ASTM E2714-09

(Test Method)Standard Test Method for Creep-Fatigue Testing

Standard Test Method for Creep-Fatigue Testing

SIGNIFICANCE AND USE

Creep-fatigue testing is typically performed at elevated temperatures and involves the sequential or simultaneous application of the loading conditions necessary to generate cyclic deformation/damage enhanced by creep deformation/damage or vice versa. Unless such tests are performed in vacuum or an inert environment, oxidation can also be responsible for important interaction effects relating to damage accumulation. The purpose of creep-fatigue tests can be to determine material property data for (a) assessment input data for the deformation and damage condition analysis of engineering structures operating at elevated temperatures (b) the verification of constitutive deformation and damage model effectiveness (c) material characterization, or (d) development and verification of rules for new construction and life assessment of high-temperature components subject to cyclic service with low frequencies or with periods of steady operation, or both.

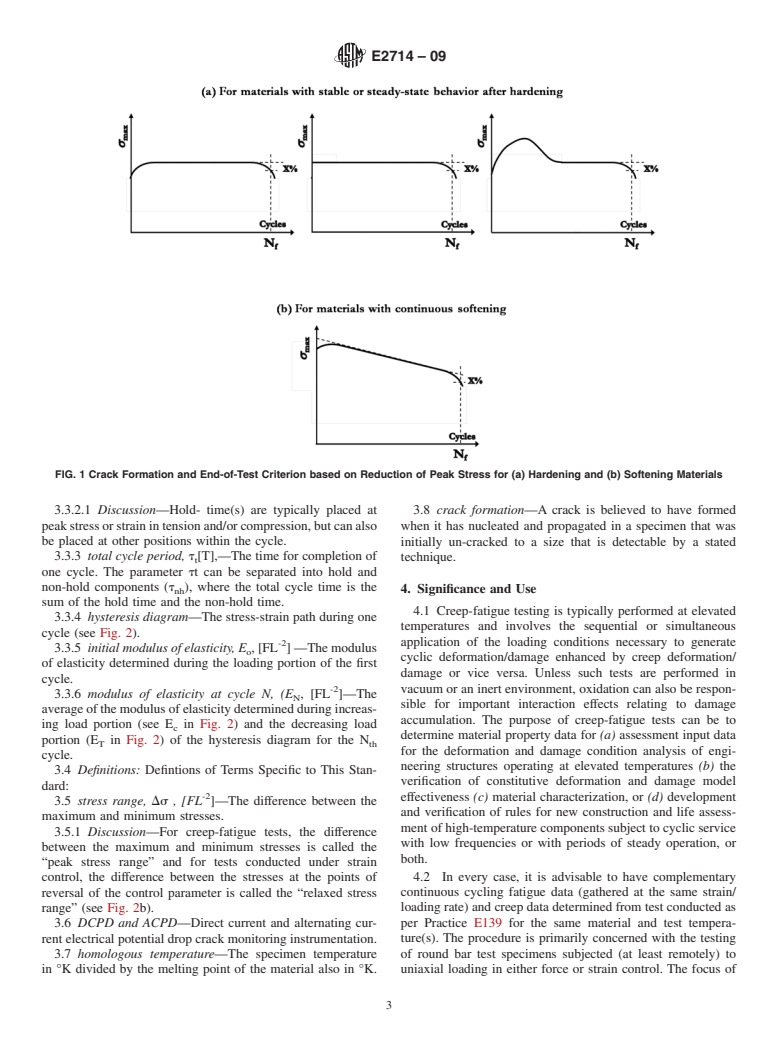

In every case, it is advisable to have complementary continuous cycling fatigue data (gathered at the same strain/loading rate) and creep data determined from test conducted as per Practice E139 for the same material and test temperature(s). The procedure is primarily concerned with the testing of round bar test specimens subjected (at least remotely) to uniaxial loading in either force or strain control. The focus of the procedure is on tests in which creep and fatigue deformation and damage is generated simultaneously within a given cycle. Data which may be determined from creep-fatigue tests performed under such conditions may characterize (a) cyclic stress-strain deformation response (b) cyclic creep (or relaxation) deformation response (c) cyclic hardening, cyclic softening response or (d) cycles to crack formation, or both.

4.3 While there are a number of testing Standards and Codes of Practice that cover the determination of low cycle fatigue deformation and cycles to crack initiation properties (See Practice E...

SCOPE

1.1 This test method covers the determination of mechanical properties pertaining to creep-fatigue deformation or crack formation in nominally homogeneous materials, or both by the use of test specimens subjected to uniaxial forces under isothermal conditions. It concerns fatigue testing at strain rates or with cycles involving sufficiently long hold times to be responsible for the cyclic deformation response and cycles to crack formation to be affected by creep (and oxidation). It is intended as a test method for fatigue testing performed in support of such activities as materials research and development, mechanical design, process and quality control, product performance, and failure analysis. The cyclic conditions responsible for creep-fatigue deformation and cracking vary with material and with temperature for a given material.

1.2 The use of this test method is limited to specimens and does not cover testing of full-scale components, structures, or consumer products.

1.3 This test method is primarily aimed at providing the material properties required for assessment of defect-free engineering structures containing features that are subject to cyclic loading at temperatures that are sufficiently high to cause creep deformation.

1.4 This test method is applicable to the determination of deformation and crack formation or nucleation properties as a consequence of either constant-amplitude strain-controlled tests or constant-amplitude force-controlled tests. It is primarily concerned with the testing of round bar test specimens subjected to uniaxial loading in either force or strain control. The focus of the procedure is on tests in which creep and fatigue deformation and damage is generated simultaneously within a given cycle. It does not cover block cycle testing in which creep and fatigue damage is generated sequentially. Data that may be determined from creep-fatigue tests performed under conditions in whic...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2714 – 09

Standard Test Method for

1

Creep-Fatigue Testing

This standard is issued under the fixed designation E2714; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope response (d) cycles to formation of a single crack or multiple

cracks in test specimens.

1.1 Thistestmethodcoversthedeterminationofmechanical

properties pertaining to creep-fatigue deformation or crack

NOTE 1—Acrack is believed to have formed when it has nucleated and

formation in nominally homogeneous materials, or both by the

propagated in a specimen that was initially uncracked to a specific size

that is detectable by a stated technique. For the purpose of this standard,

use of test specimens subjected to uniaxial forces under

the formation of a crack is evidenced by a measurable increase in

isothermal conditions. It concerns fatigue testing at strain rates

compliance of the specimen or by a size detectable by potential drop

or with cycles involving sufficiently long hold times to be

technique. Specific details of how to measure cycles to crack formation

responsible for the cyclic deformation response and cycles to

are described in 9.5.1.

crack formation to be affected by creep (and oxidation). It is

1.5 This test method is applicable to temperatures and strain

intended as a test method for fatigue testing performed in

rates for which the magnitudes of time-dependent inelastic

support of such activities as materials research and develop-

strains (creep) are on the same order or larger than time-

ment, mechanical design, process and quality control, product

independent inelastic

performance, and failure analysis. The cyclic conditions re-

sponsibleforcreep-fatiguedeformationandcrackingvarywith

NOTE 2—The term inelastic is used herein to refer to all nonelastic

material and with temperature for a given material. strains. The term plastic is used herein to refer only to time dependant

(that is, non-creep) component of inelastic strain. A useful engineering

1.2 The use of this test method is limited to specimens and

estimate of time-independent strain can be obtained when the strain rate

does not cover testing of full-scale components, structures, or

-3 -1

exceeds some value. For example, a strain rate of 1310 sec is often

consumer products.

used for this purpose. This value should increase with increasing test

1.3 This test method is primarily aimed at providing the

measurement.

material properties required for assessment of defect-free

1.6 The values stated in SI units are to be regarded as

engineering structures containing features that are subject to

standard. No other units of measurement are included in this

cyclicloadingattemperaturesthataresufficientlyhightocause

standard.

creep deformation.

1.7 This standard does not purport to address all of the

1.4 This test method is applicable to the determination of

safety concerns, if any, associated with its use. It is the

deformation and crack formation or nucleation properties as a

responsibility of the user of this standard to establish appro-

consequence of either constant-amplitude strain-controlled

priate safety and health practices and determine the applica-

tests or constant-amplitude force-controlled tests. It is primar-

bility of regulatory limitations prior to use.

ily concerned with the testing of round bar test specimens

subjected to uniaxial loading in either force or strain control.

2. Referenced Documents

The focus of the procedure is on tests in which creep and

2

2.1 ASTM Standards:

fatigue deformation and damage is generated simultaneously

E4 Practices for Force Verification of Testing Machines

within a given cycle. It does not cover block cycle testing in

E8/E8M Test Methods for Tension Testing of Metallic

whichcreepandfatiguedamageisgeneratedsequentially.Data

Materials

that may be determined from creep-fatigue tests performed

E83 Practice for Verification and Classification of Exten-

under conditions in which creep-fatigue deformation and

someter Systems

damage is generated simultaneously include (a) cyclic stress-

E111 Test Method forYoung’s Modulus, Tangent Modulus,

strain deformation response (b) cyclic creep (or relaxation)

and Chord Modulus

deformation response (c) cyclic hardening, cyclic softening

E139 Test Methods for Conducting Creep, Creep-Rupture,

and Stress-Rupture Tests of Metallic Materials

1

This test method is under the jurisdiction ofASTM Committee E08 on Fatigue

and Fracture and is the direct responsibility of Subcommittee E08.05 on Cyclic

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Deformation and Fati

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.