ASTM A213/A213M-15a

(Specification)Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes

Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes

ABSTRACT

This specification covers seamless ferritic and austenitic steel boiler, superheater, and heat-exchanger tubes. Grades containing the letter H in their designation have requirements different from those of similar grades not containing the letter H. These different requirements provide higher creep-rupture strength than normally achievable in similar grades without these different requirements. The tubes shall be made by the seamless process and shall be either hot finished or cold finished, as specified. Grade TP347HFG shall be cold finished. Heat treatment shall be done separately and in addition to heating for hot forming. The ferritic alloy and ferritic stainless steels shall be reheated. On the other hand, austenitic stainless steel tubes shall be furnished in the heat-treated condition. Alternatively, immediately after hot forming, while the temperature of the tubes is not less than the minimum solution temperature, tubes may be individually quenched in water or rapidly cooled by other means. Tension test, hardness test, flattening test, and flaring test shall be done to each tube. Also, each tube shall be subjected to the nondestructive electric test or hydrostatic test.

SCOPE

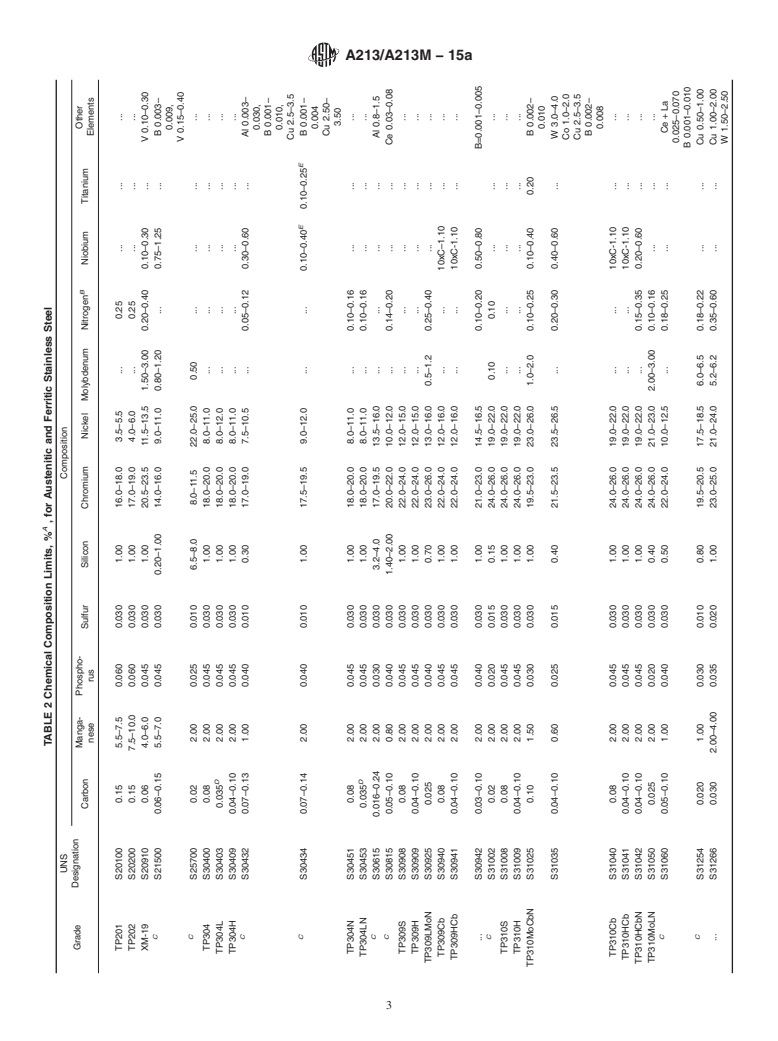

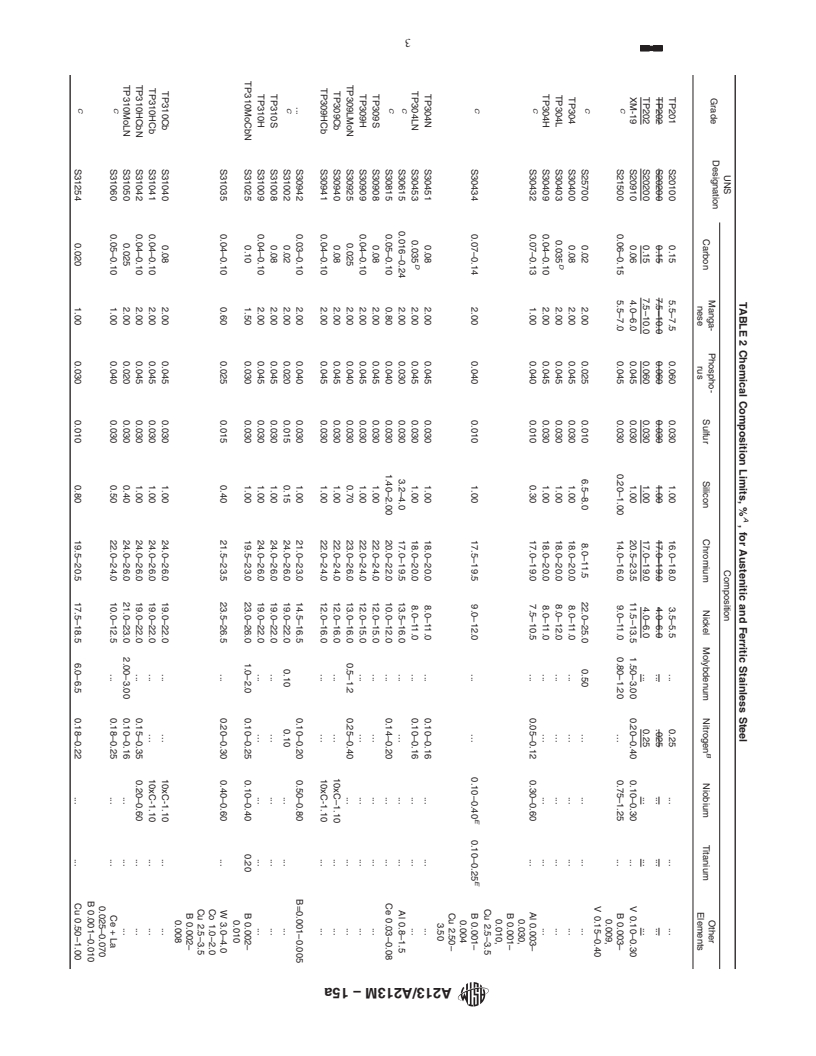

1.1 This specification2 covers seamless ferritic and austenitic steel boiler, superheater, and heat-exchanger tubes, designated Grades T5, TP304, etc. These steels are listed in Tables 1 and 2. (A) Maximum, unless range or minimum is indicated. Where ellipses (...) appear in this table, there is no requirement, and analysis for the element need not be determined or reported.(B) It is permissible to order T2 and T12 with a sulfur content of 0.045 max. See 16.3.(C) Alternatively, in lieu of this ratio minimum, the material shall have a minimum hardness of 275 HV in the hardened condition, defined as after austenitizing and cooling to room temperature but prior to tempering. Hardness testing shall be performed at mid-thickness of the product. Hardness test frequency shall be two samples of product per heat treatment lot and the hardness testing results shall be reported on the material test report. (A) Maximum, unless a range or minimum is indicated. Where ellipses (...) appear in this table, there is no minimum and analysis for the element need not be determined or reported.(B) The method of analysis for Nitrogen shall be a matter of agreement between the purchaser and the producer.(C) For these alloys, there is no common grade designation. The UNS number uniquely identifies these alloys.(D) For small diameter or thin walls, or both, where many drawing passes are required, a carbon maximum of 0.040% is necessary in Grades TP304L, TP304LN, TP316L, and TP316LN.(E) Grade S30434 shall have (Ti + 1/2 Nb) of not less than 2 times and not more than 4 times the carbon content.(F) Grade TP347LN shall have an Nb content of not less than 15 times the carbon content.(G) Grade TP348 shall have an Nb + Ta content of not less than 10 times the carbon content and not more than 1.10%.(H) Grade TP348H shall have an Nb + Ta content of not less than 8 times the carbon content and not more than 1.10%.(I) Iron shall be determined arithmetically by difference of 100 minus the sum of the other specified elements.(J) (Al + Ti) 0.85–1.20.(K) Grade TP444 shall have Ni + Cu = 1.00 max.(L) Grade TP444 shall have Ti + Nb = 0.20 + 4(C + N)–0.80.(M) N08020 shall have an Nb + Ta content of not less than 8 times the carbon content and not more than 1.00%.

1.2 Grades containing the letter, H, in their designation, have requirements different from those of similar grades not containing the letter, H. These different requirements provide higher creep-rupture strength than normally achievable in similar grades without these different requirements.

1.3 The tubing sizes and thicknesses usually furnished to this specification are 1/8 in. [3.2 mm] in inside diameter to 5 in. [127 mm] in outside diameter and 0.015 to 0.500 in. [0.4 to 12.7 mm], inclusive, in m...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A213/A213M −15a Usedin USDOE-NE standards

Standard Specification for

Seamless Ferritic and Austenitic Alloy-Steel Boiler,

1

Superheater, and Heat-Exchanger Tubes

This standard is issued under the fixed designationA213/A213M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* A262 Practices for Detecting Susceptibility to Intergranular

2 Attack in Austenitic Stainless Steels

1.1 This specification covers seamless ferritic and auste-

A941 TerminologyRelatingtoSteel,StainlessSteel,Related

nitic steel boiler, superheater, and heat-exchanger tubes, des-

Alloys, and Ferroalloys

ignated GradesT5,TP304, etc.These steels are listed in Tables

A1016/A1016M Specification for General Requirements for

1 and 2.

Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless

1.2 Grades containing the letter, H, in their designation,

Steel Tubes

have requirements different from those of similar grades not

E112 Test Methods for Determining Average Grain Size

containing the letter, H. These different requirements provide 4

2.2 AWS Specifications

higher creep-rupture strength than normally achievable in

A5.5/A5.5M Specification for Low-Alloy Steel Electrodes

similar grades without these different requirements.

for Shielded Metal Arc Welding

1.3 The tubing sizes and thicknesses usually furnished to A5.23/A5.23M Specification for Low-Alloy Steel Elec-

1

this specification are ⁄8 in. [3.2 mm] in inside diameter to 5 in.

trodes and Fluxes for Submerged Arc Welding

[127 mm] in outside diameter and 0.015 to 0.500 in. [0.4 to A5.28/A5.28M Specification for Low-Alloy Steel Elec-

12.7mm],inclusive,inminimumwallthicknessor,ifspecified

trodes for Gas Shielded Arc Welding

in the order, average wall thickness. Tubing having other A5.29/A5.29M Low-Alloy Steel Electrodes for Flux Cored

diameters may be furnished, provided such tubes comply with Arc Welding

all other requirements of this specification.

3. Terminology

1.4 The values stated in either SI units or inch-pound units

3.1 Definitions—For definitions of terms used in this

are to be regarded separately as standard. Within the text, the

specification, refer to Terminology A941.

SI units are shown in brackets. The values stated in each

system may not be exact equivalents; therefore, each system

4. Ordering Information

shall be used independently of the other. Combining values

from the two systems may result in non-conformance with the 4.1 It shall be the responsibility of the purchaser to specify

all requirements that are necessary for products under this

standard. The inch-pound units shall apply unless the “M”

designation of this specification is specified in the order. specification. Such requirements to be considered include, but

are not limited to, the following:

4.1.1 Quantity (feet, metres, or number of lengths),

2. Referenced Documents

4.1.2 Name of material (seamless tubes),

3

2.1 ASTM Standards:

4.1.3 Grade (Tables 1 and 2),

4.1.4 Condition (hot finished or cold finished),

4.1.5 Controlled structural characteristics (see 6.3),

1

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

4.1.6 Size (outside diameter and minimum wall thickness,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

unless average wall thickness is specified),

A01.10 on Stainless and Alloy Steel Tubular Products.

4.1.7 Length (specific or random),

Current edition approved April 1, 2015. Published April 2015. Originally

approved in 1939. Last previous edition approved in 2015 as A213/A213M–15.

4.1.8 Hydrostatic Test or Nondestructive Electric Test (see

DOI: 10.1520/A0213_A0213M-15A.

10.1),

2

For ASME Boiler and Pressure Vessel Code applications see related Specifi-

4.1.9 Specification designation and year of issue,

cation SA-213 in Section II of that Code.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4

Standards volume information, refer to the standard’s Document Summary page on Available from American Welding Society (AWS), 550 NW LeJeune Rd.,

the ASTM website. Miami, FL 33126, http://www.aws.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A213/A213M−15a

2

A

TABLE 1 Chemical Composition Limits, % , for Low Alloy Steel

UNS

Grade Composition, %

Designation

Carbon Manga-

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A213/A213M − 15 A213/A213M − 15a Used in USDOE-NE standards

Standard Specification for

Seamless Ferritic and Austenitic Alloy-Steel Boiler,

1

Superheater, and Heat-Exchanger Tubes

This standard is issued under the fixed designation A213/A213M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

2

1.1 This specification covers seamless ferritic and austenitic steel boiler, superheater, and heat-exchanger tubes, designated

Grades T5, TP304, etc. These steels are listed in Tables 1 and 2.

1.2 Grades containing the letter, H, in their designation, have requirements different from those of similar grades not containing

the letter, H. These different requirements provide higher creep-rupture strength than normally achievable in similar grades without

these different requirements.

1

1.3 The tubing sizes and thicknesses usually furnished to this specification are ⁄8 in. [3.2 mm] in inside diameter to 5 in. [127

mm] in outside diameter and 0.015 to 0.500 in. [0.4 to 12.7 mm], inclusive, in minimum wall thickness or, if specified in the order,

average wall thickness. Tubing having other diameters may be furnished, provided such tubes comply with all other requirements

of this specification.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text, the SI units

are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used

independently of the other. Combining values from the two systems may result in non-conformance with the standard. The

inch-pound units shall apply unless the “M” designation of this specification is specified in the order.

2. Referenced Documents

3

2.1 ASTM Standards:

A262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

A941 Terminology Relating to Steel, Stainless Steel, Related Alloys, and Ferroalloys

A1016/A1016M Specification for General Requirements for Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless Steel

Tubes

E112 Test Methods for Determining Average Grain Size

4

2.2 AWS Specifications

A5.5/A5.5M Specification for Low-Alloy Steel Electrodes for Shielded Metal Arc Welding

A5.23/A5.23M Specification for Low-Alloy Steel Electrodes and Fluxes for Submerged Arc Welding

A5.28/A5.28M Specification for Low-Alloy Steel Electrodes for Gas Shielded Arc Welding

A5.29/A5.29M Low-Alloy Steel Electrodes for Flux Cored Arc Welding

3. Terminology

3.1 Definitions—For definitions of terms used in this specification, refer to Terminology A941.

4. Ordering Information

4.1 It shall be the responsibility of the purchaser to specify all requirements that are necessary for products under this

specification. Such requirements to be considered include, but are not limited to, the following:

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.10

on Stainless and Alloy Steel Tubular Products.

Current edition approved March 1, 2015April 1, 2015. Published March 2015April 2015. Originally approved in 1939. Last previous edition approved in 20142015 as

A213/A213M–14.–15. DOI: 10.1520/A0213_A0213M-15.10.1520/A0213_A0213M-15A.

2

For ASME Boiler and Pressure Vessel Code applications see related Specification SA-213 in Section II of that Code.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

4

Available from American Welding Society (AWS), 550 NW LeJeune Rd., Miami, FL 33126, http://www.aws.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A213/A213M − 15a

2

A

TABLE 1 Chemical Composition Limits, % , for Low Alloy Steel

UNS

Grade Composition, %

Designation

Carbon Manga- Phospho- Sul- Silicon Nickel Chromium Molybdenum Vana- Boron Niobium Nitrogen Aluminum Tungsten Other

nese rus f

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.