ASTM D352-97(2003)

(Test Method)Standard Test Methods for Pasted Mica Used in Electrical Insulation

Standard Test Methods for Pasted Mica Used in Electrical Insulation

SIGNIFICANCE AND USE

This test determines the compressive creep under laboratory conditions or under conditions that may be encountered during manufacture of electrical equipment. It has special significance if the material to be tested is applied as commutator segment insulation. It serves as a measure under specified conditions of the ability of the material to resist deformation while under compressive load, during exposure to elevated temperature for a specified time. This test is suitable for acceptance tests and for manufacturing control.

SCOPE

1.1 These test methods cover the testing of bonded mica splittings and bonded mica paper to be used for commutator insulation, hot molding, heater plates, and other similar insulating purposes.

1.2 These test methods appear in the following sections:

Test SectionsCompressive Creep4-10 Dielectric Strength38-41 Mica or Binder Content19Molding Test31-36 Organic Binder20-24 Resistivity42-46 Silicone Binder25-.30 Stability Under Heat and Pressure 11-18

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See 40.1 and 45.1 for specific hazard statements.

1.4 The values stated in inch-pound units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D352–97 (Reapproved 2003)

Standard Test Methods for

Pasted Mica Used in Electrical Insulation

This standard is issued under the fixed designation D352; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.1 binder content, n, (of pasted mica)—the percent by

weight of binder relative to the original weight of a specimen

1.1 These test methods cover the testing of bonded mica

as determined by procedures specified herein.

splittings and bonded mica paper to be used for commutator

3.2.1.1 Discussion—Binder content includes any residual

insulation, hot molding, heater plates, and other similar insu-

solvent.Pastedmicamaterialsnotfullycured(suchasmolding

lating purposes.

and flexible plates) may contain appreciable quantities of

1.2 These test methods appear in the following sections:

solvent in the binder. This solvent is usually later removed

Test Sections

when the material is cured in the manufacture of electrical

Compressive Creep 4-10

equipment. In such cases, the binder content after cure is less

Dielectric Strength 38-41

Mica or Binder Content 19 (by the amount of solvent removed) than would be determined

Molding Test 31-36

by this method. To determine the binder content after cure of

Organic Binder 20-24

materialsthatarenotfullycured,butsubsequentlywillbe,itis

Resistivity 42-46

necessary, before initially weighing the specimen, to heat the

Silicone Binder 25-30

specimenforatimeandatatemperaturethatdependsuponthe

Stability Under Heat and Pressure 11-18

material from which the specimen is prepared.

1.3 This standard does not purport to address all of the

3.2.2 compressive creep, n—the change in thickness of a

safety concerns, if any, associated with its use. It is the

bondedmicaceousmaterialresultingfromexposuretoelevated

responsibility of the user of this standard to establish appro-

temperature for a specified time while a specimen is under a

priate safety and health practices and determine the applica-

specified compressive load.

bility of regulatory limitations prior to use. See 40.1 and 45.1

3.2.3 mica content, n, (of pasted mica)—the percent by

for specific hazard statements.

weight of mica relative to the original weight equal to 100%

1.4 The values stated in inch-pound units are to be regarded

minusthebindercontentasdeterminedbyproceduresspecified

as the standard.

herein.

2. Referenced Documents

COMPRESSIVE CREEP

2.1 ASTM Standards:

4. Significance and Use

D149 Test Method for Dielectric Breakdown Voltage and

Dielectric Strength of Solid Electrical Insulating Materials 4.1 This test determines the compressive creep under labo-

at Commercial Power Frequencies ratory conditions or under conditions that may be encountered

D257 Test Methods for DC Resistance or Conductance of during manufacture of electrical equipment. It has special

Insulating Materials significance if the material to be tested is applied as commu-

D1711 Terminology Relating to Electrical Insulation tatorsegmentinsulation.Itservesasameasureunderspecified

conditions of the ability of the material to resist deformation

3. Terminology

while under compressive load, during exposure to elevated

3.1 Definitions: temperature for a specified time. This test is suitable for

3.1.1 For definitions of terms relating to electrical insula-

acceptance tests and for manufacturing control.

tion, refer to Terminology D1711.

5. Apparatus

3.2 Definitions of Terms Specific to This Standard:

5.1 Hydraulic Press—Ahydraulicpresshavingtemperature

controlled, electrically heated platens, or a press with other

These test methods are under the jurisdiction of ASTM Committee D09 on

provisions for heating the specimen and controlling the tem-

Electrical and Electronic Insulating Materials and are the direct responsibility of

perature. The platens shall be at least 4 by 4 in. (102 by 102

Subcommittee D09.19 on Dielectric Sheet and Roll Products.

Current edition approved March 10, 2003. Published April 2003. Originally

mm) in size. The press shall be capable of exerting a force of

approved in 1932. Last previous edition approved in 1997 as D352–97.

at least 4000 lb (18 kN). The apparatus shall be capable of

Annual Book of ASTM Standards,Vol 10.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D352–97 (2003)

be allowed to circulate in ducts provided in the platens. The rate of water

maintaining a specimen temperature of at least 200 6 5°C. It

flow, if used, should be adjusted to give a cooling rate no greater than the

ispreferablethattheapparatushaveplatenswithwaterductsor

rate at which the specimen was initially heated.

other provisions for cooling the specimen. (See Note 1 in 7.3.)

5.2 Pressure Gage—A pressure gage capable of determin-

8. Calculation

ing the pressure on the specimen with an accuracy of 65%.

8.1 Calculate the percentage compressive creep, C, as fol-

5.3 Thickness Gage—A thickness gage capable of measur-

lows:

ingthethicknessofthespecimentothenearest0.001in.(0.025

C,% 5 @~T 2 T8!/T# 3100 (1)

mm).

5.4 Potentiometer—Temperature measuring instrument and

where:

a No. 30AWG or smaller thermocouple with overall accuracy

T = thickness of the stack at 1000 psi (7 MPa) before

of 62°C for measurement of specimen temperature.

heating, and

5.5 Steel Plates—Two4by4-in.(102by102-mm)orlarger

T8 = thickness of the stack at 1000 psi after heating.

polished steel plates of at least ⁄16-in. (1.6-mm) thickness,

surface ground so that the top and bottom surfaces of each

9. Report

piece are parallel, one plate each for the top and bottom of the

9.1 Report the following information:

test specimen.

9.1.1 The identity of the material,

9.1.2 The nominal thickness of the pasted mica,

6. Test Specimen

9.1.3 The observed values of T and T8,

6.1 Thetestspecimenshallconsistofasufficientnumberof

9.1.4 The percentage compressive creep, and

pieces of bonded micaceous plate, 2 by 2 in. (51 by 51 mm) in

9.1.5 The specimen temperature.

size, to form a stack approximately but not greater than 1.000

in. (25.40 mm) in thickness. The pieces shall be selected so as

10. Precision and Bias

toberepresentativeoftheentiresheet.Atleastthreespecimens

10.1 This method has been in use for many years but no

shall be tested for each lot of material.

statement for precision has been made and no activity is

7. Procedure

planned to develop such a statement.

10.2 A statement of bias is not possible due to a lack of a

7.1 Centerthestackedspecimenbetweenthe4by4-in.(102

standard reference material.

by 102-mm) steel plates and then center this assembly in the

press. Place the thermocouple between pieces near the middle

STABILITY UNDER HEAT AND PRESSURE

of the stack. Carefully align the stack to form a right parallel-

epiped.Apply a pressure of 1000 psi (7 MPa) to the specimen

11. Scope

surfaces, and carefully determine the average thickness of the

11.1 The test for stability under heat and pressure deter-

stack by means of the gage. Where inside gages are used,

minesmicaorbinderdisplacement,orboth,underthespecified

measurethethicknessateachofthefourcornersasclosetothe

conditions of test.

specimen as possible. Measurements shall be made within 5

min.

12. Significance and Use

7.2 Pack approximately 2 in. (51 mm) of thermal insulation

12.1 This test serves as a measure of the ability of bonded

material around the specimen without disturbing it. Heat the

micaceous materials to maintain their physical integrity under

specimen to 1606 5°C or 200 6 5°C as specified. The time

exposuretoheatandpressure.Ithasspecialsignificancewhere

required to reach the specified temperature should be not less

the material to be tested is employed as commutator segment

than 30 min nor more than 75 min. The platen temperature

insulation. This test is suitable for acceptance tests and for

shall not exceed the specified temperature by more than the

manufacturing control.

specified tolerance. If the specimen is heated by other means,

the surrounding medium shall not exceed the specified tem-

13. Nature of Test

perature by more than the specified tolerance. Allow the

13.1 This test method utilizes the application of a shearing

specimen to remain at the specified temperature for 2 h after

forceaswellasacompressiveforce,whichisaccomplishedby

reaching that temperature, and at the same time maintain the

1000-psi pressure. placing the specimens between specified wedges, thereby

causingtheappliedforcetoresolveintocompressionandshear

7.3 Remove the thermal insulation and, while maintaining

the pressure, allow the specimen to cool until the temperature components.Thistestisparticularlyusefulformaterialusedin

commutator assemblies where shearing as well as compressive

is 5°C above the temperature (room ambient) at which the

original thickness was measured. Control the rate of cooling forces are encountered. Test results are expressed quantita-

tively as units of linear deflection.

such that it does not exceed the rate at which the temperature

was raised. Then determine the thickness of the stack while

14. Apparatus

under 1000-psi compressive load.

14.1 Hydraulic Press, Pressure Gage, and Thermocou-

NOTE 1—Experience has shown that in order to cool the specimen to

ple as described in Section 5, except that the hydraulic press

the specified temperature within a reasonable time, forced-cooling means

shall be capable of producing a force of 26400 lb (118 kN) on

must be employed. It is suggested that a fan be initially utilized to force

air across the specimen for the first 5 min, after which cooling water may the specimen,

D352–97 (2003)

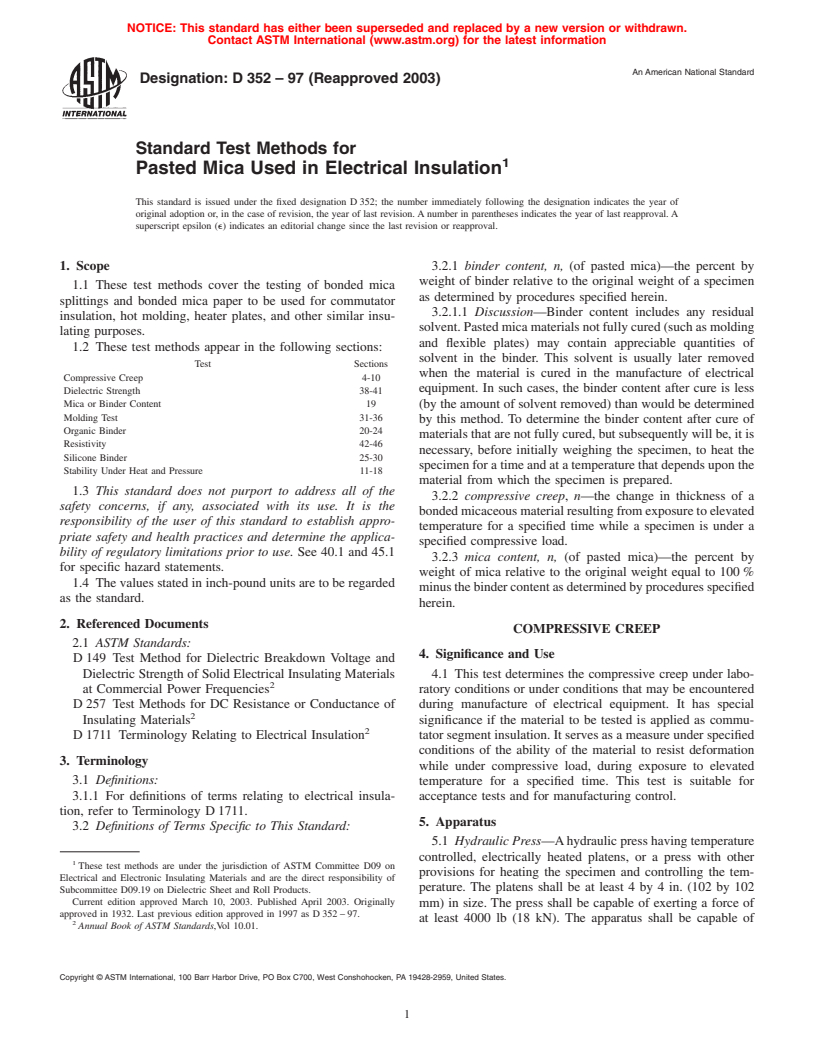

14.2 Steel Wedges—Two steel wedges of the same size as 17.1.2 The dimensions of the specimen used,

the specimen by approximately ⁄4 in. (19 mm) thick, with one 17.1.3 The temperature used, and

face tapered at an angle of 3° with the horizontal and a center 17.1.4 Theaveragedeflectionateachofthetimeintervalsin

wedge as shown in Fig. 1. They shall be hardened and surface accordance with 16.3.

ground top and bottom.

18. Precision and Bias

14.3 Dial Gages—Two dial gages having 0.001-in. (0.02-

mm) graduations and a range of at least ⁄2-in. (13-mm), 18.1 See 10.1.

18.2 See 10.2.

designed to be accurate at the specified test temperature, and

suitably mounted on the steel wedges described in 14.2.

MICA OR BINDER CONTENT

NOTE 2—Where the dial gages are mounted through nonmetallic

bushings,orifsomeothersuitablemethodisusedtointerruptthemetallic 19. Significance and Use

thermal path, it shall not be necessary to utilize gages designed to be

19.1 Physical (such as the ability to hot mold, flexibility)

accurate at the test temperature.

andelectrical(suchasdielectricstrength,resistivity)properties

15. Test Specimen of bonded micaceous materials are affected, among other

things,bytheproportionalcontentsofthebinderandmica.The

15.1 Thespecimenshallconsistoftworectangularpiecesof

methods for mica or binder content are suitable for acceptance

bonded micaceous plate between 4 and 6 in. (2580 and 3870

2 tests and manufacturing control.

mm ) in area, the shorter side being not less than 1 ⁄2 in. (38

mm).

ORGANIC BINDER

16. Procedure

20. Apparatus

16.1 Insert the specimen between the wedges, as shown in

20.1 Burner—Bunsen burner or muffle furnace.

Fig. 1. Center the assembly in the press and carefully align,

20.2 Dishes—Platinum or porcelain dishes or crucibles.

usingjustenoughpressuretoholdtheassemblytogether.Insert

the thermocouple and fit it tightly in the hole provided in the 21. Test Specimen

center wedge. Cement the thermocouple into the hole.Apply a

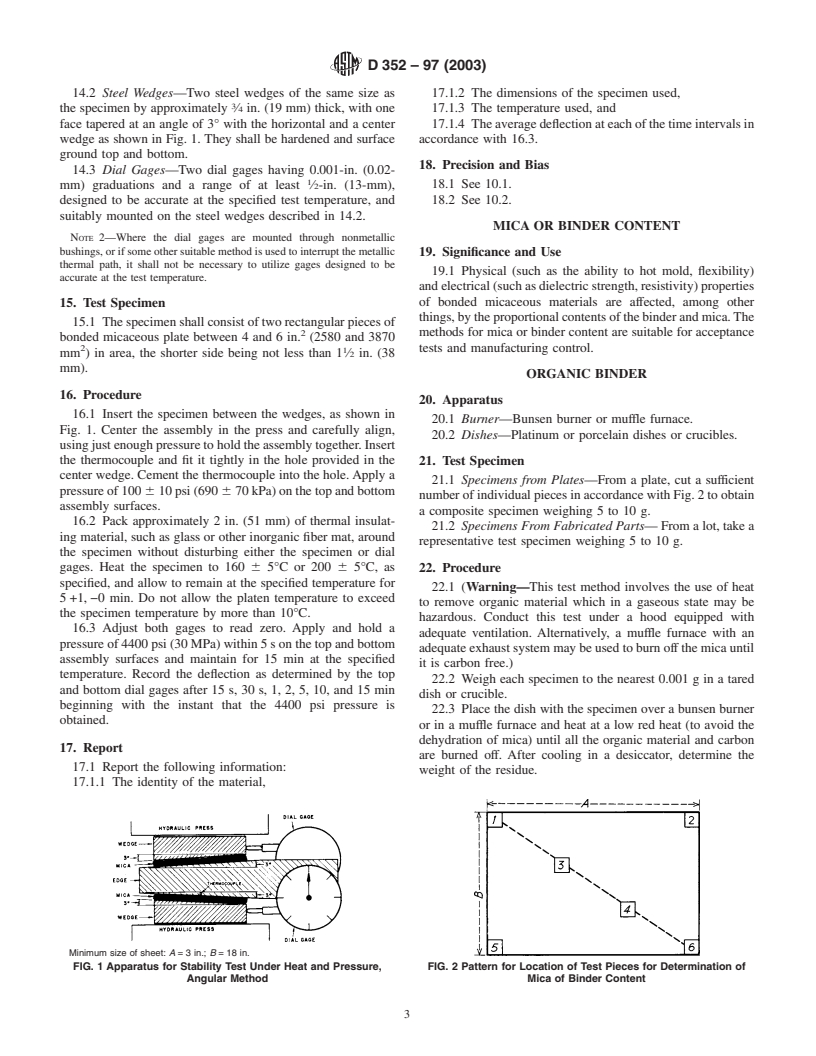

21.1 Specimens from Plates—From a plate, cut a sufficient

pressureof100 610psi(690 670kPa)onthetopandbottom

numberofindividualpiecesinaccordancewithFig.2toobtain

assembly surfaces.

a composite specimen weighing 5 to 10 g.

16.2 Pack approximately 2 in. (51 mm) of thermal insulat-

21.2 Specimens From Fabricated Parts—Fromalot,takea

ing material, such as glass or other inorganic fiber mat, around

representative test specimen weighing 5 to 10 g.

the specimen without disturbing either the specimen or dial

gages. Heat the specimen to 160 6 5°C or 200 6 5°C, as 22. Procedure

specified, and allow to remain at the specified temperature for

22.1 (Warning—This test method involves the use of heat

5+1,−0 min. Do not allow the platen temperature to exceed

to remove organic material which in a gaseous state may be

the specimen temperature by more than 10°C.

hazardous. Conduct this test under a hood equipped with

16.3 Adjust both gages to read zero. Apply and hold a

adequate ventilation. Alternatively, a muffle furnace with an

pressureof4400psi(30MPa)within5sonthetopandbottom

adequateexhaustsystemmaybeusedtoburnoffthemicauntil

assembly surfaces and maintain for 15 min at the specified

it is carbon free.)

temperature. Record the deflection as determined by the top

22.2 Weigh each specimen to the nearest 0.001 g in a tared

and bottom dial gages after 15 s, 30 s, 1, 2, 5, 10, and 15 min

dish or crucible.

beginning with the instant that the 4400 psi pressure is

22.3 Place the dish with the specimen over a bunsen burner

obtained.

or in a muffle furnace and heat at a low red heat (to avoid the

dehydration of mica) until all the organic material and carbon

17. Report

are burned off. After cooling in a desiccator, determine the

17.1 Report the following information:

weight of the residue.

17.1.1 The identity of the material,

Minimum size of sheet: A = 3 in.; B=18in.

FIG. 1 Apparatus for Stability Test Under Heat and Pressure, FIG. 2 Pattern for Location of Test Pieces for Determination of

Angular Method Mica of Binder Content

D352–97 (2003)

23. Report the alkali-resistant 500-mL beaker. Add sufficient alkaline

solvent to the beaker to completely cover the mica sample so

23.1 Report the following information:

that the level of the solvent will be flush with the top of the

23.1.1 The identity of the material,

crucible. Place a cover with the condenser over the beaker and

23.1.2 Percentagelossinweightofeachspecimenindicated

boil vigorously for 4 h, taking care not to boil mica flakes out

as binder, and

of the crucible.

23.1.3 Percentage of residue in the crucible indicated as

28.3 Remove the crucible, taking care not to lose any of the

mica.

fine mica flakes, and place it in the suction flask fitted with a

24. Precision and Bias

suitable crucible adaptor.Wash with the contents of the beaker

using a glass rod, if necessary, to return any fine m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.