ASTM E1124-97(2004)

(Test Method)Standard Test Method for Field Measurement of Sound Power Level by the Two-Surface Method

Standard Test Method for Field Measurement of Sound Power Level by the Two-Surface Method

SCOPE

1.1 This test method covers the field, or in situ measurement of sound power level by the two-surface method. The test method is designed to minimize the effects of reverberant conditions, directivity of the noise source under consideration, and the effects of ambient noise from other nearby equipment operating at the same time.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E1124 – 97 (Reapproved 2004)

Standard Test Method for

Field Measurement of Sound Power Level by the Two-

Surface Method

This standard is issued under the fixed designation E1124; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.2 constituent surface area—a portion of the conformal

surface.

1.1 Thistestmethodcoversthefield,or in situmeasurement

of sound power level by the two-surface method. The test

4. Summary of Test Method

method is designed to minimize the effects of reverberant

4.1 The average one-third or full octave band sound pres-

conditions, directivity of the noise source under consideration,

sure levels are measured over two different conformal surfaces

and the effects of ambient noise from other nearby equipment

which envelop the equipment. These conformal surfaces

operating at the same time.

should be selected to consist of rectangular, cylindrical, and

1.2 This standard does not purport to address all of the

hemispherical constituent surfaces so that the surface areas

safety concerns, if any, associated with its use. It is the

may be easily calculated. From the difference between the two

responsibility of the user of this standard to establish appro-

average sound pressure levels taken at each surface and from

priate safety and health practices and determine the applica-

the areas of the surfaces, the sound power level may be

bility of regulatory limitations prior to use.

calculated. The calculation accounts for both the effect of the

2. Referenced Documents reverberant field and the noise of other equipment. It is

permissible to define conformal surfaces that completely en-

2.1 ASTM Standards:

velope the source, yet only measure over a portion of the

C634 Terminology Relating to Building and Environmental

conformalsurfaceduetorestrictionsfromprocessconnections

Acoustics

or accessibility.

2.2 ANSI Standard:

S1.4 Specification for Sound Level Meters

5. Significance and Use

3. Terminology 5.1 The function and operation of equipment in the field

often preclude the measurement of the free-field sound pres-

3.1 Definitions—For definitions of terms used in this test

4 sure levels of a single piece of equipment in the absence of

method, refer to Terminology C634.

interfering sound from other equipment operating at the same

3.2 Definitions of Terms Specific to This Standard:

time. The two-surface method will provide, in most cases, a

3.2.1 conformal surface—the locus of points which lie at a

reliable estimate of the normal sound power levels of a

fixed distance from the reference surface of a piece of

specimen operating in an adverse environment.

equipment. Two conformal surfaces are used in this test

5.2 This test method is intended for use in the field in the

method. These are surfaces over which the measuring micro-

presence of what is normally regarded as interfering back-

phones are swept. They are located at two different distances

ground noise. This test method is based upon the work of

from the equipment. Fig. 1 shows a typical arrangement of

,

56 7

Hubner and Diehl, but differs from all other current sound

these surfaces for a generalized piece of equipment.

power measurement procedures by requiring simultaneous

measurement at both conformal surfaces and by resolving

This test method is under the jurisdiction of ASTM Committee E33 on

time-averaged sound pressure levels at both surfaces to within

EnvironmentalAcousticsandisthedirectresponsibilityofSubcommitteeE33.08on

Mechanical and Electrical System Noise.

Current edition approved April 1, 2004. Published April 2004. Originally

approved in 1986. Last previous edition approved in 1997 as E1124–97. DOI:

10.1520/E1124-97R04. Hubner,G.,“AnalysisofErrorsinMeasuringMachineNoiseUnderFreeField

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Conditions,” Journal of the Acoustical Society of America,Vol 54, No. 4, 1973, pp.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 967–977.

Standards volume information, refer to the standard’s Document Summary page on Hubner, G., “Qualification Procedures for Free Field Conditions for Sound

the ASTM website. Power Determination of Sound Sources and Methods for the Determination of the

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St., Appropriate Environmental Correction,” Journal of the Acoustical Society of

4th Floor, New York, NY 10036. America, Vol 61, No. 2, 1977, pp. 456–464.

4 7

Terminology C634 – 85 was the edition used during the development of this Diehl, G. M., Machinery Acoustics, J. Wiley and Sons, New York, NY, 1973,

test method. pp. 97–103.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E1124 – 97 (2004)

FIG. 1 Configuration of Conformal Surfaces, General Case

0.1dB.Thesetwofeatures,simultaneousrecordingand0.1-dB 6. Operating Conditions

resolution, enable source sound power to be calculated when

6.1 Whenever possible, equipment under test must be oper-

the direct sound field of the source is actually lower in level

ating in a mode acceptable to all parties involved in the test.

than the ambient noise.

Otherwise operating conditions must at least be monitored in

5.3 The use of this test method is expected to be primarily

order that the test results are properly qualified in terms of

for the relative assessment of the sound power from similar

running speeds, flow rate, production rate, etc.

sources or for the prediction of sound levels in a plant based

upon measurements of similar sources in another plant. This

7. Apparatus

test method is believed to be capable of yielding a reasonably

7.1 Due to the amount of data which must be gathered and

good estimate of absolute power level with proper care of

processed, the following are considered to be the minimum

application and full conformance to the provisions of this

equipment necessary to meet the requirements of this test

procedure.

procedure.

5.4 Thetwo-surfacemethodisapplicableonlywhenthetwo

7.1.1 Microphones, that are matched in terms of frequency

measurement surfaces can be physically selected to produce

and pressure response. Begin by calibrating each data channel,

positive values of the difference in average sound pressure

using the same calibrator on each channel. Connect both

level.That is, the inner surface sound pressure level minus the

microphone channels to the cables, connectors, amplifiers, and

outer surface sound pressure level must be at least+0.1 dB.

recorder to be used in data gathering. Then arrange the

This limitation applies to each frequency band and each

microphones side by side in the presence of broad band

constituent surface area investigated. Only the frequency band

ambient noise and record for 60 s on both channels. The

in which a zero or negative difference occurs is it considered

differences in the averaged sound pressure levels in each

invalid and usually adjacent bands will be valid. In practice,

frequency band are calibration corrections which may be

only rarely will all three one-third octave bands of a given

applied to either channel prior to any calculation.

octaveyieldinvaliddataatallconstituentareas.Therefore,less

7.1.2 Magnetic Tape Recorder,two-channelinstrumentation

than complete results are permissible when one-third octave

grade having a frequency response of 61 dB over the

analysis is used and full octave results are reported.

frequency range of interest.

5.5 The two-surface method may not produce results when 7.1.2.1 It is recognized that even high-quality Amplitude

testing some very large machines in very reverberant rooms or Modulation (AM) tape recorders cannot maintain channel-to-

in rooms having a volume less than about 20 times the space channel frequency response within 0.1 dB. It is believed,

enclosed by an envelope around the larger dimensions of the however, that the requirement for determining the corrections

machine. In such cases, the sound pressure level close to the in 7.1.1 based on 60-s average readings sufficiently compen-

machine may not decrease in any regular way with increasing sates for expected instabilities, channel-to-channel. If digital

distancefromamachinesurface,makingitimpossibletoselect frequency modulation (FM) or pulse code modulation (PCM)

two measurement surfaces producing positive differences of tape recorders are used, the procedure of 7.1.1 should still be

sound pressure level. used.

E1124 – 97 (2004)

NOTE 1—The frequency response and accuracy of the acoustical

that will yield a measurable drop in average sound pressure

instruments are different from the interchannel resolution of the tape

level between the two surfaces for the frequency range of

recorder. Both the frequency response discussed in 7.1.2 and the accuracy

interest. As stated in Section 5, merely a 0.1-dB difference in

of the acoustical calibrators are distinctly different from the 0.1-dB

average sound pressure levels constitutes a measurable drop.

resolution discussed in 5.2.

However, the surfaces should be chosen so as to maximize the

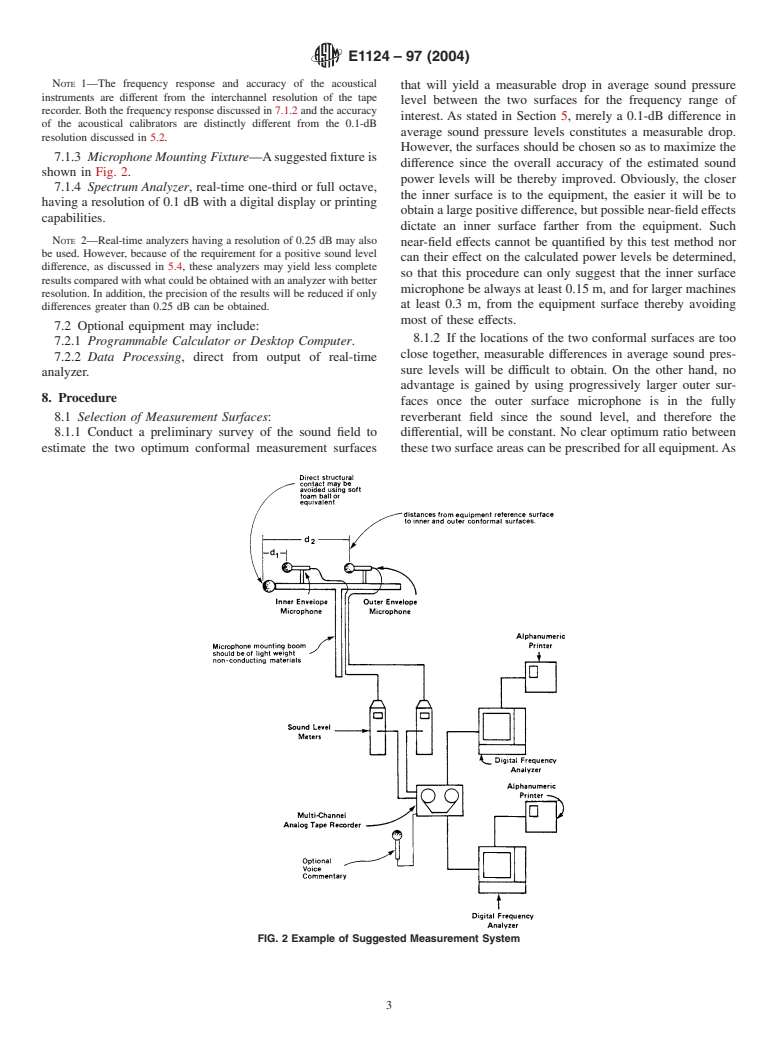

7.1.3 Microphone Mounting Fixture—Asuggestedfixtureis

difference since the overall accuracy of the estimated sound

shown in Fig. 2.

power levels will be thereby improved. Obviously, the closer

7.1.4 Spectrum Analyzer, real-time one-third or full octave,

the inner surface is to the equipment, the easier it will be to

having a resolution of 0.1 dB with a digital display or printing

obtainalargepositivedifference,butpossiblenear-fieldeffects

capabilities.

dictate an inner surface farther from the equipment. Such

NOTE 2—Real-time analyzers having a resolution of 0.25 dB may also

near-field effects cannot be quantified by this test method nor

be used. However, because of the requirement for a positive sound level

can their effect on the calculated power levels be determined,

difference, as discussed in 5.4, these analyzers may yield less complete

so that this procedure can only suggest that the inner surface

resultscomparedwithwhatcouldbeobtainedwithananalyzerwithbetter

microphone be always at least 0.15 m, and for larger machines

resolution. In addition, the precision of the results will be reduced if only

at least 0.3 m, from the equipment surface thereby avoiding

differences greater than 0.25 dB can be obtained.

most of these effects.

7.2 Optional equipment may include:

8.1.2 If the locations of the two conformal surfaces are too

7.2.1 Programmable Calculator or Desktop Computer.

close together, measurable differences in average sound pres-

7.2.2 Data Processing, direct from output of real-time

sure levels will be difficult to obtain. On the other hand, no

analyzer.

advantage is gained by using progressively larger outer sur-

8. Procedure

faces once the outer surface microphone is in the fully

reverberant field since the sound level, and therefore the

8.1 Selection of Measurement Surfaces:

8.1.1 Conduct a preliminary survey of the sound field to differential, will be constant. No clear optimum ratio between

estimate the two optimum conformal measurement surfaces thesetwosurfaceareascanbeprescribedforallequipment.As

FIG. 2 Example of Suggested Measurement System

E1124 – 97 (2004)

a guide, however, experience has shown that an area ratio of and lower pedestal. Less than 100% coverage was used and

about 1.4 to 2.0, between the outer and inner surfaces, is a was accounted for as discussed in 9.4.

reasonable range that may be used in most cases.

8.1.6 No optimum distances from the equipment surface to

8.1.3 Select simple geometric shapes for conformal sur-

either conformal surface can be prescribed for all equipment.

faces. Fig. 1 shows an example of a generalized situation. In

However, for sources whose smallest dimension is 1 m, it is

Fig. 1, even though the equipment itself can be approximated

recommendedtheinnersurfacedistancebeatleast0.2m.Also,

by rectangular or cylindrical surfaces which just enclose the

for sources whose smallest dimension is 3 m, it is recom-

equipment, the reference surface is chosen so that the two

mended the outer surface distance be less than 2 m.

conformalmeasurementsurfacesareconvex.Itmaybehelpful

8.2 Data Acquisition:

to imagine the major equipment reference surfaces to be

8.2.1 Obtain simultaneous measurements of the sound pres-

defined by a membrane stretched over the equipment after the

surelevelatthetwomicrophonepositionsalongalinenormal,

removal of minor projections, gages, tubes, and cables not

that is perpendicular to, the inner conformal surface. See 7.1.3

expected to be noise sources themselves. Ideally, the sound

for a suggested microphone mounting fixture. Determine the

intensityvectorwouldbenormaltobothmeasurementsurfaces

atallpoints.Althoughthiscannotbedeterminedusingthistest averagesoundpressurelevelovereachconstituentsurfacearea

using a continuous uniform microphone sweep as indicated in

method, it may be helpful if the surveyor will attempt to

visualize the expected sound field and so might adjust the Fig. 4.

selection of conformal surfaces accordingly.

8.2.2 If the inner and outer measurement surfaces are

8.1.4 It is permissible to subdivide the conformal surfaces

subdivided into smaller constituent areas for the survey, the

intoseveralconstituentsurfaceareasforeaseofdatacollection

average sound pressure levels over the entire inner and outer

or because of inaccessibility. Any number of constituent

conformal surfaces are determined by summing the values

surface areas may be used to cover the conformal surface.

obtained for the respective constituent areas, as shown in 9.3.

Since the conformal surfaces will be measured simultaneously

8.2.3 The microphone sweeping speed shall be sufficiently

withtheinnerandoutermicrophones,careshouldbetakenthat

slow, continuous, and uniform that when the data are continu-

the constituent surface area boundaries define related regions

ouslyrecorded,arepresentativeaveragesoundpressurelevelis

ontheinnerandoutersurfaces.Theseconstituentsurfaceareas

obtainedforeachconstituentareasweptbythemicrophone(s).

willnotnecessarilybecomposedofgeometricallysimilarinner

Areasonable averaging period is usually between 30 and 60 s

andoutersurfacesbecauseoftheusuallycomplexshapeofthe

for each constituent area. A reasonable sweeping speed is

equipment sources themselves.

usually about 0.5 m/s.

8.1.5 Fig. 3 is an example of the application of these

8.2.4 Fig. 5 illustrates an alternate data

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.