ASTM F778-88(2001)

(Test Method)Standard Methods for Gas Flow Resistance Testing of Filtration Media

Standard Methods for Gas Flow Resistance Testing of Filtration Media

SCOPE

1.1 The flow resistance of any fabricated filter device will depend on the flow resistance of the media used.

1.2 This standard offers procedures sufficient to determine the gas flow characteristics of flat specimens of media used in the filtration process. The methods are extended to include pleated specimens and bulk media as well.

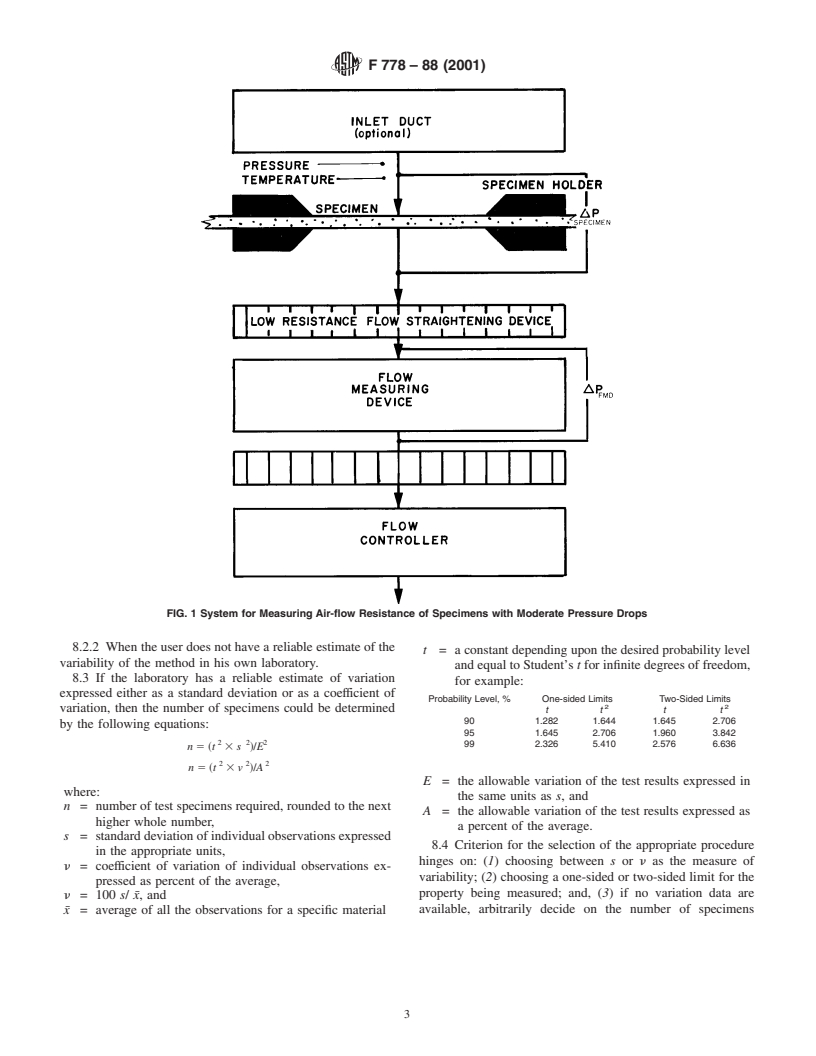

1.3 In all cases, flow rates through the specimen are determined in accordance with procedures outlined in ASME "Fluid Meters." The test fluid is air.

1.4 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 778 – 88 (Reapproved 2001)

Standard Methods for

1

Gas Flow Resistance Testing of Filtration Media

This standard is issued under the fixed designation F 778; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope with a Specified Tolerable Error, the Average for a Char-

acteristic of a Lot or Process

1.1 The flow resistance of any fabricated filter device will

2.2 ASME Document:

depend on the flow resistance of the media used.

3

“Fluid Meters,” Sixth Edition, 1971

1.2 This standard offers procedures sufficient to determine

the gas flow characteristics of flat specimens of media used in

3. Terminology

the filtration process. The methods are extended to include

3.1 Definitions of Terms Specific to This Standard:

pleated specimens and bulk media as well.

3.1.1 air density, r—mass per unit volume.

1.3 In all cases, flow rates through the specimen are

3.1.2 air flow resistance, DP—pressure drop or pressure

determined in accordance with procedures outlined in ASME

differential across a test specimen of filter medium at a

“Fluid Meters.” The test fluid is air.

specified air face velocity or mass flow rate.

1.4 This standard may involve hazardous materials, opera-

3.1.3 constituted bulk media—those types of filter media

tions, and equipment. This standard does not purport to

formed from bonded aggregates or discrete solid materials.

address all of the safety problems associated with its use. It is

3.1.4 edge leakage—air flow that passes into or bypasses

the responsibility of the user of this standard to establish

the test specimen in geometric planes other than those intended

appropriate safety and health practices and determine the

for resistance measurement.

applicability of regulatory limitations prior to use.

3.1.5 face area, A— cross-sectional area perpendicular to

2. Referenced Documents air flow at the specimen test boundary.

2

2.1 ASTM Standards:

NOTE 1—If specimen inlet and exit face areas are different, “Inlet” or

D 461 Test Methods for Testing Felt “Exit” shall be used to describe the face area in question.

D 585 Practice for Sampling andAccepting a Single Lot of

3.1.6 face velocity, V— volumetric flow rate per unit face

Paper, Paperboard, Fiberboard, and Related Product

area.

D 645 Test for Thickness of Paper and Paperboard

NOTE 2—If specimen inlet and exit face areas are different, “Inlet” or

D 685 Method for Conditioning Paper and Paper Products

“Exit” shall be used to describe the face velocity in question.

for Testing

D 737 Test Method for Air Permeability of Textile Fabrics 3.1.7 mass rate of flow, m˙—mass transport of air per unit

time through the test specimen.

D 1776 Practice for Conditioning Textiles For Testing

D 1777 Method for Measuring Thickness of Textile Mate- 3.1.8 medium area, A —total area of filtration media ex-

m

posed to air flow.

rials

D 2905 Practice for Statements on Number of Specimens

NOTE 3—Medium area may be greater than face area due to pleating,

for Textiles

folding, etc.

D 3574 TestMethodsforFlexibleCellularMaterials—Slab,

3.1.9 medium velocity, V —volumetric flow rate per unit

m

Bonded, and Molded Urethane Foams

medium area.

E 105 Practice for Probability Sampling of Materials

3.1.10 normalized resistance, sDP—product of sigma and

E 122 Practice for Calculating Sample Size to Estimate,

measured air flow resistance.

3.1.11 sigma, s—ratio of air density existing at test condi-

tions to standard air density. Density at standard conditions is

1 3 3

These methods are under the jurisdiction of ASTM Committee D22 on Air

taken to be 0.075 lb/ft (1.201 kg/m ).

Quality and are the direct responsibility of Subcommittee D22.03 on Ambient

3.1.12 unconstituted bulk media—those types of filter me-

Atmospheres and Source Emissions.

dia formed from unbonded aggregates or discrete solid mate-

Current edition approved March 10, 1988. Published March 1988. Originally

published as F 788 – 82. Last previous edition F 788 – 82. rials.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from American Society of Mechanical Engineers, 345 E. 47th St.,

the ASTM website. New York, NY 10017.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F 778 – 88 (2001)

3.1.13 volumetric rate of flow, Q—air volume transport per multiple samples is adequate. However, for design, develop-

unit time through

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.