ISO 13083:2015

(Main)Surface chemical analysis — Scanning probe microscopy — Standards on the definition and calibration of spatial resolution of electrical scanning probe microscopes (ESPMs) such as SSRM and SCM for 2D-dopant imaging and other purposes

Surface chemical analysis — Scanning probe microscopy — Standards on the definition and calibration of spatial resolution of electrical scanning probe microscopes (ESPMs) such as SSRM and SCM for 2D-dopant imaging and other purposes

ISO 13083:2015 describes a method for measuring the spatial (lateral) resolution of scanning capacitance microscopes (SCMs) or scanning spreading resistance microscopes (SSRMs), which are widely used in imaging the distribution of carriers and other electrical properties in semiconductor devices. The method involves the use of a sharp-edged artefact.

Analyse chimique des surfaces - Microscopie à sonde à balayage - Normes sur la définition et l'étalonnage de la résolution spatiale des microscopes électriques à sonde à balayage (ESPMs) comme SSRM et SCM pour l'imagerie 2D-dopant et d'autres fins

General Information

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 13083

First edition

2015-08-15

Surface chemical analysis — Scanning

probe microscopy — Standards on the

definition and calibration of spatial

resolution of electrical scanning probe

microscopes (ESPMs) such as SSRM

and SCM for 2D-dopant imaging and

other purposes

Analyse chimique des surfaces - Microscopie à sonde à balayage -

Normes sur la définition et l’étalonnage de la résolution spatiale des

microscopes électriques à sonde à balayage (ESPMs) comme SSRM et

SCM pour l’imagerie 2D-dopant et d’autres fins

Reference number

©

ISO 2015

© ISO 2015, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2015 – All rights reserved

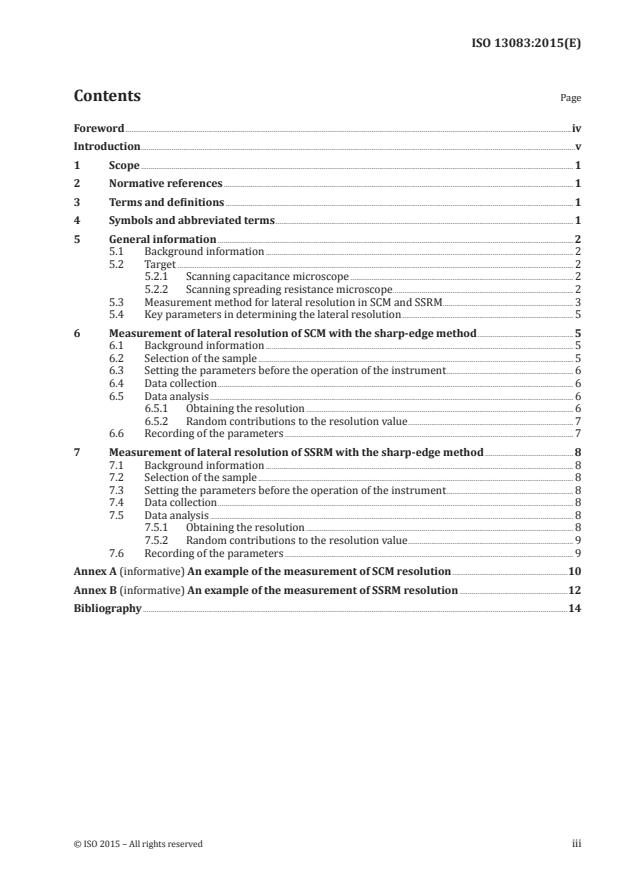

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Symbols and abbreviated terms . 1

5 General information . 2

5.1 Background information . 2

5.2 Target . 2

5.2.1 Scanning capacitance microscope . 2

5.2.2 Scanning spreading resistance microscope . 2

5.3 Measurement method for lateral resolution in SCM and SSRM . 3

5.4 Key parameters in determining the lateral resolution . 5

6 Measurement of lateral resolution of SCM with the sharp-edge method .5

6.1 Background information . 5

6.2 Selection of the sample . 5

6.3 Setting the parameters before the operation of the instrument . 6

6.4 Data collection . 6

6.5 Data analysis . 6

6.5.1 Obtaining the resolution . 6

6.5.2 Random contributions to the resolution value . 7

6.6 Recording of the parameters . 7

7 Measurement of lateral resolution of SSRM with the sharp-edge method .8

7.1 Background information . 8

7.2 Selection of the sample . 8

7.3 Setting the parameters before the operation of the instrument . 8

7.4 Data collection . 8

7.5 Data analysis . 8

7.5.1 Obtaining the resolution . 8

7.5.2 Random contributions to the resolution value . 9

7.6 Recording of the parameters . 9

Annex A (informative) An example of the measurement of SCM resolution .10

Annex B (informative) An example of the measurement of SSRM resolution .12

Bibliography .14

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical

Barriers to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 201, Surface chemical analysis, Subcommittee

SC 9, Scanning probe microscopy.

iv © ISO 2015 – All rights reserved

Introduction

Electrical scanning probe microscopy (ESPM) is a branch of scanning probe microscopy (SPM) with

the capability of electrical imaging at nanometre spatial resolution. ESPM includes electrostatic force

microscopy (EFM), scanning capacitance microscopy (SCM), scanning spreading resistance microscopy

(SSRM), etc. Because ESPM can observe electrical or electronic properties with molecule-scale

resolution, it is applied to many fields such as semiconductors, displays, etc. However, there has been no

standard measurement method for the spatial resolution.

In this International Standard, standardized procedures to determine the spatial (lateral) resolution

of SSRM and SCM, which are widely used to image the distribution of carrier and other electrical

properties in semiconductor devices, are provided with the use of suitable reference materials. This

International Standard uses the sharp-edge method to measure the lateral resolution of ESPM in a

similar manner to that already used in measuring the resolution in micro-beam spectroscopy and in

depth-profiling measurements with Auger electron spectroscopy and X-ray photoelectron spectroscopy

(refer to ISO 18516).

INTERNATIONAL STANDARD ISO 13083:2015(E)

Surface chemical analysis — Scanning probe microscopy

— Standards on the definition and calibration of spatial

resolution of electrical scanning probe microscopes

(ESPMs) such as SSRM and SCM for 2D-dopant imaging and

other purposes

1 Scope

This International Standard describes a method for measuring the spatial (lateral) resolution of

scanning capacitance microscopes (SCMs) or scanning spreading resistance microscopes (SSRMs),

which are widely used in imaging the distribution of carriers and other electrical properties in

semiconductor devices. The method involves the use of a sharp-edged artefact.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 18115-2, Surface chemical analysis – Vocabulary – Part 2: Terms used in scanning-probe microscopy

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 18115-2 and the following apply.

3.1

electrical scanning probe microscopy

ESPM

SPM mode in which a conductive tip is used to measure electrical properties such as capacitance,

resistance, electrical field, etc.

3.2

contact mode

mode of scanning the probe tip over the sample surface, adjusting the relative heights of the probe and

sample, in which there is always a repulsive force between the probe and the sample

Note 1 to entry: This mode can be, for example, either the constant-height or constant-force mode.

[SOURCE: ISO 18115-2:2013, 6.35]

4 Symbols and abbreviated terms

AC alternating current

DC direct current

ESPM electrical scanning probe microscopy

SPM scanning probe microscopy

AFM atomic force microscopy

MIS metal-insulator-semiconductor

MOS metal-oxide-semiconductor

SCM scanning capacitance microscopy

SIMS secondary ion mass spectroscopy

S/N signal to noise ratio

SSRM scanning spreading resistance microscopy

TEM transmission electron microscope

2D two dimension

Δx spatial resolution of ESPM

5 General information

5.1 Background information

ESPM is a branch of scanning probe microscope that can be used to image an electrical or electronic

property of a sample surface using an electrically conducting probe. Since this conductive probe is

scanned over the sample surface in the contact mode, its lateral resolution is strongly related to the

size and shape of the probe apex. Currently, this can be as small as a few nanometres, enabling sub-10

nanometre spatial resolution to be achieved. Such a high resolution, shown in ESPM images, allows the

investigation of the two-dimensional distribution of carriers in nanoscale semiconductor devices.

5.2 Target

There are a number of types of ESPM categorized by the methods of electrical characterization. Among

these ESPMs, this International Standard is for SCM and SSRM.

5.2.1 Scanning capacitance microscope

Scanning capacitance microscopy (SCM) is a modification of scanning probe microscopy in which a

conductive probe is in contact with the surface of a sample, with an applied AC bias, and scanned across

it. SCM characterizes the change in electrostatic capacitance between the sample and the probe on

the surface of the sample. SCM uses an ultra-sharp conducting probe made from etched silicon (often

coated with Pt/Ir or Co/Cr alloy) to form a metal-insulator-semiconductor (MIS/MOS) capacitor with a

semiconductor sample if a native oxide exists on the sample. When the conducting probe is in contact

to the surface under an AC bias, generated capacitance variations on the surface can be detected using

a GHz resonant capacitance sensor. The probe is then scanned acr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.