particularly when there is an urgent market requirement for such documents, a

technical committee may decide to publish other types of normative document:

— an ISO Publicly Available Specification (ISO/PAS) represents an agreement between technical experts in

an ISO working group and is accepted for publication if it is approved by more than 50 % of the members

of the parent committee casting a vote;

— an ISO Technical Specification (ISO/TS) represents an agreement between the members of a technical

committee and is accepted for publication if it is approved by 2/3 of the members of the committee casting

a vote.

An ISO/PAS or ISO/TS is reviewed after three years in order to decide whether it will be confirmed for a

further three years, revised to become an International Standard, or withdrawn. If the ISO/PAS or ISO/TS is

confirmed, it is reviewed again after a further three years, at which time it must either be transformed into an

International Standard or be withdrawn.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO/TS 16878 was prepared by Technical Committee ISO/TC 102, Iron ore and direct reduced iron,

Subcommittee SC 2, Chemical analysis.

This document is issued as a Technical Specification (according to the ISO/IEC Directives, Part 1, 3.1.1.1) as

a “prospective standard for provisional application” in the field of direct reduced iron and hot briquetted iron

because there is an urgent need for guidance on how standards in this field should be used to meet an

identified need.

This document is not to be regarded as an “International Standard”. It is proposed for provisional application

so that information and experience of its use in practice may be gathered. Comments on the content of this

document should be sent to Technical Committee ISO/TC 102, Subcommittee SC 2.

A review of this Technical Specification will be carried out not later than 3 years after its publication with the

options of: extension for another 3 years; conversion into an International Standard; or withdrawal.

iv © ISO 2010 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/TS 16878:2010(E)

Introduction

The determination of metallic iron has in the past been carried out by a method using bromine-methanol

(ISO 5416). Due to the undesirability of using bromine, a method using iron(III) chloride has been developed.

This method is also more likely than ISO 5416 to determine all relevant metallic iron.

As insufficient participants took part in the inter-laboratory test programme conducted to derive precision

values for this method, the method cannot be used for referee purposes.

© ISO 2010 – All rights reserved v

---------------------- Page: 5 ----------------------

TECHNICAL SPECIFICATION ISO/TS 16878:2010(E)

Direct reduced iron and hot briquetted iron — Determination of

metallic iron — Iron(III) chloride titrimetric method

WARNING — This Technical Specification may involve hazardous materials, operations and

equipment. This Technical Specification does not purport to address all of the safety problems

associated with its use. It is the responsibility of the user of this Technical Specification to establish

appropriate safety and health practices and to determine the applicability of regulatory limitations

prior to use.

1 Scope

This Technical Specification specifies an iron(III) chloride titrimetric method for the determination of the mass

fraction of metallic iron in hot briquetted iron (HBI) and direct reduced iron (DRI).

This method cannot be used for referee purposes.

NOTE The term 'metallic iron' means those forms of iron not bonded to oxygen and not present as pyrite; it includes

iron present as cementite (Fe C).

3

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 385-1, Laboratory glassware — Burettes — Part 1: General requirements

ISO 648, Laboratory glassware — Single-volume pipettes

ISO 1042, Laboratory glassware — One-mark volumetric flasks

ISO 3696, Water for analytical laboratory use — Specification and test methods

ISO 11323, Iron ore and direct reduced iron — Vocabulary

ISO 10835, Direct reduced iron and hot briquetted iron — Sampling and sample preparation

3 Principle

0 +2

Iron present in the oxidation state Fe in the sample is oxidized to Fe by the action of FeCl according to the

3

reaction:

⎯⎯→

0 +3 +2

Fe + 2Fe 3Fe

+2

The Fe is titrated with a solution of potassium dichromate using sodium diphenylamine sulfonate as an

indicator.

© ISO 2010 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO/TS 16878:2010(E)

4 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 11323 apply.

5 Reagents

All reagents used in this procedure are to be prepared using analytical reagent-grade chemicals, unless

otherwise specified. The water used for preparing solutions shall comply with grade 2 of ISO 3696.

5.1 Iron(III) chloride hexahydrate

To a 2 000 ml container holding 600 ml of water, add 250 g of iron(III) chloride hexahydrate and agitate until it

is completely dissolved. Dilute with water to a volume of 1 l.

5.2 Sulfuric acid (1,84 g/ml).

5.3 Phosphoric acid (1,7 g/ml).

5.4 Sulfuric acid (15 %)/phosphoric acid (15 %) mixture.

To a 3 000 ml beaker add 1 000 ml of water. Place the beaker in a cool place and add slowly, while stirring,

300 ml of phosphoric acid (5.3). Allow to cool. Add slowly, while stirring, 300 ml of sulfuric acid (5.2) and allow

to cool. Dilute this mixture to 2 000 ml while stirring. Store the solution in a 2 000 ml high-density polyethylene

bottle or equivalent container.

5.5 Sodium diphenylamine sulfonate

Dissolve 0,2 g of sodium diphenylamine sulfonate in 100 ml of water.

5.6 Standard potassium dichromate solution (0,1 N)

Dry potassium dichromate at 150 °C for 3 h. Remove potassium dichromate from the oven and cool to room

temperature in a desiccator or over silica gel. Weigh 9,806 3 g of potassium dichromate [with a minimum

purity of 99,9 % (mass fraction)] into a weighing scoop and transfer qualitatively to a 2 000 ml volumetric flask.

Add 1 500 ml of water an

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.