ASTM D2539-93(2001)

(Test Method)Standard Test Method for Shock Sensitivity of Liquid Monopropellants by the Card-Gap Test (Withdrawn 2003)

Standard Test Method for Shock Sensitivity of Liquid Monopropellants by the Card-Gap Test (Withdrawn 2003)

SCOPE

1.1 In considering the handling properties of a liquid propellant, serious consideration is given to the possibility of hazard initiated by hydrodynamic shock. The consequences of such a shock may include: (1) nonpropagating explosion, (2) propagating but low-velocity detonation, and (3) propagating high-velocity detonation. All three are hazards; the test described herein is useful for one hazard only, namely propagating high-velocity detonation.

1.2 This standard should be used to measure and describe the properties of materials, products, or assemblies in response to heat and flame under controlled laboratory conditions and should not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions. However, results of this test may be used as elements of a fire risk assessment which takes into account all of the factors which are pertinent to an assessment of the fire hazard of a particular end use.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 2539 – 93 (Reapproved 2001)

Standard Test Method for

Shock Sensitivity of Liquid Monopropellants by the Card-

Gap Test

This standard is issued under the fixed designation D 2539; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope as the number of cards required to attenuate the booster shock

just enough that the liquid detonates in 50 % of the trials. For

1.1 In considering the handling properties of a liquid pro-

an unknown liquid, 15 to 25 shots (requiring up to 1000 mL of

pellant, serious consideration is given to the possibility of

liquid) can be needed to define its sensitivity value. Because of

hazard initiated by hydrodynamic shock. The consequences of

the destructive nature of the test, a sufficient supply of

such a shock may include: (1) nonpropagating explosion, (2)

expendable parts must be available before a sensitivity deter-

propagating but low-velocity detonation, and (3) propagating

mination is attempted.

high-velocity detonation. All three are hazards; the test de-

2.2 The card-gap test described is a measure of the hydro-

scribed herein is useful for one hazard only, namely propagat-

dynamic shock required to produce a stable, high-velocity

ing high-velocity detonation.

2 detonation in a 1-in. standard steel pipe. Because of the large

1.2 This standard should be used to measure and describe

sample size subjected to this detonability test, the test is not to

the properties of materials, products, or assemblies in response

be done in the laboratory. The advantages of the card-gap test

to heat and flame under controlled laboratory conditions and

are its practical scale, reproducibility, and moderate material

should not be used to describe or appraise the fire hazard or

cost. The interpretation of results of the test is a matter of

fire risk of materials, products, or assemblies under actual fire

considerable judgment. While a propellant may show a low

conditions. However, results of this test may be used as

sensitivity in the card-gap test, this does not preclude the

elements of a fire risk assessment which takes into account all

possibility of other dangers. On the other hand, a very high

of the factors which are pertinent to an assessment of the fire

card-gap sensitivity does not always preclude the usability of

hazard of a particular end use.

such a liquid propellant, since it is possible that suitable

1.3 This standard does not purport to address all of the

engineering design can incorporate preventative measures

safety concerns, if any, associated with its use. It is the

against propagation of detonation. It is known that the degree

responsibility of the user of this standard to establish appro-

of confinement, size, and material of the container, among

priate safety and health practices and determine the applica-

other parameters, influence detonation propagation; therefore,

bility of regulatory limitations prior to use.

the results of any specific test may be highly apparatus-

1.4 The values stated in SI units are to be regarded as the

dependent.

standard. The values given in parentheses are for information

only.

NOTE 1—Gap tests for determining explosive sensitivity are new. A

technique of using paper cards for the gap materials and steep pipe for

2. Summary of Test Method

containers was developed in England at the Explosives Research and

Development Establishment. The version described herein is essentially

2.1 This test method gives an evaluation of the sensitivity of

the Naval Ordnance Laboratory modification. The test is valuable because

a high-energy liquid propellant in terms of a stack of plastic

it yields reproducible data and it has been found that results of different

cards inserted between a sample of liquid and a standard

investigators show close agreement.

booster charge of high explosive. The sensitivity value is taken

3. Significance and Use

3.1 The property measured is the tendency of a propellant to

This test method is under the jurisdiction of ASTM Committee F07 on

undergo a high-order detonation when subjected to a given

Aerospace and Aircraft and is the direct responsibility of Subcommittee F07.90 on

Executive.

hydrodynamic shock. One limitation of the test is the difficulty

Current edition approved March 15, 1993. Published May 1993. Originally

of applying it to materials under conditions where the vapor

published as D 2539 – 66 T. Last previous edition D 2539 – 70 (1980).

2 pressure exceeds 1 atm.

This test method is identical in substance with the Card Gap Test for Shock

Sensitivity of Liquid Monopropellants recommended by the Interagency Chemical

Rocket Propulsion Group, and published by the Chemical Propulsion Information

Agency, Test No. 1, March 1960.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 2539 – 93 (2001)

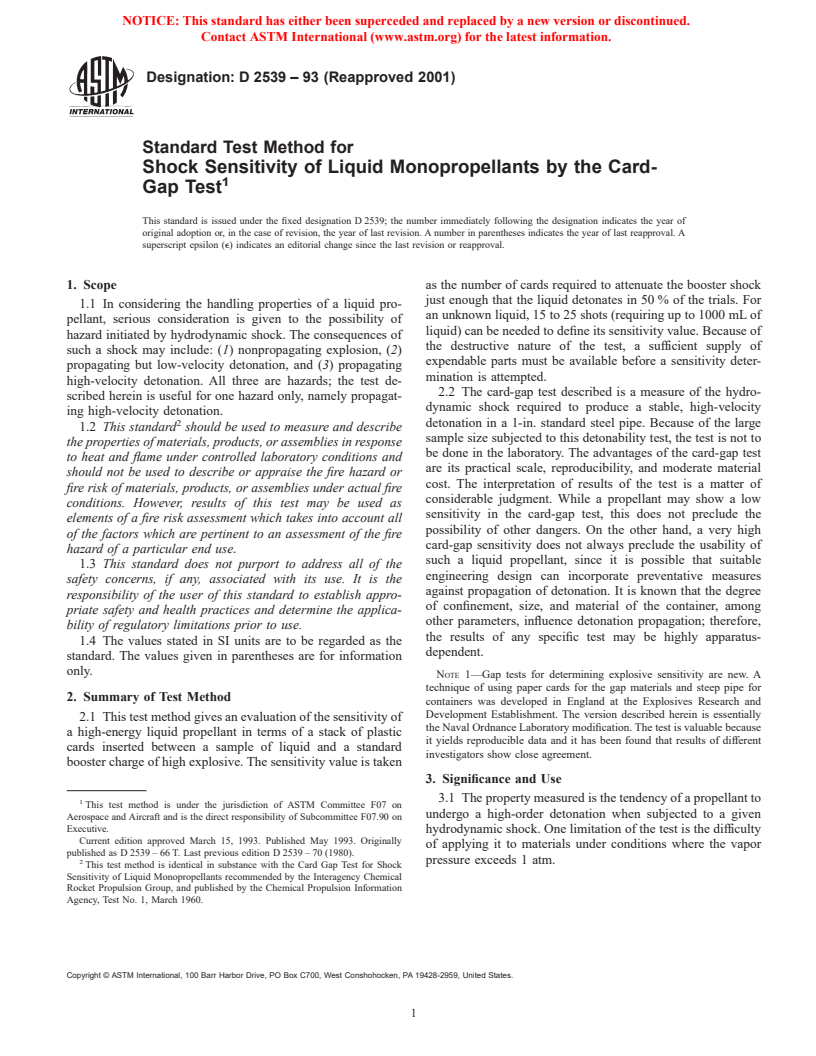

TABLE 2 Data of Table 1, Arranged to Show 50 % Point

3.2 The test is valuable because it yields very reproducible

data, and it has been found that results of different investigators No. of Cards Result

show close agreement.

0+

16 +

18 +

4. Apparatus

19 ++++−

4.1 Cup—The liquid under test is held in a cylindrical steel

20 ++++−−−−

21 −−−−+

cup, closed at the bottom by a thin, flat diaphragm. It shall be

22 −−

fabricated as follows (Fig. 1):

24 −

4.1.1 Each end of a section of 1-in. Schedule 40 extruded

32 −

black steel pipe shall be faced in a lathe to produce an overall

length of 3.0 in. (76.2 mm).

4.1.2 The pipe shall be degreased in a solvent bath. The

on a cushion of six layers of glass cloth stacked on a solid

inside must be very smooth, clean, and free from pitting and

backing. The coated pipe shall be set on top of the tape,

rust to facilitate coating. Superficial rust can be removed by

weighted with 60 lb (27 kg), and heated for 15 min at 380°C.

burnishing with a suitable wire brush.

The weight shall be kept in place during the 15-min cooling

4.1.3 The pipe shall be dipped into a bath of undiluted

period. Excess tape shall be trimmed off.

polytetrafluoroethylene (PTFE) black enamel and set upright

4.1.6 The finished cup shall be tested for leaks before use.

on blotting paper for a draining period of at least 10 min. After

4.1.7 Alternatively, the diaphragm can be formed from

drying in an oven at 90°C for 10 min, it shall be baked at 380°C

0.002-in. (0.05-mm) polyethylene film secured by a rubber

for 15 min. The enamel coating produced in this manner

band or the cardboard spacer. The film shall be stretched taut

provides sufficient protection from liquids as corrosive as 90 %

and is perfectly acceptable as long as it does not leak or react

nitric acid (HNO ) at room temperature. For further protection,

3 with the liquid to be contained.

the pipe can be given supplemental coats of PTFE aqueous

4.2 Booster—The booster charge shall consist of a cylindri-

dispersion. These shall be applied in exactly the same manner 5

cal tetryl pellet (Note 2) nominally 1 in. (25.4 mm) high by 1 ⁄8

as that used for the original coat of black enamel. Each coat can

in. (41.3 mm) in diameter, weighing about 50 g. The density of

be dried and fused before applying the next one.

these pellets should be 1.57 6 0.03 g/cm in accordance with

4.1.4 The diaphragm shall be made from 0.003-in. (0.08-

Army ordnance Drawing 82-3-591C. (Warning—Tetryl is a

mm) PTFE tape. As received from the manufacturer, the tape is

highly toxic material; those who handle it should exercise

not suitable for use, since there are unrelieved stresses present

particular care to avoid spreading the dust by contact of the

which produce wrinkling in the finished diaphragm. To correct

hands with other parts of the body. Frequent washing of the

this condition, the material shall be annealed as follows: the

hands with soap and water is desirable. Working garments

tape shall be cut into 1 ⁄4-in. (44.5-mm) lengths which are

should be free from dust-collecting features such as trouser

placed between two pieces of glass-cloth tape. One layer of

cuffs, and should be laundered frequently. Although not re-

these sandwiches shall be placed on a smooth sheet of stainless

garded as unusually sensitive, tetryl is a very powerful explo-

steel and covered with a flat piece of asbestos paper ⁄16-in. (1.6

sive and shall be handled with due respect. Rough or careless

mm) thick. The entire assembly shall be baked in a furnace at

treatment of any sort shall be entirely avoided.)

380°C for 30 to 40 min, after which time the oven shall be

NOTE 2—Pentolite may not be substituted.

turned off and allowed to cool for 1 to 2 h. After it is removed

4.3 Cards —The variable gap shall be built from circular

from the furnace and cooled to room temperature, the tape is

cards, 1.55 in. (39.4 mm) in diameter, punched from cellulose

ready for use.

acetate sheet nominally 0.010 in. (0.254 mm) thick. The sheet

4.1.5 The diaphragm shall be fused to the PTFE coating on

stock shall have smooth surfaces free from ripples, thick spots,

the pipe as follows: a piece of annealed tape shall be supported

and dimples, and should be dimensionally stable; thickness

shall be held to close tolerances. Because of its thermoplastic

TABLE 1 Typical Experimental Data From a Sensitivity

nature, acetate sheet is not suitable as a gap material where

Evaluation

sensitivity determinations are being carried out at temperatures

Shot No. of Shot No. of

A A

Result Result

No. Cards No. Cards

much in excess of 100°C. In the event that such investigations

are undertaken, it will be necessary to find a gap material

1 0+14 20−

2 32−15 19+

dimensionally stable at high temperature.

3 16+16 20−

4.4 Target Plate—Following a test shot, evidence is re-

4 24−17 19+

quired to show whether or not the liquid has detonated. This

5 20+18 20+

6 22−19 21−

evidence is provided by the condition of the target plate, a

7 21−20 20−

cold-rolled mild steep plate 4 by 4 by ⁄8 in. (102 by 102 by 9.5

8 20−21 19−

mm), which shall be placed in a horizontal position directly

9 19+22 18+

10 20+23 19+

above the cup. It shall rest on a cardboard collar which fits

11 21+24 20+

tightly around the outside of the cup and supports the plate at

12 22−25 21−

13 21 −

A

Key: + = liquid detonated.

− = liquid failed to detonate. Eastman Kodak Co.’s Kodapak IV has been found satisfactory for this purpose.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 2539 – 93 (2001)

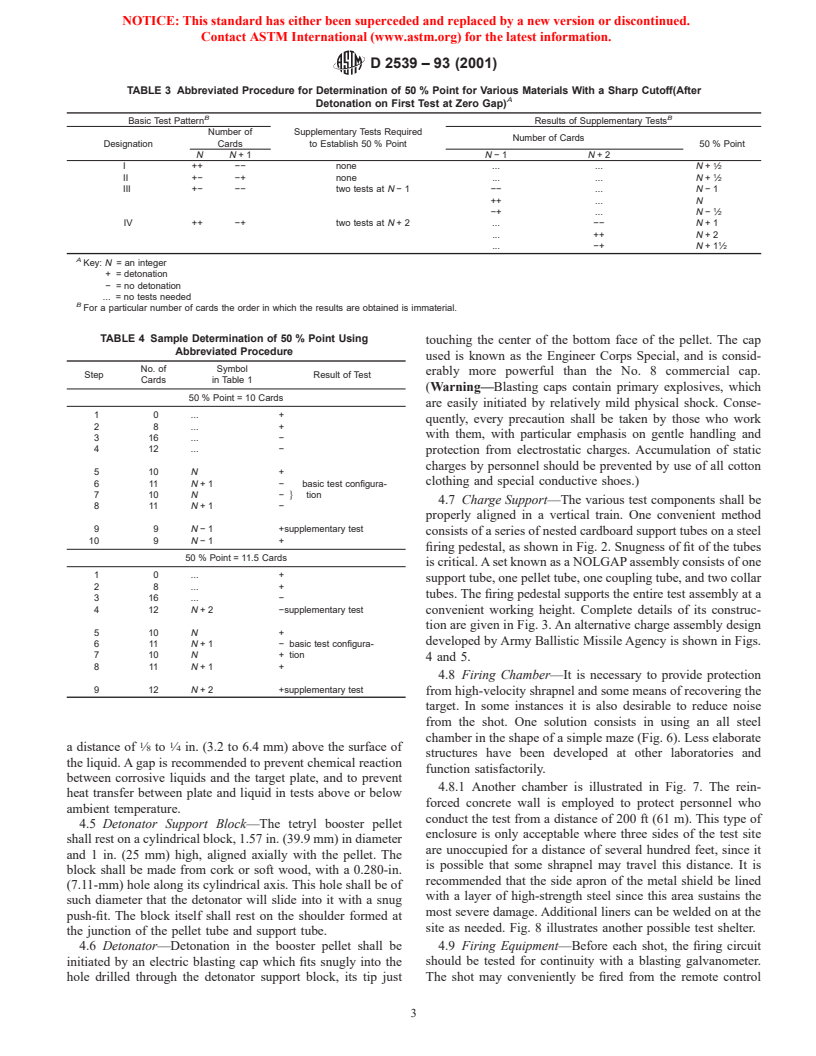

TABLE 3 Abbreviated Procedure for Determination of 50 % Point for Various Materials With a Sharp Cutoff(After

A

Detonation on First Test at Zero Gap)

B B

Basic Test Pattern Results of Supplementary Tests

Number of Supplementary Tests Required

Number of Cards

Cards to Establish 50 % Point

Designation 50 % Point

NN +1 N−1 N+2

I ++ −− none . . N + ⁄2

II +− −+ none . . N + ⁄2

III +− −− two tests at N−1 −− . N−1

++ . N

−+ . N − ⁄2

IV ++ −+ two tests at N + 2 . −− N+1

... ++ N+2

... −+ N+1 ⁄2

A

Key: N = an integer

+ = detonation

− = no detonation

... = no tests needed

B

For a particular number of cards the order in which the results are obtained is immaterial.

TABLE 4 Sample Determination of 50 % Point Using

touching the center of the bottom face of the pellet. The cap

Abbreviated Procedure

used is known as the Engineer Corps Special, and is consid-

No. of Symbol

erably more powerful than the No. 8 commercial cap.

Step Result of Test

Cards in Table 1

(Warning—Blasting caps contain primary explosives, which

50 % Point = 10 Cards

are easily initiated by relatively mild physical shock. Conse-

1 0 . +

quently, every precaution shall be taken by those who work

2 8 . +

with them, with particular emphasis on gentle handling and

3 16 . −

4 12 . −

protection from electrostatic charges. Accumulation of static

charges by personnel should be prevented by use of all cotton

510 N +

clothing and special conductive shoes.)

611 N + 1 − basic test configura-

710 N − % tion

4.7 Charge Support—The various test components shall be

811 N+1 −

properly aligned in a vertical train. One convenient method

99 N − 1 +supplementary test

consists of a series of nested cardboard support tubes on a steel

10 9 N−1 +

firing pedestal, as shown in Fig. 2. Snugness of fit of the tubes

50 % Point = 11.5 Cards

is critical. A set known as a NOLGAP assembly consists of one

1 0 . +

support tube, one pellet tube, one coupling tube, and two collar

2 8 . +

tubes. The firing pedestal supports the entire test assembly at a

3 16 . −

412 N + 2 −supplementary test

convenient working height. Complete details of its construc-

tion are given in Fig. 3. An alternative charge assembly design

510 N +

developed by Army Ballistic Missile Agency is shown in Figs.

611 N + 1 − basic test configura-

710 N + tion

4 and 5.

811 N+1 +

4.8 Firing Chamber—It is necessary to provide protection

912 N + 2 +supplementary test

from high-velocity shrapnel and some means of recovering the

target. In some instances it is also desirable to reduce noise

from the shot. One solution consists in using an all steel

chamber in the shape of a simple maze (Fig. 6). Less elaborate

1 1

a distance of ⁄8 to ⁄4 in. (3.2 to 6.4 mm) above the surface of

structures have been developed at other laboratories and

the liquid. A gap is recommended to prevent chemical reaction

function satisfactorily.

between corrosive liquids and the target plate, and to prevent

4.8.1 Another chamber is illustrated in Fig. 7. The rein-

heat transfer between plate and liquid in tests above or below

forced concrete wall is employed to protect personnel who

ambient temperature.

conduct the test from a distance of 200 ft (61 m). This type of

4.5 Detonator Support Block—The tetryl booster pellet

enclosure is only acceptable where three sides of the test site

shall rest on a cylindrical block, 1.57 in. (39.9 mm) in diameter

are unoccupied for a distance of several hundred feet, since it

and 1 in. (25 mm) high, aligned axially with the pellet. The

is possible that some shrapnel may travel this distance. It is

block shall be made from cork or soft wood, with a 0.280-in.

recommended that the side apron of the metal shield be lined

(7.11-mm) hole along its cylindrical axis. This hole shall be of

with a layer of high-strength steel since this area s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.