ASTM D4367-02(2007)

(Test Method)Standard Test Method for Benzene in Hydrocarbon Solvents by Gas Chromatography

Standard Test Method for Benzene in Hydrocarbon Solvents by Gas Chromatography

SIGNIFICANCE AND USE

Benzene is classed as a toxic and carcinogenic material. A knowledge of the concentration of this compound may be an aid in evaluating the possible health hazards to persons handling and using hydrocarbon solvents, but this test method is not intended to evaluate such hazards.

SCOPE

1.1 This test method covers the determination by gas chromatography of benzene at levels from 0.01 to 1 volume % in hydrocarbon solvents.Note 1

For benzene levels lower than 0.01 volume %, use Test Method D 6229.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 For purposes of determining conformance of an observed or a calculated value using this test method to relevant specifications, test result(s) shall be rounded off "to the nearest unit" in the last right-hand digit used in expressing the specification limit, in accordance with the rounding-off method of Practice E 29.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 For hazard information and guidance, see the supplier's Material Safety Data Sheet. For specific hazard statements, see Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4367 − 02 (Reapproved 2007)

StandardTest Method for

Benzene in Hydrocarbon Solvents by Gas Chromatography

This standard is issued under the fixed designation D4367; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3. Summary of Test Method

3.1 An internal standard, methyl ethyl ketone (MEK), is

1.1 This test method covers the determination by gas

added to the material and then introduced into a gas chromato-

chromatography of benzene at levels from 0.01 to 1 volume %

graph equipped with two columns connected in series. The

in hydrocarbon solvents.

specimen passes first through a column packed with the

NOTE 1—For benzene levels lower than 0.01 volume %, use Test

nonpolar phase, methyl silicone, which separates the compo-

Method D6229.

nents by boiling point. After octane has eluted, the flow

1.2 The values stated in SI units are to be regarded as the through the nonpolar column is reversed, flushing out the

standard. The values given in parentheses are for information

components heavier than octane. The octane and lighter

only. components then pass through a column with the highly polar

phase, 1,2,3-tris(2-cyanoethoxy)propane, that separates the

1.3 For purposes of determining conformance of an ob-

aromatic and nonaromatic compounds. The eluted components

served or a calculated value using this test method to relevant

are detected by a conventional detector and recorded on a strip

specifications, test result(s) shall be rounded off “to the nearest

chart. The peak areas are measured and the concentration of

unit” in the last right-hand digit used in expressing the

each component is calculated by reference to the internal

specification limit, in accordance with the rounding-off method

standard.

of Practice E29.

4. Significance and Use

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4.1 Benzene is classed as a toxic and carcinogenic material.

responsibility of the user of this standard to establish appro-

Aknowledge of the concentration of this compound may be an

priate safety and health practices and determine the applica-

aid in evaluating the possible health hazards to persons

bility of regulatory limitations prior to use.

handling and using hydrocarbon solvents, but this test method

1.5 For hazard information and guidance, see the supplier’s

is not intended to evaluate such hazards.

Material Safety Data Sheet. For specific hazard statements, see

5. Apparatus

Section 7.

5.1 Chromatograph—Any gas chromatographic instrument

2. Referenced Documents

that has a backflush system and flame ionization detector and

that can be operated at the conditions given in Table 1. The

2.1 ASTM Standards:

detector-recordercombinationmustproducea4-mmdeflection

D6229 Test Method for Trace Benzene in Hydrocarbon

for a 1-µL specimen containing 0.05 volume % MEK when

Solvents by Capillary Gas Chromatography

operated at maximum sensitivity.

E29 Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications 5.2 Columns, one 0.8-m (2.5-ft) length of 3.2-mm ( ⁄8-in.)

E300 Practice for Sampling Industrial Chemicals outside diameter stainless steel tubing and one 4.6-m (15-ft)

length of 3.2-mm ( ⁄8-in.) outsider diameter stainless steel

tubing.

This test method is under the jurisdiction of ASTM Committee D01 on Paint 5.3 Recorder, Strip Chart—Potentiometer with a full-scale

and Related Coatings, Materials, andApplications and is the direct responsibility of

deflection of 1 mV, a full-scale response time of2sor less, and

Subcommittee D01.35 on Solvents, Plasticizers, and Chemical Intermediates.

a maximum noise level of 60.3 % of full scale.

Current edition approved June 1, 2007. Published June 2007. Originally

approved in 1984. Last previous edition approved in 2002 as D4367 – 02. DOI:

5.4 Microsyringe, 5-µL capacity.

10.1520/D4367-02R07.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 5.5 Pipets, measuring 1 and 2 mL, graduated in 0.01 mL; 5,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

10, and 20-mL capacity.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 5.6 Flasks, volumetric, 25 and 100-mL capacity.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4367 − 02 (Reapproved 2007)

TABLE 1 Instrument Conditions Found Satisfactory for

6.6 Methanol.

Measuring Low Concentrations of Benzene in

6.7 Methylene Chloride.

Hydrocarbon Solvents (Note 2)

Detector flame ionization

6.8 Methyl Ethyl Ketone (MEK), 99.9 mol %.

Columns two, stainless steel

Length, m (A) 0.8; (B) 4.6

6.9 Methyl Silicone.

Outside diameter, mm 3.2

Stationary phases (A) methyl silicone, 10 weight %

6.10 1,2,3-Tris(2-Cyanoethoxy) Propane (TCEP).

(B) TCEP, 25 weight %

Support (A) acid-washed calcined diatomite, 60 to 6.11 Calibration Standards.

+

80-mesh

6.11.1 Benzene, 99 mol %.

(B) acid-washed pink diatomaceous

+

6.11.2 Isooctane, 99 mol %.

earth, 80 to 100-mesh

+

Reference column any column or restriction may be used

6.11.3 n-Nonane, 99 mol %.

Temperature, °C

Injection port 150

Column, isothermal 100

7. Hazards

Detector block 150

Carrier gas helium 7.1 Many hydrocarbon solvents are flammable and hazard-

Flow rate, mL/min approximately 30

ous; use special precautions when handling them. Of the

Recorder range, mV 0 to 1

reagents used in this procedure, methanol, chloroform, meth-

Chart speed, mm/min 10

Specimen size, µL 1.0 ylenechloride,acetone,methylethylketone,benzene(see4.1),

Time to backflush, min approximately 2

and n-nonane are hazardous.

Total cycle time, min approximately 30

7.2 Benzene is volatile and highly flammable. Exercise care

to prevent accidental ignition. Benzene is also carcinogenic

and toxic; acute or chronic poisoning may result from inhala-

5.7 Vibrator, electric.

tion of benzene vapor, absorption of benzene through the skin,

5.8 Vacuum Source.

or drinking benzene.

5.9 Evaporator, vacuum, rotary.

8. Sampling

5.10 Flask, boiling, round-bottom, short-neck, with 24/40 T

joint, 500-mL capacity. Suitable for use with the evaporator

8.1 Take samples of solvents to be analyzed by this test

(see 5.9).

method using the procedures described in Practice E300.

5.11 Lamp, infrared.

9. Preparation of Columns

5.12 Burets, automatic, with integral reservoir, 25-mL ca-

pacity. 9.1 Column Packing Preparation—Prepare the two packing

materials, one containing 10 % methyl silicone and the other

NOTE 2—Suppliers of stationary phases and supports can be found in

25 % TCEP, as follows:

Research Report RR:D01-1038, available from ASTM International

Headquarters. 9.1.1 Weigh 45 g of the acid-washed calcined diatomite

support60to80mesh,intoa500-mLflask(see5.10).Dissolve

6. Reagents and Materials

5 g of the methyl silicone in approximately 50 mL of

6.1 Purity of Reagents—Reagent grade chemicals shall be chloroform. (Warning—Chloroform is a toxic material and

inhalation must be avoided.) Pour the methyl silicone–chloro-

used in all tests. Unless otherwise indicated, it is intended that

all reagents shall conform to the specifications of the Commit- form solution into the flask containing the support. Attach the

flask to the evaporator (see 5.9), connect the vacuum, and start

tee onAnalytical Reagents of theAmerican Chemical Society,

where such specifications are available. Other grades may be the motor. Turn on the infrared lamp and allow the packing to

used, provided it is first ascertained that the reagent is of mix thoroughly until dry.

sufficiently high purity to permit its use without lessening the

9.1.2 Weigh 75 g of acid-washed pink diatomaceous earth,

accuracy of the determination.

80 to 100 mesh, into a 500-mL flask (see 5.10). Dissolve 25 g

of TCEP in 200 mL of methanol and pour into the flask

6.2 Acetone.

containing the support. Attach the flask to the evaporator (see

6.3 Chloroform.

5.9), connect the vacuum, and start the motor. Turn on the

6.4 Diatomaceous Earth —Acid-washed, 60 to 80 mesh infrared lamp and allow the packing to mix thoroughly until

and 80 to 100 mesh.

dry, but do not heat the packing above 180°C.

6.5 Helium, 99.99 % pure.

9.2 Column Preparation:

9.2.1 Clean the stainless steel tubing as follows: Attach a

3 metal funnel to one end of the steel tubing. Hold or mount the

Reagent Chemicals, American Chemical Society Specifications, American

stainless steel tubing in an upright position and place a beaker

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

listed by the American Chemical Society, see Analar Standards for Laboratory

under the outlet end of the tubing. Pour about 50 mL of

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

methylenechlorideintothefunnelandallowittodrainthrough

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

thesteeltubingintothebeaker.Repeatthewashingwith50mL

MD.

See Note 2. of acetone. Remove the funnel and connect the steel tubing to

D4367 − 02 (Reapproved 2007)

an air line, by means of vinyl tubing. Remove all solvent from 10.2 Connect the outlet of Column B to the detector port.

the steel tubing by blowing filtered, oil-free air through or Adjust the operating conditions to those listed in Table 1, but

applying a vacuum. do not turn on the detector circuits. Check the system for leaks.

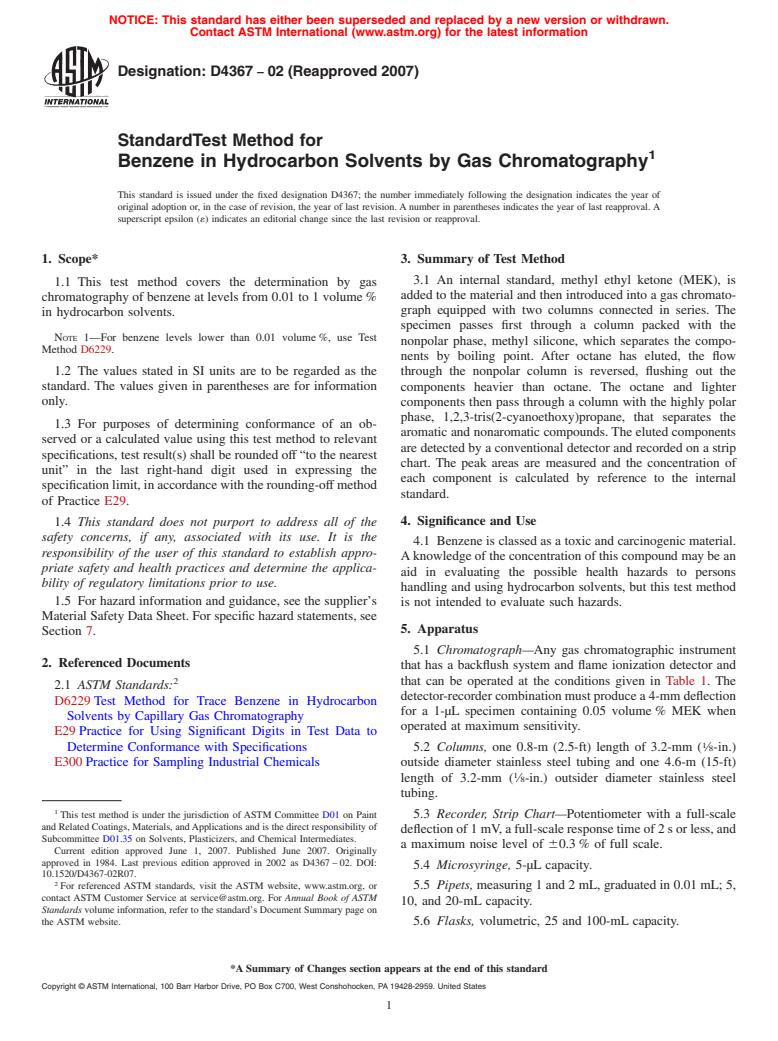

9.2.2 Pack the 0.8-m (2.5-ft) tubing (Column A) with the

10.3 Adjust the flow rate as follows:

methylsiliconepacking(see9.1.1)andthe4.6-m(15-ft)tubing

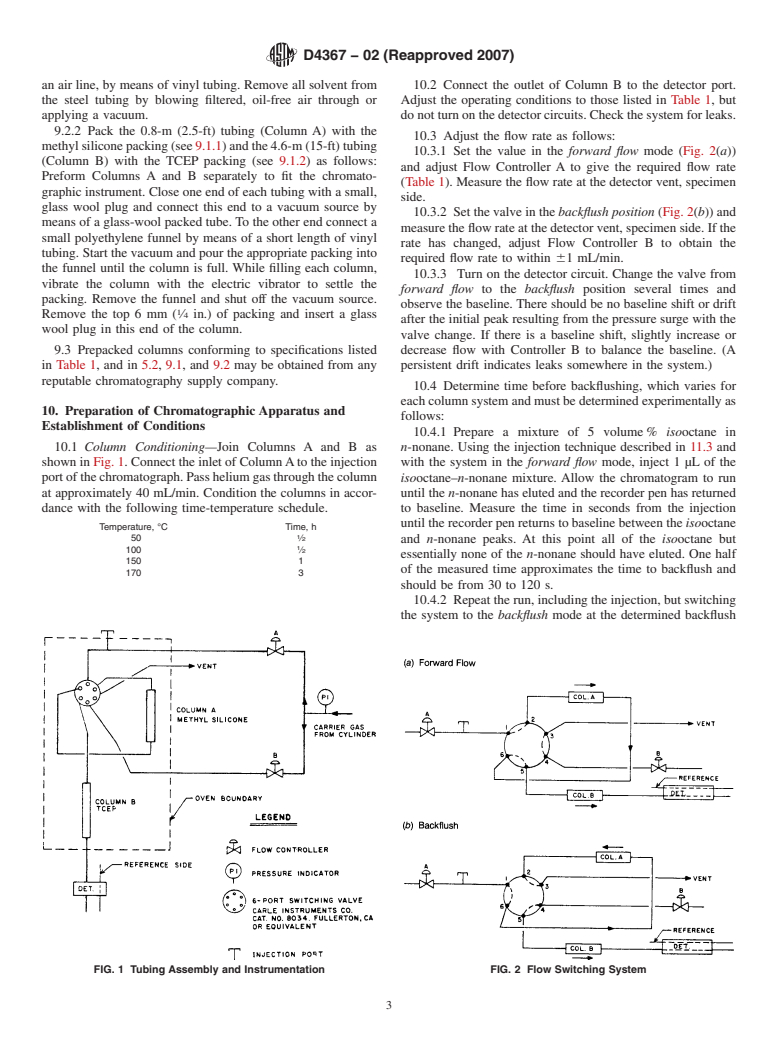

10.3.1 Set the value in the forward flow mode (Fig. 2(a))

(Column B) with the TCEP packing (see 9.1.2) as follows:

and adjust Flow Controller A to give the required flow rate

Preform Columns A and B separately to fit the chromato-

(Table 1). Measure the flow rate at the detector vent, specimen

graphic instrument. Close one end of each tubing with a small,

side.

gla

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.