ASTM B478-85(2003)

(Test Method)Standard Test Method for Cross Curvature of Thermostat Metals

Standard Test Method for Cross Curvature of Thermostat Metals

SIGNIFICANCE AND USE

This procedure provides the means for defining the magnitude and direction of cross curvature (an inherent property in thermostat metal).

SCOPE

1.1 This test method covers the determination of cross curvature of thermostat metals.

Note 1—This test method is not limited to thermostat metals and can be used for other materials for which the cross curvature must be measured accurately.

Note 2—This standard includes means for calculating cross curvature for widths other than that of the specimen having the same radius of curvature.

1.2 The values stated in inch-pound units are to be regarded as the standard. The metric equivalents of the inch-pound units may be approximate.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B 478–85(Reapproved2003)

Standard Test Method for

Cross Curvature of Thermostat Metals

This standard is issued under the fixed designation B 478; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of cross

curvature of thermostat metals.

NOTE 1—This test method is not limited to thermostat metals and can

be used for other materials for which the cross curvature must be

measured accurately.

NOTE 2—This standard includes means for calculating cross curvature

for widths other than that of the specimen having the same radius of

curvature.

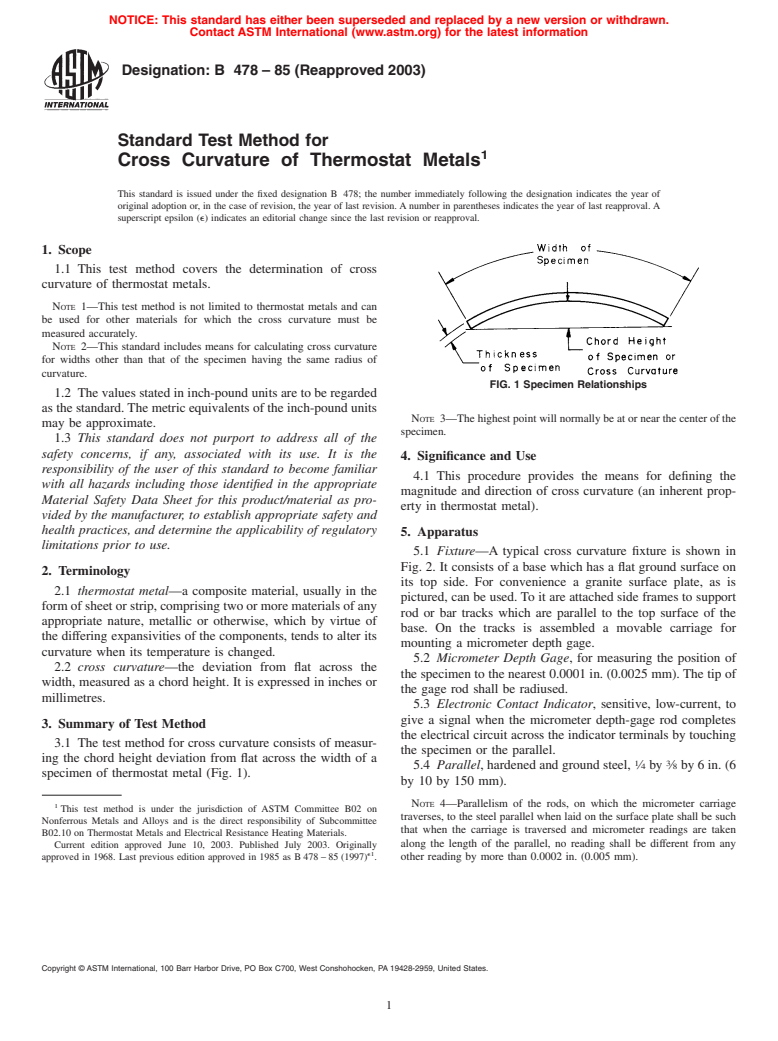

FIG. 1 Specimen Relationships

1.2 The values stated in inch-pound units are to be regarded

as the standard.The metric equivalents of the inch-pound units

NOTE 3—The highest point will normally be at or near the center of the

may be approximate.

specimen.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Significance and Use

responsibility of the user of this standard to become familiar

4.1 This procedure provides the means for defining the

with all hazards including those identified in the appropriate

magnitude and direction of cross curvature (an inherent prop-

Material Safety Data Sheet for this product/material as pro-

erty in thermostat metal).

vided by the manufacturer, to establish appropriate safety and

health practices, and determine the applicability of regulatory

5. Apparatus

limitations prior to use.

5.1 Fixture—A typical cross curvature fixture is shown in

Fig. 2. It consists of a base which has a flat ground surface on

2. Terminology

its top side. For convenience a granite surface plate, as is

2.1 thermostat metal—a composite material, usually in the

pictured, can be used. To it are attached side frames to support

formofsheetorstrip,comprisingtwoormorematerialsofany

rod or bar tracks which are parallel to the top surface of the

appropriate nature, metallic or otherwise, which by virtue of

base. On the tracks is assembled a movable carriage for

the differing expansivities of the components, tends to alter its

mounting a micrometer depth gage.

curvature when its temperature is changed.

5.2 Micrometer Depth Gage, for measuring the position of

2.2 cross curvature—the deviation from flat across the

the specimen to the nearest 0.0001 in. (0.0025 mm).The tip of

width, measured as a chord height. It is expressed in inches or

the gage rod shall be radiused.

millimetres.

5.3 Electronic Contact Indicator, sensitive, low-current, to

give a signal when the micrometer depth-gage rod completes

3. Summary of Test Method

the electrical circuit across the indicator terminals by touching

3.1 The test method for cross curvature consists of measur-

the specimen or the parallel.

ing the chord height deviation from flat across the width of a

1 3

5.4 Parallel, hardened and ground steel, ⁄4 by ⁄8 by 6 in. (6

specimen of thermostat metal (Fig. 1).

by 10 by 150 mm).

NOTE 4—Parallelism of the rods, on which the micrometer carriage

This test method is under the jurisdiction of ASTM Committee B02 on

traverses, to the steel parallel when laid on the surface plate shall be such

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

that when the carriage is traversed and micrometer readings are taken

B02.10 on Thermostat Metals and Electrical Resistance Heating Materials.

along the length of the parallel, no reading shall be different from any

Current edition approved June 10, 2003. Published July 2003. Originally

e1

approved in 1968. Last previous edition approved in 1985 as B478–85(1997) . other reading by more than 0.0002 in. (0.005 mm).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 478–85 (2003)

FIG. 2 A Typical Design of Apparatus

6. Sampling specimen and determine its thickness within 60.0001 in.

(60.0025 mm) by means of micrometer calipers having

6.1 The method of sampling shall be mutually agreed upon

radiused anvils. Take all measurements at a temperature of 75

between the manufacturer and the purchaser.

61°F(24 60.5°C)withsufficienttimeallowedforthesample

7. Preparation of Sample for Measurement to have reached

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.