ASTM D4332-22

(Practice)Standard Practice for Conditioning Containers, Packages, or Packaging Components for Testing

Standard Practice for Conditioning Containers, Packages, or Packaging Components for Testing

SIGNIFICANCE AND USE

4.1 Many materials from which containers and packages are made, especially cellulosic materials, undergo changes in physical properties as the temperature and the relative humidity (RH) to which they are exposed are varied. Therefore, the package should be placed and kept in a specified atmosphere for a length of time such that subsequent measurements of physical properties will be meaningful and reproducible.

4.2 The conditions described in this practice are either historically accepted standard conditions or special laboratory conditions chosen to represent particular phases of the distribution environment. These special conditions do not necessarily duplicate actual field conditions, but tend to simulate them and have effects on packages and materials which may be related to their field performance.

SCOPE

1.1 This practice provides for standard and special conditioning and testing atmospheres that may be used to simulate particular field conditions that a container, package, or packaging component may encounter during its life or testing cycle.

1.2 This practice describes procedures for conditioning these containers, packages, or packaging components so that they approach or reach equilibrium with the atmosphere to which they may be exposed. This standard is commonly used for conditioning when conducting transit simulation tests.

1.3 Practice D685 should be used as the relevant conditioning standard when quantification of box compression strength at standard atmosphere conditions is required.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4332 − 22

Standard Practice for

Conditioning Containers, Packages, or Packaging

Components for Testing

This standard is issued under the fixed designation D4332; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E171 Practice for Conditioning and Testing Flexible Barrier

Packaging

1.1 This practice provides for standard and special condi-

E337 Test Method for Measuring Humidity with a Psy-

tioning and testing atmospheres that may be used to simulate

chrometer (the Measurement of Wet- and Dry-Bulb Tem-

particular field conditions that a container, package, or pack-

peratures)

aging component may encounter during its life or testing cycle.

F2825 Practice for Climatic Stressing of Packaging Systems

1.2 This practice describes procedures for conditioning

for Single Parcel Delivery

these containers, packages, or packaging components so that

they approach or reach equilibrium with the atmosphere to 3. Terminology

which they may be exposed. This standard is commonly used

3.1 Terms and definitions used in this practice may be found

for conditioning when conducting transit simulation tests.

in Terminology D996, Terminology D1968, or Specification

1.3 Practice D685 should be used as the relevant condition- E171.

ing standard when quantification of box compression strength

4. Significance and Use

at standard atmosphere conditions is required.

4.1 Many materials from which containers and packages are

1.4 This standard does not purport to address all of the

made, especially cellulosic materials, undergo changes in

safety concerns, if any, associated with its use. It is the

physicalpropertiesasthetemperatureandtherelativehumidity

responsibility of the user of this standard to establish appro-

(RH) to which they are exposed are varied. Therefore, the

priate safety, health, and environmental practices and deter-

package should be placed and kept in a specified atmosphere

mine the applicability of regulatory limitations prior to use.

for a length of time such that subsequent measurements of

1.5 This international standard was developed in accor-

physical properties will be meaningful and reproducible.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

4.2 The conditions described in this practice are either

Development of International Standards, Guides and Recom-

historically accepted standard conditions or special laboratory

mendations issued by the World Trade Organization Technical

conditions chosen to represent particular phases of the distri-

Barriers to Trade (TBT) Committee.

bution environment. These special conditions do not necessar-

ily duplicate actual field conditions, but tend to simulate them

2. Referenced Documents

and have effects on packages and materials which may be

2.1 ASTM Standards:

related to their field performance.

D685 Practice for Conditioning Paper and Paper Products

5. Atmospheric Conditions

for Testing

D996 Terminology of Packaging and Distribution Environ-

5.1 Preconditioning Atmosphere—20 °C to 40 °C (68 °F to

ments

104 °F) and 10 % to 35 % relative humidity.

D1968 Terminology Relating to Paper and Paper Products

5.2 Standard Conditioning Atmosphere—23 °C 6 1°C

(73.4 °F 6 2 °F) and 50 % 6 2 % relative humidity.

This practice is under the jurisdiction of ASTM Committee D10 on Packaging

NOTE 1—Average values must fall within these limits. Short-term

and is the direct responsibility of Subcommittee D10.21 on Shipping Containers and

fluctuations and measurement limitations may cause individual measure-

Systems - Application of Performance Test Methods.

ments to vary up to 62°C(63.6 °F) and 65 % relative humidity without

Current edition approved May 1, 2022. Published June 2022. Originally

significant impairment of test precision.

approved in 1984. Last previous edition approved in 2014 as D4332 – 14. DOI:

10.1520/D4332-22.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4332 − 22

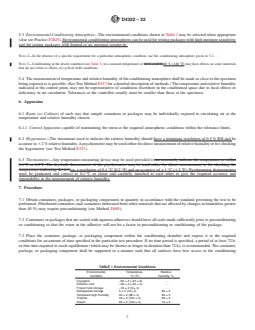

5.3 Environmental ConditioningAtmosphere—The environ- to be performed. Fiberboard containers (and containers fabri-

mental conditions shown in Table 1 may be selected when cated from other materials that are affected by changes in

appropriate (also see Practice F2825). Environmental condi- humiditiesgreaterthan40 %)mayrequirepreconditioning(see

tioning atmospheres can be used for testing packages with high Method D685).

moisture sensitivity and for testing packages with limited or no

7.2 Containers or packages that are sealed with aqueous

moisture sensitivity.

adhesives should have all seals made sufficiently prior to

preconditioning or conditioning so that the water in the

NOTE 2—In the absence of a specific requirement for a particular

atmospheric condition, use the conditioning atmosphere given in 5.2. adhesive will not be a factor in p

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4332 − 14 D4332 − 22

Standard Practice for

Conditioning Containers, Packages, or Packaging

Components for Testing

This standard is issued under the fixed designation D4332; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice provides for standard and special conditioning and testing atmospheres that may be used to simulate particular

field conditions that a container, package, or packaging component may encounter during its life or testing cycle.

1.2 This practice describes procedures for conditioning these containers, packages, or packaging components so that they approach

or reach equilibrium with the atmosphere to which they may be exposed. This standard is commonly used for conditioning when

conducting transit simulation tests.

1.3 Practice D685 should be used as the relevant conditioning standard when quantification of box compression strength at

standard atmosphere conditions is required.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D685 Practice for Conditioning Paper and Paper Products for Testing

D996 Terminology of Packaging and Distribution Environments

E41D1968 Terminology Relating to ConditioningPaper and Paper Products (Withdrawn 2019)

E171 Practice for Conditioning and Testing Flexible Barrier Packaging

E337 Test Method for Measuring Humidity with a Psychrometer (the Measurement of Wet- and Dry-Bulb Temperatures)

F2825 Practice for Climatic Stressing of Packaging Systems for Single Parcel Delivery

3. Terminology

3.1 Terms and definitions used in this practice may be found in Terminology D996, Terminology E41D1968, or Specification

E171.

This practice is under the jurisdiction of ASTM Committee D10 on Packaging and is the direct responsibility of Subcommittee D10.21 on Shipping Containers and

Systems - Application of Performance Test Methods.

Current edition approved Nov. 1, 2014May 1, 2022. Published January 2015June 2022. Originally approved in 1984. Last previous edition approved in 20132014 as

D4332D4332 – 14. –13. DOI: 10.1520/D4332-14.10.1520/D4332-22.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4332 − 22

4. Significance and Use

4.1 Many materials from which containers and packages are made, especially cellulosic materials, undergo changes in physical

properties as the temperature and the relative humidity (RH) to which they are exposed are varied. Therefore, the package should

be placed and kept in a specified atmosphere for a length of time such that subsequent measurements of physical properties will

be meaningful and reproducible.

4.2 The conditions described in this practice are either historically accepted standard conditions or special laboratory conditions

chosen to represent particular phases of the distribution environment. These special conditions do not necessarily duplicate actual

field conditions, but tend to simulate them and have effects on packages and materials which may be related to their field

performance.

5. Atmospheric Conditions

5.1 Preconditioning Atmosphere—2020 °C to 40°C (6840 °C (68 °F to 104°F)104 °F) and 1010 % to 35 % relative humidity.

5.2 Standard Conditioning Atmosphere— 23 6 1°C (73.4 6 2°F) and 5023 °C 6 1 °C (73.4 °F 6 2 °F) and 50 % 6 2 % relative

humidity.

NOTE 1—Average values must fall within these limits. Short-term fluctuations and measurement limitations may cause individual measurements to vary

up to 62°C (63.6°F)62 °C (63.6 °F) and 65 % relative humidity without significant impairment of test precision.

D4332 − 22

5.3 Environmental Conditioning Atmosphere—The environmental conditions shown in Table 1 may be selected when appropriate

(also see Practice F2825). Environmental conditioning atmospheres can be used for testing packages with high moisture sensitivity

and for testing packages with limited or no moisture sensitivity.

NOTE 2—In the absence of a specific requirement for a particular atmospheric condition, use the conditioning atmosphere given in 5.2.

NOTE 3—Conditioning at the desert condition (see Table 1) at a constant temperature of 60°C (140°F)60 °C (140 °F) may have effects on some materials

that do not relate to effects of cyclical field conditions.

5.4 The measurement of temperature and relative humidity of the conditioning atmosphere shall be made as close to the specimen

being exposed as is possible. (See Test Method E337 for a detailed description of methods.) T

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.