ASTM C792-23

(Test Method)Standard Test Method for Effects of Heat Aging on Weight Loss, Cracking, and Chalking of Elastomeric Sealants

Standard Test Method for Effects of Heat Aging on Weight Loss, Cracking, and Chalking of Elastomeric Sealants

SIGNIFICANCE AND USE

5.1 Weight loss through volatilization of components of a sealant in a building joint may affect sealant appearance because of shrinkage, and sealant performance because of the loss of functional sealant components. Exposure to high-temperature environments will accelerate the loss of volatiles.

5.2 This test method measures weight loss. It can be used in combination with a knowledge of sealant density to estimate shrinkage. In addition, when compared to sealant theoretical weight solids, it provides an estimate of the extent to which functional sealant components can be volatilized when exposed to high service temperatures. Substantial losses of this type may help predict early failures in durability. Also, development of cracks or chalking, or both, lessens sealant service life. However, a sealant that develops no cracks or chalking, or low weight loss in this test method, does not necessarily assure good durability.

SCOPE

1.1 This test method covers a laboratory procedure for determining the effects of heat aging on weight loss, cracking, and chalking of cured-in-place elastomeric joint sealants (single- and multi-component) for use in building construction.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.3 There is no known ISO equivalent to this test method.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C792 − 23

Standard Test Method for

Effects of Heat Aging on Weight Loss, Cracking, and

1

Chalking of Elastomeric Sealants

This standard is issued under the fixed designation C792; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope for 7 days at standard conditions. Immediately following this

initial cure time two specimens are exposed in a forced-draft

1.1 This test method covers a laboratory procedure for

oven maintained at 70 °C 6 2 °C (158 °F 6 3.6 °F) for 21

determining the effects of heat aging on weight loss, cracking,

days. At the end of this exposure the percentage weight loss of

and chalking of cured-in-place elastomeric joint sealants

the sealant is determined and examination is made for presence

(single- and multi-component) for use in building construction.

of cracks and chalking.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5. Significance and Use

responsibility of the user of this standard to establish appro-

5.1 Weight loss through volatilization of components of a

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use. sealant in a building joint may affect sealant appearance

because of shrinkage, and sealant performance because of the

1.3 There is no known ISO equivalent to this test method.

loss of functional sealant components. Exposure to high-

1.4 This international standard was developed in accor-

temperature environments will accelerate the loss of volatiles.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

5.2 This test method measures weight loss. It can be used in

Development of International Standards, Guides and Recom-

combination with a knowledge of sealant density to estimate

mendations issued by the World Trade Organization Technical

shrinkage. In addition, when compared to sealant theoretical

Barriers to Trade (TBT) Committee.

weight solids, it provides an estimate of the extent to which

functional sealant components can be volatilized when exposed

2. Referenced Documents

to high service temperatures. Substantial losses of this type

2

2.1 ASTM Standards:

may help predict early failures in durability. Also, development

C717 Terminology of Building Seals and Sealants

of cracks or chalking, or both, lessens sealant service life.

However, a sealant that develops no cracks or chalking, or low

3. Terminology

weight loss in this test method, does not necessarily assure

3.1 Definitions—See Terminology C717 for definitions of good durability.

the following terms used in this test method: compound,

elastomeric, non-sag sealant, sealant, standard conditions, and 6. Apparatus

self-leveling sealant.

6.1 Forced-Draft Oven, controlled at 70 °C 6 2 °C (158 °F

6 3.6 °F).

4. Summary of Test Method

4.1 Three sealant specimens are spread on thin aluminum 6.2 Balance, sensitive to 0.01 g.

plates and, after determining net weights of sealant, are cured

6.3 Rectangular Brass Frame, with inside dimensions

1 1

130 mm by 40 mm by 6.4 mm (5 in. by 1 ⁄2 in. by ⁄4 in.).

1

This test method is under the jurisdiction of ASTM Committee C24 on Building

6.4 Aluminum Plates, three, each 152 mm by 80 mm by

Seals and Sealants and is the direct responsibility of Subcommittee C24.20 on

General Test Methods. 0.6 mm to 1.6 mm (24 gauge to 16 gauge).

Current edition approved May 1, 2023. Published May 2023. Originally

6.5 Straightedge, metal or plastic, about 152 mm (6 in.)

approved in 1975. Last previous edition approved in 2020 as C792 – 15 (2020).

DOI: 10.1520/C0792-23.

long.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.6 Thin Knife Blade.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 6.7 Spatula, steel, about 152 mm (6 in.) long.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C792 − 23

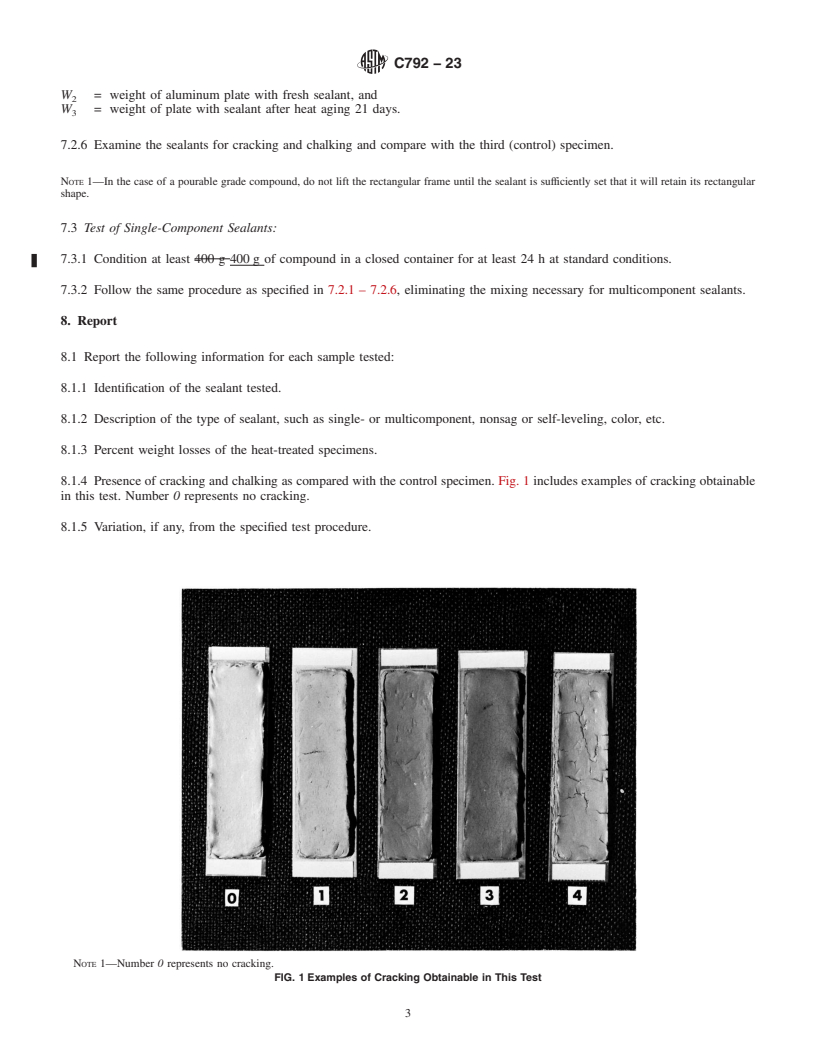

7. Procedure 7.2.6 Examine the sealants for cracking and chalking and

compare with the third (control) specimen.

7.1 Unless otherwise specified by those authorizing the test,

stand

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C792 − 15 (Reapproved 2020) C792 − 23

Standard Test Method for

Effects of Heat Aging on Weight Loss, Cracking, and

1

Chalking of Elastomeric Sealants

This standard is issued under the fixed designation C792; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This test method covers a laboratory procedure for determining the effects of heat aging on weight loss, cracking, and chalking

of cured-in-place elastomeric joint sealants (single- and multi-component) for use in building construction.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.3 There is no known ISO equivalent to this test method.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C717 Terminology of Building Seals and Sealants

3. Terminology

3.1 Definitions—See Terminology C717 for definitions of the following terms used in this test method: compound, elastomeric,

non-sag sealant, sealant, standard conditions, and self-leveling sealant.

4. Summary of Test Method

4.1 Three sealant specimens are spread on thin aluminum plates and, after determining net weights of sealant, are cured for 7 days

at Standard Conditions.standard conditions. Immediately following this initial cure time two specimens are exposed in a

forced-draft oven maintained at 70 6 2°C (1586 3.6°F) 70 °C 6 2 °C (158 °F 6 3.6 °F) for 21 days. At the end of this exposure

the percentage weight loss of the sealant is determined and examination is made for presence of cracks and chalking.

1

This test method is under the jurisdiction of ASTM Committee C24 on Building Seals and Sealants and is the direct responsibility of Subcommittee C24.20 on General

Test Methods.

Current edition approved Jan. 15, 2020May 1, 2023. Published February 2020May 2023. Originally approved in 1975. Last previous edition approved in 20152020 as

C792 – 15.C792 – 15 (2020). DOI: 10.1520/C0792-15R20.10.1520/C0792-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C792 − 23

5. Significance and Use

5.1 Weight loss through volatilization of components of a sealant in a building joint may affect sealant appearance because of

shrinkage, and sealant performance because of the loss of functional sealant components. Exposure to high-temperature

environments will accelerate the loss of volatiles.

5.2 This test method measures weight loss. It can be used in combination with a knowledge of sealant density to estimate

shrinkage. In addition, when compared to sealant theoretical weight solids, it provides an estimate of the extent to which functional

sealant components can be volatilized when exposed to high service temperatures. Substantial losses of this type may help predict

early failures in durability. Also, development of cracks or chalking, or both, lessens sealant service life. However, a sealant that

develops no cracks or chalking, or low weight loss in this test method, does not necessarily assure good durability.

6. Apparatus

6.1 Forced-Draft Oven, controlled at 70 6 2°C (158 6 3.6°F).70 °C 6 2 °C (158 °F 6 3.6 °F).

6.2 Balance, sensitive to 0.01 g.

1 1

6.3 Rectangular Brass Frame, with inside dimensions 130 by 40130 mm by 40 mm by 6.4 mm (5(5 in. by 1 ⁄2 in. by ⁄4 in.). in.).

6.4 Aluminum Plates, three, each 152 by 80 by 0.6 to 1.6 mm (24 152 mm by 80 mm by 0.6 mm to 1.6 mm (24 gauge to 16 gauge).

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.