ASTM A469-94a(1999)

(Specification)Standard Specification for Vacuum-Treated Steel Forgings for Generator Rotors

Standard Specification for Vacuum-Treated Steel Forgings for Generator Rotors

SCOPE

1.1 This specification covers vacuum-treated basic electric steel forgings for generator rotors.

1.2 The values stated in inch-pound units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 469 – 94a (Reapproved 1999)

Standard Specification for

Vacuum-Treated Steel Forgings for Generator Rotors

This standard is issued under the fixed designation A 469; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope tion, production analysis variations, and additional

supplementary requirements.

1.1 This specification covers vacuum-treated basic electric

3.3 If the requirements of this specification are in conflict

steel forgings for generator rotors.

with the requirements of Specification A 788, the requirements

1.2 The values stated in inch-pound units are to be regarded

of this specification shall prevail.

as the standard.

4. Materials and Manufacture

2. Referenced Documents

4.1 The vacuum degassing requirements of Specification

2.1 ASTM Standards:

A 788 are mandatory. In addition to these requirements,

A 275/A 275M Test Method for Magnetic Particle Exami-

hydrogen testing per Supplementary Requirement S4 is man-

nation of Steel Forgings

datory.

A 341 Test Method for Direct-Current Magnetic Properties

4.1.1 When the ladle degassing process is used, the evacu-

of Materials Using D-C Permeameters and the Ballistic

ation system shall be capable of reducing the system vacuum

Test Methods

pressure to a low level (usually less then 1000 μm). The molten

A 370 Test Methods and Definitions for Mechanical Testing

metal shall be adequately stirred for a sufficient length of time

of Steel Products

to maximize exposure to the evacuated atmosphere. When this

A 418 Test Method for Ultrasonic Examination of Turbine

process is used, hydrogen testing per Supplementary Require-

and Generator Steel Rotor Forgings

ment S4 is mandatory.

A 773 Test Method for D-C Magnetic Properties of Mate-

4.1.2 Other methods of degassing may be used if the

rials Using Ring and Permeameter Procedures with D-C

supplier can demonstrate their adequacy to the satisfaction of

Electronic Hysteresigraphs

the purchaser. When other processes are used, hydrogen testing

A 788 Specification for Steel Forgings, General Require-

2 per Supplementary Requirement S4 is mandatory.

ments

4.2 Heat Treatment:

3. Ordering Information and General Requirements 4.2.1 If possible, forgings should be heat treated in the

vertical position. Supplementary Requirement S3 makes this

3.1 In addition to the ordering information required by

mandatory, if activated in the ordering information.

Specification A 788, the purchaser shall include with the

4.2.2 The heat treatment for mechanical properties shall

inquiry and order, a dimensioned drawing showing the me-

consist of quenching and tempering, but normalizing and

chanical test specimen locations, and details of magnetic

tempering is permissible with prior purchaser approval. Also,

permeability tests, if required.

with prior purchaser approval, the post rough machining stress

3.2 Material supplied to this specification shall conform to

relief in 4.2.3 may be omitted when double tempering is used,

the requirements of Specification A 788, which outlines addi-

instead of a single temper, to complete this heat treatment

tional ordering information, manufacturing requirements, test-

cycle.

ing and retesting methods and procedures, marking, certifica-

4.2.3 After heat treatment and the subsequent rough ma-

chining, the forging shall be stress relieved at a minimum

This specification is under the jurisdiction of ASTM Committee A-1 on Steel,

temperature of 1050°F (566°C), unless otherwise specified by

Stainless Steel, and Related Alloys, and is the direct responsibility of Subcommittee

the purchaser.

A01.06 on Steel Forgings and Billets.

4.3 Machining:

Current edition approved Aug. 15, 1994. Published October 1994. Originally

published as A 469 – 62 T. Last previous edition A 469 – 94. 4.3.1 Boring—The manufacturer may bore the forging at

Annual Book of ASTM Standards, Vol 01.05.

any time prior to stress-relief anneal. (See Supplementary

Annual Book of ASTM Standards, Vol 03.04.

Requirement S1).

Annual Book of ASTM Standards, Vol 01.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 469 – 94a (1999)

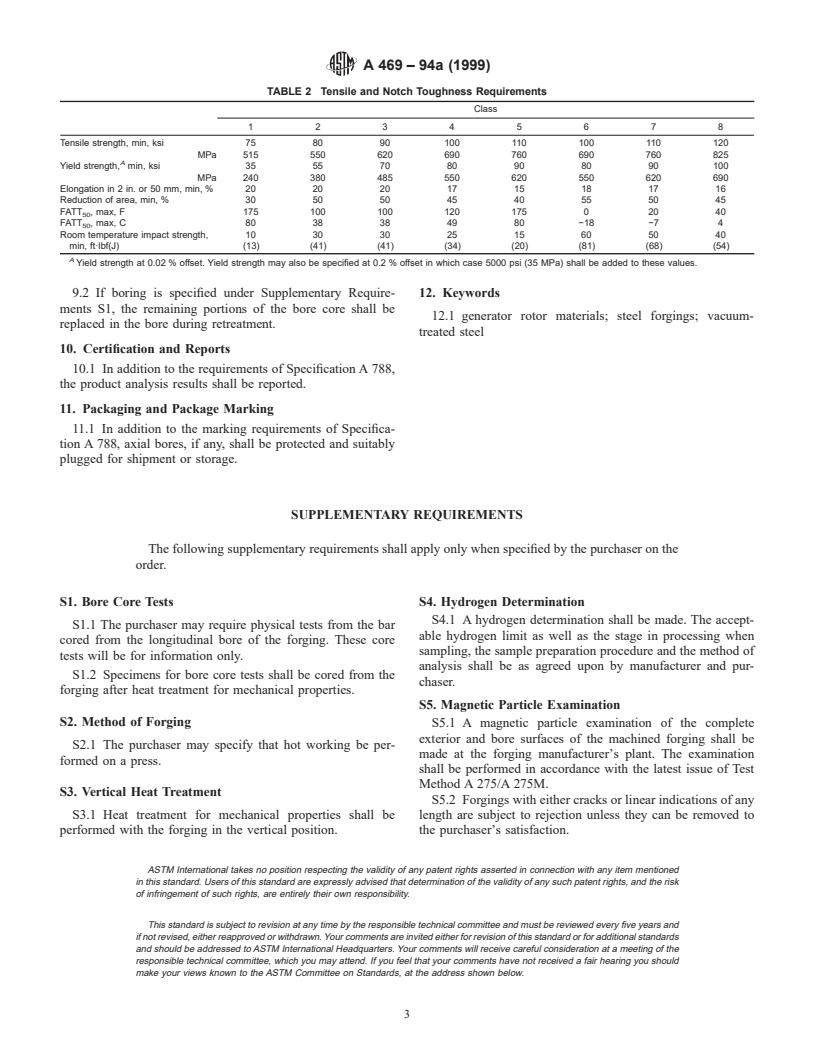

5. Chemical Composition specimens shall conform to the Charpy V-notch specimen

configuration, as shown in the latest issue of Test Methods and

5.1 Heat Analysis—The heat analysis obtained from sam-

Definitions A 370.

pling in accordance with Specification A 788 shall comply with

Table 1.

8. Nondestructive Test Requirements

5.2 Product Analysis—The manufacturer shall use the prod-

uct analysis provision of Specification A 788 to obtain a

8.1 General Requirements:

product analysis from a forging representing each heat or

8.1.1 The forgings shall be free of cracks, seams, laps,

multiple heat.

shrinkage, and other injurious imperfections.

8.1.2 The purchaser may request such tests and inspection

6. Magnetic Properties

methods including ultrasonic, magnetic particle, or etch tests,

6.1 When specified in the ordering information, a perme-

as are necessary to ensure compliance with this requirement.

ability test shall be performed in accordance with the latest

8.2 Ultrasonic Inspection:

issue of Test Method A 341 or Test Method A 773.

8.2.1 An ultrasonic inspection shall be made at the forging

manufacturer’s plant on the machined forgings. In making the

7. Mechanical Properties

ultrasonic inspection, reference shall be made to the latest issue

7.1 Tension Test:

of Test Method A 418.

7.1.1 The steel shall conform to the requirements of Table 2.

8.2.2 Forgings having recordable ultrasonic indications

7.1.2 The number of locations of tension test specimens

shall be referred to the purchaser and evaluated on the basis of

shall be as specified on the forging drawings furnished by the

nature, frequency, and locations of indications both traveling

purchaser.

and stationary. If the ultrasonic indications are considered

7.1.3 Tests for acceptance shall be made after heat treatment

objectionable, it shall be determined by conventional or mutu-

of the forging for mechanical properties. The purchaser may

ally acceptable inspection procedures whether the forging will

require check tests after completion of all heating cycles

be rejected.

including stress relieving in accordance with 4.2.3.

8.2.3 Forgings shall be ultrasonically tested prior to removal

7.1.4 Testing shal

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.