ASTM F3122-14(2022)

(Guide)Standard Guide for Evaluating Mechanical Properties of Metal Materials Made via Additive Manufacturing Processes

Standard Guide for Evaluating Mechanical Properties of Metal Materials Made via Additive Manufacturing Processes

SCOPE

1.1 This standard serves as a guide to existing standards or variations of existing standards that may be applicable to determine specific mechanical properties of materials made with an additive manufacturing process.

1.2 As noted in many of these referenced standards, there are several factors that may influence the reported properties, including material, material anisotropy, method of material preparation, porosity, method of specimen preparation, testing environment, specimen alignment and gripping, testing speed, and testing temperature. These factors should be recorded, to the extent that they are known, according to Practice F2971 and the guidelines of the referenced standards.

1.3 The following standards are not referred to directly in the guide but also have information that may be useful in the testing of metal test specimens made via additive manufacturing: A370, A1058, B211, B348, B557, B565, B724, B769, E3, E6, E7, E290, E467, E468, E837, E915, E1049,E1823, E1942.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F3122 − 14 (Reapproved 2022)

Standard Guide for

Evaluating Mechanical Properties of Metal Materials Made

via Additive Manufacturing Processes

This standard is issued under the fixed designation F3122; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This standard serves as a guide to existing standards or

variations of existing standards that may be applicable to A370 Test Methods and Definitions for Mechanical Testing

of Steel Products

determine specific mechanical properties of materials made

with an additive manufacturing process. A1058 Test Methods for Mechanical Testing of Steel

Products—Metric

1.2 As noted in many of these referenced standards, there

B211 Specification for Aluminum and Aluminum-Alloy

are several factors that may influence the reported properties,

Rolled or Cold-Finished Bar, Rod, and Wire (Metric)

including material, material anisotropy, method of material

B0211_B0211M

preparation, porosity, method of specimen preparation, testing

B348 Specification for Titanium and Titanium Alloy Bars

environment, specimen alignment and gripping, testing speed,

and Billets

and testing temperature. These factors should be recorded, to

B557 Test Methods for Tension Testing Wrought and Cast

the extent that they are known, according to Practice F2971

Aluminum- and Magnesium-Alloy Products

and the guidelines of the referenced standards.

B565 Test Method for Shear Testing of Aluminum and

1.3 The following standards are not referred to directly in

Aluminum-Alloy Rivets and Cold-Heading Wire and

the guide but also have information that may be useful in the

Rods

testing of metal test specimens made via additive manufactur-

B645 Practice for Linear-Elastic Plane-Strain Fracture

ing: A370, A1058, B211, B348, B557, B565, B724, B769, E3,

Toughness Testing of Aluminum Alloys

E6, E7, E290, E467, E468, E837, E915, E1049,E1823, E1942.

B646 Practice for Fracture Toughness Testing of Aluminum

Alloys

1.4 The values stated in SI units are to be regarded as

B647 Test Method for Indentation Hardness of Aluminum

standard. No other units of measurement are included in this

Alloys by Means of a Webster Hardness Gage

standard.

B648 Test Method for Indentation Hardness of Aluminum

1.5 This standard does not purport to address all of the

Alloys by Means of a Barcol Impressor

safety concerns, if any, associated with its use. It is the

B724 Test Method for Indentation Hardness of Aluminum

responsibility of the user of this standard to establish appro-

Alloys by Means of a Newage, Portable, Non-Caliper-

priate safety, health, and environmental practices and deter-

Type Instrument (Withdrawn 2013)

mine the applicability of regulatory limitations prior to use.

B769 Test Method for Shear Testing of Aluminum Alloys

1.6 This international standard was developed in accor-

B909 Guide for Plane Strain Fracture Toughness Testing of

dance with internationally recognized principles on standard-

Non-Stress Relieved Aluminum Products

ization established in the Decision on Principles for the

E3 Guide for Preparation of Metallographic Specimens

Development of International Standards, Guides and Recom-

E6 Terminology Relating to Methods of Mechanical Testing

mendations issued by the World Trade Organization Technical

E7 Terminology Relating to Metallography

Barriers to Trade (TBT) Committee.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

This guide is under the jurisdiction of ASTM Committee F42 on Additive contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Manufacturing Technologies and is the direct responsibility of Subcommittee Standards volume information, refer to the standard’s Document Summary page on

F42.01 on Test Methods. the ASTM website.

Current edition approved April 1, 2022. Published April 2022. Originally The last approved version of this historical standard is referenced on

approved in 2014 as F3122–14. DOI: 10.1520/F3122-14R22. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F3122 − 14 (2022)

E8/E8M Test Methods for Tension Testing of Metallic Ma- E1450 Test Method for Tension Testing of StructuralAlloys

terials in Liquid Helium

E1457 Test Method for Measurement of Creep Crack

E9 Test Methods of Compression Testing of Metallic Mate-

Growth Times in Metals

rials at Room Temperature

E1681 Test Method for Determining Threshold Stress Inten-

E10 Test Method for Brinell Hardness of Metallic Materials

sityFactorforEnvironment-AssistedCrackingofMetallic

E18 Test Methods for Rockwell Hardness of Metallic Ma-

Materials

terials

E1820 Test Method for Measurement of Fracture Toughness

E21 TestMethodsforElevatedTemperatureTensionTestsof

E1823 TerminologyRelatingtoFatigueandFractureTesting

Metallic Materials

E1875 Test Method for Dynamic Young’s Modulus, Shear

E23 Test Methods for Notched Bar Impact Testing of Me-

Modulus, and Poisson’s Ratio by Sonic Resonance

tallic Materials

E1876 Test Method for Dynamic Young’s Modulus, Shear

E111 Test Method for Young’s Modulus, Tangent Modulus,

Modulus, and Poisson’s Ratio by Impulse Excitation of

and Chord Modulus

Vibration

E132 Test Method for Poisson’s Ratio at Room Temperature

E1942 Guide for Evaluating DataAcquisition Systems Used

E140 Hardness Conversion Tables for Metals Relationship

in Cyclic Fatigue and Fracture Mechanics Testing

Among Brinell Hardness, Vickers Hardness, Rockwell

E2368 Practice for Strain Controlled Thermomechanical

Hardness, Superficial Hardness, Knoop Hardness, Sclero-

Fatigue Testing

scope Hardness, and Leeb Hardness

E2472 Test Method for Determination of Resistance to

E143 Test Method for Shear Modulus at Room Temperature

Stable Crack Extension under Low-Constraint Conditions

E209 PracticeforCompressionTestsofMetallicMaterialsat

E2714 Test Method for Creep-Fatigue Testing

Elevated Temperatures with Conventional or Rapid Heat-

E2760 TestMethodforCreep-FatigueCrackGrowthTesting

ing Rates and Strain Rates

E2789 Guide for Fretting Fatigue Testing

E238 Test Method for Pin-Type Bearing Test of Metallic

F2971 Practice for Reporting Data for Test Specimens Pre-

Materials

pared by Additive Manufacturing

E290 Test Methods for Bend Testing of Material for Ductil-

F2792 Terminology for Additive Manufacturing Technolo-

ity

gies (Withdrawn 2015)

E292 Test Methods for Conducting Time-for-Rupture Notch

ISO/ASTM 52921 Terminology for Additive

Tension Tests of Materials

Manufacturing—Coordinate Systems and Test Method-

E384 Test Method for Microindentation Hardness of Mate- ologies

rials 2.2 ISO Standards:

E399 Test Method for Linear-Elastic Plane-Strain Fracture EN ISO 148-1 Metallic materials—Charpy pendulum im-

Toughness of Metallic Materials pact test—Part 1: Test method

ISO 148-3 Metallic materials—Charpy pendulum impact

E448 Practice for Scleroscope Hardness Testing of Metallic

test—Part 3: Preparation and characterization of Charpy

Materials (Withdrawn 2017)

V-notch test pieces for indirect verification of pendulum

E466 Practice for Conducting Force Controlled Constant

impact machines

Amplitude Axial Fatigue Tests of Metallic Materials

ISO 377 Steel and steel products—Location and preparation

E467 Practice for Verification of Constant Amplitude Dy-

of samples and test pieces for mechanical testing

namic Forces in an Axial Fatigue Testing System

ISO 1099 Metallic materials—Fatigue testing—Axial force-

E468 Practice for Presentation of Constant Amplitude Fa-

controlled method

tigue Test Results for Metallic Materials

ISO 1143 Metallic materials—Rotating bar bending fatigue

E606 Test Method for Strain-Controlled Fatigue Testing

testing

E647 Test Method for Measurement of Fatigue Crack

ISO 1352 Metallic materials—Torque-controlled fatigue

Growth Rates

testing

E740 Practice for Fracture Testing with Surface-Crack Ten-

EN ISO 4545-1 Metallic materials—Knoop hardness test—

sion Specimens

Part 1: Test method

E837 Test Method for Determining Residual Stresses by the

ISO/DIS 5173 Destructive tests on welds in metallic

Hole-Drilling Strain-Gage Method

materials—Bend tests

E915 PracticeforVerifyingtheAlignmentofX-RayDiffrac-

EN ISO 6506-1 Metallic materials—Brinell hardness test—

tion Instruments for Residual Stress Measurement

Part 1: Test method

E1049 Practices for Cycle Counting in Fatigue Analysis

EN ISO 6507-1 Metallic materials—Vickers hardness test—

E1221 Test Method for Determining Plane-Strain Crack-

Part 1: Test method

Arrest Fracture Toughness, K , of Ferritic Steels

Ia

EN ISO 6508 Metallic materials—Rockwell hardness test—

E1290 Test Method for Crack-Tip Opening Displacement

Part 1: Test method (scales A, B, C, D, E, F, G, H, K, N,

(CTOD) Fracture Toughness Measurement (Withdrawn

T)

2013)

E1304 Test Method for Plane-Strain (Chevron-Notch) Frac- 4

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

ture Toughness of Metallic Materials 4th Floor, New York, NY 10036, http://www.ansi.org.

F3122 − 14 (2022)

ISO 6892-1 Metallic materials—Tensile testing—Part 1: wire-, and rod-shaped specimens with small diameters are

Method of test at room temperature difficult to build through an additive process.

ISO 6892-2 Metallic materials—Tensile testing—Part 2:

4.1.2 In the tension testing procedures outlined in Test

Method of test at elevated temperature

Methods E292 (for determining a material’s rupture strength)

EN ISO 7438 Metallic materials—Bend test

and Practice E740 (for determining metal plate yield strength),

ISO 11531 Metallic materials—Earing test

TestMethodsE8/E8M’smethodsarefollowed,butthesamples

ISO 12106 Metallic materials—Fatigue testing—Axial-

are first prepared with a notch or surface-crack before subject-

strain-controlled method

ing them to tension. While Test Method E292 is applicable to

ISO 12108 Metallic materials—Fatigue testing—Fatigue

materials made additively, it must be noted that thin specimens

crack growth method

made according to Practice E740 may be challenging to make

ISO 12111 Metallic materials—Fatigue testing—Strain-

in some additive manufacturing processes.

controlled thermomechanical fatigue testing method

4.1.3 Two ISO Standards, ISO 26203-1 and ISO 26203-2,

ISO 12135 Metallic materials—Unified method of test for

describe testing sheet metal, such as the material used for

the determination of quasistatic fracture toughness

automotive bodies, at high strain rates. These standards are not

ISO 12737 Metallic materials—Determination of plane-

applicable to materials made additively, because sheet material

strain fracture toughness

would not be made with such a process.

ISO 14556 Steel—Charpy V-notch pendulum impact test—

4.2 Compression:

Instrumented test method

4.2.1 The procedures outlined in Test Methods E9 and

EN ISO 14577 Metallic materials—Instrumented indenta-

Practice E209 describe the basic method for uniaxial compres-

tion test for hardness and materials parameters—Part 1:

sion testing of metallic samples at various temperatures. The

Test method

procedures are used in determining a material’s compressive

ISO/TR 14936 Metallic materials—Strain analysis report

yield strength and compression strength. These standards are

ISO 15579 Metallic materials—Tensile testing at low tem-

applicable to materials made additively, but not all of the

perature

sample types (thin sheets) can be successfully built through an

ISO 19819 Metallic materials—Tensile testing in liquid

additive process.

helium

ISO 22889 Metallic materials—Method of test for the deter-

4.3 Bearing:

mination of resistance to stable crack extension using

4.3.1 TheproceduresoutlinedinTestMethodE238describe

specimens of low constraint

the method used to determine bearing yield strength and

ISO 26203-1 Metallic materials—Tensile testing at high

bearing strength for a rectangular metal specimen containing a

strain rates—Part 1: Elastic-bar-type systems

hole for a bearing pin. This standard is applicable to materials

ISO 26203-2 Metallic materials—Tensile testing at high

made additively, but the surface finish requirements and some

strain rates—Part 2: Servo-hydraulic and other test sys-

thickness requirements for the specimen may be problematic

tems

for some additive manufacturing processes.

ISO 27306 Metallic materials—Method of constraint loss

4.4 Bend:

correctionofCTODfracturetoughnessforfractureassess-

ment of steel components

4.4.1 Practice E209 describes the methods that determine

ISO/TR 29381 Metallic materials—Measurement of me-

the limit of plastic deformation allowed in a metallic material

chanical properties by an instrumented indentation test—

during bending. The criterion used to evaluate the quality of

Indentation tensile properties materials includes their ability to resist cracking or other

ISO 3369 Impermeable sintered metal materials and

surface irregularities. ISO 7438 includes plastic deformation

hardmetals—Determination of density methods to evaluate a material’s ability to resist cracking. ISO

ISO 3452-1 Non-destructive-testing—Penetration testing—

7438 also includes the methodology behind measuring the

Part 1: General principles bending strength, the limit of elasticity bending, bending

moments and the bending angle using plastic deformation

3. Terminology

methods. These standards are also applicable for metal based

3.1 Definitions:

additive manufactured parts.

3.1.1 Terminology relating to additive manufacturing in

4.5 Modulus:

Terminology F2792 shall apply.

4.5.1 The following section includes standard test methods

3.1.2 Terminology relating to additive manufacturing in

to evaluate elastic moduli and Poisson’s Ratio. These test

ISO/ASTM 52921 shall apply.

methods could be used in the determination of elastic proper-

4. Measuring Deformation Properties

ties of metal based AM materials.

4.1 Tension: 4.5.2 Tension tests, as described by Test Methods E8/E8M,

4.1.1 The procedures outlined in Test Methods E8/E8M, can be used to determine the Young’s modulus, tangent

E21, E1450, ISO 6892-1, ISO 6892-2, ISO 15579, and ISO modulus and chord modulus of AM structural materials. Test

19819 explain guidelines for tension testing under various Method E111 describes how to determine the elastic material

conditions to determine a material’s yield and tensile strengths. property based on the ten

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F3122 − 14 (Reapproved 2022)

Standard Guide for

Evaluating Mechanical Properties of Metal Materials Made

via Additive Manufacturing Processes

This standard is issued under the fixed designation F3122; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This standard serves as a guide to existing standards or 2.1 ASTM Standards:

variations of existing standards that may be applicable to A370 Test Methods and Definitions for Mechanical Testing

determine specific mechanical properties of materials made of Steel Products

with an additive manufacturing process. A1058 Test Methods for Mechanical Testing of Steel

Products—Metric

1.2 As noted in many of these referenced standards, there

B211 Specification for Aluminum and Aluminum-Alloy

are several factors that may influence the reported properties,

Rolled or Cold-Finished Bar, Rod, and Wire (Metric)

including material, material anisotropy, method of material

B0211_B0211M

preparation, porosity, method of specimen preparation, testing

B348 Specification for Titanium and Titanium Alloy Bars

environment, specimen alignment and gripping, testing speed,

and Billets

and testing temperature. These factors should be recorded, to

B557 Test Methods for Tension Testing Wrought and Cast

the extent that they are known, according to Practice F2971

Aluminum- and Magnesium-Alloy Products

and the guidelines of the referenced standards.

B565 Test Method for Shear Testing of Aluminum and

1.3 The following standards are not referred to directly in

Aluminum-Alloy Rivets and Cold-Heading Wire and

the guide but also have information that may be useful in the

Rods

testing of metal test specimens made via additive manufactur-

B645 Practice for Linear-Elastic Plane-Strain Fracture

ing: A370, A1058, B211, B348, B557, B565, B724, B769, E3,

Toughness Testing of Aluminum Alloys

E6, E7, E290, E467, E468, E837, E915, E1049,E1823, E1942.

B646 Practice for Fracture Toughness Testing of Aluminum

Alloys

1.4 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this B647 Test Method for Indentation Hardness of Aluminum

Alloys by Means of a Webster Hardness Gage

standard.

B648 Test Method for Indentation Hardness of Aluminum

1.5 This standard does not purport to address all of the

Alloys by Means of a Barcol Impressor

safety concerns, if any, associated with its use. It is the

B724 Test Method for Indentation Hardness of Aluminum

responsibility of the user of this standard to establish appro-

Alloys by Means of a Newage, Portable, Non-Caliper-

priate safety, health, and environmental practices and deter-

Type Instrument (Withdrawn 2013)

mine the applicability of regulatory limitations prior to use.

B769 Test Method for Shear Testing of Aluminum Alloys

1.6 This international standard was developed in accor-

B909 Guide for Plane Strain Fracture Toughness Testing of

dance with internationally recognized principles on standard-

Non-Stress Relieved Aluminum Products

ization established in the Decision on Principles for the

E3 Guide for Preparation of Metallographic Specimens

Development of International Standards, Guides and Recom-

E6 Terminology Relating to Methods of Mechanical Testing

mendations issued by the World Trade Organization Technical

E7 Terminology Relating to Metallography

Barriers to Trade (TBT) Committee.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

This guide is under the jurisdiction of ASTM Committee F42 on Additive contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Manufacturing Technologies and is the direct responsibility of Subcommittee Standards volume information, refer to the standard’s Document Summary page on

F42.01 on Test Methods. the ASTM website.

Current edition approved April 1, 2022. Published April 2022. Originally The last approved version of this historical standard is referenced on

approved in 2014 as F3122–14. DOI: 10.1520/F3122-14R22. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F3122 − 14 (2022)

E8/E8M Test Methods for Tension Testing of Metallic Ma- E1450 Test Method for Tension Testing of Structural Alloys

in Liquid Helium

terials

E1457 Test Method for Measurement of Creep Crack

E9 Test Methods of Compression Testing of Metallic Mate-

Growth Times in Metals

rials at Room Temperature

E1681 Test Method for Determining Threshold Stress Inten-

E10 Test Method for Brinell Hardness of Metallic Materials

sity Factor for Environment-Assisted Cracking of Metallic

E18 Test Methods for Rockwell Hardness of Metallic Ma-

Materials

terials

E1820 Test Method for Measurement of Fracture Toughness

E21 Test Methods for Elevated Temperature Tension Tests of

E1823 Terminology Relating to Fatigue and Fracture Testing

Metallic Materials

E1875 Test Method for Dynamic Young’s Modulus, Shear

E23 Test Methods for Notched Bar Impact Testing of Me-

Modulus, and Poisson’s Ratio by Sonic Resonance

tallic Materials

E1876 Test Method for Dynamic Young’s Modulus, Shear

E111 Test Method for Young’s Modulus, Tangent Modulus,

Modulus, and Poisson’s Ratio by Impulse Excitation of

and Chord Modulus

Vibration

E132 Test Method for Poisson’s Ratio at Room Temperature

E1942 Guide for Evaluating Data Acquisition Systems Used

E140 Hardness Conversion Tables for Metals Relationship

in Cyclic Fatigue and Fracture Mechanics Testing

Among Brinell Hardness, Vickers Hardness, Rockwell

E2368 Practice for Strain Controlled Thermomechanical

Hardness, Superficial Hardness, Knoop Hardness, Sclero-

Fatigue Testing

scope Hardness, and Leeb Hardness

E2472 Test Method for Determination of Resistance to

E143 Test Method for Shear Modulus at Room Temperature

Stable Crack Extension under Low-Constraint Conditions

E209 Practice for Compression Tests of Metallic Materials at

E2714 Test Method for Creep-Fatigue Testing

Elevated Temperatures with Conventional or Rapid Heat-

E2760 Test Method for Creep-Fatigue Crack Growth Testing

ing Rates and Strain Rates

E2789 Guide for Fretting Fatigue Testing

E238 Test Method for Pin-Type Bearing Test of Metallic

F2971 Practice for Reporting Data for Test Specimens Pre-

Materials

pared by Additive Manufacturing

E290 Test Methods for Bend Testing of Material for Ductil-

F2792 Terminology for Additive Manufacturing Technolo-

ity

gies (Withdrawn 2015)

E292 Test Methods for Conducting Time-for-Rupture Notch

ISO/ASTM 52921 Terminology for Additive

Tension Tests of Materials

Manufacturing—Coordinate Systems and Test Method-

E384 Test Method for Microindentation Hardness of Mate-

ologies

rials 2.2 ISO Standards:

E399 Test Method for Linear-Elastic Plane-Strain Fracture EN ISO 148-1 Metallic materials—Charpy pendulum im-

pact test—Part 1: Test method

Toughness of Metallic Materials

ISO 148-3 Metallic materials—Charpy pendulum impact

E448 Practice for Scleroscope Hardness Testing of Metallic

test—Part 3: Preparation and characterization of Charpy

Materials (Withdrawn 2017)

V-notch test pieces for indirect verification of pendulum

E466 Practice for Conducting Force Controlled Constant

impact machines

Amplitude Axial Fatigue Tests of Metallic Materials

ISO 377 Steel and steel products—Location and preparation

E467 Practice for Verification of Constant Amplitude Dy-

of samples and test pieces for mechanical testing

namic Forces in an Axial Fatigue Testing System

ISO 1099 Metallic materials—Fatigue testing—Axial force-

E468 Practice for Presentation of Constant Amplitude Fa-

controlled method

tigue Test Results for Metallic Materials

ISO 1143 Metallic materials—Rotating bar bending fatigue

E606 Test Method for Strain-Controlled Fatigue Testing

testing

E647 Test Method for Measurement of Fatigue Crack

ISO 1352 Metallic materials—Torque-controlled fatigue

Growth Rates

testing

E740 Practice for Fracture Testing with Surface-Crack Ten-

EN ISO 4545-1 Metallic materials—Knoop hardness test—

sion Specimens

Part 1: Test method

E837 Test Method for Determining Residual Stresses by the

ISO/DIS 5173 Destructive tests on welds in metallic

Hole-Drilling Strain-Gage Method

materials—Bend tests

E915 Practice for Verifying the Alignment of X-Ray Diffrac-

EN ISO 6506-1 Metallic materials—Brinell hardness test—

tion Instruments for Residual Stress Measurement

Part 1: Test method

E1049 Practices for Cycle Counting in Fatigue Analysis

EN ISO 6507-1 Metallic materials—Vickers hardness test—

E1221 Test Method for Determining Plane-Strain Crack-

Part 1: Test method

Arrest Fracture Toughness, K , of Ferritic Steels

Ia

EN ISO 6508 Metallic materials—Rockwell hardness test—

E1290 Test Method for Crack-Tip Opening Displacement

Part 1: Test method (scales A, B, C, D, E, F, G, H, K, N,

(CTOD) Fracture Toughness Measurement (Withdrawn

T)

2013)

E1304 Test Method for Plane-Strain (Chevron-Notch) Frac- 4

Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

ture Toughness of Metallic Materials 4th Floor, New York, NY 10036, http://www.ansi.org.

F3122 − 14 (2022)

ISO 6892-1 Metallic materials—Tensile testing—Part 1: wire-, and rod-shaped specimens with small diameters are

Method of test at room temperature difficult to build through an additive process.

ISO 6892-2 Metallic materials—Tensile testing—Part 2:

4.1.2 In the tension testing procedures outlined in Test

Method of test at elevated temperature

Methods E292 (for determining a material’s rupture strength)

EN ISO 7438 Metallic materials—Bend test

and Practice E740 (for determining metal plate yield strength),

ISO 11531 Metallic materials—Earing test

Test Methods E8/E8M’s methods are followed, but the samples

ISO 12106 Metallic materials—Fatigue testing—Axial-

are first prepared with a notch or surface-crack before subject-

strain-controlled method

ing them to tension. While Test Method E292 is applicable to

ISO 12108 Metallic materials—Fatigue testing—Fatigue

materials made additively, it must be noted that thin specimens

crack growth method

made according to Practice E740 may be challenging to make

ISO 12111 Metallic materials—Fatigue testing—Strain-

in some additive manufacturing processes.

controlled thermomechanical fatigue testing method

4.1.3 Two ISO Standards, ISO 26203-1 and ISO 26203-2,

ISO 12135 Metallic materials—Unified method of test for

describe testing sheet metal, such as the material used for

the determination of quasistatic fracture toughness

automotive bodies, at high strain rates. These standards are not

ISO 12737 Metallic materials—Determination of plane-

applicable to materials made additively, because sheet material

strain fracture toughness

would not be made with such a process.

ISO 14556 Steel—Charpy V-notch pendulum impact test—

4.2 Compression:

Instrumented test method

4.2.1 The procedures outlined in Test Methods E9 and

EN ISO 14577 Metallic materials—Instrumented indenta-

Practice E209 describe the basic method for uniaxial compres-

tion test for hardness and materials parameters—Part 1:

sion testing of metallic samples at various temperatures. The

Test method

procedures are used in determining a material’s compressive

ISO/TR 14936 Metallic materials—Strain analysis report

yield strength and compression strength. These standards are

ISO 15579 Metallic materials—Tensile testing at low tem-

applicable to materials made additively, but not all of the

perature

sample types (thin sheets) can be successfully built through an

ISO 19819 Metallic materials—Tensile testing in liquid

additive process.

helium

ISO 22889 Metallic materials—Method of test for the deter-

4.3 Bearing:

mination of resistance to stable crack extension using

4.3.1 The procedures outlined in Test Method E238 describe

specimens of low constraint

the method used to determine bearing yield strength and

ISO 26203-1 Metallic materials—Tensile testing at high

bearing strength for a rectangular metal specimen containing a

strain rates—Part 1: Elastic-bar-type systems

hole for a bearing pin. This standard is applicable to materials

ISO 26203-2 Metallic materials—Tensile testing at high

made additively, but the surface finish requirements and some

strain rates—Part 2: Servo-hydraulic and other test sys-

thickness requirements for the specimen may be problematic

tems

for some additive manufacturing processes.

ISO 27306 Metallic materials—Method of constraint loss

4.4 Bend:

correction of CTOD fracture toughness for fracture assess-

ment of steel components

4.4.1 Practice E209 describes the methods that determine

ISO/TR 29381 Metallic materials—Measurement of me-

the limit of plastic deformation allowed in a metallic material

chanical properties by an instrumented indentation test— during bending. The criterion used to evaluate the quality of

Indentation tensile properties

materials includes their ability to resist cracking or other

ISO 3369 Impermeable sintered metal materials and surface irregularities. ISO 7438 includes plastic deformation

hardmetals—Determination of density

methods to evaluate a material’s ability to resist cracking. ISO

ISO 3452-1 Non-destructive-testing—Penetration testing— 7438 also includes the methodology behind measuring the

Part 1: General principles

bending strength, the limit of elasticity bending, bending

moments and the bending angle using plastic deformation

3. Terminology

methods. These standards are also applicable for metal based

3.1 Definitions:

additive manufactured parts.

3.1.1 Terminology relating to additive manufacturing in

4.5 Modulus:

Terminology F2792 shall apply.

4.5.1 The following section includes standard test methods

3.1.2 Terminology relating to additive manufacturing in

to evaluate elastic moduli and Poisson’s Ratio. These test

ISO/ASTM 52921 shall apply.

methods could be used in the determination of elastic proper-

4. Measuring Deformation Properties

ties of metal based AM materials.

4.1 Tension: 4.5.2 Tension tests, as described by Test Methods E8/E8M,

4.1.1 The procedures outlined in Test Methods E8/E8M, can be used to determine the Young’s modulus, tangent

E21, E1450, ISO 6892-1, ISO 6892-2, ISO 15579, and ISO modulus and chord modulus of AM structural materials. Test

19819 explain guidelines for tension testing under various Method E111 describes how to determine the elastic material

conditions to determine a material’s yield and tensile strengths. property based on the tension test (E8/E8M) or compression

All are applicable to materials made additivel

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F3122 − 14 F3122 − 14 (Reapproved 2022)

Standard Guide for

Evaluating Mechanical Properties of Metal Materials Made

via Additive Manufacturing Processes

This standard is issued under the fixed designation F3122; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This standard serves as a guide to existing standards or variations of existing standards that may be applicable to determine

specific mechanical properties of materials made with an additive manufacturing process.

1.2 As noted in many of these referenced standards, there are several factors that may influence the reported properties, including

material, material anisotropy, method of material preparation, porosity, method of specimen preparation, testing environment,

specimen alignment and gripping, testing speed, and testing temperature. These factors should be recorded, to the extent that they

are known, according to Practice F2971 and the guidelines of the referenced standards.

1.3 The following standards are not referred to directly in the guide but also have information that may be useful in the testing

of metal test specimens made via additive manufacturing: A370, A1058, B211, B348, B557, B565, B724, B769, E3, E6, E7, E290,

E467, E468, E837, E915, E1049,E1823, E1942.

1.4 Units—The values stated in SI units are to be regarded as the standard. No other units of measurement are included in this

standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A1058 Test Methods for Mechanical Testing of Steel Products—Metric

B211 Specification for Aluminum and Aluminum-Alloy Rolled or Cold-Finished Bar, Rod, and Wire (Metric) B0211_B0211M

B348 Specification for Titanium and Titanium Alloy Bars and Billets

B557 Test Methods for Tension Testing Wrought and Cast Aluminum- and Magnesium-Alloy Products

This test method guide is under the jurisdiction of ASTM Committee F42 on Additive Manufacturing Technologies and is the direct responsibility of Subcommittee

F42.01 on Test Methods.

Current edition approved Nov. 1, 2014April 1, 2022. Published December 2014April 2022. Originally approved in 2014 as F3122–14. DOI: 10.1520/F3122-14.10.1520/

F3122-14R22.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F3122 − 14 (2022)

B565 Test Method for Shear Testing of Aluminum and Aluminum-Alloy Rivets and Cold-Heading Wire and Rods

B645 Practice for Linear-Elastic Plane-Strain Fracture Toughness Testing of Aluminum Alloys

B646 Practice for Fracture Toughness Testing of Aluminum Alloys

B647 Test Method for Indentation Hardness of Aluminum Alloys by Means of a Webster Hardness Gage

B648 Test Method for Indentation Hardness of Aluminum Alloys by Means of a Barcol Impressor

B724 Test Method for Indentation Hardness of Aluminum Alloys by Means of a Newage, Portable, Non-Caliper-Type

Instrument (Withdrawn 2013)

B769 Test Method for Shear Testing of Aluminum Alloys

B909 Guide for Plane Strain Fracture Toughness Testing of Non-Stress Relieved Aluminum Products

E3 Guide for Preparation of Metallographic Specimens

E6 Terminology Relating to Methods of Mechanical Testing

E7 Terminology Relating to Metallography

E8/E8M Test Methods for Tension Testing of Metallic Materials

E9 Test Methods of Compression Testing of Metallic Materials at Room Temperature

E10 Test Method for Brinell Hardness of Metallic Materials

E18 Test Methods for Rockwell Hardness of Metallic Materials

E21 Test Methods for Elevated Temperature Tension Tests of Metallic Materials

E23 Test Methods for Notched Bar Impact Testing of Metallic Materials

E111 Test Method for Young’s Modulus, Tangent Modulus, and Chord Modulus

E132 Test Method for Poisson’s Ratio at Room Temperature

E140 Hardness Conversion Tables for Metals Relationship Among Brinell Hardness, Vickers Hardness, Rockwell Hardness,

Superficial Hardness, Knoop Hardness, Scleroscope Hardness, and Leeb Hardness

E143 Test Method for Shear Modulus at Room Temperature

E209 Practice for Compression Tests of Metallic Materials at Elevated Temperatures with Conventional or Rapid Heating Rates

and Strain Rates

E238 Test Method for Pin-Type Bearing Test of Metallic Materials

E290 Test Methods for Bend Testing of Material for Ductility

E292 Test Methods for Conducting Time-for-Rupture Notch Tension Tests of Materials

E384 Test Method for Microindentation Hardness of Materials

E399 Test Method for Linear-Elastic Plane-Strain Fracture Toughness of Metallic Materials

E448 Practice for Scleroscope Hardness Testing of Metallic Materials (Withdrawn 2017)

E466 Practice for Conducting Force Controlled Constant Amplitude Axial Fatigue Tests of Metallic Materials

E467 Practice for Verification of Constant Amplitude Dynamic Forces in an Axial Fatigue Testing System

E468 Practice for Presentation of Constant Amplitude Fatigue Test Results for Metallic Materials

E606 Test Method for Strain-Controlled Fatigue Testing

E647 Test Method for Measurement of Fatigue Crack Growth Rates

E740 Practice for Fracture Testing with Surface-Crack Tension Specimens

E837 Test Method for Determining Residual Stresses by the Hole-Drilling Strain-Gage Method

E915 Practice for Verifying the Alignment of X-Ray Diffraction Instruments for Residual Stress Measurement

E1049 Practices for Cycle Counting in Fatigue Analysis

E1221 Test Method for Determining Plane-Strain Crack-Arrest Fracture Toughness, K , of Ferritic Steels

Ia

E1290 Test Method for Crack-Tip Opening Displacement (CTOD) Fracture Toughness Measurement (Withdrawn 2013)

E1304 Test Method for Plane-Strain (Chevron-Notch) Fracture Toughness of Metallic Materials

E1450 Test Method for Tension Testing of Structural Alloys in Liquid Helium

E1457 Test Method for Measurement of Creep Crack Growth Times in Metals

E1681 Test Method for Determining Threshold Stress Intensity Factor for Environment-Assisted Cracking of Metallic Materials

E1820 Test Method for Measurement of Fracture Toughness

E1823 Terminology Relating to Fatigue and Fracture Testing

E1875 Test Method for Dynamic Young’s Modulus, Shear Modulus, and Poisson’s Ratio by Sonic Resonance

E1876 Test Method for Dynamic Young’s Modulus, Shear Modulus, and Poisson’s Ratio by Impulse Excitation of Vibration

E1942 Guide for Evaluating Data Acquisition Systems Used in Cyclic Fatigue and Fracture Mechanics Testing

E2368 Practice for Strain Controlled Thermomechanical Fatigue Testing

E2472 Test Method for Determination of Resistance to Stable Crack Extension under Low-Constraint Conditions

E2714 Test Method for Creep-Fatigue Testing

E2760 Test Method for Creep-Fatigue Crack Growth Testing

E2789 Guide for Fretting Fatigue Testing

The last approved version of this historical standard is referenced on www.astm.org.

F3122 − 14 (2022)

F2971 Practice for Reporting Data for Test Specimens Prepared by Additive Manufacturing

F2792 Terminology for Additive Manufacturing Technologies (Withdrawn 2015)

ISO/ASTM 52921 Terminology for Additive Manufacturing—Coordinate Systems and Test Methodologies

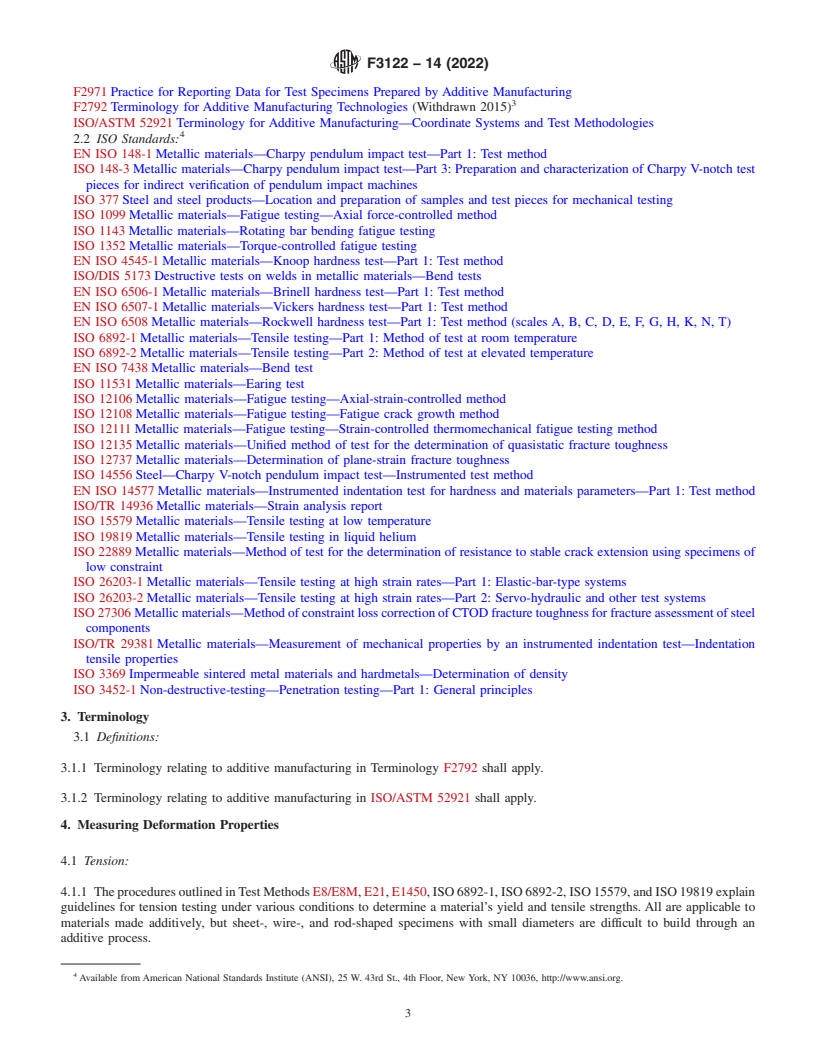

2.2 ISO Standards:

EN ISO 148-1 Metallic materials—Charpy pendulum impact test—Part 1: Test method

ISO 148-3 Metallic materials—Charpy pendulum impact test—Part 3: Preparation and characterization of Charpy V-notch test

pieces for indirect verification of pendulum impact machines

ISO 377 Steel and steel products—Location and preparation of samples and test pieces for mechanical testing

ISO 1099 Metallic materials—Fatigue testing—Axial force-controlled method

ISO 1143 Metallic materials—Rotating bar bending fatigue testing

ISO 1352 Metallic materials—Torque-controlled fatigue testing

EN ISO 4545-1 Metallic materials—Knoop hardness test—Part 1: Test method

ISO/DIS 5173 Destructive tests on welds in metallic materials—Bend tests

EN ISO 6506-1 Metallic materials—Brinell hardness test—Part 1: Test method

EN ISO 6507-1 Metallic materials—Vickers hardness test—Part 1: Test method

EN ISO 6508 Metallic materials—Rockwell hardness test—Part 1: Test method (scales A, B, C, D, E, F, G, H, K, N, T)

ISO 6892-1 Metallic materials—Tensile testing—Part 1: Method of test at room temperature

ISO 6892-2 Metallic materials—Tensile testing—Part 2: Method of test at elevated temperature

EN ISO 7438 Metallic materials—Bend test

ISO 11531 Metallic materials—Earing test

ISO 12106 Metallic materials—Fatigue testing—Axial-strain-controlled method

ISO 12108 Metallic materials—Fatigue testing—Fatigue crack growth method

ISO 12111 Metallic materials—Fatigue testing—Strain-controlled thermomechanical fatigue testing method

ISO 12135 Metallic materials—Unified method of test for the determination of quasistatic fracture toughness

ISO 12737 Metallic materials—Determination of plane-strain fracture toughness

ISO 14556 Steel—Charpy V-notch pendulum impact test—Instrumented test method

EN ISO 14577 Metallic materials—Instrumented indentation test for hardness and materials parameters—Part 1: Test method

ISO/TR 14936 Metallic materials—Strain analysis report

ISO 15579 Metallic materials—Tensile testing at low temperature

ISO 19819 Metallic materials—Tensile testing in liquid helium

ISO 22889 Metallic materials—Method of test for the determination of resistance to stable crack extension using specimens of

low constraint

ISO 26203-1 Metallic materials—Tensile testing at high strain rates—Part 1: Elastic-bar-type systems

ISO 26203-2 Metallic materials—Tensile testing at high strain rates—Part 2: Servo-hydraulic and other test systems

ISO 27306 Metallic materials—Method of constraint loss correction of CTOD fracture toughness for fracture assessment of steel

components

ISO/TR 29381 Metallic materials—Measurement of mechanical properties by an instrumented indentation test—Indentation

tensile properties

ISO 3369 Impermeable sintered metal materials and hardmetals—Determination of density

ISO 3452-1 Non-destructive-testing—Penetration testing—Part 1: General principles

3. Terminology

3.1 Definitions:

3.1.1 Terminology relating to additive manufacturing in Terminology F2792 shall apply.

3.1.2 Terminology relating to additive manufacturing in ISO/ASTM 52921 shall apply.

4. Measuring Deformation Properties

4.1 Tension:

4.1.1 The procedures outlined in Test Methods E8/E8M, E21, E1450, ISO 6892-1, ISO 6892-2, ISO 15579, and ISO 19819 explain

guidelines for tension testing under various conditions to determine a material’s yield and tensile strengths. All are applicable to

materials made additively, but sheet-, wire-, and rod-shaped specimens with small diameters are difficult to build through an

additive process.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

F3122 − 14 (2022)

4.1.2 In the tension testing procedures outlined in Test Methods E292 (for determining a material’s rupture strength) and Practice

E740 (for determining metal plate yield strength), Test Methods E8/E8M’s methods are followed, but the samples are first prepared

with a notch or surface-crack before subjecting them to tension. While Test Method E292 is applicable to materials made

additively, it must be noted that thin specimens made according to Practice E740 may be challenging to make in some additive

manufacturing processes.

4.1.3 Two ISO Standards, ISO 26203-1 and ISO 26203-2, describe testing sheet metal, such as the material used for automotive

bodies, at high strain rates. These standards are not applicable to materials made additively, because sheet material would not be

made with such a process.

4.2 Compression:

4.2.1 The procedures outlined in Test Methods E9 and Practice E209 describe the basic method for uniaxial compression testing

of metallic samples at various temperatures. The procedures are used in determining a material’s compressive yield strength and

compression strength. These standards are applicable to materials made additively, but not all of the sample types (thin sheets) can

be successfully built through an additive process.

4.3 Bearing:

4.3.1 The procedures outlined in Test Method E238 describe the method used to determine bearing yield strength and bearing

strength for a rectangular metal specimen containing a hole for a bearing pin. This standard is applicable to materials made

additively, but the surface finish requirements and some thickness requirements for the specimen may be problematic for some

additive manufacturing processes.

4.4 Bend:

4.4.1 Practice E209 describes the methods that determine the limit of plastic deformation allowed in a metallic material during

bending. The criterion used to evaluate the quality of materials includes their ability to resist cracking or other surface irregularities.

ISO 7438 includes plastic deformation methods to evaluate a material’s ability to resist cracking. ISO 7438 also includes the

methodology behind measuring the bending strength, the limit of elasticity bending, bending moments and the bending angle using

plastic deformation methods. These standards are also applicable for metal based additive manufactured parts.

4.5 Modulus:

4.5.1 The following section includes standard test methods to evaluate elastic moduli and Poisson’s Ratio. These test methods

could b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.