ASTM C1029-20

(Specification)Standard Specification for Spray-Applied Rigid Cellular Polyurethane Thermal Insulation

Standard Specification for Spray-Applied Rigid Cellular Polyurethane Thermal Insulation

ABSTRACT

This specification covers the types and physical properties of spray applied rigid cellular polyurethane intended for use as thermal insulation. Spray-applied rigid-cellular polyurethane thermal insulation shall be classified into four type: Type I; Type II; Type III; and Type IV. Spray-applied rigid-cellular polyurethane thermal insulation shall be produced by the catalyzed chemical reaction of polyisocyanates with polyhydroxyl compounds and by the catalyzed polymerization of polyisocyanates. The following test methods shall be performed: thermal resistance; compressive strength; water vapor permeability; water absorption; tensile strength; response to thermal and humid aging; closed cell content; and surface burning characteristics.

SCOPE

1.1 This specification covers the types and physical properties of spray applied rigid cellular polyurethane intended for use as thermal insulation. The operating temperatures of the surfaces to which the insulation is applied shall not be lower than −22°F (−30°C) or greater than +225°F (+107°C). For specific applications, the actual temperature limits shall be as agreed upon between the manufacturer and the purchaser.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C1029 −20

Standard Specification for

Spray-Applied Rigid Cellular Polyurethane Thermal

1

Insulation

This standard is issued under the fixed designation C1029; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope the Guarded-Hot-Plate Apparatus

C518Test Method for Steady-State Thermal Transmission

1.1 This specification covers the types and physical proper-

Properties by Means of the Heat Flow Meter Apparatus

ties of spray applied rigid cellular polyurethane intended for

C1303/C1303MTest Method for Predicting Long-Term

use as thermal insulation. The operating temperatures of the

Thermal Resistance of Closed-Cell Foam Insulation

surfaces to which the insulation is applied shall not be lower

C1363Test Method for Thermal Performance of Building

than−22°F (−30°C) or greater than+225°F (+107°C). For

Materials and Envelope Assemblies by Means of a Hot

specific applications, the actual temperature limits shall be as

Box Apparatus

agreed upon between the manufacturer and the purchaser.

D883Terminology Relating to Plastics

1.2 The values stated in inch-pound units are to be regarded

D1621Test Method for Compressive Properties of Rigid

as standard. The values given in parentheses are mathematical

Cellular Plastics

conversions to SI units that are provided for information only

D1622/D1622MTest Method forApparent Density of Rigid

and are not considered standard.

Cellular Plastics

1.3 This standard does not purport to address all of the

D1623Test Method for Tensile and TensileAdhesion Prop-

safety concerns, if any, associated with its use. It is the

erties of Rigid Cellular Plastics

responsibility of the user of this standard to establish appro-

D2126Test Method for Response of Rigid Cellular Plastics

priate safety, health, and environmental practices and deter-

to Thermal and Humid Aging

mine the applicability of regulatory limitations prior to use.

D2842Test Method for Water Absorption of Rigid Cellular

1.4 This international standard was developed in accor-

Plastics

dance with internationally recognized principles on standard-

D6226TestMethodforOpenCellContentofRigidCellular

ization established in the Decision on Principles for the

Plastics

Development of International Standards, Guides and Recom-

E84Test Method for Surface Burning Characteristics of

mendations issued by the World Trade Organization Technical

Building Materials

Barriers to Trade (TBT) Committee.

E96/E96MTest Methods for Water Vapor Transmission of

Materials

2. Referenced Documents

2

2.1 ASTM Standards:

3. Terminology

C165TestMethodforMeasuringCompressivePropertiesof

3.1 Definitions:For definitions of terms used in this

Thermal Insulations

specification, refer to Terminologies C168 and D883.

C168Terminology Relating to Thermal Insulation

C177Test Method for Steady-State Heat Flux Measure-

4. Classification

ments and Thermal Transmission Properties by Means of

4.1 Spray-applied rigid-cellular polyurethane thermal insu-

lation covered by this specification is classified into four types

1

This specification is under the jurisdiction of ASTM Committee C16 on

as follows:

Thermal Insulation and is the direct responsibility of Subcommittee C16.22 on

Organic and Nonhomogeneous Inorganic Thermal Insulations.

4.1.1 Type I—Compressive strength 15 psi (104 kPa) mini-

Current edition approved Dec. 1, 2020. Published January 2021. Originally

mum.

approved in 1985. Last previous edition approved in 2015 as C1029–15. DOI:

10.1520/C1029-20. 4.1.2 Type II—Compressive strength 25 psi (173 kPa) mini-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

mum.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.1.3 Type III—Compressive strength 40 psi (276 kPa)

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. minimum.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1029 − 20

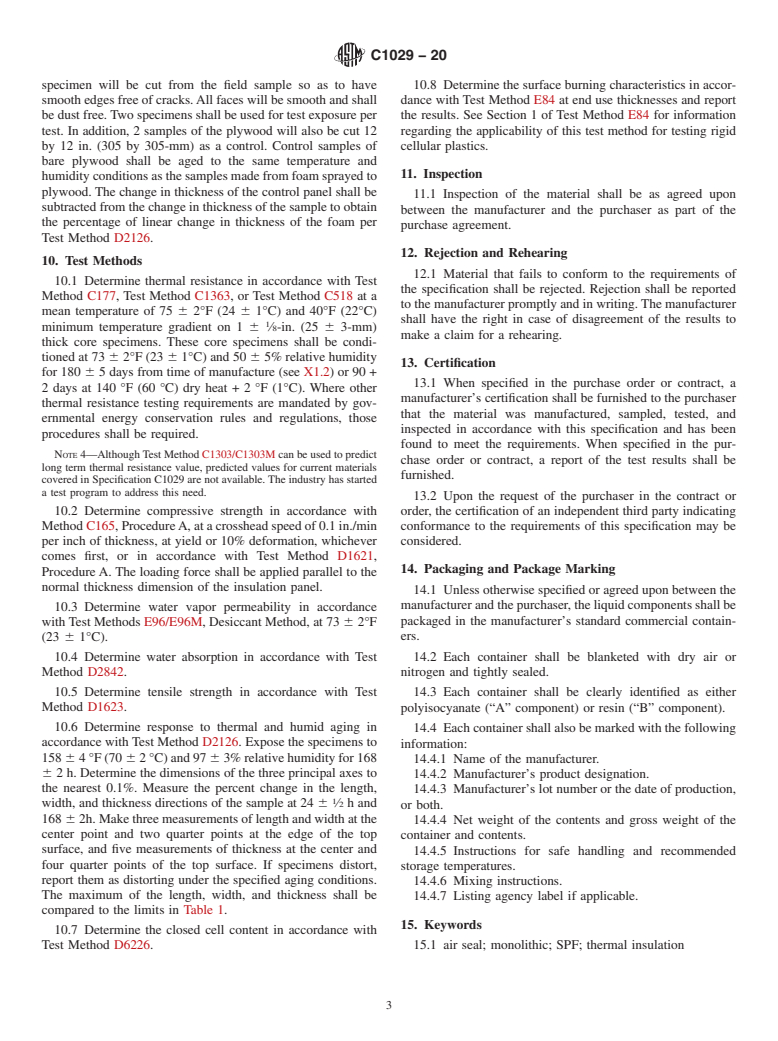

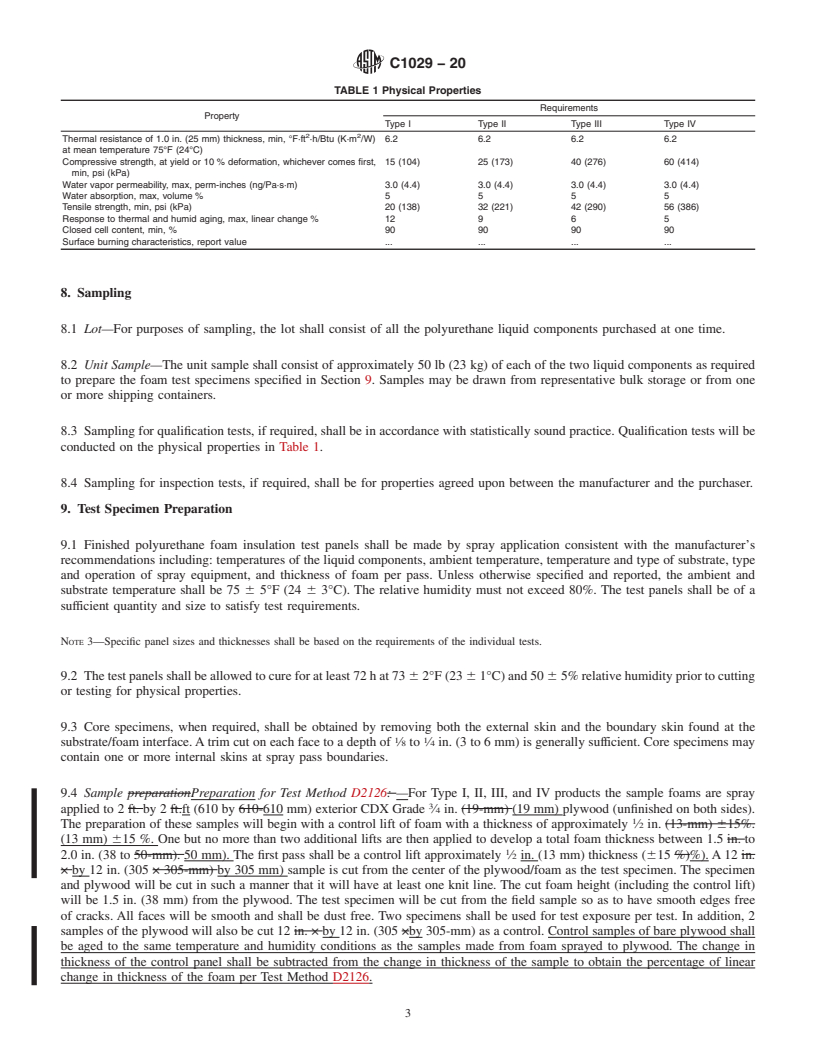

4.1.4 Type IV—Compressive strength 60 psi (414 kPa) 8.3 Sampling for qualification tests, if required, shall be in

minimum. accordance with statistically sound practice. Qualification tests

will be conducted on the physical properties in Table 1.

5. Ordering Information

8.4 Sampling for inspection tests, if required, shall be for

5.1 O

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1029 − 15 C1029 − 20

Standard Specification for

Spray-Applied Rigid Cellular Polyurethane Thermal

1

Insulation

This standard is issued under the fixed designation C1029; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This specification covers the types and physical properties of spray applied rigid cellular polyurethane intended for use as

thermal insulation. The operating temperatures of the surfaces to which the insulation is applied shall not be lower than −22°F

(−30°C) or greater than +225°F (+107°C). For specific applications, the actual temperature limits shall be as agreed upon between

the manufacturer and the purchaser.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C165 Test Method for Measuring Compressive Properties of Thermal Insulations

C168 Terminology Relating to Thermal Insulation

C177 Test Method for Steady-State Heat Flux Measurements and Thermal Transmission Properties by Means of the

Guarded-Hot-Plate Apparatus

C518 Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus

C1303/C1303M Test Method for Predicting Long-Term Thermal Resistance of Closed-Cell Foam Insulation

C1363 Test Method for Thermal Performance of Building Materials and Envelope Assemblies by Means of a Hot Box Apparatus

D883 Terminology Relating to Plastics

D1621 Test Method for Compressive Properties of Rigid Cellular Plastics

D1622/D1622M Test Method for Apparent Density of Rigid Cellular Plastics

D1623 Test Method for Tensile and Tensile Adhesion Properties of Rigid Cellular Plastics

1

This specification is under the jurisdiction of ASTM Committee C16 on Thermal Insulation and is the direct responsibility of Subcommittee C16.22 on Organic and

Nonhomogeneous Inorganic Thermal Insulations.

Current edition approved May 15, 2015Dec. 1, 2020. Published September 2015January 2021. Originally approved in 1985. Last previous edition approved in 20132015

as C1029 – 13.C1029 – 15. DOI: 10.1520/C1029-15.10.1520/C1029-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1029 − 20

D2126 Test Method for Response of Rigid Cellular Plastics to Thermal and Humid Aging

D2842 Test Method for Water Absorption of Rigid Cellular Plastics

D6226 Test Method for Open Cell Content of Rigid Cellular Plastics

E84 Test Method for Surface Burning Characteristics of Building Materials

E96/E96M Test Methods for Water Vapor Transmission of Materials

3. Terminology

3.1 Definitions:For definitions of terms used in this specification, refer to Terminologies C168 and D883.

4. Classification

4.1 Spray-applied rigid-cellular polyurethane thermal insulation covered by this specification is classified into four types as

follows:

4.1.1 Type I—Compressive strength 15 psi (104 kPa) minimum.

4.1.2 Type II—Compressive strength 25 psi (173 kPa) minimum.

4.1.3 Type III—Compressive strength 40 psi (276 kPa) minimum.

4.1.4 Type IV—Compressive strength 60 psi (414 kPa) minimum.

5. Ordering Information

5.1 Orders for materials purc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.