ASTM D1623-17(2023)

(Test Method)Standard Test Method for Tensile and Tensile Adhesion Properties of Rigid Cellular Plastics

Standard Test Method for Tensile and Tensile Adhesion Properties of Rigid Cellular Plastics

ABSTRACT

This test method establishes standard procedure for determining the tensile and tensile adhesion properties of rigid cellular plastics in the form of test specimens of standard shape under defined conditions of temperature, humidity, and testing machine speed. Tensile properties shall be measured using any of three types of specimens: Type A shall be the preferred specimen in those cases where enough sample material exists to form the necessary specimen; Type B shall be the preferred specimen when only smaller specimens are available, as in sandwich panels, etc.; Type C shall be the preferred specimen for the determination of tensile adhesive properties of a cellular plastic to a substrate as in a sandwich panel or the bonding strength of a cellular plastic to a single substrate. This test method requires the use of the following apparatuses: a constant-rate-of-crosshead-movement type testing machine; self-aligning type grips for holding test specimens; an extension indicator; and a lathe specimen cutter.

SCOPE

1.1 This test method covers the determination of the tensile and tensile adhesion properties of rigid cellular materials in the form of test specimens of standard shape under defined conditions of temperature, humidity, and testing machine speed.

1.2 Tensile properties shall be measured using any of three types of specimens:

1.2.1 Type A shall be the preferred specimen in those cases where enough sample material exists to form the necessary specimen.

1.2.2 Type B shall be the preferred specimen when only smaller specimens are available, as in sandwich panels, etc.

1.2.3 Type C shall be the preferred specimen for the determination of tensile adhesive properties of a cellular plastic to a substrate as in a sandwich panel (top and bottom substrate) or the bonding strength of a cellular plastic to a single substrate.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

Note 1: There is no known ISO equivalent to this test method.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D1623 − 17 (Reapproved 2023)

Standard Test Method for

Tensile and Tensile Adhesion Properties of Rigid Cellular

Plastics

This standard is issued under the fixed designation D1623; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This test method covers the determination of the tensile

D638 Test Method for Tensile Properties of Plastics

and tensile adhesion properties of rigid cellular materials in the

D883 Terminology Relating to Plastics

form of test specimens of standard shape under defined

E691 Practice for Conducting an Interlaboratory Study to

conditions of temperature, humidity, and testing machine

Determine the Precision of a Test Method

speed.

1.2 Tensile properties shall be measured using any of three

3. Terminology

types of specimens:

3.1 Definitions of terms applying to this test method appear

1.2.1 Type A shall be the preferred specimen in those cases

in Test Method D638, Annex A2.

where enough sample material exists to form the necessary

specimen.

4. Apparatus

1.2.2 Type B shall be the preferred specimen when only

4.1 Testing Machine—A testing machine that is capable of

smaller specimens are available, as in sandwich panels, etc.

applying a constant rate of crosshead movement, comprising

1.2.3 Type C shall be the preferred specimen for the deter-

essentially the following:

mination of tensile adhesive properties of a cellular plastic to a

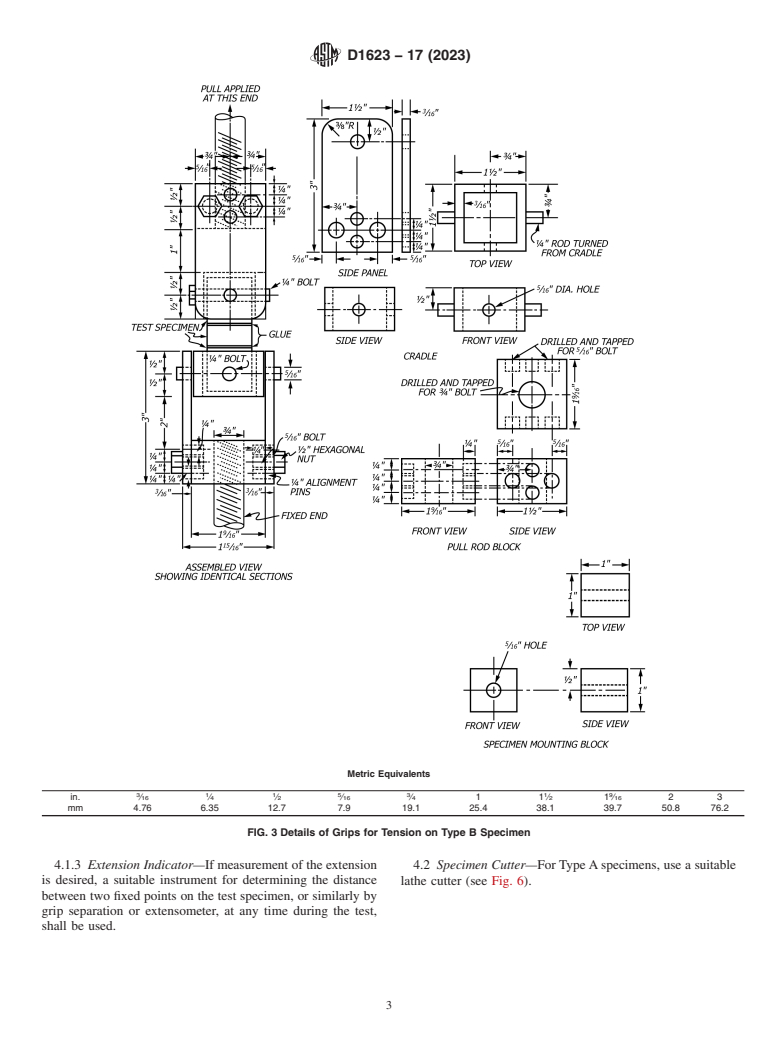

4.1.1 Grips—Grips for holding the test specimen shall be

substrate as in a sandwich panel (top and bottom substrate) or

the self-aligning type; that is, they must be attached to the fixed

the bonding strength of a cellular plastic to a single substrate.

and movable members of the testing machine in such a way

1.3 The values stated in SI units are to be regarded as that they will move freely into alignment as soon as any load

standard. The values given in parentheses are mathematical is applied, so that the long axis of the test specimen will

conversions to inch-pound units that are provided for informa- coincide with the direction of the applied pull through the

tion only and are not considered standard. center line of the grip assembly. Universal-type joints imme-

diately above and below the specimen grips are recommended.

NOTE 1—There is no known ISO equivalent to this test method.

The test specimen shall be held in such a way that slippage

1.4 This international standard was developed in accor-

relative to the grips is prevented, insofar as possible. For Type

dance with internationally recognized principles on standard-

A specimens, use a grip assembly like the one shown in Fig. 1

ization established in the Decision on Principles for the

and Fig. 2. For Type B specimens, one suitable grip assembly

Development of International Standards, Guides and Recom-

is shown in Fig. 3 and Fig. 4. For Type C specimen, a suitable

mendations issued by the World Trade Organization Technical

grip assembly is shown in Fig. 5.

Barriers to Trade (TBT) Committee.

4.1.2 Load Indicator—A load cell or suitable load-

indicating mechanism, capable of showing the total tensile load

This test method is under the jurisdiction of ASTM Committee D20 on Plastics

and is the direct responsibility of Subcommittee D20.22 on Cellular Materials -

Plastics and Elastomers. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2023. Published May 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1959. Last previous edition approved in 2017 as D1623 – 17. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D1623-17R23. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1623 − 17 (2023)

Metric Equivalents

1 1 1 9 11 1 1 1 5

in. ⁄8 ⁄4 ⁄2 ⁄16 ⁄16 1 1.130 1 ⁄2 2 2 ⁄4 2 ⁄2 3 3 ⁄16

mm 3.18 6.35 12.7 14.3 17.5 25.4 28.7 38.1 50.8 57.2 63.5 76.2 84.1

FIG. 1 Details of Grips for Tension Test on Type A Specimen

FIG. 2 Grip Assembly for Type A Specimen

exerted on the test specimen when held in the grips, shall be

used. Choose an indicator that will permit precision to within

61 %.

D1623 − 17 (2023)

Metric Equivalents

3 1 1 5 3 1 9

in. ⁄16 ⁄4 ⁄2 ⁄16 ⁄4 1 1 ⁄2 1 ⁄16 2 3

mm 4.76 6.35 12.7 7.9 19.1 25.4 38.1 39.7 50.8 76.2

FIG. 3 Details of Grips for Tension on Type B Specimen

4.1.3 Extension Indicator—If measurement of the extension 4.2 Specimen Cutter—For Type A specimens, use a suitable

is desired, a suitable instrument for determining the distance lathe cutter (see Fig. 6).

between two fixed points on the test specimen, or similarly by

grip separation or extensometer, at any time during the test,

shall be used.

D1623 − 17 (2023)

FIG. 4 Grip Assembly for Type B Specimen

FIG. 5 Grip Assembly for Type C Specimen

5. Test Specimen

5.1 All surfaces of the specimen shall be free of large visible

flaws or imperfections. If it is necessary to place gauge marks

on the specimen, do this in such a way as not to affect the

surfaces of the test specimen. Gauge marks shall not be

scratched, punched, or impressed on the specimen.

5.2 When testing materials that are suspected to be

anisotropic, prepare duplicate sets of specimens having their

long axes parallel and perpendicular to the direction of the cell

orientation.

Metric Equivalents

1 15 3 1 1 1

in. ⁄4 ⁄32 ⁄4 1 ⁄2 2 ⁄8 4 ⁄4

5.3 Preparation of Type A Specimens—The recommended

mm 6.35 11.9 19.1 38.1 54.0 108.0

Type A test specimen shall conform to the dimensions given in

Fig. 7. It shall be prepared by normal molding procedures

FIG. 6 Cutter for Preparing Type A Specimen

wherever possible, but the “skin” effect which results cannot be

eliminated and will cause a variance in the final result. Another

D1623 − 17 (2023)

vibrations or heat buildup, which could weaken the bond

between the cellular plastic and the substrate.

5.5.3 When adhesion test involves only one surface, the

other side shall be trimmed to provide a smooth, parallel

bonding surface.

5.5.4 Bond the specimen mounting (or grip assembly)

blocks to the top and bottom of the test specimen by a suitable

method that does not affect the material being tested.

6. Conditioning

Metric Equivalents

15 5 1

in. 1.129 ⁄32 1 ⁄8 4 ⁄4

6.1 Conditioning—Condition the test specimens at 23 6

mm 28.7 11.9 41.3 108.0

2°C (73.4 6 3.6°F) and 50 6 10 % relative humidity for not

FIG. 7 Dimensions of Type A Specimen less than 24 h prior to testing.

6.2 Test Conditions—Conduct tests in the standard labora-

tory atmosphere of 23 6 2°C (73.4 6 3.6°F) and 50 6 10 %

method of preparation of the specimen, which would eliminate

relative humidity, unless otherwise specified.

the “skin effect” variable, is to machine the desired geometry

on a small lathe, using a cutter like the one shown in Fig. 6.

7. Number of Test Specimens

Insert a 50 by 50 by 150-mm (2 by 2 by 6-in.) block of the

7.1 A minimum of three specimens shall be tested. Speci-

material to be tested into the four-jaw chuck, which had been

mens that break at some obvious flaw shall be discarded and

previously centered. Prepare the other end of the block to

retests made, unless such flaws constitute a variable that is to

receive the 60° tapered end of the tailstock center. Set the lathe

be studied.

at its highest speed. The appropriate rate of entry of the cutter

blade will depend on the density of the foam. Advance the

8. Speed of Testing

cutter until it reaches a stop, at which time the diameter of the

8.1 The standard speed of testing shall be such that rupture

specimen test section shall be 28.7 mm (1.130 in.), giving a

occurs in 3 to 6 min. A suggested rate of crosshead movement

2 2

645 mm (1 in. ) cross sectional area. Using a band saw, cut off

is 1.3 mm (0.05 in.)/min for each 25.4 mm (1 in.) of test section

the excess sample end (up to the taper). The lathe assembly and

gauge length.

completed specimen are shown in Fig. 6 and Fig. 7. The

9. Procedure

recommended gauge length shall be 25.4 mm (1 in.) with a

radius of curvature of 11.9 mm ( ⁄32 in.) at each end joining it

9.1 Meas

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.