ISO 2302:2005

(Main)Isobutene-isoprene rubber (IIR) — Evaluation procedures

Isobutene-isoprene rubber (IIR) — Evaluation procedures

ISO 2302:2005 specifies physical and chemical tests on raw rubbers; standardized materials, a standardized test formulation, equipment and processing methods for evaluating the vulcanization characteristics of all types of isobutene-isoprene rubber (IIR). The precision data in ISO 2302:2005 have been taken, with permission of ASTM, from ASTM D 3188-95, Standard Test Methods for Rubber -- Evaluation of IIR (Isobutene-Isoprene Rubber), copyright ASTM.

Caoutchouc isobutène-isoprène (IIR) — Méthodes d'évaluation

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 2302

Fifth edition

2005-01-15

Corrected version

2007-03-01

Isobutene-isoprene rubber (IIR) —

Evaluation procedures

Caoutchouc isobutène-isoprène (IIR) — Méthodes d'évaluation

Reference number

ISO 2302:2005(E)

©

ISO 2005

---------------------- Page: 1 ----------------------

ISO 2302:2005(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2005

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2005 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 2302:2005(E)

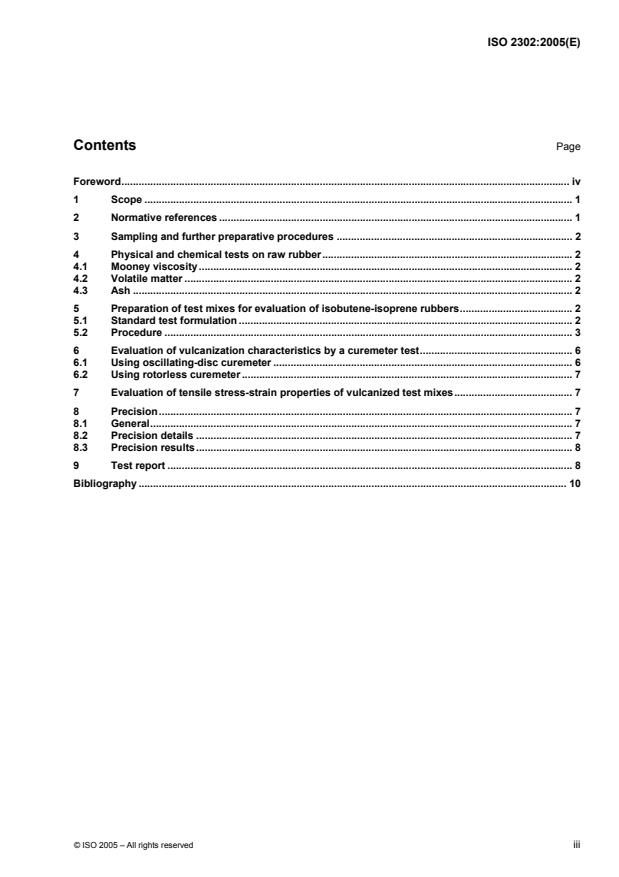

Contents Page

Foreword. iv

1 Scope . 1

2 Normative references . 1

3 Sampling and further preparative procedures . 2

4 Physical and chemical tests on raw rubber.2

4.1 Mooney viscosity. 2

4.2 Volatile matter . 2

4.3 Ash . 2

5 Preparation of test mixes for evaluation of isobutene-isoprene rubbers. 2

5.1 Standard test formulation . 2

5.2 Procedure . 3

6 Evaluation of vulcanization characteristics by a curemeter test. 6

6.1 Using oscillating-disc curemeter . 6

6.2 Using rotorless curemeter . 7

7 Evaluation of tensile stress-strain properties of vulcanized test mixes. 7

8 Precision. 7

8.1 General. 7

8.2 Precision details . 7

8.3 Precision results. 8

9 Test report . 8

Bibliography . 10

© ISO 2005 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 2302:2005(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 2302 was prepared by Technical Committee ISO/TC 45, Rubber and rubber products, Subcommittee

SC 3, Raw materials (including latex) for use in the rubber industry.

This fifth edition cancels and replaces the fourth edition (ISO 2302:1995), which has been technically revised.

The precision data in this edition have been taken, with permission of ASTM, from ASTM D 3188-95,

Standard Test Methods for Rubber — Evaluation of IIR (Isobutene-Isoprene Rubber), copyright ASTM.

In this corrected version of ISO 2302:2005, the reference in the Bibliography to ASTM D 3188-95 has been

transferred to Clause 1.

iv © ISO 2005 – All rights reserved

---------------------- Page: 4 ----------------------

INTERNATIONAL STANDARD ISO 2302:2005(E)

Isobutene-isoprene rubber (IIR) — Evaluation procedures

WARNING — Persons using this International Standard should be familiar with normal laboratory

practice. This standard does not purport to address all of the safety problems, if any, associated with

its use. It is the responsibility of the user to establish appropriate safety and health practices and to

ensure compliance with any national regulatory conditions.

1 Scope

This International Standard specifies

physical and chemical tests on raw rubbers;

standardized materials, a standardized test formulation, equipment and processing methods for

evaluating the vulcanization characteristics of all types of isobutene-isoprene rubber (IIR).

The precision data in this International Standard have been taken, with permission of ASTM, from

ASTM D 3188-95, Standard Test Methods for Rubber — Evaluation of IIR (Isobutene-Isoprene Rubber),

copyright ASTM.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 37, Rubber, vulcanized or thermoplastic — Determination of tensile stress-strain properties

ISO 247:1990, Rubber — Determination of ash

ISO 248, Rubbers, raw — Determination of volatile-matter content

ISO 289-1, Rubber, unvulcanized — Determinations using a shearing-disc viscometer — Part 1:

Determination of Mooney viscosity

ISO 1795:2000, Rubber, raw natural and raw synthetic — Sampling and further preparative procedures

ISO 2393:1994, Rubber test mixes — Preparation, mixing and vulcanization — Equipment and procedures

ISO 3417, Rubber — Measurement of vulcanization characteristics with the oscillating disc curemeter

ISO 6502, Rubber — Guide to the use of curemeters

ISO 23529, Rubber — General procedures for preparing and conditioning test pieces for physical test

methods

© ISO 2005 – All rights reserved 1

---------------------- Page: 5 ----------------------

ISO 2302:2005(E)

3 Sampling and further preparative procedures

A laboratory sample of approximately 1,5 kg shall be taken in accordance with the method described in

ISO 1795. Preparation of the sample shall be in accordance with ISO 1795.

4 Physical and chemical tests on raw rubber

4.1 Mooney viscosity

Prepare a test portion in accordance with the preferred procedure in ISO 1795, i.e. without milling, cutting the

test portion directly from the laboratory sample. The test portion shall be as free as possible from air and

pockets that may trap air against the rotor and die surface.

If agreed between the interested parties or if the condition of the sample (e.g. excessive porosity) makes

milling necessary, it shall be performed in accordance with ISO 1795:2000, Subclause 8.3.2.2, paragraphs 1

and 2.

Determine the Mooney viscosity in accordance with ISO 289-1 on this test portion, as ML(1+8) at 125 °C.

4.2 Volatile matter

Determine the volatile-matter content by the hot-mill method or by the oven method as specified in ISO 248.

4.3 Ash

Determine the ash in accordance with either method A or method B of ISO 247:1990.

5 Preparation of test mixes for evaluation of isobutene-isoprene rubbers

5.1 Standard test formulation

The standard test formulation is given in Table 1. The materials shall be national or international standard

reference materials (or as agreed by the interested parties).

Table 1 — Standard test formulation

Material Parts by mass

Isobutene-isoprene rubber (IIR) 100,00

a

1,00

Stearic acid

b

50,00

Industry reference black

a

3,00

Zinc oxide

a

1,75

Sulfur

a

1,00

Tetramethylthiuram disulfide(TMTD)

Total 156,75

a

Powder materials shall be used (standard curing ingredients used in the industry).

b

The current industry reference black shall be used.

2 © ISO 2005 – All rights reserved

---------------------- Page: 6 ----------------------

ISO 2302:2005(E)

5.2 Procedure

5.2.1 Equipment and procedure

The equipment and procedure for the preparation, mixing and vulcanization shall be in accordance with

ISO 2393:1994, Clauses 6, 7, 8 and 9.

5.2.2 Mixing procedures

5.2.2.1 General

Three alternative mixing procedures are specified:

Method A: mixing with a laboratory mill;

Method B: mixing with a miniature internal mixer (MIM);

Method C: mixing with an internal mixer.

NOTE These procedures may not give identical results.

5.2.2.2 Method A — Mixing with a laboratory mill

The standard laboratory mill-batch mass, in grams, shall be based on four times the formulation mass (i.e.

4 × 156,75 g = 627 g). The surface temperature of the rolls shall be maintained at 45 °C ± 5 °C throughout the

mixing.

A good rolling bank at the nip of the rolls shall be maintained during mixing. If this is not obtained with the nip

settings specified hereunder, small adjustments to the mill openings may be necessary.

A mill batch mass based on two times the formulation mass may also be used, but, in this case, more

adjustments to the mill openings will be necessary.

Duration Cumulative

time

(min) (min)

a) Band the rubber with the mill opening set at 0,65 mm. 1,0 1,0

b) Mix the carbon black and the stearic acid and add evenly across the mill rolls10,0 11,0

at a uniform rate. Increase the mill opening at intervals to maintain a constant

rolling bank. When all the carbon black has been incorporated, make a 3/4 cut

from each side.

Do not cut the batch while free carbon black is evident in the bank or on the

milling surface. Be certain to return to the batch any materials that drop

through the mill.

c) Add the zinc oxide, the sulfur and the TMTD. 3,0 14,0

d) Make three alternating 3/4 cuts from each side. 2,0 16,0

e) Cut the batch from the mill. Set the mill opening to 0,8 mm and pass the rolled 2,0 18,0

batch endwise through the mill six times.

f) Sheet the batch to approximately 6 mm and check-weigh the batch (see ISO 2393). If the mass of the

+ 0,5

batch differs from the theoretical value b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.