ASTM D1083-91(1998)

(Test Method)Standard Test Methods for Mechanical Handling of Unitized Loads and Large Shipping Cases and Crates (Withdrawn 2001)

Standard Test Methods for Mechanical Handling of Unitized Loads and Large Shipping Cases and Crates (Withdrawn 2001)

SCOPE

1.1 These test methods are suitable for testing the integrity of large shipping cases and unitized loads as well as the ability of the contents to endure normal handling. Not all of the methods are applicable to all products, containers, and loads. The test methods described are applicable to common means of material handling including: forklift, pull pack, clamp truck, crane, and spade lift type handling systems as follows:

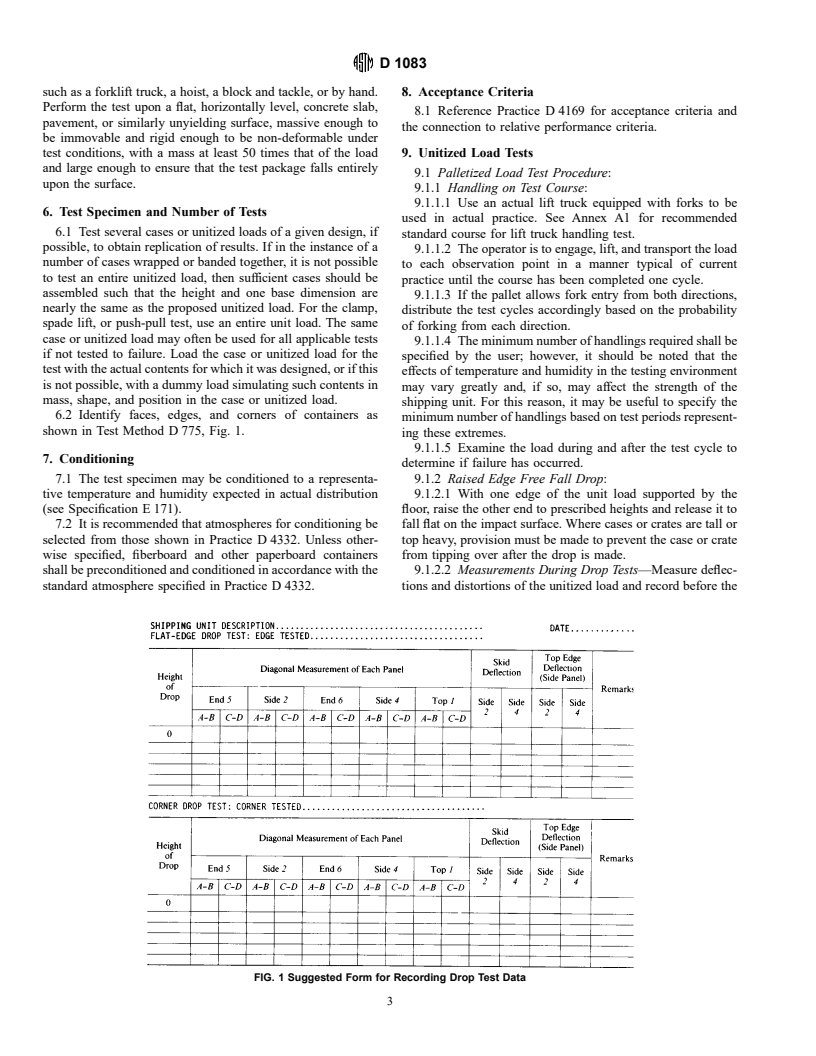

1.1.1 Drop Test -For measuring the ability of the case or unitized load to withstand rough handling and provide information useful in improving the design of the container (see 9.1.2 and 10.1).

1.1.2 Spade Lift Test -For lifting by spade lift attachment to determine the ability of the handling flap of the case or shipping unit to withstand repeated lifting and handling by this method (see 9.2).

1.1.3 Clamp Lift Test -For lifting by hydraulic clamp attachment, to determine the ability of the case or shipping unit, to withstand squeeze clamp handling consisting of repeated side compressions and lifting (see 9.3).

1.1.4 Push-Pull Handling Test -For testing the ability of the slip sheet tab to withstand repeated pulls by the gripper jaws without tearing (see 9.4).

1.1.5 Grabhook Test -For lifting by grabhooks to determine the ability of the case or unitized load to withstand the horizontal pressures of grabhooks (see 10.2).

1.1.6 Sling Test -For lifting by wire rope, cable, or woven fiber slings to determine the ability of the case or unitized load to withstand the compression of slings (see 10.3).

1.1.7 Tip Test -For determining the ability of tall or top heavy cases or crates to resist tipping over (see Section 11).

1.1.8 Tipover Test -For determining the ability of filled large shipping containers to resist the impacts associated with tipover hazards, and for determining the ability of the packaging and packing methods to provide protection to the contents, when the pack is tipped over (see Section 12). Note 1-This test method fulfills the requirements of International Organization for Standardization standard ISO 8768. The ISO standard may not meet the requirements for this test method.>

1.1.9 Rolling Test -For determining the ability of a complete, filled transport package to withstand the effects of rolling (see Section 13). Note 2-This test method fulfills the requirements of International Organization for Standardization standard ISO 2876. The ISO standard may not meet the requirements for this test method.>

1.2 Additional Test Procedures:

1.2.1 Additional tests that apply to mechanical handling of unitized loads and large cases and crates include incline impact tests, described in Test Method D880 and horizontal impact tests, described in Test Method D4003. Test Method D4003 includes a special pallet marshalling test and Test Method D1185 provides test methods for pallets and related structures.

1.2.2 Test Method D4169 provides a series of options for selecting and running performance tests on all types of shipping containers and systems.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.>

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: D 1083 – 91 (Reapproved 1998)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Methods for

Mechanical Handling of Unitized Loads and Large Shipping

1

Cases and Crates

This standard is issued under the fixed designation D 1083; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 1.1.9 Rolling Test—For determining the ability of a com-

plete, filled transport package to withstand the effects of rolling

1.1 These test methods are suitable for testing the integrity

(see Section 13).

of large shipping cases and unitized loads as well as the ability

of the contents to endure normal handling. Not all of the

NOTE 2—This test method fulfills the requirements of International

methods are applicable to all products, containers, and loads.

Organization for Standardization standard ISO 2876. The ISO standard

may not meet the requirements for this test method.

The test methods described are applicable to common means of

material handling including: forklift, pull pack, clamp truck,

1.2 Additional Test Procedures:

crane, and spade lift type handling systems as follows:

1.2.1 Additional tests that apply to mechanical handling of

1.1.1 Drop Test—For measuring the ability of the case or

unitized loads and large cases and crates include incline impact

unitized load to withstand rough handling and provide infor-

tests, described in Test Method D 880 and horizontal impact

mation useful in improving the design of the container (see

tests, described in Test Method D 4003. Test Method D 4003

9.1.2 and 10.1).

includes a special pallet marshalling test and Test Method

1.1.2 Spade Lift Test—For lifting by spade lift attachment to

D 1185 provides test methods for pallets and related structures.

determine the ability of the handling flap of the case or

1.2.2 Test Method D 4169 provides a series of options for

shipping unit to withstand repeated lifting and handling by this

selecting and running performance tests on all types of

method (see 9.2).

shipping containers and systems.

1.1.3 Clamp Lift Test—For lifting by hydraulic clamp at-

1.3 This standard does not purport to address all of the

tachment, to determine the ability of the case or shipping unit,

safety concerns, if any, associated with its use. It is the

to withstand squeeze clamp handling consisting of repeated

responsibility of the user of this standard to establish appro-

side compressions and lifting (see 9.3).

priate safety and health practices and determine the applica-

1.1.4 Push-Pull Handling Test—For testing the ability of

bility of regulatory limitations prior to use.

the slip sheet tab to withstand repeated pulls by the gripper

2. Referenced Documents

jaws without tearing (see 9.4).

1.1.5 Grabhook Test—For lifting by grabhooks to determine

2.1 ASTM Standards:

2

the ability of the case or unitized load to withstand the

D 775 Test Method for Drop Test for Loaded Boxes

horizontal pressures of grabhooks (see 10.2).

D 880 Test Method for Impact Testing for Shipping Con-

2

1.1.6 Sling Test—For lifting by wire rope, cable, or woven

tainers and Systems

fiber slings to determine the ability of the case or unitized load

D 996 Terminology of Packaging and Distribution Environ-

2

to withstand the compression of slings (see 10.3).

ments

1.1.7 Tip Test—For determining the ability of tall or top

D 1185 Test Methods for Pallets and Related Structures

2

heavy cases or crates to resist tipping over (see Section 11).

Employed in Materials Handling and Shipping

1.1.8 Tipover Test—For determining the ability of filled

D 3332 Test Methods for Mechanical-Shock Fragility of

2

large shipping containers to resist the impacts associated with

Products, Using Shock Machines

tipover hazards, and for determining the ability of the packag-

D 4003 Test Methods for Programmable Horizontal Impact

2

ing and packing methods to provide protection to the contents,

Test for Shipping Containers and Systems

when the pack is tipped over (see Section 12).

D 4169 Practice for Performance Testing of Shipping Con-

2

tainers and Systems

NOTE 1—This test method fulfills the requirements of International

D 4332 Practice for Conditioning Containers, Packages, or

Organization for Standardization standard ISO 8768. The ISO standard

2

may not meet the requirements for this test method. Packaging Components for Testing

E 171 Specification for Standard Atmospheres for Condi-

2

1

tioning and Testing Flexible Barrier Materials

These test methods are under the jurisdiction of ASTM Co

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.