ASTM F1484-05

(Test Method)Standard Test Methods for Performance of Steam Cookers

Standard Test Methods for Performance of Steam Cookers

SIGNIFICANCE AND USE

The maximum energy input rate test is used to confirm that the steam cooker is operating at the manufacturer’rated input. This test would also indicate any problems with the electric power supply, gas service pressure, or steam supply flow or pressure.

Preheat energy and duration can be useful to food service operators for managing power demands and knowing how quickly the steam cooker can be ready for operation.

Idle energy rate and pilot energy rate can be used to estimate energy consumption.

Green pea load cooking energy efficiency is an indicator of steam cooker energy performance when cooking frozen products under various loading conditions. This allows the food service operator to consider energy costs when selecting a steam cooker.

Potato load cooking energy efficiency is an indicator of steam cooker energy performance when cooking foods that require long cook times (for example, potatoes, beans, rice, lasagna or casserole rethermalization). The test demonstrates the difference in energy efficiency between pressure and pressureless steam cookers for this type of cooking event. The information may help a food service operator to evaluate what type of steamer to select (pressure versus pressureless versus dual pressure mode) from an energy performance perspective.

Green pea load production capacity and potato load production capacity can be used by food service operators to choose a steam cooker to match their particular food output requirements.

Water consumption characterization is useful for estimating water and sewerage costs associated with appliance operation.

Condensate temperature measurement is useful to verify that the temperature does not exceed regional building code limits.

Cooking uniformity provides information regarding the steamer’s ability to cook food at the same rate throughout the steamer’s compartment.

SCOPE

1.1 These test methods evaluate the energy consumption and cooking performance of steam cookers. The food service operator can use this evaluation to select a steam cooker and understand its energy consumption.

1.2 These test methods are applicable to the following steam cookers: high-pressure, low-pressure, and pressureless steam cookers (Specification F 1217 Grades A, B, and C); convection and non-convection steam cookers; steam cookers with self-contained gas-fired, electric, or steam coil steam generators, and those connected directly to an external potable steam source (Specification F 1217 Styles i, ii, iii, and iv). The steam cookers will be tested for the following (where applicable):

1.2.1 Maximum energy input rate (see 10.2).

1.2.2 Preheat energy consumption and duration (see 10.3).

1.2.3 Idle energy rate (see 10.4).

1.2.4 Pilot energy rate (see 10.5).

1.2.5 Frozen green pea load cooking energy efficiency (see 10.7).

1.2.6 Frozen green pea load production capacity (see 10.7).

1.2.7 Whole potato load cooking energy efficiency (see 10.9).

1.2.8 Whole potato load production capacity (see 10.9).

1.2.9 Water consumption (see 10.7 and 10.9).

1.2.10 Condensate temperature (see 10.7 and 10.9).

1.2.11 Cooking uniformity (see 10.10).

1.3 The values stated in inch-pound units are to be regarded as standard. The SI units given in parentheses are for information only.

1.4 This standard may involve hazardous materials, operations, and equipment. It does not address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1484 − 05 AnAmerican National Standard

Standard Test Methods for

1

Performance of Steam Cookers

This standard is issued under the fixed designation F1484; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 These test methods evaluate the energy consumption 2.1 ASTM Standards:

D3588Practice for Calculating Heat Value, Compressibility

and cooking performance of steam cookers. The food service

Factor, and Relative Density of Gaseous Fuels

operator can use this evaluation to select a steam cooker and

F1217Specification for Cooker, Steam

understand its energy consumption.

3

2.2 ASHRAE Documents:

1.2 Thesetestmethodsareapplicabletothefollowingsteam

ASHRAEHandbookofFundamentals,ThermalandRelated

cookers: high-pressure, low-pressure, and pressureless steam

Properties of Food and Food Materials, Chapter 30, Table

cookers (Specification F1217 GradesA, B, and C); convection

1, 1989.

and non-convection steam cookers; steam cookers with self-

ASHRAE Handbook of Fundamentals, Thermodynamic

contained gas-fired, electric, or steam coil steam generators,

Properties of Water at Saturation, Chapter 6, Table 2,

and those connected directly to an external potable steam

1989.

source (Specification F1217 Styles i, ii, iii, and iv). The steam

4

2.3 Other Document:

cookers will be tested for the following (where applicable):

Developmentand Application of a Uniform Testing Proce-

1.2.1 Maximum energy input rate (see 10.2).

dure for Steam Cookers

1.2.2 Preheat energy consumption and duration (see 10.3).

1.2.3 Idle energy rate (see 10.4).

3. Terminology

1.2.4 Pilot energy rate (see 10.5).

3.1 Definitions:

1.2.5 Frozen green pea load cooking energy efficiency (see

3.1.1 boiler, n—self-contained vessel, separate from the

10.7).

cooking cavity, wherein water is boiled to produce steam for

1.2.6 Frozen green pea load production capacity (see 10.7).

the steam cooker. Also called a steam generator.

1.2.7 Whole potato load cooking energy efficiency (see

3.1.2 condensate, n—mixture of condensed steam and cool-

10.9).

ing water, exiting the steam cooker and directed to the floor

1.2.8 Whole potato load production capacity (see 10.9).

drain.

10.7 and 10.9).

1.2.9 Water consumption (see

3.1.3 cooking energy effıciency, n—quantity of energy im-

1.2.10 Condensate temperature (see 10.7 and 10.9).

parted to the specified food product expressed as a percentage

1.2.11 Cooking uniformity (see 10.10).

of energy consumed by the steam cooker during the cooking

1.3 Thevaluesstatedininch-poundunitsaretoberegarded

event.

as standard. The SI units given in parentheses are for informa-

3.1.4 cooking energy rate, n—average rate of energy con-

tion only.

sumption (kBtu/h or kW) during the cooking energy efficiency

1.4 This standard may involve hazardous materials,

test. Refers to any loading scenario in the green pea or potato

operations, and equipment. It does not address all of the safety

load tests.

concerns, if any, associated with its use. It is the responsibility

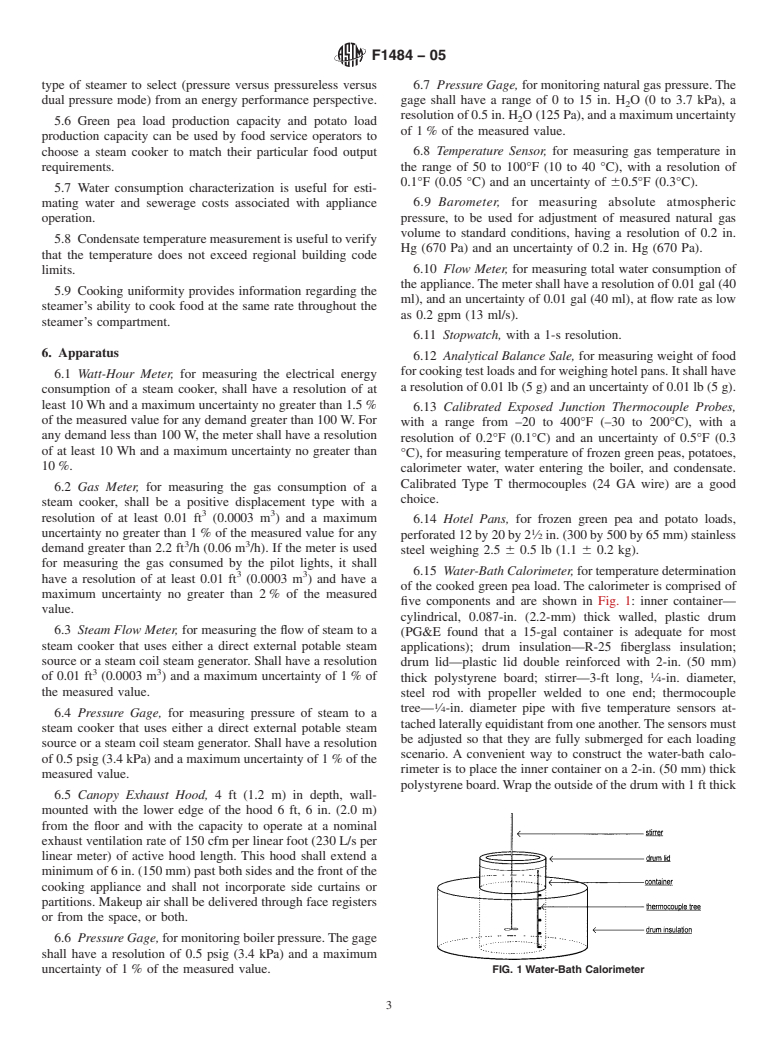

3.1.5 electricenergyrate,n—referstorateofelectricenergy

of the user of this standard to establish appropriate safety and

consumption (kW) by steam cookers whose primary fuel

health practices and determine the applicability of regulatory

source is not electricity (for example, gas). Electric energy is

limitations prior to use.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

ThesetestmethodsareunderthejurisdictionofASTMCommitteeF26onFood Standards volume information, refer to the standard’s Document Summary page on

Service Equipment and is the direct responsibility of Subcommittee F26.06 on the ASTM website.

3

Productivity and Energy Protocol. Available fromAmerican Society of Heating, Refrigerating andAir Condition-

Current edition approved March 1, 2005. Published March 2005. Originally ing Engineers, Inc., 1791 Tullie Circle, NE, Atlanta, GA 30329.

4

approved in 1993. Last previous edition approved in 2004 as F1484–04a. DOI: Available from the Food Service Technology Center, 12949 Alcosta Blvd.,

10.1520/F1484-05. #101, San Ramon, CA 94583.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1484 − 05

measuredandreportedseparatelyfromtheprimaryfuelenergy sured input rate is not within 5% of the rated input, all further

so that the respective fuel prices can be applied to estimate testing ceases and the manufacturer is contact

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.