ASTM D2105-01(2019)

(Test Method)Standard Test Method for Longitudinal Tensile Properties of “Fiberglass” (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe and Tube

Standard Test Method for Longitudinal Tensile Properties of “Fiberglass” (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe and Tube

SIGNIFICANCE AND USE

4.1 Tensile properties include modulus of elasticity, yield stress, elongation beyond yield point, tensile strength, elongation at break, and energy absorption. Materials possessing a low order of ductility may not exhibit a yield point. Stress-strain data at several levels of temperature, humidity, time, or other variables may be needed to furnish reasonably accurate indications of the behavior of the material.

4.2 Tension tests may provide data for research and development, engineering design, quality control, acceptance or rejection under specifications, and for special purposes (Note 3). The tests cannot be considered significant for applications differing widely from the load-time scale of the standard test (Note 4). Such applications require more suitable tests, such as impact, creep, and fatigue.

Note 3: It is realized that the method of preparation of a material is one of the many variables that affect the results obtained in testing a material. Hence, when comparative tests of materials per se are desired, the greatest care must be exercised to ensure that all samples are prepared in exactly the same way; similarly, for referee or comparative tests of any given series of specimens, care must be taken to secure the maximum degree of uniformity in details of preparation, treatment, and handling.

Note 4: Reinforcements of plastics with glass fiber offer wide opportunities for designing and producing products with markedly different responses to loading even when the basic geometry of the product is similar. For example, a tubular product may be designed to give maximum resistance to torsion loading, but such a product might develop a twist or bow if tested in tension or under internal pressure loading. In the case of pipe for general field use, internal pressure, as well as loads in tension, compression, torsion, and flexure must be resisted to some degree. Different pipe producers have chosen, by design, to offer products having different balances of ...

SCOPE

1.1 This test method covers the determination of the comparative longitudinal tensile properties of fiberglass pipe when tested under defined conditions of pretreatment, temperature, and testing machine speed. Both glass-fiber-reinforced thermosetting-resin pipe (RTRP) and glass-fiber-reinforced polymer mortar pipe (RPMP) are fiberglass pipes.

Note 1: For the purposes of this standard, polymer does not include natural polymer.

1.2 This test method is generally limited to pipe diameter of 6 in. (150 mm) or smaller. Larger sizes may be tested if required apparatus is available.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for information purposes only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 2: There is no known ISO equivalent to this standard.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D2105 − 01 (Reapproved 2019)

Standard Test Method for

Longitudinal Tensile Properties of “Fiberglass” (Glass-Fiber-

Reinforced Thermosetting-Resin) Pipe and Tube

This standard is issued under the fixed designation D2105; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D618 Practice for Conditioning Plastics for Testing

D638 Test Method for Tensile Properties of Plastics

1.1 This test method covers the determination of the com-

D638M Test Method for Tensile Properties of Plastics (Met-

parative longitudinal tensile properties of fiberglass pipe when

ric) (Withdrawn 1996)

tested under defined conditions of pretreatment, temperature,

D883 Terminology Relating to Plastics

and testing machine speed. Both glass-fiber-reinforced

D1600 Terminology forAbbreviatedTerms Relating to Plas-

thermosetting-resin pipe (RTRP) and glass-fiber-reinforced

tics

polymer mortar pipe (RPMP) are fiberglass pipes.

D3567 Practice for Determining Dimensions of “Fiberglass”

NOTE 1—For the purposes of this standard, polymer does not include

(Glass-Fiber-Reinforced Thermosetting Resin) Pipe and

natural polymer.

Fittings

1.2 This test method is generally limited to pipe diameter of

E4 Practices for Force Verification of Testing Machines

6 in. (150 mm) or smaller. Larger sizes may be tested if

E83 Practice for Verification and Classification of Exten-

required apparatus is available.

someter Systems

F412 Terminology Relating to Plastic Piping Systems

1.3 The values stated in inch-pound units are to be regarded

as the standard. The values given in parentheses are provided

3. Terminology

for information purposes only.

3.1 General—Definitions are in accordance with Terminol-

1.4 This standard does not purport to address all of the

ogy D883 and F412 and abbreviations are in accordance with

safety concerns, if any, associated with its use. It is the

Terminology D1600, unless otherwise indicated.

responsibility of the user of this standard to establish appro-

3.2 Other definitions of terms and symbols relating to

priate safety, health, and environmental practices and deter-

tension testing of plastics appear in theAnnex to Test Methods

mine the applicability of regulatory limitations prior to use.

D638 and D638M.

NOTE 2—There is no known ISO equivalent to this standard.

3.3 Definitions of Terms Specific to This Standard:

1.5 This international standard was developed in accor-

3.3.1 aggregate—a siliceous sand conforming to the re-

dance with internationally recognized principles on standard-

quirements of Specification C33, except that the requirements

ization established in the Decision on Principles for the

for gradation shall not apply.

Development of International Standards, Guides and Recom-

3.3.2 exterior surface resin layer—a resin layer, with or

mendations issued by the World Trade Organization Technical

without filler or reinforcement, or both, applied to the exterior

Barriers to Trade (TBT) Committee.

surface of the pipe structural wall.

2. Referenced Documents 3.3.3 fiberglass pipe—a tubular product containing glass

fiber reinforcement embedded in or surrounded by cured

2.1 ASTM Standards:

thermosetting resin; the composite structure may contain

C33 Specification for Concrete Aggregates

aggregate, granular or platelet fillers, thixotropic agents,

pigments, or dyes; thermoplastic or thermosetting liners may

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

be included.

and is the direct responsibility of Subcommittee D20.23 on Reinforced Plastic

3.3.4 liner—the inner portion of the wall at least 0.005 in.

Piping Systems and Chemical Equipment.

(0.13 mm) in thickness, as determined in 9.1.2, which does not

Current edition approved Nov. 15, 2019. Published December 2019. Originally

approved in 1962. Last previous edition approved in 2014 as D2105 – 01(2014).

contribute to the strength in the determination of the hydro-

DOI: 10.1520/D2105-01R19.

static design basis.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2105 − 01 (2019)

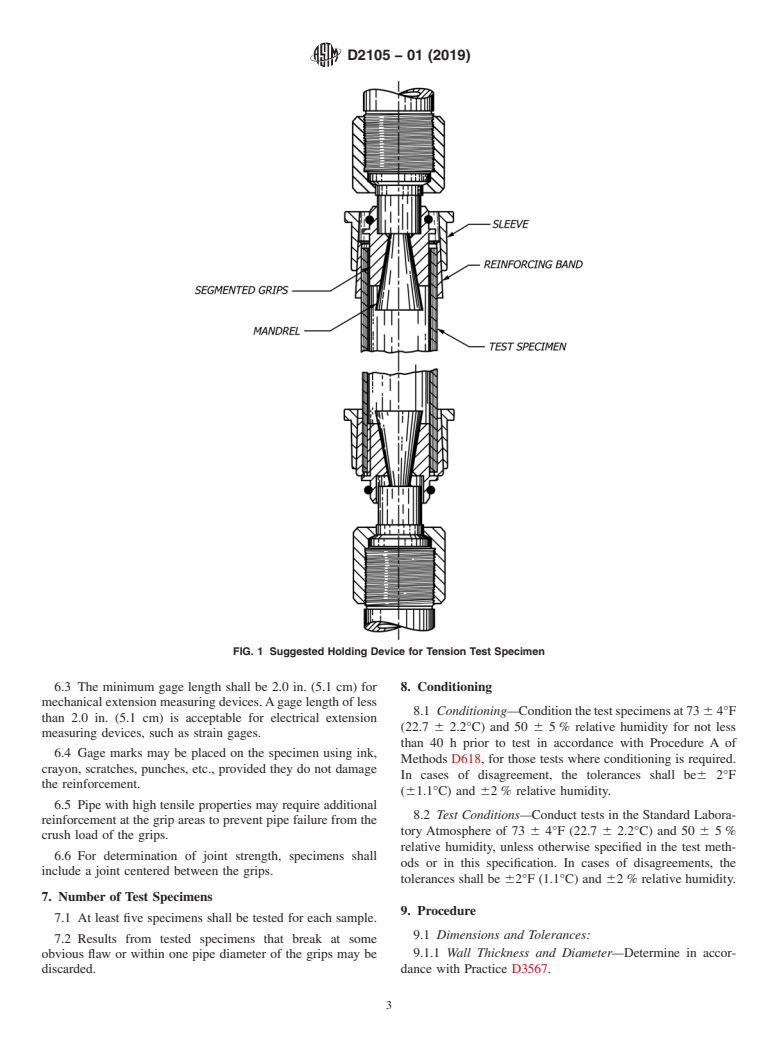

3.3.5 reinforced polymer mortar pipe (RPMP)—afiberglass 5.1.3 Grips—Grips for holding the test specimen between

pipe with aggregate. the fixed member and the movable member. The grips shall be

3.3.6 reinforced thermosetting resin pipe (RTRP)—a fiber- self-aligning; that is, they shall be attached to the fixed and

glass pipe without aggregate. movable member, respectively, in such a manner that they will

3.3.7 reinforced wall thickness—the total wall thickness movefreelyintoalignmentassoonasanyloadisapplied.With

minus the liner or exterior coating thickness, or both. this arrangement, the long axis of the test specimen will

coincide with the direction of the applied pull through the

4. Significance and Use

centerlineofthegripassembly.Thetestspecimenshallbeheld

in such a way that slippage relative to the grips is prevented

4.1 Tensile properties include modulus of elasticity, yield

insofar as possible. The grips shall be designed so that no

stress, elongation beyond yield point, tensile strength, elonga-

crushing load shall be applied to the pipe ends.Asuggested set

tion at break, and energy absorption. Materials possessing a

of grips and mandrels is shown in Fig. 1 and Fig. 2.

low order of ductility may not exhibit a yield point. Stress-

5.1.4 Drive Mechanism—A drive mechanism for imparting

strain data at several levels of temperature, humidity, time, or

to the movable member a uniform, controlled velocity with

other variables may be needed to furnish reasonably accurate

respect to the stationary member, this velocity to be regulated

indications of the behavior of the material.

as specified in 9.3.

4.2 Tension tests may provide data for research and

5.1.5 Load Indicator—A suitable load-indicating mecha-

development, engineering design, quality control, acceptance

nism capable of showing the total tensile load carried by the

or rejection under specifications, and for special purposes

test specimen when held by the grips.This mechanism shall be

(Note 3). The tests cannot be considered significant for

essentially free from inertia lag at the specified rate of testing

applications differing widely from the load-time scale of the

and shall indicate the load with an accuracy of 61 % of the

standard test (Note 4). Such applications require more suitable

indicated value, or better. The accuracy of the testing machine

tests, such as impact, creep, and fatigue.

shall be verified in accordance with Practice E4.

NOTE 3—It is realized that the method of preparation of a material is

NOTE 6—Experience has shown that many testing machines now in use

one of the many variables that affect the results obtained in testing a

material. Hence, when comparative tests of materials per se are desired, are incapable of maintaining accuracy for as long as the periods between

inspection recommended in Practice E4. Hence, it is recommended that

the greatest care must be exercised to ensure that all samples are prepared

in exactly the same way; similarly, for referee or comparative tests of any each machine be studied individually and verified as often as necessary. It

will frequently be necessary to perform this function daily.

given series of specimens, care must be taken to secure the maximum

degree of uniformity in details of preparation, treatment, and handling.

5.1.6 The fixed member, movable member, drive

NOTE 4—Reinforcements of plastics with glass fiber offer wide oppor-

mechanism, and grips shall be constructed of such materials

tunities for designing and producing products with markedly different

responses to loading even when the basic geometry of the product is and in such proportions that the total elastic longitudinal strain

similar.Forexample,atubularproductmaybedesignedtogivemaximum

of the system constituted by these parts does not exceed 1 % of

resistance to torsion loading, but such a product might develop a twist or

the total longitudinal strain between the two gage marks on the

bow if tested in tension or under internal pressure loading. In the case of

test specimen at any time during the test and at any load up to

pipe for general field use, internal pressure, as well as loads in tension,

the rated capacity of the machine.

compression, torsion, and flexure must be resisted to some degree.

Different pipe producers have chosen, by design, to offer products having

5.2 Extension Indicator—A suitable instrument for deter-

different balances of resistance to such stressing conditions.As a result, it

mining the distance between two fixed points located within

is important that the purchaser and the seller both have a clear under-

standing and agreement on the significance of this test method relative to

the gage length of the test specimen at any time during the test.

the intended use.

It is desirable, but not essential, that this instrument automati-

cally record this distance (or any change in it) as a function of

5. Apparatus

the load on the test specimen or of the elapsed time from the

5.1 Testing Machine—A testing machine of the constant- start of the test, or both. If only the latter is obtained, load-time

rate-of-crosshead-movement type (Note 5) and comprising

data must also be taken. This instrument shall be free of inertia

essentially the following: lag at the specified speed of testing and shall be accurate to6

1 % of strain or better.

NOTE 5—It is recognized that the constant rate-of-crosshead-movement

type of test leaves much to be desired from a theoretical standpoint, that

NOTE 7—Reference is made to Practice E83.

wide differences may exist between gage marks on the specimen, and that

the testing speeds specified disguise important effects characteristic of

5.3 Micrometers—Suitable micrometers, reading to at least

materials in the plastic state. Further, it is realized that variations in the

0.001in.(0.025mm),formeasuringthediameterandthickness

thicknesses of test specimens, which are permitted by these procedures,

of the test specimens.

produce variations in the surface-volume ratios of such specimens, and

that these variations may influence the test results. Hence, where directly

comparable

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.