ASTM A471-94(1999)

(Specification)Standard Specification for Vacuum-Treated Alloy Steel Forgings for Turbine Rotor Disks and Wheels

Standard Specification for Vacuum-Treated Alloy Steel Forgings for Turbine Rotor Disks and Wheels

SCOPE

1.1 This specification covers vacuum-treated alloy steel forgings intended for use as turbine rotor disks and wheels.

1.2 The values stated in inch-pound units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 471 – 94 (Reapproved 1999)

Standard Specification for

Vacuum-Treated Alloy Steel Forgings for Turbine Rotor

Disks and Wheels

This standard is issued under the fixed designation A 471; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4.2 Vacuum Degassing:

4.2.1 The molten steel shall be vacuum treated prior to or

1.1 This specification covers vacuum-treated alloy steel

during the pouring of the ingot, in order to remove objection-

forgings intended for use as turbine rotor disks and wheels.

able gases, particularly hydrogen.

1.2 The values stated in inch-pound units are to be regarded

4.2.1.1 When the vacuum stream degassing process is

as the standard.

used, the vacuum system must be of sufficient capacity to effect

2. Referenced Documents a blank-off pressure low enough (usually less than 1000 μm) to

break up the normal tight, rope-like stream of molten metal

2.1 ASTM Standards:

into a wide-angled conical stream of relatively small droplets.

A 275/A 275M Test Method for Magnetic Particle Exami-

The capacity of the system must also be sufficiently high to

nation of Steel Forgings

reduce the initial surge pressure at the start of the pour to a low

A 370 Test Methods and Definitions for Mechanical Testing

level within 2 min.

of Steel Products

4.2.1.2 When the vacuum-lift process is utilized, the mol-

A 388/A 388M Practice for Ultrasonic Examination of

ten metal shall be repeatedly drawn into the evacuated vessel to

Heavy Steel Forgings

give a recirculation factor (Note 1) of at least 2.5 to ensure

E 30 Test Methods for Chemical Analysis of Steel, Cast

thorough degassing and mixing of the entire heat. The evacu-

Iron, Open-Hearth Iron, and Wrought Iron

ation system shall be capable of reducing the pressure surges,

E 139 Practice for Conducting Creep, Creep-Rupture, and

which occur each time a new portion of steel is admitted to the

Stress-Rupture Tests of Metallic Materials

vessel, to increasingly lower levels until a blank-off pressure

3. Ordering Information

(usually less than 1000 μm) is achieved.

3.1 The purchaser shall specify in the inquiry and order the

NOTE 1—The recirculation factor is obtained as follows:

class of steel desired and test and purchase options (see 4.5.5,

tons of steel lifted per cycle 3 number of cycles

5.2.2, 6.1, 6.3, 7, and 15.1).

heat weight in tons

3.2 Forging Drawing—Each forging shall be manufactured

4.2.1.3 When the ladle degassing process is used, the

in accordance with a purchaser-supplied drawing showing the

evacuation system shall be capable of reducing the system

finished dimensions and the locations of mechanical test

vacuum pressure to a low level (usually less than 1000 μm).

specimens.

The molten metal shall be adequately stirred for a sufficient

3.3 Supplementary requirements are provided and shall

length of time to maximize exposure to the evacuated atmo-

apply only when specified in the purchaser’s order.

sphere. When this process is used, hydrogen testing per

4. Materials and Manufacture

Supplemental Requirement S2 is mandatory.

4.2.1.4 Other methods of degassing may be used if the

4.1 Melting Process—The steel shall be made by one or

supplier can demonstrate their adequacy to the satisfaction of

more of the following processes: electric-arc, electric-

the purchaser. When other processes are used, hydrogen testing

induction, or consumable-electrode.

per the supplemental requirement S2 is mandatory.

4.3 Discard—Sufficient discard shall be taken from each

This specification is under the jurisdiction of ASTM Committee A-1 on Steel,

ingot to secure freedom from pipe and undue segregation in the

Stainless Steel, and Related Alloys, and is the direct responsibility of Subcommittee

finished forging.

A01.06 on Steel Forgings and Billets.

Current edition approved June 15, 1994. Published August 1994. Originally

published as A 471 – 62 T. Last previous edition A 471 – 93.

Annual Book of ASTM Standards, Vol 01.05.

3 6

Annual Book of ASTM Standards, Vol 01.03. Details of the vacuum stream degassing process may be found in the Journal

Annual Book of ASTM Standards, Vol 03.05. of the Iron and Steel Institute, Vol 191, January 1959; “Vacuum Pouring of Ingots

Annual Book of ASTM Standards, Vol 03.01. for Heavy Forgings” by J. H. Stoll.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

A 471 – 94 (1999)

4.4 Forging Process—The forgings shall receive their hot 4.6 Machining:

mechanical work under a press, hammer, or mill of sufficient 4.6.1 Preliminary Machining—The forgings shall be pre-

power to work the metal throughout its section. The forgings liminarily machined on all surfaces prior to heat treatment for

shall be upset by forming from a block having an axial length mechanical properties (see 4.5.3).

before upsetting of at least two times the thickness of the 4.6.2 Machining to Purchaser’s Requirements for

forging after upsetting. Shipment—After heat treatment for mechanical properties (see

4.4.1 The as-forged dimensions of each forging shall be 4.5.3), the forgings shall be machined to the dimensions of the

planned so the metal is shaped by forging as close as is purchaser’s forging drawing or instructions on his order.

practical to the dimensions shown on the purchaser’s drawing

5. Chemical Composition

so as to keep subsequent machining to a minimum.

4.4.2 The axial center of the forging shall be maintained in 5.1 The steel shall conform to the requirements for chemical

common with the axial center of the ingot. composition prescribed in Table 1.

4.5 Heat Treatment: 5.2 Chemical Analysis:

4.5.1 Cooling Prior to Heat Treatment— After forging and 5.2.1 Heat Analysis—An analysis of each heat of steel shall

before reheating for heat treatment, the forging shall be be made by the manufacturer to determine the percentages of

allowed to cool in a manner to prevent damage and to those elements specified in Table 1. This analysis shall be made

accomplish transformation. from a test ingot taken during the pouring of the heat.

4.5.2 Preliminary Heat Treatment—The forgings shall be 5.2.1.1 If the test sample taken for the ladle analysis is lost

given such preliminary heat treatment as is proper for the or declared inadequate for chemical determinations, the manu-

design and composition. The forgings shall be heated to a facturer may take alternative samples from appropriate loca-

suitable temperature for a sufficient length of time for complete tions near the surface of the ingot or forging as necessary to

austenitization and shall be suitably cooled to bring about establish the analysis of the heat in question.

complete transformation. 5.2.2 Product Analysis—A product analysis may be made

4.5.3 Heat Treatment for Mechanical Properties—The forg- by the purchaser on each forging. Sample for an analysis may

ings shall be reheated to a temperature above the upper critical be taken from the forging at any point from the mid-radius to

temperature, held a sufficient length of time for complete the outside diameter or from a full-size prolongation, or

austenitization, and liquid quenched. turnings may be taken from a test specimen. The chemical

4.5.4 Tempering Temperature—The forgings shall be tem- composition thus determined shall not vary from the require-

pered to develop the specified properties. The final tempering ments specified in Table 1 more than the amounts prescribed in

temperature for Class 1 to 6 and 11 through 14 shall be not less Table 2.

than 1100°F (593°C), and for Class 10 not less than 1200°F 5.3 Test Methods of Analysis—Test Methods E 30 shall be

(649°C). The forgings shall be cooled under suitable conditions used for referee purposes.

from the tempering temperature.

6. Mechanical Properties

4.5.5 Stress Relief—Unless otherwise specified by the pur-

chaser, the forgings shall be stress relieved after machining 6.1 Tension Test—The material shall conform to the require-

(see 4.6.2) by heating slowly to a temperature within 100°F ment for tensile properties prescribed in Table 3 when tested in

(56°C) below the final tempering temperature but in no case accordance with Test Methods and Definitions A 370. Tension

below 1025°F (552°C) for Classes 1 to 6 and 11 through 14 and test specimens shall be the standard round, ⁄2 -in. (12.7-mm)

1150°F (621°C) for Class 10. They shall be held for a sufficient diameter, 2-in. (50.8-mm) gage length as shown in Test

length of time and then cooled under suitable conditions. This Methods and Definitions A 370. The yield strength prescribed

stress-relief temperature may be omitted provided the metal in Table 3 shall be determined by the 0.2 % offset method of

removed in accordance with 4.6.2, excluding test metal, does Test Methods and Definitions A 370. The offset shall be 0.2 %

not exceed ⁄16 in. (4.8 mm) on any surface. unless 0.02 % is specified in the ordering information.

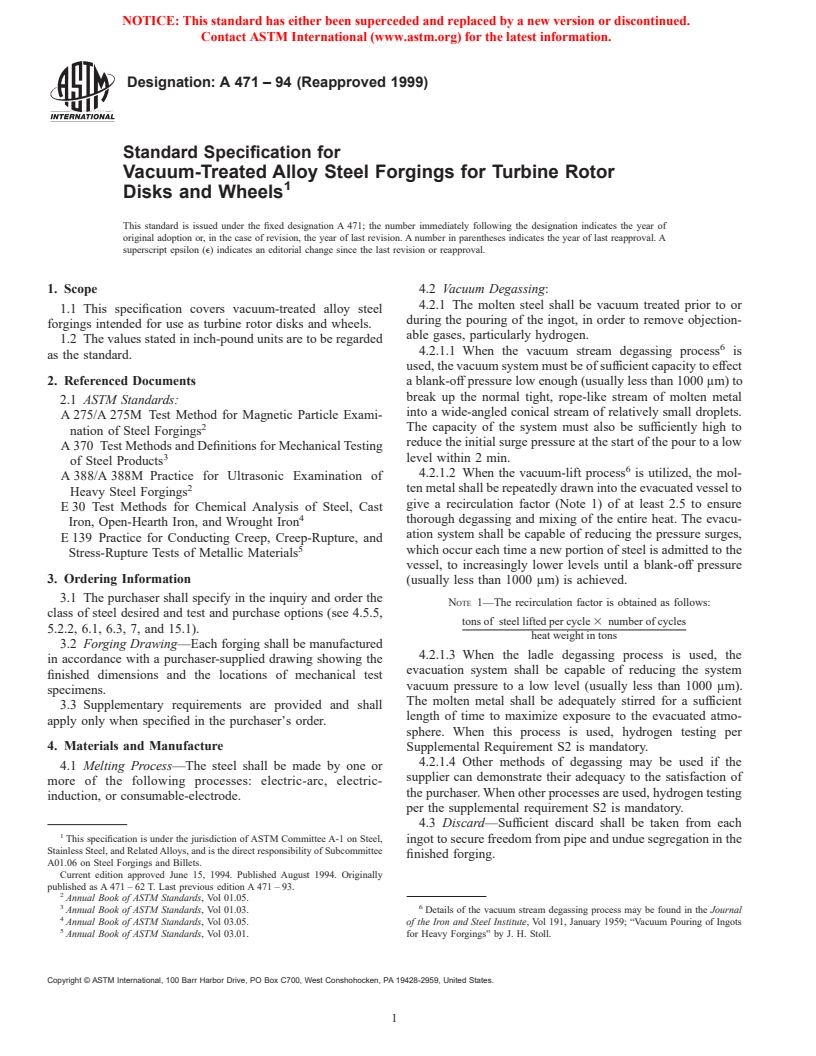

TABLE 1 Chemical Requirements

Composition, %

Classes 1 to 6, Class 10 Classes 11 to 13, Class 14

incl incl

A

Carbon 0.28 max 0.27–0.37 0.38–0.43 0.45 max

Manganese 0.70 max 0.70–1.00 0.60–1.00 0.60–1.00

Phosphorus 0.012 max 0.012 max 0.012 max 0.012 max

Sulfur 0.015 max 0.015 max 0.015 max 0.015 max

B

Silicon 0.15–0.35 0.20 min 0.15–0.35 0.15–0.35

Nickel 2.00–4.00 0.50 max 0.50 max 1.65–3.50

Chromium 0.75–2.00 0.85–1.25 0.80–1.10 0.50–1.25

Molybdenum 0.20–0.70 1.00–1.50 0.15 min 0.20 min

Vanadium 0.05 min 0.20–0.30 0.06 max optional

CCCC

Antimony

A

0.35 % C max for Classes 4 and 5; 0.40 % C, max, for Class 6.

B

When vacuum deoxidation is specified, silicon content shall be 0.10 max.

C

To be reported for information only.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

A 471 – 94 (1999)

TABLE 2 Permissible Variations in Product Analysis

NOTE—Product cross-sectional area is defined as either:

(a) maximum cross-sectional area of rough machined forging (excluding boring),

(b) maximum cross-sectional area of the unmachined forging, or

(c) maximum cross-sectional area of the billet, bloom, or slab.

Area taken at right angles to the axis of the original ingot or billet

Permissible Variation Over the Specified Maximum Limit or

Under the Specified Minimum Limit, %

Up to and Over 100 Over 200 Over 400 Over 800 Over 1600

Unit or Maximum Specified

Element 2 2 2 2

including to 200 in. to 400 in. to 800 in. to 1600 in.

Range, %

2 2

100 in. (645 to (1290 to (2580 to in. (5160 (10 320

2 2 2 2 2

(645 cm ) 1290 cm ), 2580 cm ), 5160 cm ), to 10 320 cm )

incl incl incl cm ), incl

Carbon . . . 0.03 0.04 0.04 0.05 0.06 0.06

Manganese up to and including 0.90 0.03 0.04 0.05 0.06 0.07 0.08

0.91 and over 0.06 0.06 0.07 0.08 0.08 0.09

Phosphorus . . . 0.008 0.008 0.010 0.010 0.015 0.015

Sulfur . . . 0.005 0.005 0.005 0.005 0.006 0.006

Silicon . . . 0.02 0.03 0.04 0.04 0.05 0.06

Nickel up to and including 1.00 0.03 0.03 0.03 0.03 0.03 0.03

1.01 to 2.00, incl 0.05 0.05 0.05 0.05 0.05 0.05

2.01 and over 0.07 0.07 0.07 0.07 0.07 0.07

Chromium up to and including 0.90 0.03 0.04 0.04 0.05 0.05 0.06

0.91 and over 0.05 0.06 0.06 0.07 0.07 0.08

Molybdenum up to and including 0.20 0.01 0.02 0.02 0.02 0.03 0.03

0.21 to 0.40, incl 0.02 0.03 0.03 0.03 0.04 0.04

0.41 to 1.15, incl 0.03 0.04 0.05 0.06 0.07 0.08

1.16 and over 0.05 0.06 0.08 0.10 0.12 0.12

Vanadium up to and including 0.10 0.01 0.01 0.01 0.01 0.01 0.01

0.11 to 0.25, incl 0.02 0.02 0.02 0.02 0.02 0.02

0.26 and over 0.03 0.03 0.03 0.03 0.03 0.03

TABLE 3 Tensile and Charpy Impact Requirements

Class 1 Class 2 Class 3 Class 4 Class 5 Class 6

Tensile strength, min, ksi (MPa) 100 105 110 120 130 140

(690) (725) (760) 830) (900) (965)

Yield strength, ksi (MPa)

0.2 % offset 80–100 90–110 100–120 110–130 120–140 130–150

(550–690) (620–760) (690–825) (760–895) (825–965) (895–1035)

0.02 % offset 75–95 85–105 95–115 105–125 115–135 125–145

(520–655) (585–725) (655–790) (725–860) (790–930) (860–1000)

Elongation in 2 in. or 50 mm, min, % 20 19 18 17 16 15

Reduction of area, min, % 50 50 47 45 43 43

Charpy V-notch impact, room temperature, ft·lb, min 50 50 45 45 40 40

Transition temperature, FATT,°F,max 0000 10 10

Brinell hardness number . . . . . . . . . . . . . . . . . .

Class 10 Class 11 Class 12 Class 13 Class 14

Tensile strength, min, ksi (MPa) 105 100 110 125 125

(725) (690) (760) (860) (860)

Yield strength, ksi (MPa)

0.2 % offset 90–105 . . . . . . . .

... ... ...

(620–725) . . . . . . . . . . . .

0.02 % offset 85–100 75–95 85–105 105–125 105–125

(585–690) (515–655) (585–725) (725–860) (725–860)

Elongation in 2 in. or 50 mm, min, % 15 20.0 18.0 16.0 18.0

Reduction of area, min, % 30 50.0 48.0 45.0 45.0

Charpy V-notch impact, room temperature, ft·lb, min 10 15 (20) 15 (20) 15 (20) 15 (20)

AAAA

Transition temperature, FATT , °F, max 200

Brinell hardness number . . . 207–255 229–269 255–302 255–302

A

Not required.

6.2 Impact Test—The material shall conform to the require- 6.3 Hardness—Forgings made from Classes 11 to 14 and

ments for impact (both transition-temperature and room- subjected to group testing in accordance with 6.4.1 shall

temperature impact value) as prescribed in Table 3. The impact conform to the Brinell hardness requirements prescribed in

tests shall be performed in accordance with Test Methods and Table 3 when tested in accordance with Test Methods and

Definitions A 370 using standard full-size specimens. Definitions A 370.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

A 471 – 94 (1999)

6.4 Location and Number of Tests—Classes 1 through 10 10.1.2 Room temperature impact values lower than the

tension and impact test specimen shall be identified and taken minimum specified, but not less than 80 % of the minimum

from the locations as specified by the purchaser and agreed to shall be cause for retest. In this event, two additional adjacent

by the producer. One tension test and a transition-temperature bars shall be broken to represent each failed bar. Both

determination, including room-temperature impact strength specimens shall have an impact strength a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.