ASTM D5492-98(2003)

(Test Method)Standard Test Method for Determination of Xylene Solubles in Propylene Plastics

Standard Test Method for Determination of Xylene Solubles in Propylene Plastics

SCOPE

1.1 This test method is to be used for determining the 25°C ortho-xylene-soluble fraction of polypropylene and propylene-ethylene copolymers.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—This standard is similar to ISO 6427-1982 in title only. The technical content is significantly different.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 5492 – 98 (Reapproved 2003)

Standard Test Method for

Determination of Xylene Solubles in Propylene Plastics

This standard is issued under the fixed designation D 5492; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope %. When the solution is cooled the insoluble portion precipi-

tates and is isolated by filtration. The orthoxylene is evaporated

1.1 This test method is to be used for determining the 25°C

from the filtrate, leaving the soluble fraction in the residue. The

ortho-xylene-soluble fraction of polypropylene and propylene-

percentage of this fraction in the plastic is determined gravi-

ethylene copolymers.

metrically.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5. Significance and Use

responsibility of the user of this standard to establish appro-

5.1 The results of this test provide a relative measure of the

priate safety and health practices and determine the applica-

total soluble fraction of polypropylene and copolymers. The

bility of regulatory limitations prior to use.

soluble fraction can be approximately correlated to the amor-

NOTE 1—This standard is similar to ISO 6427-1982 in title only. The

phous fraction in the polypropylene. Xylene is widely used for

technical content is significantly different.

determining the soluble fraction in polypropylene. The concen-

tration of a soluble fraction obtained with a specific solvent has

2. Referenced Documents

been found to relate closely to the performance characteristics

2.1 ASTM Standards:

of a product in certain applications, for example film and fiber.

D 883 Terminology Relating to Plastics

Data obtained by one solvent and at one precipitation time

D 1600 Terminology of Abbreviated Terms Relating to

cannot be compared with data obtained by another solvent or

Plastics

precipitation time, respectively. Xylene is more specific to the

2.2 ISO Standard:

atactic fraction than other solvents.

ISO 6427-1982 Plastics—Determination of Matter Ex-

tracted by Organic Solvents (Conventional Methods) An-

6. Interferences

nex B Standard Method of Test for Determination of

6.1 Materials with solubilities similar to the polymer frac-

Polypropylene Solubility in Cold Xylene

tion, such as additives, may interfere with the measurement of

solubles. When present in concentrations that are judged to

3. Terminology

impart a significant error to the soluble-fraction data, the level

3.1 For definitions of plastic terms see Terminology D 883

of interference must be determined and corrections made.

and for abbreviations see Terminology D 1600.

6.2 Small-particle fillers and pigments that may pass

3.2 There are no terms in this test method that require new

through the filter and insoluble gels present in the polymer may

or other-than-dictionary definitions.

cause errors in the measurement.

6.3 The polymer flakes and spheres must be dried before

4. Summary of Test Method

testing to eliminate moisture that can influence the initial

4.1 A weighed amount of sample is dissolved in orthoxylene

weight of sample added to the flask.

under reflux conditions. The solution is cooled under con-

trolled conditions and maintained at a 25°C equilibrium

7. Apparatus

temperature so that the crystallization of the insoluble fraction

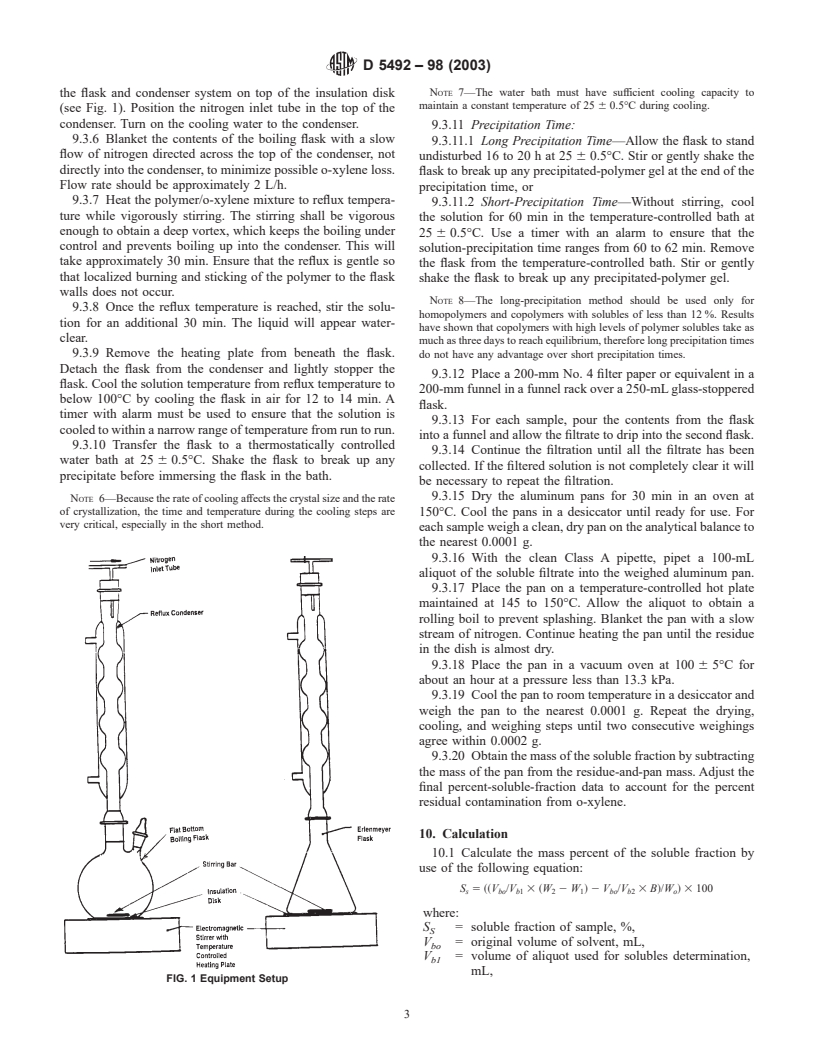

7.1 Reflux-Condenser Apparatus, 400 mm, with 24/40 glass

takes place. One of two precipitation-time periods can be used,

joint.

although the longer precipitation time should be used for

7.2 Flat-Bottom Boiling Flask, with one or two necks, 400

homopolymers and copolymers with solubles less than 12 mass

mL with 24/40 joint, Erlenmeyer flask, or cylindrical bottle.

7.3 Insulation Disk, made of fiberglass or rock wool.

7.4 Electromagnetic Stirrer, with temperature-controlled

This test method is under the jurisdiction of ASTM Committee D20 on Plastics

and is the direct responsibility of Subcommittee D20.12 on Olefin Plastics. heating plate, thermostated oil bath, or heater block capable of

Current edition approved July 10, 2003. Published September 2003. Originally

maintaining 145 to 150°C.

approved in 1994. Last previous edition approved in 1998 as D 5492 – 98.

7.5 Stirring Bar.

Annual Book of ASTM Standards, Vol 08.01.

7.6 Pipette, Class A, 200 mL.

Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 5492 – 98 (2003)

7.7 Pipette, Class A, 100 mL. 9.2.4 For each sample blank, pour the contents from the

7.8 Glass-Stoppered Volumetric Flask, 250 mL. flask into a funnel and allow the filtrate to drip into a second

7.9 Thermostatically Controlled Water Bath, at 25°C. flask. Continue the filtration until all the filtrate has been

7.10 Electromagnetic Stirrers. collected.

7.11 Filter Paper, fluted, Whatman No. 4, No. 541, or 9.2.5 Dry the aluminum pans for 30 min in an oven at

equivalent, 200 mm. 150°C. Cool the pans in a desiccator until ready to use. For

7.12 Funnel, 60°, 200 mm. each sample weigh a clean, dry pan on the analytical balance to

7.13 Heated Vacuum Oven. the nearest 0.0001 g.

7.14 Disposable Aluminum Pans, 300-mL capacity, with 9.2.6 With a Class A pipette, pipet a 100-mL aliquot of the

smooth sides. filtered o-xylene into the weighed aluminum pan.

7.15 Temperature-Controlled Heating Plate. 9.2.7 Place the pan on a temperature-controlled heating

7.16 Analytical Balance, with minimum weighing sensitiv- plate maintained at 145 to 150°C. Allow the aliquot to obtain

ity to 0.0001 g (a sensitivity of 0.00001 is preferred). a rolling boil to prevent splashing. Blanket the pan with a slow

7.17 Desiccator, containing appropriate desiccant. stream of nitrogen. Continue heating the pan until the residue

7.18 Timer with Alarms, in minutes. in the dish is almost dry.

9.2.8 Place the pan into a vacuum oven at 100 6 5°C for

8. Reagents

about an hour at a pressure less than 13.3 kPa.

9.2.9 Cool the pan to room temperature in a desiccator and

8.1 Reagent-Grade Ortho-Xylene (o-Xylene)—Assay gas

weigh the pan to the nearest 0.0001 g. Repeat the drying,

chromatography (GC) = 98 % min; less than 2 % ethylbenzene

cooling, and weighing steps until two consecutive weighings

as established by GC; evaporation residue at 140°C less than

agree within 0.0002 g. Calculate the average blank-residual

0.002 g/100 mL; boiling point 144°C.

mass of the three determinations.

9.3 Determine the Percent Soluble Fraction in the Polymer:

9. Procedure

9.3.1 Dry the polypropylene powder or spheres before

9.1 Preparation of the o-Xylene:

analysis. It is not necessary to dry the pellets unless it is known

9.1.1 It is not necessary to stabilize the o-xylene before

that they contain high levels of moisture pellets or spheres

using, but it may be stabilized if desired.

before analysis. If necessary, dry the samples in a vacuum oven

5 6 7

NOTE 2—BHT, Irganox 1010, and Santonox R have been found to be

at 70 6 5°C, in a vacuum of 13.3 kPa for a minimum of 20

effective stabilizers for o-xylene.

min. Cool the sample in a desiccator to prevent moisture

9.1.2 Degas the o-xylene. Using nitrogen gas, purge the

pickup.

o-xylene for a minimum of 1 h every 24 h.

NOTE 4—For large pellets or spheres, where there is concern that the

9.2 Determine the Level of Contamination in the o-Xylene

polymer sample will not dissolve in a reasonable time frame, the pellets or

(Solvent Blank):

spheres may be ground to an appropriate size to afford a faster dissolution.

9.2.1 The purpose of the solvent blank is to determine

Ground material should be dried as specified in 9.3.1.

whether the o-xylene to be used contains significant amounts of

9.3.2 Weigh out a sample in accordance with Table 1. When

evaporation residue or foreign components. A solvent-blank

the expected solubles level is unknown use a 2.0 6 0.1 g

test for residue should be run on every new lot of o-xylene.

sample. For referee testing between laboratories a sample

Run and average the solvent-blank results, for three aliquots

2.0 6 0.1 g shall be used, unless there is agreement between

per bottle or lot of o-xylene. Each aliquot shall be 200 mL.

the laboratories to use a different sample size. Determine mass

NOTE 3—It is recommended that o-xylene be purchased in glass or of the sample to the nearest 0.0001 g. Pour the sample into a

glass-lined containers and of a size such that the o-xylene will be used

flat-bottom boiling flask. Place a magnetic stirring bar in the

within three days, once opened. Containers of larger size may be used if

flask.

the o-xylene is used up within a short period of time. The purpose of the

NOTE 5—Table 1 provides a choice of sample mass. Use the largest

short time period is to ensure purity and minimize moisture pickup and

sample mass possible to minimize variability of the test data, unless from

other contaminants.

prior experience it is known that the polymer/o-xylene solution does not

9.2.2 Pipet 200 mL of unstabilized or stabilized o-xylene

filter readily as in 9.3.11.

into a clean empty flask.

9.3.3 Pipet 200 mL of unstabilized or stabilized o-xylene

9.2.3 Place a 200-mm No. 4 filter paper or equivalent in a

into the flask.

200-mm funnel in a funnel rack over a 250-mL glass-stoppered

9.3.4 Attach the flask to the condenser.

flask.

9.3.5 Place an insulation disk on top of the electromagnetic

stirrer plate to prevent localized heating of the flask. Position

Available from Whatman Intl. Ltd., Maidstone, England or from Fisher

TABLE 1 Sample Size

Scientific, 711 Forbes Ave., Pittsburgh, PA 15219.

A

Available from Uniroyal Chemical Co., Inc., Specialty Chemicals Division,

Expected Solubles Initial Sample Mass, g

World Headquarters, Benson Rd., Middlebury, CT 06749.

6 <8 % by mass 4.0000 6 0.1000 or 2.000 6 0.1000

Available from CIBA-GEIGY Corp., Additive Division, Seven Skyline Drive,

8.0 to 30.0 % by mass 2.0000 6 0.1000

Hawthorne, NY 10532.

>30.0 % by mass 2.0000 6 0.1000 or 1.0000 6 0.1000

Available from Monsanto Co., Chemical Group, 800 N. Lindberg Blvd., St.

A

Louis, MO 63167. See Note 1.

D 5492 – 98 (2003)

NOTE 7—The water bath must have sufficient cooling capacity to

the flask and condenser system on top of the insulation disk

maintain a constant temperature of 25 6 0.5°C during cooling.

(see Fig. 1). Position the nitrogen inlet tube in the top of the

condenser. Turn on the cooling water to the condenser.

9.3.11 Precipitation Time:

9.3.6 Blanket the contents of the boiling flask with a slow

9.3.11.1 Long Precipitation Time—Allow the flask to stand

flow of nitrogen directed across the top of the condenser, not

undisturbed 16 to 20 h at 25 6 0.5°C. Stir or gently shake the

directly into the condenser, to minimize possible o-xylene loss.

flask to break up any precipitated-polymer gel at the end of the

Flow rate should be approximately 2 L/h.

precipitation time, or

9.3.7 Heat the polymer/o-xylene mixture to reflux tempera-

9.3.11.2 Short-Precipitation Time—Without stirring, cool

ture while vigorously stirring. The stirring shall be vigorous

the solution for 60 min in the temperature-controlled bath at

enough to obtain a deep vortex, which keeps the boiling under

25 6 0.5°C. Use a timer with an alarm to ensure that the

control and prevents boiling up into the condenser. This will

solution-precipitation time ranges from 60 to 62 min. Remove

take approximately 30 min. Ensure that the reflux is gentle so

the flask from the temperature-controlled bath. Stir or gently

that localized burning and sticking of the polymer to the flask

shake the flask to break up any precipitated-polymer gel.

walls does not occur.

NOTE 8—The long-precipitation method should be used only for

9.3.8 Once the reflux temperature is reached, stir the solu-

homopolymers and copolymers with solubles of less than 12 %. Results

tion for an additional 30 min. The liquid will appear water-

have shown that copolymers with high levels of polymer solubles take as

clear.

much as three days to reach equilibrium, therefore long precipitation times

9.3.9 Remove the heating plate from beneath the flask.

do not have any advantage over short precipitation times.

Detach the flask from the condenser and lightly stopper the

9.3.12 Place a 200-mm No. 4 filter paper or equivalent in a

flask. Cool the solution temperature from reflux temperature to

200-mm funnel in a funnel rack over a 250-mL glass-stoppered

below 100°C by cooling the flask in air for 12 to 14 min. A

flask.

timer with alarm must be used to ensure that the solution is

9.3.13 For each sample, pour the contents from the flask

cooled to within a narrow range of temperature from run to run.

into a funnel and allow the filtrate to drip into the second flask.

9.3.10 Transfer the flask to a thermostatically controlled

9.3.14 Continue the filtration until all the filtrate has been

water bath at 25 6 0.5°C. Shake the flask to break up any

collected. If the filtered solution is not completely clear it will

precipitate before immersing the flask in the bath.

be necessary to repeat the filtration.

9.3.15 Dry the aluminum pans for 30 min in an oven at

NOTE 6—Because the rate of cooling affects the crystal size and the rate

of crystallization, the time and temperature during the cooling steps are 150°C. Cool the pans in a desiccator until ready for use. For

very critical, especially in the short method.

each sample weigh a clean, dry pan on the analytical balance to

the nearest 0.0001 g.

9.3.16 With the clean Class A pipette, pipet a 100-mL

aliquot of the soluble filtrate into the weighed aluminum pan.

9.3.17 Place the pan on a temperature-controlled hot plate

maintained at 145 to 150°C. Allow the aliquot to obtain a

rolling boil to prevent splashing. Blanket the pan with a slow

stream of nitrogen. Continue heating the pan until the residue

in the dish is almost dry.

9.3.18 Place the pan in a vacuum oven at 100 6 5°C for

about an hour at a pressure less than 13.3 kPa.

9.3.19 Cool the pan to room temperature in a desiccator and

weigh the pan to the nearest 0.0001 g. Repeat the drying,

cooling, and weighing steps until two consecutive weighings

agree within 0.0002 g.

9.3.20 Obtain the mass of the soluble fraction by subtracting

the mass of the pan from the residue-and-pan mass. Adjust the

final percent-soluble-fraction data to account for the percent

residual contamination from o-xylene.

10. Calculation

10.1 Calculate the mass percent of the soluble fraction by

use of the following equation:

S 5 V /V 3 W 2 W

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.